Professional Documents

Culture Documents

Astm A 659

Astm A 659

Uploaded by

talhadikenCopyright:

Available Formats

You might also like

- ASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFDocument14 pagesASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFMOHAMAD NIZAMUDINNo ratings yet

- GplistDocument10 pagesGplistDean Fanning50% (2)

- vxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityDocument1 pagevxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityAlok PatilNo ratings yet

- A322-13 Standard Specification For Steel Bars, Alloy, Standard GradesDocument4 pagesA322-13 Standard Specification For Steel Bars, Alloy, Standard GradesDiego Egoávil Méndez100% (1)

- Astm A624Document5 pagesAstm A624Tri-Sure More Than ClosuresNo ratings yet

- Astm A653 15 PDFDocument13 pagesAstm A653 15 PDFDaniel Vasquez100% (2)

- A478-97 (2013) Standard Specification For Chromium-Nickel Stainless Steel Weaving and Knitting WireDocument2 pagesA478-97 (2013) Standard Specification For Chromium-Nickel Stainless Steel Weaving and Knitting Wiretjt4779No ratings yet

- Astm A519 PDFDocument13 pagesAstm A519 PDFAlexa Diaz100% (3)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Muslim Rajputs of RajouriDocument10 pagesMuslim Rajputs of RajouriEPILOGUE MAGAZINE100% (2)

- Astm A659-06 PDFDocument3 pagesAstm A659-06 PDFHumberto GalvezNo ratings yet

- A659A659M-12 Standard Specification For Commercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-RolledDocument3 pagesA659A659M-12 Standard Specification For Commercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-Rolledtjt4779No ratings yet

- Commercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-RolledDocument3 pagesCommercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-RolledWael ElewaNo ratings yet

- A 794 - 97 QTC5NC05NWDocument3 pagesA 794 - 97 QTC5NC05NWAndresNo ratings yet

- Steel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistanceDocument4 pagesSteel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistancePham Huu Loc Ho100% (1)

- Astm A659-18Document3 pagesAstm A659-18Ryan ZhangNo ratings yet

- A794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-RolledDocument3 pagesA794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-Rolledtjt4779No ratings yet

- A606a606m 2895Document4 pagesA606a606m 2895Jaleel ClaasenNo ratings yet

- Steel, Carbon (0.15 Maximum, Percent), Hot-Rolled Sheet and Strip CommercialDocument2 pagesSteel, Carbon (0.15 Maximum, Percent), Hot-Rolled Sheet and Strip CommercialRafael CossolinoNo ratings yet

- A 1018 - A 1018m - 03 QtewmtgtmdnbDocument5 pagesA 1018 - A 1018m - 03 QtewmtgtmdnbGsuslionelNo ratings yet

- A263-12 Stainless Chromium Steel-Clad PlateDocument6 pagesA263-12 Stainless Chromium Steel-Clad PlatemehmetNo ratings yet

- ASTM A 924 A924M - 2010aDocument12 pagesASTM A 924 A924M - 2010attilokkulNo ratings yet

- A653.1501849-1 - Hot Dipped Steel GalvanizationDocument13 pagesA653.1501849-1 - Hot Dipped Steel Galvanizationsubhaschandranath1No ratings yet

- Steel, Sheet and Strip, High-Strength, Low-Alloy, Columbium or Vanadium, or Both, Hot-Rolled and Cold-RolledDocument4 pagesSteel, Sheet and Strip, High-Strength, Low-Alloy, Columbium or Vanadium, or Both, Hot-Rolled and Cold-Rolledruben castroNo ratings yet

- Astm A493-09Document3 pagesAstm A493-09krkmurthyNo ratings yet

- Astm A313-10Document8 pagesAstm A313-10krkmurthyNo ratings yet

- Austempered Ductile Iron Castings: Standard Specification ForDocument9 pagesAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- Alloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsDocument13 pagesAlloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsJohn HollandNo ratings yet

- Astm A1018m PDFDocument7 pagesAstm A1018m PDFrgi178No ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthDocument9 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthlinamariamonroyginetNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthDocument7 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthfaroukNo ratings yet

- A653A653MDocument13 pagesA653A653MfelipeNo ratings yet

- A 254 - A 254M - 12 PDFDocument4 pagesA 254 - A 254M - 12 PDFأسامة وحيد الدين رمضانNo ratings yet

- Astm A 1011M PDFDocument8 pagesAstm A 1011M PDFJuan CarlosNo ratings yet

- Steel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilityDocument3 pagesSteel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilitySinan ChenNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityDocument8 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityRuy AlvesNo ratings yet

- Astm A82Document5 pagesAstm A82Darwin DarmawanNo ratings yet

- Astm A690Document2 pagesAstm A690Genesis Lissette Loyola Ortiz100% (1)

- Astm A263 2009Document6 pagesAstm A263 2009DenilsonRomãoNo ratings yet

- Seamless Stainless Steel Mechanical Tubing: Standard Specification ForDocument8 pagesSeamless Stainless Steel Mechanical Tubing: Standard Specification ForNur Achmad BusairiNo ratings yet

- Astm-A79210pdf PDFDocument6 pagesAstm-A79210pdf PDFLian HoaNo ratings yet

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocument7 pagesHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesRoland CepedaNo ratings yet

- A 635Document9 pagesA 635Mahiro MacNo ratings yet

- Astm A101 PDFDocument8 pagesAstm A101 PDFtrjithinrajNo ratings yet

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocument5 pagesStainless Chromium Steel-Clad Plate: Standard Specification ForErick ERICKNo ratings yet

- A 564 - A 564M - 01 Qtu2nc0wmqDocument7 pagesA 564 - A 564M - 01 Qtu2nc0wmqPRASANTH PRASANTHNo ratings yet

- High-Strength Low-Alloy Nickel, Copper, Phosphorus Steel H-Piles and Sheet Piling With Atmospheric Corrosion Resistance For Use in Marine EnvironmentsDocument3 pagesHigh-Strength Low-Alloy Nickel, Copper, Phosphorus Steel H-Piles and Sheet Piling With Atmospheric Corrosion Resistance For Use in Marine EnvironmentsSama UmateNo ratings yet

- 011-Astm A 131 2008 Structural Steel For Ships PDFDocument7 pages011-Astm A 131 2008 Structural Steel For Ships PDFgraduateNo ratings yet

- A401A401M-10 Standard Specification For Steel Wire, Chromium-Silicon AlloyDocument4 pagesA401A401M-10 Standard Specification For Steel Wire, Chromium-Silicon Alloytjt4779No ratings yet

- Astm A351 2006Document5 pagesAstm A351 2006Almas AthifNo ratings yet

- Astm A1008a1008m - 08Document9 pagesAstm A1008a1008m - 08Laboratório MateriaisNo ratings yet

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocument5 pagesStainless Chromium Steel-Clad Plate: Standard Specification ForHoem ITNo ratings yet

- Astm A493-16Document4 pagesAstm A493-16Eugene DerkachNo ratings yet

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessKannanNo ratings yet

- Astm A1008 CRC Crs PDFDocument9 pagesAstm A1008 CRC Crs PDFArul Edwin VijayNo ratings yet

- Astm A1011 2010Document9 pagesAstm A1011 2010ACEROVIALNo ratings yet

- Astm A568 A568m 03Document10 pagesAstm A568 A568m 03comprasacsa1208No ratings yet

- Stainless Steel Spring Wire: Standard Specification ForDocument8 pagesStainless Steel Spring Wire: Standard Specification Forsharon blushteinNo ratings yet

- Standard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessDocument4 pagesStandard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessarchahmedassafNo ratings yet

- Steel Sheet, Terne (Lead-Tin Alloy) Coated by The Hot-Dip ProcessDocument5 pagesSteel Sheet, Terne (Lead-Tin Alloy) Coated by The Hot-Dip ProcessHoem ITNo ratings yet

- CR CRK CRS CRSK: Group Steel GradeDocument6 pagesCR CRK CRS CRSK: Group Steel GradetalhadikenNo ratings yet

- Astm A 681Document14 pagesAstm A 681talhadikenNo ratings yet

- Astm A 664Document3 pagesAstm A 664talhadikenNo ratings yet

- Astm A 683Document5 pagesAstm A 683talhadikenNo ratings yet

- Üretim Akış Şeması Ve Nihai Ürünler IngDocument8 pagesÜretim Akış Şeması Ve Nihai Ürünler IngtalhadikenNo ratings yet

- Organ Izasyo N Standart No Document Name Kabul TarihiDocument4 pagesOrgan Izasyo N Standart No Document Name Kabul TarihitalhadikenNo ratings yet

- Abs EuropeDocument3 pagesAbs EuropetalhadikenNo ratings yet

- Essential English For Foreign Students Book 3Document317 pagesEssential English For Foreign Students Book 3talhadikenNo ratings yet

- A 530 - A 530M - 02 Qtuzmc0wmgDocument8 pagesA 530 - A 530M - 02 Qtuzmc0wmgtalhadikenNo ratings yet

- Case Study1Document5 pagesCase Study1Samiul IslamNo ratings yet

- Self - Assessment Guide: Can I? YES NODocument3 pagesSelf - Assessment Guide: Can I? YES NOJohn Castillo100% (1)

- Omm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretDocument663 pagesOmm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretSTGN100% (1)

- Annotated BibliographyDocument7 pagesAnnotated Bibliographyapi-340711045No ratings yet

- CFED Midterm MasterDocument25 pagesCFED Midterm MasterMinette Fritzie MarcosNo ratings yet

- MY MAGIC TUT ListDocument21 pagesMY MAGIC TUT ListViet Cube0% (1)

- English - Fine - Tune Your English 2019Document3 pagesEnglish - Fine - Tune Your English 2019NishaNo ratings yet

- Hasil To SBMPTN Gratis 7Document129 pagesHasil To SBMPTN Gratis 7MauzNo ratings yet

- Input Filter Design by EricksonDocument49 pagesInput Filter Design by EricksonshrikrisNo ratings yet

- Enfermedades Emergentes y Embarazo - EID - November 2006 - Volume CompletoDocument187 pagesEnfermedades Emergentes y Embarazo - EID - November 2006 - Volume CompletoRuth Vargas GonzalesNo ratings yet

- Paper 8911Document8 pagesPaper 8911IJARSCT JournalNo ratings yet

- Form LRA 42Document3 pagesForm LRA 42Godfrey ochieng modiNo ratings yet

- 13 3friedman PDFDocument20 pages13 3friedman PDFfreedownloads1No ratings yet

- Mini Cex 1 POP CTTDocument10 pagesMini Cex 1 POP CTTZAHRA RIZQIKA ALIYYA SAFITRI -No ratings yet

- Dinagat HVADocument55 pagesDinagat HVARolly Balagon CaballeroNo ratings yet

- 4 Step Formula For A Killer IntroductionDocument8 pages4 Step Formula For A Killer IntroductionSHARMINE CABUSASNo ratings yet

- Copyright Issues in Digital Age DisserationDocument98 pagesCopyright Issues in Digital Age DisserationMayank SainiNo ratings yet

- Persons With Disabilities: Key PointsDocument8 pagesPersons With Disabilities: Key PointsShane ArroyoNo ratings yet

- Motion Media and InformationDocument2 pagesMotion Media and InformationLovely PateteNo ratings yet

- Hospital Managing QR Code Web Application Using Django and PythonDocument5 pagesHospital Managing QR Code Web Application Using Django and PythonSihemNo ratings yet

- HW On Receivables CDocument5 pagesHW On Receivables CAmjad Rian MangondatoNo ratings yet

- Recruitment Requisition FormDocument1 pageRecruitment Requisition FormrahulNo ratings yet

- SDL Atlas Catalog 23 2015Document150 pagesSDL Atlas Catalog 23 2015Tahir NizamNo ratings yet

- Chapter Ii Review of Related LiteratureDocument12 pagesChapter Ii Review of Related LiteratureJane Drelle AgustinNo ratings yet

- Detail of Common Toilet: Section Elevation C - C' Section Elevation D - D'Document1 pageDetail of Common Toilet: Section Elevation C - C' Section Elevation D - D'RichaNo ratings yet

- Annexure-10b) MA5620 & MA5626 Product Description PDFDocument52 pagesAnnexure-10b) MA5620 & MA5626 Product Description PDFFares DamNo ratings yet

- How To Install The Data Protector License KeyDocument4 pagesHow To Install The Data Protector License KeyHillary Johnson0% (1)

Astm A 659

Astm A 659

Uploaded by

talhadikenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm A 659

Astm A 659

Uploaded by

talhadikenCopyright:

Available Formats

Designation: A 659/A 659M – 06

Standard Specification for

Commercial Steel (CS), Sheet and Strip, Carbon (0.16

Maximum to 0.25 Maximum Percent), Hot-Rolled1

This standard is issued under the fixed designation A 659/A 659M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* J 1086 Numbering Metals and Alloys

1.1 This specification covers hot-rolled carbon steel (CS) 3. Ordering Information

sheet and strip, in coils and cut lengths, in which the maximum

of the specified carbon range is over 0.15 and not over 0.25 % 3.1 It is the purchaser’s responsibility to specify in the

and the maximum of the specified manganese range is not over purchase order all ordering information necessary to purchase

0.90 %. This material is ordered to chemical composition. the needed material. Examples of such information include but

1.2 This specification is not applicable to the steels covered are not limited to the following:

by Specification A 635/A 635M. 3.1.1 ASTM specification number and year of issue,

1.3 The values stated in either acceptable SI (metric) units 3.1.2 Name of material (hot-rolled commercial steel (CS)

or in other units shall be regarded separately as standard. The sheet, or hot-rolled commercial steel (CS) strip),

values stated in each system may not be exact equivalents; 3.1.3 Grade designation or chemical composition, or both,

therefore, each system must be used independently of the other, 3.1.4 Copper-bearing steel (if required),

without combining values in any way. 3.1.5 Condition (as-rolled, pickled, or blast cleaned) (see

4.1),

2. Referenced Documents 3.1.5.1 Material to this specification is furnished in the

2.1 ASTM Standards: 2 hot-rolled condition. Pickled (or blast cleaned) must be speci-

A 568/A 568M Specification for Steel, Sheet, Carbon, fied if required,

Structural, and High-Strength, Low-Alloy, Hot-Rolled and 3.1.6 Oiling (see 7.2),

Cold-Rolled, General Requirements for 3.1.7 Edges (see 7.1),

A 635/A 635M Specification for Steel, Sheet and Strip, 3.1.8 Dimensions (thickness, width, and whether cut lengths

Heavy-Thickness Coils, Hot-Rolled, Carbon, Structural, or coils),

High-Strength Low-Alloy, and High-Strength Low-Alloy 3.1.8.1 As agreed upon between the purchaser and the

with Improved Formability, General Requirements for producer, material ordered to this specification will be supplied

A 749/A 749M Specification for Steel, Strip, Carbon and to meet the appropriate standard or restricted thickness toler-

High-Strength, Low-Alloy, Hot-Rolled, General Require- ance table shown in Specification A 568/A 568M.

ments for NOTE 1—Not all producers are capable of meeting all of the limitations

E 527 Practice for Numbering Metals and Alloys (UNS) of the thickness tolerance tables in Specification A 568/A 568M. The

2.2 Society of Automotive Engineers Standard:3 purchaser should contact the producer regarding possible limitations prior

to placing an order.

1

3.1.9 Coil size (must include inside diameter, outside diam-

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

eter, and maximum mass),

A01.19 on Steel Sheet and Strip. 3.1.10 Quantity,

Current edition approved Oct. 1, 2006. Published October 2006. Originally 3.1.11 Application (show part identification and descrip-

approved in 1972. Last previous edition approved in 2001 as A 659/A 659M – 97 tion),

(2001).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 3.1.12 Special requirements (if required), and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 3.1.13 Cast or heat analysis report (request, if required).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. NOTE 2—A typical ordering description is as follows:

3

Available from Society of Automotive Engineers (SAE), 400 Commonwealth “ASTM A659-XX [or A659M-XX], Hot-Rolled Commercial Steel (CS)

Dr., Warrendale, PA 15096-0001, http://www.sae.org. Sheet, Grade 1017, Pickled and Oiled, Cut Edge, 0.075 by 36 in. [or 1.85

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

A 659/A 659M – 06

by 900 mm], by coil, ID 24 in., OD 48 in., max weight 11 250 lb max [or appendix and is discussed in more detail in Specifications

ID 600 mm, OD 1200 mm, max, weight 7500 kg, max], 100 000 lb [or 45 A 568/A 568M, and A 749/A 749M. When tighter bend radii

000 kg] for Part No. 6509, Shelf Leg, Cast or heat analysis report are required, or curved or offset bends are involved, or when

required.”

stretching or drawing are also a consideration, the producers

4. Materials and Manufacture shall be consulted.

4.1 Condition—Unless otherwise specified, the material is 7. Workmanship, Finish, and Appearance

furnished in the as-rolled condition (not annealed or pickled). 7.1 Edge:

5. Chemical Composition 7.1.1 Sheet can be supplied with mill edge or cut edge.

7.1.2 Strip can be supplied with mill edge or slit (cut) edge.

5.1 The Cast or Heat Analysis of the steel shall conform to

--`,,```,,,,````-`-`,,`,,`,`,,`---

7.2 Oiling—Hot-rolled, non-pickled material is commonly

the chemical requirements shown in Table 1, or chemical

furnished not oiled, while hot-rolled pickled (or blast cleaned)

compositions can be specified from carbon 0.16 maximum to

material is commonly furnished oiled. When required, pickled

0.25 % maximum, inclusive, and manganese 0.90 % maxi-

(or blast cleaned) material may be specified to be furnished not

mum, inclusive, which conform to the standard chemical

oiled, and non-pickled material may be specified to be fur-

ranges and limits tables in the Appendixes of Specifications

nished oiled.

A 568/A 568M and A 749/A 749M.

5.1.1 Unspecified elements may be present. Limits on ele- 8. General Requirements for Delivery

ments shall be as stated in Table 2. 8.1 Material furnished under this specification shall con-

5.1.1.1 Each of the elements listed in Table 2 shall be form to the applicable requirements of the current edition of

included in the report of the heat analysis. When the amount of Specification A 568/A 568M for sheet, and Specification

copper, nickel, chromium, or molybdenum is less than 0.02 %, A 749/A 749M for strip, unless otherwise provided herein.

the analysis may be reported as “<0.02 %.” When the amount

of vanadium or columbium is less than 0.008 %, the analysis 9. Certification and Reports

may be reported as “<0.008 %.” 9.1 When requested, the producer shall furnish copies of a

5.2 Where material is used for fabrication by welding, care report showing test results of the cast or heat analysis. The

must be exercised in selection of the chemical composition to report shall include the purchase order number, the ASTM

assure compatibility with the welding process and its effect on designation number, and the cast or heat number representing

altering the properties of the steel. the material.

6. Bending Properties 10. Keywords

6.1 The minimum forming radius (radii) that steel covered 10.1 carbon steel sheet; carbon steel strip; hot rolled steel

by this specification can be expected to sustain is listed in the sheet; hot rolled steel strip; steel sheet; steel strip

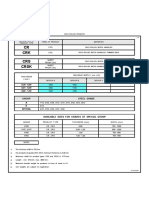

TABLE 1 Typical Grade Designations and Chemical CompositionsA

UNS DesignationB Grade Designation Carbon, % Manganese, % Phosphorus, max, % Sulfur, max, %

G10150 1015 0.13–0.18 0.30–0.60 0.030 0.035

G10160 1016 0.13–0.18 0.60–0.90 0.030 0.035

G10170 1017 0.15–0.20 0.30–0.60 0.030 0.035

G10180 1018 0.15–0.20 0.60–0.90 0.030 0.035

G10200 1020 0.18–0.23 0.30–0.60 0.030 0.035

G10210 1021 0.18–0.23 0.60–0.90 0.030 0.035

G10230 1023 0.20–0.25 0.30–0.60 0.030 0.035

A

Copper, when specified, shall have a minimum content of 0.20 % by cast or heat analysis.

B

Designation established in accordance with Practice E 527 and SAE J 1086.

Copyright ASTM International 2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

A 659/A 659M – 06

TABLE 2 Limits on Unspecified Elements (see 5.1.1)

Copper, max %A Heat analysis 0.20

Product analysis 0.23

A

Nickel, max % Heat analysis 0.20

Product analysis 0.23

Chromium, max %A Heat analysis 0.15

Product analysis 0.19

Molybdenum, max %A Heat analysis 0.06

Product analysis 0.07

Vanadium, max % Heat analysis 0.008

Product analysis 0.018

Columbium, max % Heat analysis 0.008

Product analysis 0.018

A

The sum of copper, nickel, chromium, and molybdenum shall not exceed

0.50 % on heat analysis. When one or more of these elements are specified, the

sum does not apply; in which case, only the individual limits on the remaining

unspecified elements will apply.

--`,,```,,,,````-`-`,,`,,`,`,,`---

APPENDIX

(Nonmandatory Information)

X1. BENDING PROPERTIES

X1.1 Table X1.1 shows suggested minimum inside radii for

cold bending.

TABLE X1.1 Suggested Minimum Inside Radii for Cold BendingA

NOTE 1—(t) equals a radius equivalent to the steel thickness.

NOTE 2—The suggested radii should be used as minimums for 90°

bends in actual shop practice.

Maximum of Specified Minimum Inside Radius for Cold

Manganese Range, % Bending

To 0.60 incl. 2t

Over 0.60 to 0.90 incl. 21⁄2 t

A

Material that does not perform satisfactorily, when fabricated in accordance

with the above requirements, may be subject to rejection pending negotiation with

the steel supplier.

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this standard since the last issue

(A 659/A 659M – 97 (2001)) that may impact the use of this standard. (Approved Oct. 1, 2006.)

(1) Revised 5.1. (2) Revised Table 1.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- ASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFDocument14 pagesASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFMOHAMAD NIZAMUDINNo ratings yet

- GplistDocument10 pagesGplistDean Fanning50% (2)

- vxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityDocument1 pagevxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityAlok PatilNo ratings yet

- A322-13 Standard Specification For Steel Bars, Alloy, Standard GradesDocument4 pagesA322-13 Standard Specification For Steel Bars, Alloy, Standard GradesDiego Egoávil Méndez100% (1)

- Astm A624Document5 pagesAstm A624Tri-Sure More Than ClosuresNo ratings yet

- Astm A653 15 PDFDocument13 pagesAstm A653 15 PDFDaniel Vasquez100% (2)

- A478-97 (2013) Standard Specification For Chromium-Nickel Stainless Steel Weaving and Knitting WireDocument2 pagesA478-97 (2013) Standard Specification For Chromium-Nickel Stainless Steel Weaving and Knitting Wiretjt4779No ratings yet

- Astm A519 PDFDocument13 pagesAstm A519 PDFAlexa Diaz100% (3)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Muslim Rajputs of RajouriDocument10 pagesMuslim Rajputs of RajouriEPILOGUE MAGAZINE100% (2)

- Astm A659-06 PDFDocument3 pagesAstm A659-06 PDFHumberto GalvezNo ratings yet

- A659A659M-12 Standard Specification For Commercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-RolledDocument3 pagesA659A659M-12 Standard Specification For Commercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-Rolledtjt4779No ratings yet

- Commercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-RolledDocument3 pagesCommercial Steel (CS), Sheet and Strip, Carbon (0.16 Maximum To 0.25 Maximum Percent), Hot-RolledWael ElewaNo ratings yet

- A 794 - 97 QTC5NC05NWDocument3 pagesA 794 - 97 QTC5NC05NWAndresNo ratings yet

- Steel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistanceDocument4 pagesSteel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistancePham Huu Loc Ho100% (1)

- Astm A659-18Document3 pagesAstm A659-18Ryan ZhangNo ratings yet

- A794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-RolledDocument3 pagesA794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-Rolledtjt4779No ratings yet

- A606a606m 2895Document4 pagesA606a606m 2895Jaleel ClaasenNo ratings yet

- Steel, Carbon (0.15 Maximum, Percent), Hot-Rolled Sheet and Strip CommercialDocument2 pagesSteel, Carbon (0.15 Maximum, Percent), Hot-Rolled Sheet and Strip CommercialRafael CossolinoNo ratings yet

- A 1018 - A 1018m - 03 QtewmtgtmdnbDocument5 pagesA 1018 - A 1018m - 03 QtewmtgtmdnbGsuslionelNo ratings yet

- A263-12 Stainless Chromium Steel-Clad PlateDocument6 pagesA263-12 Stainless Chromium Steel-Clad PlatemehmetNo ratings yet

- ASTM A 924 A924M - 2010aDocument12 pagesASTM A 924 A924M - 2010attilokkulNo ratings yet

- A653.1501849-1 - Hot Dipped Steel GalvanizationDocument13 pagesA653.1501849-1 - Hot Dipped Steel Galvanizationsubhaschandranath1No ratings yet

- Steel, Sheet and Strip, High-Strength, Low-Alloy, Columbium or Vanadium, or Both, Hot-Rolled and Cold-RolledDocument4 pagesSteel, Sheet and Strip, High-Strength, Low-Alloy, Columbium or Vanadium, or Both, Hot-Rolled and Cold-Rolledruben castroNo ratings yet

- Astm A493-09Document3 pagesAstm A493-09krkmurthyNo ratings yet

- Astm A313-10Document8 pagesAstm A313-10krkmurthyNo ratings yet

- Austempered Ductile Iron Castings: Standard Specification ForDocument9 pagesAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- Alloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsDocument13 pagesAlloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsJohn HollandNo ratings yet

- Astm A1018m PDFDocument7 pagesAstm A1018m PDFrgi178No ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthDocument9 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthlinamariamonroyginetNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthDocument7 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthfaroukNo ratings yet

- A653A653MDocument13 pagesA653A653MfelipeNo ratings yet

- A 254 - A 254M - 12 PDFDocument4 pagesA 254 - A 254M - 12 PDFأسامة وحيد الدين رمضانNo ratings yet

- Astm A 1011M PDFDocument8 pagesAstm A 1011M PDFJuan CarlosNo ratings yet

- Steel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilityDocument3 pagesSteel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilitySinan ChenNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityDocument8 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityRuy AlvesNo ratings yet

- Astm A82Document5 pagesAstm A82Darwin DarmawanNo ratings yet

- Astm A690Document2 pagesAstm A690Genesis Lissette Loyola Ortiz100% (1)

- Astm A263 2009Document6 pagesAstm A263 2009DenilsonRomãoNo ratings yet

- Seamless Stainless Steel Mechanical Tubing: Standard Specification ForDocument8 pagesSeamless Stainless Steel Mechanical Tubing: Standard Specification ForNur Achmad BusairiNo ratings yet

- Astm-A79210pdf PDFDocument6 pagesAstm-A79210pdf PDFLian HoaNo ratings yet

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocument7 pagesHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesRoland CepedaNo ratings yet

- A 635Document9 pagesA 635Mahiro MacNo ratings yet

- Astm A101 PDFDocument8 pagesAstm A101 PDFtrjithinrajNo ratings yet

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocument5 pagesStainless Chromium Steel-Clad Plate: Standard Specification ForErick ERICKNo ratings yet

- A 564 - A 564M - 01 Qtu2nc0wmqDocument7 pagesA 564 - A 564M - 01 Qtu2nc0wmqPRASANTH PRASANTHNo ratings yet

- High-Strength Low-Alloy Nickel, Copper, Phosphorus Steel H-Piles and Sheet Piling With Atmospheric Corrosion Resistance For Use in Marine EnvironmentsDocument3 pagesHigh-Strength Low-Alloy Nickel, Copper, Phosphorus Steel H-Piles and Sheet Piling With Atmospheric Corrosion Resistance For Use in Marine EnvironmentsSama UmateNo ratings yet

- 011-Astm A 131 2008 Structural Steel For Ships PDFDocument7 pages011-Astm A 131 2008 Structural Steel For Ships PDFgraduateNo ratings yet

- A401A401M-10 Standard Specification For Steel Wire, Chromium-Silicon AlloyDocument4 pagesA401A401M-10 Standard Specification For Steel Wire, Chromium-Silicon Alloytjt4779No ratings yet

- Astm A351 2006Document5 pagesAstm A351 2006Almas AthifNo ratings yet

- Astm A1008a1008m - 08Document9 pagesAstm A1008a1008m - 08Laboratório MateriaisNo ratings yet

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocument5 pagesStainless Chromium Steel-Clad Plate: Standard Specification ForHoem ITNo ratings yet

- Astm A493-16Document4 pagesAstm A493-16Eugene DerkachNo ratings yet

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessKannanNo ratings yet

- Astm A1008 CRC Crs PDFDocument9 pagesAstm A1008 CRC Crs PDFArul Edwin VijayNo ratings yet

- Astm A1011 2010Document9 pagesAstm A1011 2010ACEROVIALNo ratings yet

- Astm A568 A568m 03Document10 pagesAstm A568 A568m 03comprasacsa1208No ratings yet

- Stainless Steel Spring Wire: Standard Specification ForDocument8 pagesStainless Steel Spring Wire: Standard Specification Forsharon blushteinNo ratings yet

- Standard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessDocument4 pagesStandard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessarchahmedassafNo ratings yet

- Steel Sheet, Terne (Lead-Tin Alloy) Coated by The Hot-Dip ProcessDocument5 pagesSteel Sheet, Terne (Lead-Tin Alloy) Coated by The Hot-Dip ProcessHoem ITNo ratings yet

- CR CRK CRS CRSK: Group Steel GradeDocument6 pagesCR CRK CRS CRSK: Group Steel GradetalhadikenNo ratings yet

- Astm A 681Document14 pagesAstm A 681talhadikenNo ratings yet

- Astm A 664Document3 pagesAstm A 664talhadikenNo ratings yet

- Astm A 683Document5 pagesAstm A 683talhadikenNo ratings yet

- Üretim Akış Şeması Ve Nihai Ürünler IngDocument8 pagesÜretim Akış Şeması Ve Nihai Ürünler IngtalhadikenNo ratings yet

- Organ Izasyo N Standart No Document Name Kabul TarihiDocument4 pagesOrgan Izasyo N Standart No Document Name Kabul TarihitalhadikenNo ratings yet

- Abs EuropeDocument3 pagesAbs EuropetalhadikenNo ratings yet

- Essential English For Foreign Students Book 3Document317 pagesEssential English For Foreign Students Book 3talhadikenNo ratings yet

- A 530 - A 530M - 02 Qtuzmc0wmgDocument8 pagesA 530 - A 530M - 02 Qtuzmc0wmgtalhadikenNo ratings yet

- Case Study1Document5 pagesCase Study1Samiul IslamNo ratings yet

- Self - Assessment Guide: Can I? YES NODocument3 pagesSelf - Assessment Guide: Can I? YES NOJohn Castillo100% (1)

- Omm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretDocument663 pagesOmm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretSTGN100% (1)

- Annotated BibliographyDocument7 pagesAnnotated Bibliographyapi-340711045No ratings yet

- CFED Midterm MasterDocument25 pagesCFED Midterm MasterMinette Fritzie MarcosNo ratings yet

- MY MAGIC TUT ListDocument21 pagesMY MAGIC TUT ListViet Cube0% (1)

- English - Fine - Tune Your English 2019Document3 pagesEnglish - Fine - Tune Your English 2019NishaNo ratings yet

- Hasil To SBMPTN Gratis 7Document129 pagesHasil To SBMPTN Gratis 7MauzNo ratings yet

- Input Filter Design by EricksonDocument49 pagesInput Filter Design by EricksonshrikrisNo ratings yet

- Enfermedades Emergentes y Embarazo - EID - November 2006 - Volume CompletoDocument187 pagesEnfermedades Emergentes y Embarazo - EID - November 2006 - Volume CompletoRuth Vargas GonzalesNo ratings yet

- Paper 8911Document8 pagesPaper 8911IJARSCT JournalNo ratings yet

- Form LRA 42Document3 pagesForm LRA 42Godfrey ochieng modiNo ratings yet

- 13 3friedman PDFDocument20 pages13 3friedman PDFfreedownloads1No ratings yet

- Mini Cex 1 POP CTTDocument10 pagesMini Cex 1 POP CTTZAHRA RIZQIKA ALIYYA SAFITRI -No ratings yet

- Dinagat HVADocument55 pagesDinagat HVARolly Balagon CaballeroNo ratings yet

- 4 Step Formula For A Killer IntroductionDocument8 pages4 Step Formula For A Killer IntroductionSHARMINE CABUSASNo ratings yet

- Copyright Issues in Digital Age DisserationDocument98 pagesCopyright Issues in Digital Age DisserationMayank SainiNo ratings yet

- Persons With Disabilities: Key PointsDocument8 pagesPersons With Disabilities: Key PointsShane ArroyoNo ratings yet

- Motion Media and InformationDocument2 pagesMotion Media and InformationLovely PateteNo ratings yet

- Hospital Managing QR Code Web Application Using Django and PythonDocument5 pagesHospital Managing QR Code Web Application Using Django and PythonSihemNo ratings yet

- HW On Receivables CDocument5 pagesHW On Receivables CAmjad Rian MangondatoNo ratings yet

- Recruitment Requisition FormDocument1 pageRecruitment Requisition FormrahulNo ratings yet

- SDL Atlas Catalog 23 2015Document150 pagesSDL Atlas Catalog 23 2015Tahir NizamNo ratings yet

- Chapter Ii Review of Related LiteratureDocument12 pagesChapter Ii Review of Related LiteratureJane Drelle AgustinNo ratings yet

- Detail of Common Toilet: Section Elevation C - C' Section Elevation D - D'Document1 pageDetail of Common Toilet: Section Elevation C - C' Section Elevation D - D'RichaNo ratings yet

- Annexure-10b) MA5620 & MA5626 Product Description PDFDocument52 pagesAnnexure-10b) MA5620 & MA5626 Product Description PDFFares DamNo ratings yet

- How To Install The Data Protector License KeyDocument4 pagesHow To Install The Data Protector License KeyHillary Johnson0% (1)