Professional Documents

Culture Documents

Politeknik Nilai, Negeri Sembilan Jabatan Kejuruteraan Mekanikal

Politeknik Nilai, Negeri Sembilan Jabatan Kejuruteraan Mekanikal

Uploaded by

DKM3C-F1056-PRAVINESHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Politeknik Nilai, Negeri Sembilan Jabatan Kejuruteraan Mekanikal

Politeknik Nilai, Negeri Sembilan Jabatan Kejuruteraan Mekanikal

Uploaded by

DKM3C-F1056-PRAVINESHCopyright:

Available Formats

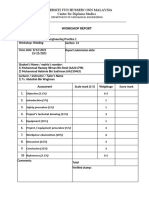

POLITEKNIK NILAI, NEGERI SEMBILAN

JABATAN KEJURUTERAAN MEKANIKAL

DJJ30082-MECHANICAL WORKSHOP PRACTICE 3

WORKSHOP REPORT

(TIG WELDING/MIG WELDING)*

CLO1 Perform welding tasks according to workshop Standard Operating Procedure.(P4, PLO5)

CLO3 Demonstrate awareness of social responsibility and safety procedures in the workshop according to the workshop

safety regulations and create a secured environment in an organization while doing practical work (A3, PLO6)

NAME REGISTRATION NO CLASS

PRAVINESH A/L PARTIBAN 23DKM20F1056 DKM4C

LECTURER NAME

1. EN MOKHSEIN ABDUL MANAP

2.

CRITERIA MARK WEIGHT TOTAL

MARKS

INRODUCTION 5 1 /5

AIM/OBJECTIVE 5 1 /5

WORK MATERIAL/EQUIPMENT 5 1 /5

WORK METHOD/PROCEDURE 5 3 /15

DISCUSSION 5 2 /10

CONCLUSION/RECOMMENDATION 5 1 /5

REFERENCES 5 1 /5

TOTAL /50

TOTAL MARKS %

DATE SUBMISSION 22 MAY 2022

*POTONG YANG MANA TIDAK BERKENAAN

INRODUCTION

Originally Inert Gas Tungsten Arc Welding (Tungsten Inert Gas) is a

type of arc welding made the atmosphere control. Tungsten electrodes

were used. Electrodes only to produce an arc only. So, for the weld when

the metal Additional required to weld, trunk filler rod should be fed to the

weld area as methods done in oxy-gas welding process acetylene. During

the welding process is a shield in the form of gas inert (argon & helium) is used

to block the welded from atmospheric air. Shield works for prevent oxidation at

the electrode tip, a puddle weld and the parent metal in the vicinity of the

welded. There are two types of commonly used welding nozzle weld TIG

operation manually. For welding use per current is low (less than 200

amperes) when welding thin material, weld nozzles are usually of the type that

can cooled in air conditioning. But, for welding require more current than

200 amperes, the nozzle weld should be cooled with water so that the

electrodes do not become overheated. TIG welding is applied in all industrial

sectors but is especially suitable for high quality welding. In manual welding,

the relatively small arc is ideal for thin sheet material or controlled

penetration (in the root run of pipe welds). Because deposition rate can

be quite low (using a separate filler rod) MMA or MIG may be preferable for

thicker material and for fill passes in thick-wall pipe welds. TIG welding is also

widely applied in mechanised systems either autogenously or with filler wire.

However, several 'off the shelf' systems are available for orbital welding of

pipes, used in the manufacture of chemical plant or boilers. The systems

require no manipulative skill, but the operator must be well trained. Because

the welder has less control over arc and weld pool behaviour, careful attention

must be paid to edge preparation (machined rather than hand-prepared), joint

fit-up and control of welding parameters.

OBJECTIVE

• To gain experience and knowledge of the use of TIG arc welding and

materials safe.

• In order to improve the quality or skill in welding.

• The real way to know how to weld with inert gas welding and accurate. •

Knowing how to weld properly.

• In order to familiarize themselves in welding while making industry

training and preparation for the job when due.

WORK MATERIAL/EQUIPMENT

TIG WELDING MACHINE

TIG WELDING TORCH

TORCH LINER

ARGON GAS

PRESSURE REGULATORS WITH FLOW METERS

TUNGSTEN ELECTRODE

EARTH CLAMP

PLIERS

WIRE BRUSH WITH CHIPPING HAMMER

WORK PLACE TABLE

WORKPIECE

BENCH GRINDER MACHINE

SAFETY EQUIPMENTS

WELDING HELMET

WELDING GLOVES

SAFETY BOOT

WELDING JACKET

SAFETY PRECAUTION

• Always listen carefully to the lecturer and follow instructions.

• Do not run / rush in the workshop.

• Know where the emergency stop buttons are positioned in the workshop.

• Always wear a face shield and welding glove before the welding is started.

• Wear good strong shoes or safety boot. Training shoes are not suitable.

• When attempting practical work, all stools should be put away.

• Bags should be stored away, during practical sessions in the workshop.

• When learning how to use a machine, listen very carefully to all the

instructions given by the lecturer. Ask questions, especially if you do not fully

understand.

• Do not use a machine, if you have not been shown how to operate it safely

by your lecturer.

• Always be patient, never rush to do the practical work.

• Always use guards, when operating machines.

• Keep hands / hair and clothing away from moving / rotating parts of

machinery.

• Use hand tools carefully, and stored it to their place properly after use.

• Report any damage / faults to machines / equipment. Damage or a faulty

part, could cause an accident.

• Keep your workbench tidy. When you have finished with a tool /

piece of equipment, return it to its storage cupboard / rack.

• Never distract another pupil, when they are working on a machine or using

tools /equipment.

WORK METHOD/PROCEDURE

1)First, the workpiece is placed on the

work table.

2) Second, the earth clamp is placed

at the foot of the work table to ensure

the current is connected.

3) Third the main switch is turned on

and also the argon gas is opened and

make sure the pressure for the

workpiece.

4) Next, the power button of the

machine is also turned on.

5) Then the voltage, current and also

resistance is adjusted according to

suitability in order to get a good

quality of welding.

6) The TIG welding torch is held at an

own convenience.

7) After that, start a slightly welding

at the end part of the workpiece as a

mark before starting re-welding on

the workpiece according to the

instructions given to complete the

task.

8) In case the tungsten electrode is

blunt, open the back of the torch and

take the tungsten electrode out then

sharpen the electrode using a bench

grinding machine.

9)Afterwards, the workpiece is re-

welded in a straight line from the right

side to the end of the left side with a

suitable speed by pressing the trigger

to obtain the lap joint.

10) Finally, the wire brush is used to

make the workpiece shine and free

from dust. Ready to submit the task.

DISCUSSION

In TIG welding, a non-consumable tungsten electrode is used to establish an

arc on the base metal. The heat of the arc produced melts the base metal and

produces a weld pool. In contrast to normal stick welding, when TIG welding,

an inert gas shields the weld area in order to prevent air from contaminating

the weld. This shielding gas prevents oxidation of the tungsten electrode,

the molten weld puddle, and the heat-affected zone adjacent to the weld bead.

In a typical TIG setup, an AC/DC welding machine is used with a flow of

shielding gas. The shielding gas goes through a regulator and flow meter and

on to the torch. The torch has a collet body combination that holds the

electrode. A heat-resistant cup or ceramic nozzle surrounds the electrode and

controls the gas shield. In addition, water-cooled TIG machines are available

for high-amperage welding applications. Tungsten inert gas (TIG) welding

became an overnight success in the 1940s for joining magnesium and

aluminium. Using an inert gas shield instead of a slag to protect the weld pool,

the process was a highly attractive replacement for gas and manual metal arc

welding. TIG has played a major role in the acceptance of aluminium for high

quality welding and structural applications. Process characteristics: In the TIG

welding process the arc is formed between a pointed tungsten electrode and

the workpiece in an inert atmosphere of argon or helium. The small intense arc

provided by the pointed electrode is ideal for high quality and precision

welding. Because the electrode is not consumed during welding, the TIG

welder does not have to balance the heat input from the arc as the metal is

deposited from the melting electrode. When filler metal is required, it must be

added separately to the weld pool.

CONCLUSION

The conclusion is, I have learned many things during this project, especially in

dealing with TIG machine. This is because there are several steps that

must be followed before conducting proper welding. We need to be

comfortable with the welding equipment. Practice welding on scrap metal. This

is a good way to become familiar with the equipment you are using, allowing

for more confidence when doing the actual welding. Besides, reducing

amperage to prevent overheating plus slightly increase travel speed or shorten

the arc length.

REFERENCES

https://www.studocu.com/my/document/politeknik-sultan-azlan-shah/

mechanical-practical/tig-welding-practical-report/21118517

https://en.wikipedia.org/wiki/Gas_tungsten_arc_welding

https://www.academia.edu/5198060/WELDING_REPORT

You might also like

- Report FittingDocument33 pagesReport FittingNaqiuddin MuhamadNo ratings yet

- Report On Metal FabricationDocument48 pagesReport On Metal Fabricationdj170263% (8)

- Djj10022 Fitting ReportDocument7 pagesDjj10022 Fitting ReportTamil passang songNo ratings yet

- Welding SOP 29 Feb 12 1Document6 pagesWelding SOP 29 Feb 12 1Trương Định100% (1)

- Report Jf303 Tunstern Inert Gas (Tig)Document12 pagesReport Jf303 Tunstern Inert Gas (Tig)aizatulasmira60% (5)

- 300 GMS Inverter Arc Welder Operators Manual (0-2419)Document52 pages300 GMS Inverter Arc Welder Operators Manual (0-2419)John Anderson100% (2)

- Productivity and EcononyDocument69 pagesProductivity and EcononyVijayan MunuswamyNo ratings yet

- Yr 8 Particle TheoryDocument4 pagesYr 8 Particle Theoryapi-354570228No ratings yet

- Politeknik Nilai, Negeri Sembilan Jabatan Kejuruteraan MekanikalDocument5 pagesPoliteknik Nilai, Negeri Sembilan Jabatan Kejuruteraan MekanikalDKM3C-F1056-PRAVINESHNo ratings yet

- Report Gas PoliteknikDocument9 pagesReport Gas PoliteknikDKMF1054 MUHAMMAD SALMANNo ratings yet

- Template Jawapan 2 Report BengkelDocument12 pagesTemplate Jawapan 2 Report BengkelSyfull musicNo ratings yet

- COVER PAGE Rubrik TIG DJF21012Document10 pagesCOVER PAGE Rubrik TIG DJF21012Alif MuqriNo ratings yet

- Milling Machine ReportDocument11 pagesMilling Machine ReportDKM4AF2025 Haris JNo ratings yet

- Fakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaDocument11 pagesFakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaAbdul AzimNo ratings yet

- Manufacturing TechnologyDocument26 pagesManufacturing TechnologyParas kapoorNo ratings yet

- DJJ40142 Lab Report EDM - IZZAT HANIF (07DKM22F1035)Document11 pagesDJJ40142 Lab Report EDM - IZZAT HANIF (07DKM22F1035)Young RussleNo ratings yet

- Chung Cheang Ping (20dkm18f2032)Document16 pagesChung Cheang Ping (20dkm18f2032)Syfull musicNo ratings yet

- MIGDocument7 pagesMIGMuhammad RedzuanNo ratings yet

- Lab Report 4 WeldingDocument8 pagesLab Report 4 Weldingayman suleriNo ratings yet

- COVER PAGE Rubrik MIG DJF21012Document10 pagesCOVER PAGE Rubrik MIG DJF21012Alif MuqriNo ratings yet

- Universiti Tun Hussein Onn Malaysia Centre For Diploma StudiesDocument15 pagesUniversiti Tun Hussein Onn Malaysia Centre For Diploma StudiesMuhammad Hazeeq Hilman Bin RosliNo ratings yet

- Mada Wulabu University College of Engineering and Instituty of TechnologyDocument9 pagesMada Wulabu University College of Engineering and Instituty of Technologyzelalem wegayehuNo ratings yet

- Welding Report Sem3Document11 pagesWelding Report Sem3hakimNo ratings yet

- Welding PDFDocument5 pagesWelding PDFg-ipgp23271000No ratings yet

- Fakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaDocument5 pagesFakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodNo ratings yet

- 4.gas Welding Butt Joint FlatDocument2 pages4.gas Welding Butt Joint FlatTayyab HussainNo ratings yet

- MST185 Manual SMLDocument44 pagesMST185 Manual SMLGreg MeyerNo ratings yet

- Corner JointDocument2 pagesCorner JointTayyab HussainNo ratings yet

- A Internship Report On (Shreyas) PDFDocument33 pagesA Internship Report On (Shreyas) PDFshreyasNo ratings yet

- A Internship Report On (Shreyas)Document33 pagesA Internship Report On (Shreyas)shreyasNo ratings yet

- Test 1 SKEI3133 - Jan2019Document4 pagesTest 1 SKEI3133 - Jan2019Saumik HeronNo ratings yet

- Final ProjectDocument50 pagesFinal ProjectIsmail BiradarNo ratings yet

- Welding and Tools: Section 3Document8 pagesWelding and Tools: Section 3juniorarmasNo ratings yet

- Harmee TooDocument26 pagesHarmee TooBirbirsa BetieNo ratings yet

- Gas Welding: Group MembersDocument10 pagesGas Welding: Group MembersMohd Faruq Azri AhmadNo ratings yet

- Basic ElectricalDocument133 pagesBasic ElectricalBk BhaiNo ratings yet

- 3.gas Welding Bead MakingDocument2 pages3.gas Welding Bead MakingTayyab HussainNo ratings yet

- Manufacture of Welding StandsDocument4 pagesManufacture of Welding Stands6dqqt6zjmjNo ratings yet

- Report Welding MigDocument15 pagesReport Welding Mighafi zackNo ratings yet

- TA-201 Lab MannualDocument19 pagesTA-201 Lab MannualAnujNagpalNo ratings yet

- Mig ReportDocument14 pagesMig ReportDhana KumaranNo ratings yet

- Mechanical Workshop Practice Mig and Tig ReportDocument16 pagesMechanical Workshop Practice Mig and Tig ReportHafiy Qursyeini100% (1)

- Tank Cover MakingDocument27 pagesTank Cover MakingAmaljithNo ratings yet

- MGF Lab Manual-IIDocument35 pagesMGF Lab Manual-IIdanielrita570No ratings yet

- DJF 3012 - Manufacturing Workshop Practice 2Document7 pagesDJF 3012 - Manufacturing Workshop Practice 2Leeahna JkNo ratings yet

- TIG Workshop ReportDocument9 pagesTIG Workshop ReportKee Zhenyuan100% (1)

- Handout - Foundry (DAM 11502)Document6 pagesHandout - Foundry (DAM 11502)Ariff ShasteraNo ratings yet

- Procedure For WeldingDocument7 pagesProcedure For WeldingMecon Hyderabad100% (2)

- Welding ReportDocument15 pagesWelding ReportSamNo ratings yet

- Laboratory Manual: College of Engineering, OsmanabadDocument47 pagesLaboratory Manual: College of Engineering, OsmanabadEngr Ali RazaNo ratings yet

- Report Welding PoliDocument15 pagesReport Welding PoliSyahzlan IskandarNo ratings yet

- Spectroanalysis of MetalsDocument9 pagesSpectroanalysis of MetalsTashrif YusufNo ratings yet

- Welding ATWDocument62 pagesWelding ATWARPIT MATHURNo ratings yet

- 2.gas Welding Pool MakingDocument2 pages2.gas Welding Pool MakingTayyab HussainNo ratings yet

- DJJ10022 Report (Sir Amri)Document6 pagesDJJ10022 Report (Sir Amri)Muhd Imran Kasyidi OmarNo ratings yet

- Engine Valves Production Summer PractiseDocument26 pagesEngine Valves Production Summer Practisestatica27100% (2)

- Gas Welding Workshop ReportDocument12 pagesGas Welding Workshop ReportDuventhirenNo ratings yet

- Mechanics L3 - Perform Plate and Tube Welding (GTAW)Document162 pagesMechanics L3 - Perform Plate and Tube Welding (GTAW)Nhựt HiếuNo ratings yet

- Edm Shahrul DKM4B 07DKM22F1011Document8 pagesEdm Shahrul DKM4B 07DKM22F1011Young RussleNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- 23DKM20F1056Document5 pages23DKM20F1056DKM3C-F1056-PRAVINESHNo ratings yet

- Front PageDocument1 pageFront PageDKM3C-F1056-PRAVINESHNo ratings yet

- CNC Worksheet - DJJ40142 Mechanical Workshop Practice 4Document7 pagesCNC Worksheet - DJJ40142 Mechanical Workshop Practice 4DKM3C-F1056-PRAVINESHNo ratings yet

- Front PageDocument1 pageFront PageDKM3C-F1056-PRAVINESHNo ratings yet

- CNC Worksheet - djj40142 Mechanical Workshop Practice 4Document7 pagesCNC Worksheet - djj40142 Mechanical Workshop Practice 4DKM3C-F1056-PRAVINESHNo ratings yet

- CNC Worksheet - DJJ40142 Mechanical Workshop Practice 4Document7 pagesCNC Worksheet - DJJ40142 Mechanical Workshop Practice 4DKM3C-F1056-PRAVINESHNo ratings yet

- Politeknik Nilai, Negeri Sembilan Jabatan Kejuruteraan MekanikalDocument5 pagesPoliteknik Nilai, Negeri Sembilan Jabatan Kejuruteraan MekanikalDKM3C-F1056-PRAVINESHNo ratings yet

- Bending TestDocument12 pagesBending TestDKM3C-F1056-PRAVINESHNo ratings yet

- Basic Hydraulic CircuitDocument12 pagesBasic Hydraulic CircuitDKM3C-F1056-PRAVINESHNo ratings yet

- Multi BeamDocument13 pagesMulti Beamlelo2k3No ratings yet

- Auxiliary System Charge Air System: Sterling and Wilson Co-Gen SolutionsDocument17 pagesAuxiliary System Charge Air System: Sterling and Wilson Co-Gen SolutionsKeshav Shrivastava KSNo ratings yet

- Stress Analysis of Angle Bar With Different Process Parameter in Hot RollingDocument7 pagesStress Analysis of Angle Bar With Different Process Parameter in Hot RollingVashishth KushwahaNo ratings yet

- ABET LAB Unitary OperationsDocument4 pagesABET LAB Unitary OperationsPaulina PerezNo ratings yet

- Transport Phenomena Drsharazad FarahDocument82 pagesTransport Phenomena Drsharazad Farahalexar40@hotmail.comNo ratings yet

- Material Testing Lab ManualDocument58 pagesMaterial Testing Lab Manualrammohan reddyNo ratings yet

- Layers of The EarthDocument20 pagesLayers of The EarthAshley Nicole VillegasNo ratings yet

- Design Application HairpinDocument23 pagesDesign Application Hairpinkinjalpatel12345No ratings yet

- King Fahd University of Petroleum & MineralsDocument15 pagesKing Fahd University of Petroleum & MineralsTommyVercettiNo ratings yet

- Santosh Kumar B: Twi India PVT LTDDocument8 pagesSantosh Kumar B: Twi India PVT LTDsrinivasyadav4No ratings yet

- Chapter 3 Diffusion Osmosis Lecture NotesDocument7 pagesChapter 3 Diffusion Osmosis Lecture Notesshammah2rashadNo ratings yet

- Introduction To Chemical Engineering Thermodynamics: (7th Edition)Document8 pagesIntroduction To Chemical Engineering Thermodynamics: (7th Edition)Shanice CabrilesNo ratings yet

- Structure of SolidsDocument16 pagesStructure of SolidsAnancy Reza Ngarbingan100% (1)

- Synthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010Document7 pagesSynthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010TigerNo ratings yet

- Gasdynamics AE4140 Chapter 1: IntroductionDocument60 pagesGasdynamics AE4140 Chapter 1: IntroductionPythonraptorNo ratings yet

- 01) Pressure Vessels and Piping-NewDocument242 pages01) Pressure Vessels and Piping-NewHaytham Mohamed0% (1)

- Application of The K J and CTOD Param PDFDocument8 pagesApplication of The K J and CTOD Param PDFchandruNo ratings yet

- Products Manufactured by Ajm, WJMDocument15 pagesProducts Manufactured by Ajm, WJMGunjan Satish NarkhedeNo ratings yet

- BrazeMaterialGuide EN 2017.05Document16 pagesBrazeMaterialGuide EN 2017.05amir hejaziNo ratings yet

- Royal Composites PVT LTD India: WWW - Royalseals.co - inDocument171 pagesRoyal Composites PVT LTD India: WWW - Royalseals.co - inAalap MankadNo ratings yet

- Question Bank MeteorologyDocument27 pagesQuestion Bank MeteorologyAnonymous fn2k34dpd100% (1)

- A Level Chemistry Scheme of Work 4.2Document55 pagesA Level Chemistry Scheme of Work 4.2Tiras NgugiNo ratings yet

- Flexural Properties of Stringer Sections (Lipped and Unlipped Angles, Channels and Z-Sections)Document6 pagesFlexural Properties of Stringer Sections (Lipped and Unlipped Angles, Channels and Z-Sections)Lênon Guimarães Silva AlípioNo ratings yet

- RBE All FluidsDocument32 pagesRBE All Fluidsapi-3700460No ratings yet

- Achievement TestDocument2 pagesAchievement Testmdbilal2812001No ratings yet

- Unit 1-TribologyDocument7 pagesUnit 1-TribologyPalak NaikNo ratings yet

- 1 s2.0 S235201242400119X MainDocument22 pages1 s2.0 S235201242400119X MainmohamedNo ratings yet

- CH 14 ThermodynamicsDocument46 pagesCH 14 ThermodynamicsHarshad MehtaNo ratings yet

- PC160LC-8 KEPB215100 RedDocument424 pagesPC160LC-8 KEPB215100 RedRexNo ratings yet