Professional Documents

Culture Documents

Injection Pump Specification: D B 2 8 2 9 Ad Em4 2 4 4+

Injection Pump Specification: D B 2 8 2 9 Ad Em4 2 4 4+

Uploaded by

johnny sabin0 ratings0% found this document useful (0 votes)

21 views1 pageThis document provides specifications and calibration procedures for an injection pump model DB2829ADE4244+. Key points include:

1. The pump is for a 6.9L diesel engine in an International Harvester cargo truck and is set for full load RPM of 3000.

2. Testing procedures include checking nozzle opening pressure, fuel settings at various RPM levels, cam movement, throttle travel, and air/fuel timing.

3. Settings are provided for roller-roller dimension, idle screw adjustment, guide stud torque, throttle lever position, and housing pressure compensation.

4. Final checks include verifying fuel settings and cam movement at various RPM and throttle positions, and torquing fasteners per specifications

Original Description:

Original Title

04244

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications and calibration procedures for an injection pump model DB2829ADE4244+. Key points include:

1. The pump is for a 6.9L diesel engine in an International Harvester cargo truck and is set for full load RPM of 3000.

2. Testing procedures include checking nozzle opening pressure, fuel settings at various RPM levels, cam movement, throttle travel, and air/fuel timing.

3. Settings are provided for roller-roller dimension, idle screw adjustment, guide stud torque, throttle lever position, and housing pressure compensation.

4. Final checks include verifying fuel settings and cam movement at various RPM and throttle positions, and torquing fasteners per specifications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

21 views1 pageInjection Pump Specification: D B 2 8 2 9 Ad Em4 2 4 4+

Injection Pump Specification: D B 2 8 2 9 Ad Em4 2 4 4+

Uploaded by

johnny sabinThis document provides specifications and calibration procedures for an injection pump model DB2829ADE4244+. Key points include:

1. The pump is for a 6.9L diesel engine in an International Harvester cargo truck and is set for full load RPM of 3000.

2. Testing procedures include checking nozzle opening pressure, fuel settings at various RPM levels, cam movement, throttle travel, and air/fuel timing.

3. Settings are provided for roller-roller dimension, idle screw adjustment, guide stud torque, throttle lever position, and housing pressure compensation.

4. Final checks include verifying fuel settings and cam movement at various RPM and throttle positions, and torquing fasteners per specifications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

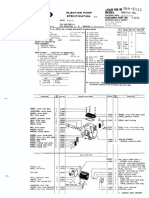

INJECTION PUMP MODEL D B 2 8 2 9 AD Em42 4 4+

MADE FROMHODEL DB2829ADE4191

SPECIFICATION Fleld service Only

L CUSTOMERS NAME 1 ADDRfSS

EDITION NO. 3 DATED 9129189 International Harvester Company

ENGINL 6.9L Hi Al t.SETTING ONLY FULLroio RPM 3000 Indianapolts. Indiana

APPL'CA'ION "s" SERIES CARGOSTARcov. REGULATION 10 X

NOTE: ALL SPEEDSARE IN ENGINE RPM ESS OTHERWISENOTED

TEST STAND USE LATEST REVISION FOR ALI :FERENCEDDOCUMENTS.

1. INJECTION LINES: ,078" I.D. BY 25” LONG(REF.S.B.81

2. NOZZLES PER SAE J96Bc WITH AB O.hn PLATE L AB 9. FOR THE RENAINDER OF THE SETTING PROCEDURE,COtiROL.

WSF 2044 A 5X SPRING THROllLE SHAFT ENf,PLAY TO .004"-:DO6" AS MEASUREDBETWEEN

3. NOZZLE OPENING PRESSURE....... 1700 t 25 PSI SPACER AND HOUSING ON THROTTLE LEVER SIDE.

4. CALIBRATING OIL-SAE 5967 (Latest Revision) IO. AT 3000RPM (WOT) (Roller-Rdller set Point1

TEMPERATUREIlO"-115°F or 43-46'C (at Inlet) b. .R.DTATE THE FAtE CAN TO ITS KAXIMUM LIti'PDSITION IN CONTACT

5. LOW PRESSUREPLUMBING SYSTEM - PER 5.8.334 FIG. 14 WITH CAM ROLLER.

(5.0i0.5 PSI At Pump Inlet) b. ADJUST TRIf+!ER SCREWFOR 3.5' CAN ADVANCE,

_ cr.r Fill-l _I-# -.lr-" .- .n -=,r-.....~-

6. CAM MOVEMENTREAD-OUT DEVICE P/N 23745

7. ALL FUEL READINGS ARE AT 1000 STROKES d. DE-ENERGIZE E‘SO. CHECK FUEi 4.Om3/STR. MAX.

PUMP OPERATING SPEED...HALF...ENGINE SPEED RE-ENERGIZE ESO.

PUMP ACCESSORIES: Il. AT 3150 RPM (WOTl

1. ELECTRIC SHUT-OFF (12V ETR) a. SET GUIDE'STUL) FOR 45-46 m3/STROKE.

2. M/LL ADVANCE 6. HOUSING PRESSURECOLD ADV. b. AFTER SETTING IS OBTAINED, TDRQUENUT (123585) TO

3. DELIVERY VALVE 7. TRAILING PORT ROTOR 80-90 lbf-in.

4. MIN-!iAX.GOVERNORIV 8. TEMPERATURECOMPENSATOR. c. CHECK DIRENSIDN 8ETWEEN.TOPDF NUT TO TOP OF GUIDE STUD AT

5. ACCUMULATORS .400" 13Ax.

PUMP CALIBRATION CHECKS: - AS’RECEIVED FOR SERVlCi .__ __

12. AT 1400 RPM

e. ADJUST THROTTLE LEVER FOR 27-29 cM3/STROKE. AND ROTATE FACE

I. OPERATEPUMP AT 2000 RPM (WDT) FOR 10 MINUTES TO CAM TO OBTAIN 3.0' CAM ADVANCE.

TO BRING TO OPERATINGTEMPERATUREAND CLEAR AIR b. AFTER SETTING s OBTAINED, TORQUESCREWP/N 22398 TO

_ _ _ _.

FROM SYSTFM. -_ -_ If&-ln.

28-30 ..__ ....

2. WITH THROTTLE LEVER IN LOW IDLE POSITION AT 400 RP C. WITH THROTTLEAT 28 MN3/STROKE PDSITION ALIGN O" ON

CHECK E.S.O. FOR PULL-IN WITH 8.8 VOLTS MAX. FUEL PROTRACTORP/N 22089 WITH CENTER RIB ON ROCKERLEVER.

DELIVERY SHOULDBE 15n&STROKE, MIN. RELEASE THROTTLE AND ROTATE 44' TOWARD1307 POSITION. ADJ.

3. CHECK POINTS: (SEQUENCEMUST BE FOLLOWEDAS LISTEC NAX. TRAVEL SCREWTO THIS 44' SETTING.

d. CHECK FACE CAM TORQUERETENTION PER S.B.361.,

THRTL. IOTE: ANY CHANGESAFTER THIS POINT WILL REQUIRE RETESTING OF PUMP

RPM pas. !+l3/STROKE CAM NOVEMENT - STARTING WITH STEP 10.

a. JODO WOT 45.5-49.5 2.5"-4.5"

b. 3000 3.0 MAX. c-m CHECK POINTS:

WOT(6d)

C. ;y;; L.I. --_ 8.D"-9.0"

d. _.~ un1 --- _-- THRTL. m3/ PRESSURE

e. 3450 iilri 16 MAX. --_ RPM PDS. STROKE t4O%ENT TP HOUSING

f. 2500 WOT --- 0;2$-29.:1'(6b) a. 3000 WOT 47.0-48.0 ---

1400 ADJ. 27-29 . -. b. 3000 L.I. --- ;2;~a3.;~'~- --_

;: 1400 WOT 47.5-55.5 c. 3150 WOT 44.5-47.5 '--: - 1:: ---

1. 650 8-16 (6a) -O"-2.75'

--- (6b) d. 3450 UOT 15 &j; --- 125 mix. ---

J. 650 ?I' -_- 0.75'-2.25"(6c) c. 2500 WOT --- 0.75*-1.75" (18h)-- ---

150 WOT' "26 MIN. --- f. 1400 WOT 50.0-53.0 ---

:: TOTAL THROTTLE TRAVEL FROM LOW IDLE TO WIDE OPEN g. 1400 ADJ. 27-29 2.75°-3.250 ::: 1::

SHOULDBE 60"-70". h. 650 L.I. 12-14 (18f) 0.75'-1.75'(18h) 8-12

4. CHECKAIR TIMING USING GAUGEP/N 24205(PERS.8.375 1. 650 L.I. --- 1.D=2.0°(18g) o-1

SET TO -4' * 0.5* j. 150 WOT 28 MIN. --- ,12 MIN. ---

5. TIMED TO THIS CYLINDER@ CHECK TOTAL THROTTLE TRAVEL 60' - 70°

;hj;;D FRO'! T.P. END CAT: . . ..RIGHT . . ..VIEWING END CAP

6. 1

~'$?T~U$' USING &AGE P/N 24205 (PER 5.8.375)

a. REiET USING LOW IDLE

b. LESS THAN READING OBTAINED IN STEP 3a. 2

;;:;;A:O-li+;$ CYLINDER (FROM END CAP) 8

C. GREATERTHAN READING OBTAINED IN STEP 3i. WITH

HOUSING PRESSURECOLD AD?ANCESOLENOIDENERGIZE a. TORQUEALL FASTENERSPER 5.8.106.

d. E.S.O. DE-ENERGIZED b. SECURETHE FOLLOWINGWITH LOCTITE 290.

PUMP SETTINGS: (FOLLOWING PUMP SERVICE ORRESETTING) 21646 MAX. TRAVEL ADJUSTING SCREW

1. ROLLER TO ROLLER DIMENSION...1.967" t .OOl

a. tlAX. ECCENTRICITY .OOB" TIR. 22398 FACE CAM SCREW

b. WITH O/s CAM RING R-R DIMENSION TO 8E.l.973. 22642 SERVOADVANCEADJUSTING SCREW

2 LIN&Lio& (REFER 5.8.338). C. HOUSING PRESSURECDLD ADVANCESOLENOID IS DE-ENERGIZED

.145" TO .165"(PER 5.8.95) EXCEPT AS REQUIRED IN STEPS 6c and 135.

3: GUIDE STUD %TOMEP TO ONE TURN OUT OF HOUSING. d. SEAL PUMP FASTERNERSPER S.B.365.

4 a. SET THROTTLEAT 49" AS MEASUREDBETWEENTHROTTL e. SEAL GUIDE STUD TO REAR COVERSCREWWITH 110408 SEALING

LEVER RETURN SPRING STUD WIRE ASSEMBLY.

OF THROTTLE SHAFT WITH f. IF ADJUSTMENTIS REOUIRED. USE L.I. SCREW. MAX. ADJUSTflENT

b. ADJUST LOW IDLE SCREWUNTIL CONTACTIS MADE WI1 IS f 1 TURN FROM POiNT SE? IN STEP 4a.

IDLE STOP BOSS. 9. GREATERTHAN READING OBTAINED IN STEP 13h WITH HOUSING

5. START TEST STtiND ANG RUN FOR 10 MINUTES C 2000 RPb PRESSURECOLD ADVANCESOLENOID ENERGIZED.

(WOT) h. LESS THAN READING OBTAINED IN STEP 13a.

6. AT 650 RPM

a. WITH THROTTLE SHAFT IN LOW IDLE POSITION, ADJU! IOTE: PVMP MOUNTING - HORIZONTAL PL?lP ROTATION - CLOCKWISE

TRANSFERPUMP PRESSURETO 58-60 PSI.

b. WITH GOVERNORCOVERREMOVED, ADJUST MN/MAX.

GOVERNOR ASSEMBLYFOR 12-14M+/STR. (FUEL

READING WITH COVER INSTALLED. CHECK HOUSING F(

18-12 PSI1

C. iriTH HOkiNG PRESSURECOLD ADVANCESOLENOID

ENERGIZED, CHECK HOUSING PRESSUREAT 1 PSI MAX.

7. AT 3000 (WOT)

a. CHECKTEST STAND BOOST PRESSUREAT 4.5-5.5 PSI,

b. WHENAIR BUBBLESCLEAR FROM RETURN LINE, SET

TRANSFERPUMP PRESSUREAT 94-96 PSI.

C. REDUCESPEED TO 1400 RPM, ADJUST RETURN OIL

TO 200-500 CC/MIN.

0. At 400 RPM (WGTJ

a. DE-ENERGIZE E.S.O. CHECK FUELDELIVERY 3m3/

STROKEWAX.

b. mU)VEWTlLE TO (LS).cIEw.S.O..FOR wLl.-Ib

WITH 10.0 -0+0.2 VOLTS. FUEL SHOULDBE 15 m

STROM MINIMUll

,.urrw cna YIY,L(IM I 1FT OF 18' HG.

You might also like

- How To Control Documents in Construction ProjectsDocument5 pagesHow To Control Documents in Construction Projectsensafeps100% (1)

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382100% (1)

- Plano de Teste e Lista de Peças DB2435-4972 KORVANDocument4 pagesPlano de Teste e Lista de Peças DB2435-4972 KORVANGiovaniBalzaniNo ratings yet

- Plano de Teste DB 2435-5686 John Deere 5425Document4 pagesPlano de Teste DB 2435-5686 John Deere 5425GiovaniBalzani100% (1)

- Bomba de Inyeccion 6068TF250Document4 pagesBomba de Inyeccion 6068TF250luishernandez100% (1)

- Supersides ModelDocument3 pagesSupersides Modeljohnny sabinNo ratings yet

- Wpersedes Model: DatedDocument3 pagesWpersedes Model: Datedjohnny sabinNo ratings yet

- DL B2825PCX272: Customer Part No. 561730Document3 pagesDL B2825PCX272: Customer Part No. 561730Ventas R11No ratings yet

- Injection Pump Specification: CUSTOMER PART NO.: 23500587 Customer'S Name & Address. Model No.: SupersedesDocument3 pagesInjection Pump Specification: CUSTOMER PART NO.: 23500587 Customer'S Name & Address. Model No.: Supersedesmarco rodNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentskhimkicityNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Ahmad SamehNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Eduardo David Castillo QuijandriaNo ratings yet

- DB2825PC3743: ModelDocument3 pagesDB2825PC3743: ModelVentas R11No ratings yet

- DB4429 6134Document4 pagesDB4429 6134OFFICE DANACNo ratings yet

- Customer PART NO. 22500241: 0 SuiersedesDocument3 pagesCustomer PART NO. 22500241: 0 SuiersedesVentas R11No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Shaft.: ScrewDocument3 pagesShaft.: ScrewVentas R11No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Kapalcrynski: Sufsrstdes ModelDocument3 pagesKapalcrynski: Sufsrstdes Modeljohnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsKevin TtitoNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Errol HuntNo ratings yet

- Plano de Teste Stanadyne DB2635-5681Document4 pagesPlano de Teste Stanadyne DB2635-5681Junior Iung100% (1)

- DB2825PC8271: ModelDocument3 pagesDB2825PC8271: ModelVentas R11No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Kevin TtitoNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Daniel Marin MoralesNo ratings yet

- RepairDocument4 pagesRepairKevin Ttito100% (1)

- STANADYNE DB4627-5762 PumpDocument4 pagesSTANADYNE DB4627-5762 Pumpmecanik.veracruzNo ratings yet

- db4429 5514Document4 pagesdb4429 5514WillianPachecoNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsMiguel RojasNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsAnonymous 5tkF5bFwONo ratings yet

- Workshop Injection Pump 05945Document4 pagesWorkshop Injection Pump 05945Kevin Ttito100% (1)

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Alejandro Manzano CumpianNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©johnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsTurbo TruckNo ratings yet

- PDFDocument4 pagesPDFAnonymous 5tkF5bFwONo ratings yet

- Diesel Systems Ce/Rnly: Injection Pump SpecificatiqnDocument3 pagesDiesel Systems Ce/Rnly: Injection Pump Specificatiqnmarco rodNo ratings yet

- 05354Document4 pages05354GiovaniBalzaniNo ratings yet

- STANADYNEDocument4 pagesSTANADYNECHRISTIAN LOZANONo ratings yet

- CALIBREDocument4 pagesCALIBREDiesel MotorsNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©johnny sabinNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Kamel BelhibaNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Port CranesNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Ahmad SamehNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Ahmad SamehNo ratings yet

- DB2335 6089Document4 pagesDB2335 6089OFFICE DANACNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©johnny sabinNo ratings yet

- DB4427-5370 Lionn Auto SoftwareDocument4 pagesDB4427-5370 Lionn Auto SoftwareOFFICE DANACNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsCenter Bombas InjetorasNo ratings yet

- Diesel Systems: Injection Pump Uooeldb2829Yl4187 1 SpecificationDocument3 pagesDiesel Systems: Injection Pump Uooeldb2829Yl4187 1 Specificationmarco rodNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Calibracion StanadineDocument3 pagesCalibracion StanadineAndres ContrerasNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Modeldbgfcc 431": - Catalog'Page NO: 580 - 3 51 6Document2 pagesModeldbgfcc 431": - Catalog'Page NO: 580 - 3 51 6johnny sabinNo ratings yet

- Kapalcrynski: Sufsrstdes ModelDocument3 pagesKapalcrynski: Sufsrstdes Modeljohnny sabinNo ratings yet

- Wpersedes Model: DatedDocument3 pagesWpersedes Model: Datedjohnny sabinNo ratings yet

- M O-352 4all: Mobel Ex-Kmx43Document2 pagesM O-352 4all: Mobel Ex-Kmx43johnny sabinNo ratings yet

- Catalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4Document2 pagesCatalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4johnny sabinNo ratings yet

- Supersides ModelDocument3 pagesSupersides Modeljohnny sabinNo ratings yet

- ,Lfd'Lalag'Pkge:Ljfj 500 - 35 L5: - . ZZ!ZZ - Mm. Per Max. Y&R. Trans. PumpDocument2 pages,Lfd'Lalag'Pkge:Ljfj 500 - 35 L5: - . ZZ!ZZ - Mm. Per Max. Y&R. Trans. Pumpjohnny sabinNo ratings yet

- 51 F3 Modeldbgfcc431-3Latl: - . C!Talog Page'NoDocument2 pages51 F3 Modeldbgfcc431-3Latl: - . C!Talog Page'Nojohnny sabinNo ratings yet

- 1 JJ Model: C"A?Al - Og No: Eititfcc93T Part No. A 35776Document2 pages1 JJ Model: C"A?Al - Og No: Eititfcc93T Part No. A 35776johnny sabinNo ratings yet

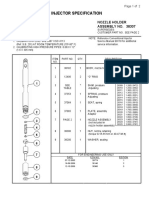

- Injector Specification: Nozzle Holder Assembly No. 38183Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38183johnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- Injection P Specificat: Thsuilo70Document2 pagesInjection P Specificat: Thsuilo70johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38307Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38307johnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- PF Pump Specification: Page 1 Di 2Document2 pagesPF Pump Specification: Page 1 Di 2johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly NO. 33732 (35057)Document2 pagesInjector Specification: Nozzle Holder Assembly NO. 33732 (35057)johnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump Specification: Page 1 Di 2Document2 pagesPF Pump Specification: Page 1 Di 2johnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- Injector Specification: Page 1 of 2Document2 pagesInjector Specification: Page 1 of 2johnny sabinNo ratings yet

- Injector Specification: Page 1 of 2Document2 pagesInjector Specification: Page 1 of 2johnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- Kyron Channelling John Magnetics Part 1Document1 pageKyron Channelling John Magnetics Part 1john100% (1)

- Lab WorkDocument22 pagesLab WorkTamil SelvanNo ratings yet

- How To Edit A Linux Live CD ISO in 30 Easy StepsDocument2 pagesHow To Edit A Linux Live CD ISO in 30 Easy StepsAndre SouzaNo ratings yet

- Weign Bridge OscillatorDocument4 pagesWeign Bridge Oscillatormanojkumar9No ratings yet

- Australian Standard: Pipelines-Gas and Liquid Petroleum Part 3: Operation and MaintenanceDocument10 pagesAustralian Standard: Pipelines-Gas and Liquid Petroleum Part 3: Operation and MaintenanceE.Kannan S.EhambaramNo ratings yet

- Hawai Chappal: - SpecificationDocument28 pagesHawai Chappal: - SpecificationAvinash MishraNo ratings yet

- HD Video USB DISK (Mini U8) ManualDocument5 pagesHD Video USB DISK (Mini U8) Manualthommcsi2013No ratings yet

- Simple Data Types in C: Alan L. Cox Alc@rice - EduDocument44 pagesSimple Data Types in C: Alan L. Cox Alc@rice - EduDavinder SinghNo ratings yet

- CoaxDocument88 pagesCoaxCarlos Henry Sánchez SNo ratings yet

- Noise ControlDocument118 pagesNoise ControlUmesh JadhaoNo ratings yet

- RX8 Manual InformationDocument49 pagesRX8 Manual InformationwillyhuaNo ratings yet

- ASSL Product ListDocument1 pageASSL Product Listmmrashid1904No ratings yet

- k18-k19 c650gt Flyer enDocument5 pagesk18-k19 c650gt Flyer enFeiming HuangNo ratings yet

- Hindustan Petroleum Corporation LimitedDocument1 pageHindustan Petroleum Corporation LimitedDinakarSatyaNo ratings yet

- Wifi Technology: by Nikhila Ann Varghese Malla Reddy Engineering CollegeDocument29 pagesWifi Technology: by Nikhila Ann Varghese Malla Reddy Engineering CollegeNeeha KuttyNo ratings yet

- Indian Wind Power, April - May 2016Document44 pagesIndian Wind Power, April - May 2016kjatin81No ratings yet

- Single Phase Induction Motors: Ans: BDocument16 pagesSingle Phase Induction Motors: Ans: BAmpolNo ratings yet

- DSLP Calc NarcDocument4 pagesDSLP Calc NarcDipanku GoswamiNo ratings yet

- Layup For Cycling Units: Requirements, Issues, and Concerns - An EPRI White PaperDocument12 pagesLayup For Cycling Units: Requirements, Issues, and Concerns - An EPRI White PaperAhmed El-ShafeiNo ratings yet

- Database Administration - The Complete Guide To Practices and Procedures Cap14 p2Document10 pagesDatabase Administration - The Complete Guide To Practices and Procedures Cap14 p2edgarNo ratings yet

- Moisture CorrectionDocument34 pagesMoisture CorrectionShitanshu SinghNo ratings yet

- Thiesclima - Wind Display LED - 30 05 2023Document3 pagesThiesclima - Wind Display LED - 30 05 2023Роман КарпенкоNo ratings yet

- Cellular Raft FoundationDocument2 pagesCellular Raft FoundationAvaniShah100% (2)

- Distance Amplitude Correction Curve (Dac) : 2.4mmø SDH 80% FSH 1 PositionDocument2 pagesDistance Amplitude Correction Curve (Dac) : 2.4mmø SDH 80% FSH 1 PositionAnonymous StO1rpYNo ratings yet

- Sero Prospekt SRZ eDocument8 pagesSero Prospekt SRZ esdafas dfNo ratings yet

- MACH2265 Sales Spec Sheet enDocument2 pagesMACH2265 Sales Spec Sheet enLord StovNo ratings yet

- Oracle EAM Failure AnalysisDocument4 pagesOracle EAM Failure AnalysisDock N DenNo ratings yet

- Discoloration of Concrete PDFDocument0 pagesDiscoloration of Concrete PDFJimmy LopezNo ratings yet

- Ashwin Chandore ResumeDocument5 pagesAshwin Chandore ResumeashwinchandoreNo ratings yet