Professional Documents

Culture Documents

Under Hood Mount, Two-Stage Filtration: Applications

Under Hood Mount, Two-Stage Filtration: Applications

Uploaded by

Mohamed MusaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Under Hood Mount, Two-Stage Filtration: Applications

Under Hood Mount, Two-Stage Filtration: Applications

Uploaded by

Mohamed MusaCopyright:

Available Formats

FTG Air Cleaners

MEDIUM DUST AIR CLEANERS

Under Hood Mount, Two-Stage Filtration

For Large Construction & Mining Equipment

The FTG Cycloflow™ Air Cleaner Tangential

is another two-stage air cleaner Inlet

with a built-in pre-cleaner. This air Service

Access

cleaner has axial seal style filters. Cover

The FTG is typically mounted

under hood with the service cover

on the outside for access.

Applications

• Allows 32-59 m³/min. airflow

throughput per air cleaner

• Horizontal installation

• Sustained temperature tolerance:

to 82 °C

Ideal for

• Large industrial and construction

equipment: crawler tractors,

crane loaders, excavators and

air compressors with large Outlet on

engines operating in severe dust this end

environments

• Agricultural machinery

• Mining equipment

• Oil and gas hydraulic fracturing

(fracking) equipment

• Off-highway vehicles

Air Cleaner Features Vacuator™

• Unique, flared inlet allows Valve

maximum airflow with low

restriction

• 21" body diameter Accessories

• Two-stage filter system — the • Mounting bands (order separately).

first stage removes up to 85% of • If the installed air cleaner will be

incoming dust with a tangential air exposed to rain, snow or debris,

inlet an inlet cap can prevent moisture

• Inlet on side, outlet on end (G flow) ingestion.

• Already tapped to accept filter • A service indicator measures the

service indicator (1/8"-27 NPT male) airflow restriction across the filter,

• Safety filter protects engine inlet thereby showing how much useful

Safety Filter

during filter change out life the filter has left and when to

• Vacuator™ Valve automatically replace the filter (see Accessories

releases the pre-cleaned dust section of this catalog). Primary Filter

• Housing is metal and coated with Note: Outlet tapped to accept filter

a black, corrosion- and chemical- service indicator (1/8"-27 NPT male).

resistant polymer paint

• Mounting the unit directly to the

engine is not recommended;

excessive engine vibration can

cause premature air cleaner

structural failure

donaldson.com Engine Air Filtration • 139

FTG Air Cleaners

MEDIUM DUST AIR CLEANERS

FLOW

G INLET

Air in the Side, Out the End (standard flow filters)

When Selecting an Air Cleaner . . .

Determine the airflow requirements of your engine, then find the

corresponding cfm airflow in the table below. The restriction numbers

(shown in inches of water) indicate the approximate initial restriction of

each model air cleaner at that cfm. When calculating total initial restriction

of the entire air intake system, include the restriction caused by ducting,

elbows, and pre-cleaners. See pages 257-258 for ducting restriction estimates.

The only difference in these two models is the position of the inlet on the air

cleaner body. For location and dimensions, see details on next page.

OUTLET

Initial Airflow Restriction

Airflow CFM @ H20 Weight

6" 8" 10" Air Cleaner Models lbs kg

1465 1680 1870 G210007 / G210010 88 40

FTG Air Cleaner Performance Curves (Restriction & Dust Capacity)*

G210007 and G210010

2011 Donaldson Company Inc.

*Results generated using laboratory testing pursuant to ISO5011. Actual performance during use may vary depending on multiple factors, including specific

product configuration, external conditions and application.

140 • Engine Air Filtration donaldson.com

FTG Air Cleaners

MEDIUM DUST AIR CLEANERS

FTG Specification Illustrations

G210007 – From Outlet View

Inlet on RIGHT side of body G210010 – From Outlet View

Inlet on LEFT side of body

FTG Specifications

Body Inlet Outlet Housing Inlet Center Line Service Outlet

Air Diameter Diameter Diameter Length Location to Valve Clearance Length

Cleaner (A) (B) (C) (D) (E) (H) (I) (F)

Models in mm in mm in mm in mm in mm in mm in mm in mm

G210007 21.00 546 10.00 254 10.00 254 24.13 613 13.00 330 17.40 442 24.13 613 3.54 90

G210010 21.00 546 10.00 254 10.00 254 24.13 613 13.00 330 17.40 442 24.13 613 3.54 90

FTG Service Parts

Gasket Primary Filter

Washer Clip P182040 Standard or

Safety Filter P105740 P105738 DBA7040, Donaldson Blue®

P117781 Wing Nut

P116175

Safety Signal™

Air Cleaner Housing X004816 Gasket

metal body Washer

P105740

Vacuator™ Valve

P105220

Mounting band, 2 required

H770068

donaldson.com Engine Air Filtration • 141

FTG & FVG Air Cleaners

MEDIUM DUST AIR CLEANERS

Service Instructions

This servicing information is provided as a best practices guide. It is not intended to replace or supersede the

service instructions supplied by your engine or vehicle manufacturer.

1 Check the Restriction

Check the restriction level of the

air cleaner filter service indicator.

Replace the filter only when the

restriction level has reached the

maximum recommended by the

engine or equipment manufacturer or

on a regular service schedule.

2 Clean Out the Vacuator™

Valve

Remove the Vacuator Valve and clean

out any dust found in the drop tube.

Reinstall Vacuator Valve or replace if Make sure the valve is flexible and not inverted,

found worn or damaged. damaged or plugged. Replace it if damaged or if

it looks like any of these images. A damaged or

missing Vacuator Valve will disrupt the designed

flow of air through the air cleaner.

3 Gently Remove the Old

Filter

Shut off the engine. Loosen and

retain the wing nut bolt, remove bolt

and washer. Replace both if damaged

or worn.

Using the metal handle, pull the

dirty filter gently from the housing.

Accidental bumping will shake dirt

loose inside the filter housing.

4 Visually Check the Safety

Filter

Visually check the safety filter without

removing it. Replace if damaged or

every three primary filter changes.

Also verify that the safety filter is

properly seated in the housing.

If the safety filter is to be replaced,

it should be done immediately or the

clean air outlet should be sealed. Use

a clean cloth to avoid contaminant

being introduced to the engine during

service.

142 • Engine Air Filtration donaldson.com

FTG & FVG Air Cleaners

MEDIUM DUST AIR CLEANERS

Service Instructions

5 Always Clean the Inside of the Housing

Dirt left in the air cleaner housing is harmful to your engine.

Use a clean, damp cloth to wipe the inside of the housing

before fitting the new filter.

Block the outlet tube of the air cleaner with a small

dampened towel prior to cleaning the seal surface to

avoid contaminating the induction system.

6 Clean the Gasket Sealing Surfaces

An improper gasket seal is one of the most common

causes of engine contamination. Make sure that all

hardened dirt ridges are completely removed, both on the

bottom and top of the air cleaner housing.

7 Inspect Your Old Filter and Check for

Uneven Dirt Patterns

Your old filter has valuable clues to dust leakage or gasket

sealing problems. A dust pattern on the filter’s clean side

is a sign that the old filter was not firmly sealed or that a

dust leak exists. Identify the cause of any leak and rectify it

before installing a new filter.

8 Inspect New Filters

Before installing the new filters, visually inspect them for

shipping damage and gasket integrity. If a filter is damaged,

do not install it. If desired, write the date of the filter

change on the outer end of the filter end cap.

9 Install the New Filters

First, if you’re servicing the safety filter at this change-out,

seat it properly into position before installing the primary

filter. Insert new filters carefully over the center bolt, hand

tighten wing nut bolt for both filters.

Make sure the primary filter gasket seats evenly to create

a proper seal. If you don’t have a good seal, dirty air can

by-pass the filter.

10 Ensure an Air-tight Fit on all

Connections and Ducts

Check that all clamps and flange joints are tight, as well

as the air cleaner mounting bolts. Attend to any leaks

immediately to avoid dirt entering your engine directly.

Reset the filter service indicator.

donaldson.com Engine Air Filtration • 143

You might also like

- Hayssen Training ElectricalDocument17 pagesHayssen Training ElectricalRoberto SanchezNo ratings yet

- PS3-PS4 Pipe Thickness MeasurementDocument25 pagesPS3-PS4 Pipe Thickness MeasurementMohamed MusaNo ratings yet

- Fleetguard OptiairDocument28 pagesFleetguard OptiairDaniel CasillasNo ratings yet

- Compressor CT Series (DD310)Document6 pagesCompressor CT Series (DD310)sanamehNo ratings yet

- Bauer Workshop ManualDocument114 pagesBauer Workshop ManualAUDRANNo ratings yet

- Q3 G11 Physical Science Module 7Document19 pagesQ3 G11 Physical Science Module 7Lebz RicaramNo ratings yet

- Brochure MVRT 2015 ENDocument8 pagesBrochure MVRT 2015 ENم.حسين العامريNo ratings yet

- FPG Air CleanerDocument14 pagesFPG Air CleanergeorgeNo ratings yet

- High Efficiency Compressed Air Filtration & Water SeparationDocument8 pagesHigh Efficiency Compressed Air Filtration & Water SeparationMelvic BinosNo ratings yet

- Compact, Radialseal, Medium-Duty Air Cleaner: Designed For Horizontal InstallationDocument8 pagesCompact, Radialseal, Medium-Duty Air Cleaner: Designed For Horizontal InstallationjuanNo ratings yet

- HOPPERTOP Wam Inc 0912 EDITDocument4 pagesHOPPERTOP Wam Inc 0912 EDITPrzemek GóźdźNo ratings yet

- KORD3!21!026 Air Intake System For CI EngineDocument9 pagesKORD3!21!026 Air Intake System For CI EnginerasdeadlineNo ratings yet

- Intake and Exhaust SystemsDocument16 pagesIntake and Exhaust SystemsBrenzell BarugNo ratings yet

- F110027 Engine Intake Systems 03-13-Heavy Dust PDFDocument32 pagesF110027 Engine Intake Systems 03-13-Heavy Dust PDFesequiel fernandezNo ratings yet

- External Air Audit Report (Priority)Document2 pagesExternal Air Audit Report (Priority)Public DemandNo ratings yet

- 1cgde09jv 337626Document4 pages1cgde09jv 337626Fati ZoraNo ratings yet

- Component Item SpecificationDocument10 pagesComponent Item SpecificationYordano PerezNo ratings yet

- Centrifugal Damper Cat PDFDocument8 pagesCentrifugal Damper Cat PDFcassindromeNo ratings yet

- Gar 11-37Document2 pagesGar 11-37moisesNo ratings yet

- Referencia Aire ComprimidoDocument9 pagesReferencia Aire ComprimidoChristian Paul Salazar SanchezNo ratings yet

- Catalogo Filtri Donaldson ContenitoriDocument6 pagesCatalogo Filtri Donaldson ContenitorimimmoNo ratings yet

- GreenJet CatalogDocument8 pagesGreenJet CatalogAmr Mohamed Ali HassanNo ratings yet

- Zeks ZFC FiltersDocument4 pagesZeks ZFC FiltersHiram MenchacaNo ratings yet

- SECTION 5.15: Air Induction SystemDocument21 pagesSECTION 5.15: Air Induction SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Mtto Fan Clutch Pro StarDocument1 pageMtto Fan Clutch Pro StarOscar MillanNo ratings yet

- All Prices IR-SULLAIR-ETCDocument6 pagesAll Prices IR-SULLAIR-ETCJeff LNo ratings yet

- Durable, Corrosion-Free Air Cleaner: Improved Reliability, Superior Engine Protection, Easiest ServiceabilityDocument6 pagesDurable, Corrosion-Free Air Cleaner: Improved Reliability, Superior Engine Protection, Easiest ServiceabilityChristian ruiz noreñaNo ratings yet

- Bag Filter Optimization in Cement IndustryDocument89 pagesBag Filter Optimization in Cement IndustryNITITN ASNANINo ratings yet

- Filtri GP, HE, AC, DPDocument4 pagesFiltri GP, HE, AC, DPjuris.ligerisNo ratings yet

- 01 - Kirloskar Oil Lubricated Electric Screw CompressorsDocument12 pages01 - Kirloskar Oil Lubricated Electric Screw CompressorsSatish PatelNo ratings yet

- Especificaciones CompresoresDocument9 pagesEspecificaciones CompresoresErnestoDarioNo ratings yet

- Donaldson ultrafilter-DFTDocument4 pagesDonaldson ultrafilter-DFTsyrinxNo ratings yet

- Delbag Filter System MultiTron 2019Document12 pagesDelbag Filter System MultiTron 2019nileshNo ratings yet

- Ambitower - A Filter Tower From Keller LufttechnikDocument4 pagesAmbitower - A Filter Tower From Keller LufttechnikYing Kei ChanNo ratings yet

- Air Conditioning ToolsDocument20 pagesAir Conditioning ToolsCarlos veraNo ratings yet

- Air Filtration Technical ReferenceDocument15 pagesAir Filtration Technical ReferenceMuhammad SaadNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Jet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesDocument8 pagesJet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesErinc CelikNo ratings yet

- Pre Filtro DONALSON P19-1249-2Document1 pagePre Filtro DONALSON P19-1249-2Wilson VelásquezNo ratings yet

- Aerzen USA G5 Hybrid Brochure 2015Document8 pagesAerzen USA G5 Hybrid Brochure 2015Eduardo rodriguez gonzalezNo ratings yet

- (TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 101-200Document100 pages(TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 101-200LUIS HERNANDO100% (1)

- Turboair Cooled 2000brochureDocument6 pagesTurboair Cooled 2000brochurechriss vzzNo ratings yet

- On Site Air Compressor Capacity TestDocument5 pagesOn Site Air Compressor Capacity TestvankayalasuryaNo ratings yet

- DP 18Document2 pagesDP 18sumeet malekarNo ratings yet

- Application & Installation Guide Air Intake Systems: LEBW4969-07Document34 pagesApplication & Installation Guide Air Intake Systems: LEBW4969-07ryan fernandezNo ratings yet

- Engineering Installation Bulletin: Air Intake SystemDocument14 pagesEngineering Installation Bulletin: Air Intake Systemmxnoxn100% (1)

- Gas Turbine Air Filter System OptimizationDocument10 pagesGas Turbine Air Filter System Optimizationsevero97100% (1)

- Air Compressors: RollairDocument12 pagesAir Compressors: RollairMAZENNo ratings yet

- Air Flow Switches: LOW WitchesDocument4 pagesAir Flow Switches: LOW Witchesnareshbv749No ratings yet

- Gas Engine - Air SystemsDocument46 pagesGas Engine - Air SystemsMauro DiazNo ratings yet

- Trane Cta ComfortDocument8 pagesTrane Cta ComfortenergeticchairNo ratings yet

- Q151 WML 204Document9 pagesQ151 WML 204Luis AlfonsoNo ratings yet

- F110027 Engine Intake Systems 03-13 PowerCore PDFDocument16 pagesF110027 Engine Intake Systems 03-13 PowerCore PDFesequiel fernandezNo ratings yet

- Air Filters - at Inlet SideDocument7 pagesAir Filters - at Inlet SideSudeep SNo ratings yet

- Air Filtration PDFDocument12 pagesAir Filtration PDFAnkit JainNo ratings yet

- Air Handling Unit-99Document41 pagesAir Handling Unit-99Masoud AmirzadehfardNo ratings yet

- Air Eliminators and Combination Air Eliminators StrainersDocument10 pagesAir Eliminators and Combination Air Eliminators StrainersadrianioantomaNo ratings yet

- Appendix: A-Series Integral Air Driven Airdryer MK2Document22 pagesAppendix: A-Series Integral Air Driven Airdryer MK2Mohamed Hichem BenzaouiNo ratings yet

- Centralised Compressed Air Supply SystemDocument48 pagesCentralised Compressed Air Supply Systemshahrul aimanNo ratings yet

- Lit 200h CFM Ssl-1215enDocument2 pagesLit 200h CFM Ssl-1215enAlexis Winston MejiaNo ratings yet

- DCI Leonardo AW139 IBFDocument18 pagesDCI Leonardo AW139 IBFahmad abdulkareemNo ratings yet

- HRO HRS High Pressure Radial Pressure Blowers Catalog 1300Document40 pagesHRO HRS High Pressure Radial Pressure Blowers Catalog 1300suresh kumarNo ratings yet

- 2 Product Manual: System DescriptionDocument30 pages2 Product Manual: System DescriptionMohammad Jahangir AlamNo ratings yet

- Energy Recovery Device: Isave 21-40Document30 pagesEnergy Recovery Device: Isave 21-40Mohamed MusaNo ratings yet

- ISave 21plus ISave 40 ManualDocument28 pagesISave 21plus ISave 40 ManualMohamed MusaNo ratings yet

- Core Technologies To Increase: The Energy Efficiency of Your Desalination SystemDocument12 pagesCore Technologies To Increase: The Energy Efficiency of Your Desalination SystemMohamed MusaNo ratings yet

- Danfoss Parts List APP 0.6 43 LDocument26 pagesDanfoss Parts List APP 0.6 43 LMohamed MusaNo ratings yet

- 11 Hydraulics, Valves, Hoses & Fittings-V1Document47 pages11 Hydraulics, Valves, Hoses & Fittings-V1Mohamed MusaNo ratings yet

- Energy Recovery Device: Isave 21-40Document24 pagesEnergy Recovery Device: Isave 21-40Mohamed MusaNo ratings yet

- High Pressure Logic Valves: Mechanical and PilotDocument6 pagesHigh Pressure Logic Valves: Mechanical and PilotMohamed MusaNo ratings yet

- Danfoss RO-Solutions - Global Price List: Couplings Couplings and Couplings KitsDocument12 pagesDanfoss RO-Solutions - Global Price List: Couplings Couplings and Couplings KitsMohamed MusaNo ratings yet

- 1MJ6 113-2CA60 Motor of BurnerDocument8 pages1MJ6 113-2CA60 Motor of BurnerMohamed MusaNo ratings yet

- Spare Parts For MAXXTEC Heater Fuel BurnerDocument3 pagesSpare Parts For MAXXTEC Heater Fuel BurnerMohamed MusaNo ratings yet

- Service Activity Reports Complete PS3-PS4Document45 pagesService Activity Reports Complete PS3-PS4Mohamed MusaNo ratings yet

- DATE: 10 January 2007 Weightage Breakdown: TotalDocument43 pagesDATE: 10 January 2007 Weightage Breakdown: TotalMohamed MusaNo ratings yet

- MTF Civ CA 0041 Rev 0 (Afc)Document20 pagesMTF Civ CA 0041 Rev 0 (Afc)Mohamed MusaNo ratings yet

- WK#41 - Progress & PlanDocument7 pagesWK#41 - Progress & PlanMohamed MusaNo ratings yet

- K04917 - Spare PartsDocument2 pagesK04917 - Spare PartsMohamed MusaNo ratings yet

- Compressor Unit Technical Data Sheet - I15.1-7.5-VDocument10 pagesCompressor Unit Technical Data Sheet - I15.1-7.5-VMohamed MusaNo ratings yet

- Air Cooled High Pressure Piston Compressors Verticus 5 by Bauer Kompressoren GMBHDocument4 pagesAir Cooled High Pressure Piston Compressors Verticus 5 by Bauer Kompressoren GMBHMohamed MusaNo ratings yet

- 2015-03 Compressors-For-Industry en N39771 SCDocument40 pages2015-03 Compressors-For-Industry en N39771 SCMohamed MusaNo ratings yet

- Extracting DnaDocument6 pagesExtracting DnaIya AlabastroNo ratings yet

- CH 12Document31 pagesCH 12asin12336No ratings yet

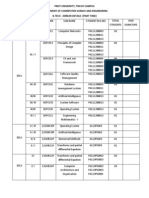

- Prist University, Trichy Campus Department of Comnputer Science and Engineering B.Tech - Arrear Details (Part Time)Document2 pagesPrist University, Trichy Campus Department of Comnputer Science and Engineering B.Tech - Arrear Details (Part Time)diltvkNo ratings yet

- ORTableAccessory Brochure INT en 05 NonUSDocument144 pagesORTableAccessory Brochure INT en 05 NonUSHarianto HarNo ratings yet

- Lab Manual (Text)Document41 pagesLab Manual (Text)tuan nguyenNo ratings yet

- RPS Akuntansi KeperilakuanDocument4 pagesRPS Akuntansi KeperilakuanNIWAYANRADHANo ratings yet

- MATHEMATICS WEEK3 2nd GRADE 4Document11 pagesMATHEMATICS WEEK3 2nd GRADE 4Jonah A. RecioNo ratings yet

- Fxrate 06 06 2023Document2 pagesFxrate 06 06 2023ShohanNo ratings yet

- Torrent WorkingDocument7 pagesTorrent WorkingsirmadamstudNo ratings yet

- Teaching Maths PDFDocument171 pagesTeaching Maths PDFAnkit Emmenual RamNo ratings yet

- PET-UT-U4 Without AnswersDocument2 pagesPET-UT-U4 Without AnswersAlejandroNo ratings yet

- Machiavellian Reflections (Part 1) : PreambleDocument9 pagesMachiavellian Reflections (Part 1) : PreambleMuhammet Fatih Cantepe100% (1)

- A&H Carrefour LayoutDocument1 pageA&H Carrefour LayoutAshraf EhabNo ratings yet

- EDTA CHEMICAL CLEANING (BLR) PDFDocument16 pagesEDTA CHEMICAL CLEANING (BLR) PDFAnudeep Chittluri100% (2)

- DT81 Data Logger DatasheetDocument2 pagesDT81 Data Logger DatasheetDuška JarčevićNo ratings yet

- Brazil Is Samba: Rhythm, Percussion, and Samba in The Formation of Brazilian National Identity (1902-1958)Document135 pagesBrazil Is Samba: Rhythm, Percussion, and Samba in The Formation of Brazilian National Identity (1902-1958)Carlos Barrientos100% (1)

- Orangutan ListDocument5 pagesOrangutan ListRam ChandiranNo ratings yet

- Pipe Pressure Drope ASEREHDocument3 pagesPipe Pressure Drope ASEREHSenghou MeasNo ratings yet

- Eb 12Document25 pagesEb 12SrewaBenshebilNo ratings yet

- DKE344 BibDocument2 pagesDKE344 BibMohamad SleimanNo ratings yet

- En 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresDocument26 pagesEn 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresGargiulo AnitaNo ratings yet

- Compiler Construction LabDocument11 pagesCompiler Construction LabSunny0% (1)

- Fin542 Individual AssignmentDocument10 pagesFin542 Individual AssignmentAliff FarhanNo ratings yet

- Arizona's Top Kitchen & Bath Remodeling ContractorDocument8 pagesArizona's Top Kitchen & Bath Remodeling ContractorPremier Kitchen and BathNo ratings yet

- Chapter 2 Indian Economy 1950-1990Document27 pagesChapter 2 Indian Economy 1950-1990Ajay pandeyNo ratings yet

- Temario Final Ingles 5°b PrimariaDocument1 pageTemario Final Ingles 5°b PrimariainstitutovalladolidNo ratings yet

- ESD122 2-Channel ESD Protection Diode For USB Type-C and HDMI 2.0Document27 pagesESD122 2-Channel ESD Protection Diode For USB Type-C and HDMI 2.0H tavangarNo ratings yet