Professional Documents

Culture Documents

Hyundai Wheel Loader New 7 Series

Hyundai Wheel Loader New 7 Series

Uploaded by

haiccdk6Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hyundai Wheel Loader New 7 Series

Hyundai Wheel Loader New 7 Series

Uploaded by

haiccdk6Copyright:

Available Formats

www.hyundai-ce.

com

Bucket Selection Guide Supplemental Specifications

2.9

(3.8) Change in operating Change in static tipping Change in static tipping

Description weight kg(lb) load-straight kg(lb)

2.7 load-40ᴋturn kg(lb)

(3.5)

NEW 7 SERIES

Bucket Capacity, m3 (yd3)

2.5

(3.3)

17.5-25 12PR L2 -308 (-679) -218 (-481) -192 (-423) HYUNDAI WHEEL LOADER

2.3

ᵉ Cummins QSB5.9-C Engine

(3.0) 17.5-25 12PR L3 -248 (-547) -175 (-386) -155 (-342) ᵉ Gross Power : 104 kW / 140 HP

2.1 ᵉ Max.Power : 108 kW / 145 HP

(2.7) 20.5-25 16PR L2 -64 (-141) -45 (-99) -40 (-88) ᵉ Bucket Capacities :

1.9

(2.5) HL740-7/HL740XTD-7 1.78 to 2.1 m3 (2.3 to 2.7 yd3)

17.5 R25 XHAᵂ -160 (-353) -113 (-249) -100 (-220) HL740TM-7 1.7 to 2.0 m3 (2.2 to 2.6 yd3)

1.7

(2.2) 3

ᵉ Operating Weight :

1400 1600 1800 2000 2200 2400 kg/m

20.5 R25 XHAᵂ +507 (+1,118) +358 (+789) +317 (+699) HL740-7 11,500 kg (25,350 lb)

2000 2500 3000 3500 4000 lb/yd3

Material Density HL740TM-7 12,050 kg (26,570 lb) Tier II Engine

HL740-7

HL740XTD-7

HL740XTD-7 11,850 kg (26,120 lb)

HL740TM-7

Standard Equipment

Electrical system ᴌengine rpm Cab Engine enclosure, lockable Remote cooling fan,

Alternator, 70A ᴌtransmission gear range Cab, ROPS/FOPS Engine fuel priming pump hydraulically-driven,

Alarms, audible and visual indicator (sound suppressed and pressurized) with : Fan guard temperature sensing type

ᴌair filter clogging ᴌjob time and distance ᴌcigar lighter & ashtray Fuel/water separator

ᴌtransmission error ᴌtemperature(coolant, hydraulic ᴌcoat hook Muffler, under hood with large Others

ᴌalternator voltage oil, T/M oil) ᴌfront/rear window defroster exhaust stack Articulation locking bar

ᴌbrake oil pressure ᴌintermittent wiper and washer, Precleaner, engine air intake Coolant level sight gauge

Lighting system

ᴌengine oil pressure Counterweight

ᴌ2 dome lights front and rear Radiator

ᴌparking brake ᴌpersonal storage space: Door and cab locks, one key

ᴌ2 stop and tail lights Starting aid (air intake heater)

ᴌfuel level Doors, service access(locking)

ᴌ4 turn signals holder, can and cup Water sensor on fuel filter

ᴌhydraulic oil temperature ᴌrear view mirrors (2 inside) Drawbar with pin

ᴌbrake lights(counterweight)

ᴌcoolant temperature ᴌrear view mirrors (2 outside) Power Train Engine oil level dipstick gauge

ᴌlicense plate light

ᴌservice brake oil pressure ᴌseat belt Brakes : Service, enclosed wet-disc Ergonomically located and slip

ᴌhead light

Batteries, 850 CCA, 12V, (2) ᴌseat, adjustable suspension Differential, Front : limited Slip resistant, left & right

2 on front tower

Rear : conventional - handrails

Gauges ᴌworking lights with armrests

ᴌtilt / telescopic steering wheel Parking brake - ladders

ᴌengine coolant temperature 2 on front roof

ᴌsteering wheel with knob Torque converter - platforms

ᴌfuel level 2 on grill

ᴌsunvisor (front window) Transmission, computer-controlled, - steps

ᴌhydraulic oil temperature Switches

ᴌtinted safety glass electronic soft shift, auto-shift and Fenders(front/rear)

ᴌspeedometer ᴌbuzzer stop

quick-shift features included Guard, bucket cylinder rod

ᴌtransmission oil temperature ᴌclutch cut-off Magazine box

Transmission oil cooler Hydraulic oil level sight gauge

ᴌvoltmeter ᴌhazard Pedals

ᴌone accelerator pedal License plate bracket

Horn, electric ᴌlgnition key, start/stop switch Hydraulics

ᴌone brake pedal Lift and tie-down hooks

Indicator lights ᴌmain light(illumination and Boom lock safety valve Steering stops, cushioned

ᴌclutch cut-off head light) Rubber floor mat Boom kickout, automatic Tires(20.5-25, 16PR,L3)

ᴌhigh beam ᴌparking Wrist rest Bucket positioner, automatic Transmission oil level dipstick

ᴌturn signal ᴌrear wiper & washer Diagnostic pressure taps

Engine gage

ᴌwork light ᴌwork light Hydraulic system,

Antifreeze Vandalism protection caplocks

LCD Display ᴌfull automatic transmission ᴌ2 spool, single lever, pilot control

Engine, Cummins QSB5.9-C

ᴌclock and fault code Starter, electric for boom and bucket actuation

ᴌLow Emission Diesel, Tier-ll

ᴌoperating hour counter Starting and charging system(24-volt) Steering, load-sensing

Optional Equipment

24-volt to 12-volt DC converter Emergency steering system Mud guard ᴌ3” retractable seat belt & Tool kit

Air condition : Fire extinguisher Open Canopy (ROPS/FOPS) adjustable air suspension Tooth, 1 piece, bolt-on type

ᴌair conditioner Fuel warmer Operator suit Tires : Guards

ᴌair conditioner with heater Hourmeter Radio cassette player ᴌ17.5 - 25, 12PR, L2 ᴌcrankcase

ᴌheater High lift arrangement with Ride control system ᴌ17.5 - 25, 12PR, L3 ᴌtransmission

Alarm, back-up optional counterweight, Seat ᴌ20.5 - 25, 16PR, L2 Wheel chock

Beacon light, rotating 760 kg (1,680 lb) ᴌ2” static seat belt & ᴌ17.5 R25 XHAᵂ

Lighting, auxilary 4 on roof Hydraulic control, 2 lever adjustable mechanical ᴌ20.5 R25 XHAᵂ

Cutting edge, bolt-on type Hydraulic control, 3 lever suspension(vinyl)

Differential, Front : no spin Hydraulic arrangement 3-valve ᴌ3” static seat belt &

Rear : limited slip Lighting, auxiliary, 4 on roof adjustable mechanical

Main disconnect switch suspension

Standard and optional equipment may vary. Consult your Hyundai dealer for more information. The machine shown may vary according to territorial specification.

␊ Photo may include optional equipment.

PLEASE CONTACT

www.hyundai-ce.com 2004. 04 rev2

Hardworking Hyundai Loaders

Meet the new generation wheel loader in Hyundai.

The HL740-7 will give you the satisfaction in higher power, lower fuel consumption,

more comfort and lower emission.

Come and experience what Hyundai has created for you by bringing together

power and up-to-the-minute technology.

Wheel Loader

Engine

Electronic Engine Control System

Engine Protection & Self-diagnosis System

Max. Power 145 HP

Transmission

2 Automatic Selection Mode

2 Kick Down Function Mode

AEB Function

␊ Photo may include optional equipment.

The all-new, deluxe operating space was engineered with

Control 3-D modeling to be your ultimate control center. The wide,

Center tinted and laminated front windshield has no framing

cutting through to ensure excellent visibility.

The Centralized Display & Attached

Instrument Panel

The centralized digital display the status and

conditions of your machine at a glance.

Easy-to-read gauges and adjustable tilting

and telescopic steering with an attached

instrument panel provide constant, and

accurate information.

Joystick Control Lever

Two kickdown switches located on top of the

loader control lever and the gear shifting lever

allow the operator to change instantly to 1st

stage lower gear, in order to drive at full

power into the material.

The Air Conditioning and

Up-to-date-technology CAN system Heating System

Engine Control Unit(ECU), Transmission Control The operator can easily control the

Unit(TCU) and Machine Control Unit(MCU) realize the temperature and air flow . The defroster

optimal performance through the mutual on the front windshield and rear window

CAN communications. makes it convenient for winter working

usage.

ECU TCU

MCU

Full automatic shift lever

A single lever on the left side of the steering Ride control system (optional)

column gives the operator fast, easy control of The ride control system is available for smooth travelling as option.

Adjustable steering column It significantly reduces machine bouncing and absorbs the shocks in the machine,

speed and direction. Push the lever forward to go

forward, pull it back for reverse. enhancing the productivity of the machine. This system reduces the fatigue of the

Travelling is automatically changed from 1st stage driver as well as the stress on the structures and components.

to given stage according to travel speed and The system is consisted of accumulators in the hydraulic lift circuit, hydraulic

40ᴮ control valve and selection switch.

tractive effort. The operator can select two

80 mm kinds of automatic modes (1st ␡ 4th, 2nd ␡ 4th). ♮ Off position : Function is cancelled ♯ On position : Function is available

This exclusive feature contributes to a step-up in ♰ Auto position : Function is available when the machine travels above

productivity and reduction of operator fatigue. 9.5km/hr(6.0mph). If the machine travels under 8 km/hr (5.0 mph), the function is

cancelled automatically.

Control Center 4 Control Center 5

Engine

The CUMMINS QSB5.9-C

A Well Rounded System electronic control engine

combines full-authority

electronic controls with

the reliable performance.

The combination of

improved airflow and

evenly dispersed fuel

results in increased

power, improved transient

response and reduced fuel

consumption.

And the QSB5.9-C used

advanced electronics

controls to meet the emission standards

(EPA TierII, EU StageII)

Multi Function

Transmission

The newly developed transmission

control represents the beating heart

of transmission. The hydraulic

Up-to-date hydraulic remote system for gearshifts is working

cooling fan with proportional valves, which

allow a very precise control of the

The minimum fuel consumption and low noise by clutches. For each gearchange, the

applying hydraulic cooling fan sensing coolant control unit performs a monitoring

temperature, transmission oil temperature, intake function to ensure the specified

air temperature and hydraulic oil temperature. shift curve is adhered to, and

readjusts the shift pressure applied

to the clutches accordingly. This

results in smooth gearshifts-even

under load-with no traction interrupt.This helps to avoid standstill

of the vehicle, sudden load changes and torque peaks under all

conditions, for example application on steep terrain with full load.

In addition, there is the option for the driver to make gearshifts

manually.

Rear Axle

Inboard type brake discs.

Heavy duty axle.

␊ Photo may include optional equipment.

Bucket cylinder guard High-rigidity frames Battery master switch Sealed loader linkage Frame lock Drive Shaft

This guard helps to prevent possible Front and rear frames are designed for A master switch disconnects the battery Fully protected fitting and the sealed Machine can be locked by this locking bar Permanent lubricating drive shaft.

damage from load material. work in the toughest applications to power to protect the electrical system loader linkage with dust seals and o-ring to prevent movement during transportation. There is no need to add grease

provide high rigidity for the power train and from excess electrical drainage. will extend lubrication intervals periodically.

loader equipment. The high-rigidity frames, remarkably.

together with the reinforced loader linkage,

resist loading stress and shock.

A Well Rounded System 6 A Well Rounded System 7

Accessible and Serviceable

Easy Access to All Engine Accessary

Here you find the engine oil check, and the main and

pre-filters. The large access engine side panels

permit easy and safe inspection. The fuel filter can be

spun on and off for quick replacements.

Cabin Air Fresh Filter

The internal pressure is maintained

to be slightly higher than that of

outside to exclude dust and to

reduce noise levels.

Fuse Box

A concentrated fuse box for easy

inspection.

Coolant Sight Gauge

The coolant sight gauge is

installed on the radiator top tank

for convenient checks of coolant

level.

␊ Photo may include optional equipment.

Accessible grease Simple air filter Central electric Remote type drain port Hydraulic tank Oil sight gauge Transmission oil port

fittings replacements controllers It is now easier to change your The hydraulic tank is located behind the cab The hydraulic oil check sight The transmission oil change

Grease fittings are highlighted The air cleaner is easily Electric controllers for this engine oil, coolant and to increase the accessibility of hydraulic gauge is installed on the side port is also located for open

and available around the replaceable by turning the Hyundai loader are hydraulic oil with the remote hoses and pipes. of the hydraulic tank for accessibility and comes with

machine for fast access when wing nut on the outer shell centralized to improve service drain port. convenient checks from an anti-vandalism lock for

doing your service checks. counter-clockwise. access. ground level. your machine protection.

Accessible and Serviceable 8 Accessible and Serviceable 9

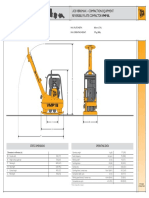

Specifications & Dimensions

Engine Axles Brakes Dimensions

Maker/Model Cummins QSB5.9-C Drive system Four-wheel drive system Hydraulically actuated, wet disc

brakes actuate all 4 wheels

Type 4-cycle, turbocharged, Mount Rigid front axle and Service brakes independent axle-by-axle system.

electronic controlled diesel engine oscillating rear axle Single pedal braking including M

clutch cut off switch.

E

Rear axle oscillation ᴦ12ᴋ(total 24ᴋ

) B

Gross power 140HP(104 kW) / 2,200rpm

F

Hub reduction Planetary reduction at wheel end Spring-applied, hydraulically

K

J

A

L

Net power 133HP(99 kW) / 2,200rpm Parking brake released wet disc brake in

Differential Limited slip front & Conventional rear front axle .

Maximum power 145HP(108 kW) / 2,000rpm

I

G H

Reduction ratio 22.846 N

C

60kg.m(434 lb.ft) / 1,500rpm

D

Maximum torque When brake oil pressure

drops, indicator light alerts mm(ft-in)

No. of cylinders 6 Emergency brake

operator and parking brake UNIT HL740-7 HL740XTD-7 HL740TM-7

Description

Bore x Stroke 102 mm (4.02”) x 120 mm (4.72”) automatically applies.

Hydraulic system Bucket Type General purpose bolt-on cutting edge

Displacement 5.9ὀ(359 cu in) A. Dumping clearance at max.

mm (ft-in) 2,850 (9’ 4”) 3,270 (10’ 9”) 2,915 (9’ 7”)

height and 45o dump angle.

Compression ratio 18.0 : 1 Open-centered, tandem circuit system. Full lift

mm(ft-in) 970 (3’ 2”) 965 (3’ 2”) 1,275 (4’ 2”)

Air cleaner Dry, dual elements Type Pilot-operated controls. B. Reach

7ft height mm(ft-in) 1,500 (4’ 11”) 1,860 (6’ 1”) 1,790 (5’ 10”)

Closed with pressure and vacuum relief.

Alternator 24V, 70 Amp Steering system C. Digging depth(mm (in)) mm(ft-in) 93 (3.7”) 130 (5.1”) 100 (3.9”)

Helical gear type, 177 liters/min on ground mm(ft-in) 7,270 (23’ 10”) 7,750 (25’ 5”) 7,550 (24’ 9”)

Battery 2 x 12V, 100 Ah. Pump (46.8 USgpm)@governed rpm D. Overall length

at carry mm(ft-in) 7,230 (23’ 9”) 7,720 (25’ 4”) 7,390 (24’ 3”)

Type Full hydraulic power steering

Starting motor 24V, 3.7 kW Two function valve with single or E. Overall height (fully raised) mm(ft-in) 5,070 (16’ 8”) 5,480 (18’) 5,150 (16’ 11”)

Pump Gear type, 99 liters/min(26.2 USgpm)

Control valve two lever controls : F. Bucket pivot max. height mm(ft-in) 3,830 (12’ 7”) 4,250 (13’ 11”) 3,990 (13’ 1”)

Cooling Hydraulic remote cooling system @ governed rpm

Optional third-function valve G. Front overhang mm(ft-in) 2,400 (7’ 10”) 2,810 (9’ 3”) 2,625 (8’ 7”)

Net power output of standard engine as installed in this with auxiliary lever. Relief valve setting 210 kg/cm2 (2,990 psi) H. Wheelbase mm(ft-in) 2,900 (9’ 6”) 2,900 (9’ 6”) 2,900 (9’ 6”)

vehicle(per SAE J1349) complete with fan, air cleaner, Relief valve setting 220 kg/cm2 (3,130 psi) I. Ground clearance mm(ft-in) 417 (1’ 4”) 417 (1’ 4”) 417 (1’ 4”)

Cylinder

alternator, water pump, lubricating oil pump and fuel Pilot system J. Height over exhaust mm(ft-in) 2,900 (9’ 6”) 2,900 (9’ 6”) 2,900 (9’ 6”)

pump. No derating for continuous operating required up Type Double acting

K. Height over cab mm(ft-in) 3,260 (10’ 8”) 3,260 (10’ 8”) 3,260 (10’ 8”)

to 3048m (10000ft). This engine meets the EPA(Tierௗ) / Type Pilot oil pressure is generated Bore x stroke 65 mm(2.5") x 420 mm(16.5") L.. Roll-back on ground deg 42 42 50

EU(Stageௗ) Emission regulation. by the pilot oil supply unit

Relief valve setting Steering angle 40o(each direction) angle at carry deg 47 49 54

30 kg/cm2 (427 psi)

M. Dump angle(deg) deg 48 48 50

Bucket controls Features Clearance circle mm(ft-in) 11,770 (38’ 7”) 12,110 (39’ 9”) 11,840 (38’ 10”)

Transmission - Center-point frame articulation N. Overall width mm(ft-in) 2,550 (8’ 4”) 2,550 (8’ 4”) 2,550 (8’ 4”)

Type Pilot operated lift and tilt circuit,

single-lever(joystick) control standard. - Load-sensing system

Full automatic power shift, countershaft type with soft- - Steering-wheel operated metering pump controls

shift in range and direction. Properly matched torque flow to steering cylinders

The valve has four functions ; Overview

converter to engine and transmission for excellent - Tilt and telescopic steering column

raise, hold, lower and float.

working ability. Two mode automatic shifting system. Lift circuit

Can adjust automatic kickout Description UNIT HL740-7 HL740XTD-7 HL740TM-7

from horizontal to full lift. Operating weight kg (lb) 11,500 (25,350) 11,850(26,120) 12,050 (26,570)

3-elements, single-stage

Torque converter type Heaped m3 (yd3) 2.1 (2.7) 2.1(2.7) 2.0 (2.6)

single-phase The valve has three functions ; Bucket capacity

Struck m3 (yd3) 1.78 (2.3) 1.78(2.3) 1.7 (2.2)

Stall torque ratio 2.910 :1 tilt back, hold and dump Service refill capacities Breakout force-bucket kg (lb) 11,880(26,190) 11,730(25,860) 10,650(23,480)

Tilt circuit Can adjust automatic bucket

Straight kg (lb) 9,180(20,240) 8,320(18,340) 7,950(17,530)

Travel speed km/h (mph) positioner to desired load angle. Fuel tank 228 liters (60.2 USgal)

Tipping load

Full turn kg (lb) 7,930(17,490) 7,210(15,900) 6,860(15,120)

20.25-25, L3

Cylinder Type : Double acting Cooling system 35 liters (9.2 USgal)

1st 6.9 (4.3) No. of cylinders-bore x stroke; Crankcase 16.4 liters (4.3 USgal) Tires

Forward

Lift 2-120 mm(4.7") x 738 mm(29.1")

2nd 12.6 (7.8) Tilt HL740-7 1-140 mm(5.5") x 500 mm(19.7") Transmission 24 liters (6.3 USgal)

Type Tubeless, loader design tires

3rd 24.0 (14.9) HL740TM-7 2-100 mm(3.9") x 745 mm(29.3") Front axle 21.2 liters (5.6 USgal)

Standard 20.5-25, 16 PR, L3

4th 38.2 (23.8) Cycle time HL740-7/HL740XTD-7 HL740TM-7 Rear axle 21.2 liters (5.6 USgal)

17.5-25, 12 PR, L2

Reverse 1st 7.3 (4.5) Raise (with load) 5.5 sec 5.5 sec Hydraulic tank 105 liters (27.7 USgal) 17.5-25, 12 PR, L3

Dump 1.2 sec 1.4 sec Options include 20.5-25, 16 PR, L2

2nd 13.3 (8.3) Hydraulic system

Lower (empty) 2.8 sec 2.8 sec 165 liters (43.6 USgal) 17.5 R25 XHAᵂ

3rd 25.3 (15.7) Total 9.5 sec 9.7 sec (including tank) 20.5 R25 XHAᵂ

Specifications & Dimensions 10 Specifications & Dimensions 11

You might also like

- Ford Escape-Training-Manual PDFDocument436 pagesFord Escape-Training-Manual PDFKen Krut82% (11)

- Piaggio Carnaby Cruiser 300 Ie (En)Document326 pagesPiaggio Carnaby Cruiser 300 Ie (En)Manualles78% (9)

- dct250 Powershift Rebuild ManualDocument94 pagesdct250 Powershift Rebuild ManualSanyok Ganz100% (1)

- EX15 enDocument4 pagesEX15 enhaiccdk6No ratings yet

- Hyundai D4da 98HP PDFDocument2 pagesHyundai D4da 98HP PDFNguyễn Thanh Tín75% (4)

- Commercial Blower Coil Air Handlers: TraneDocument2 pagesCommercial Blower Coil Air Handlers: TraneWan Norhisyam Wan Mohamad100% (2)

- Toyota - Automatic Transmissions - 25 Diagnostic ProceduresDocument32 pagesToyota - Automatic Transmissions - 25 Diagnostic Proceduresvagdesign60% (5)

- Operation Manual Envasadora Automatica JX021-1 Powder Packaging MachineDocument36 pagesOperation Manual Envasadora Automatica JX021-1 Powder Packaging MachineCirilo Garfias Contreras100% (1)

- CB360 Searchable ManualDocument174 pagesCB360 Searchable Manualanon_682444343No ratings yet

- CatalogDocument100 pagesCatalogFrancis Lebel100% (1)

- Ce Eng Hl740-7a Dec2012 Rev.4 WebDocument6 pagesCe Eng Hl740-7a Dec2012 Rev.4 WebviedinsonNo ratings yet

- Ficha Técnica Cargador-Frontal-Hyundai-HL740-7Document6 pagesFicha Técnica Cargador-Frontal-Hyundai-HL740-7Michael GalassiNo ratings yet

- Chieftain 2100X (3-Deck) Data SheetDocument1 pageChieftain 2100X (3-Deck) Data SheetbrianNo ratings yet

- DAIKIN VRV Systems Comparison (May-15)Document1 pageDAIKIN VRV Systems Comparison (May-15)zafar.ucNo ratings yet

- Atlas Copco: Small Portable Air CompressorsDocument2 pagesAtlas Copco: Small Portable Air CompressorsAsad AijazNo ratings yet

- Tata 1109 G LPT BrochureDocument2 pagesTata 1109 G LPT BrochureVishal Karad100% (1)

- Lampiran A Spesifikasi Excavator Komatsu PC 400Document3 pagesLampiran A Spesifikasi Excavator Komatsu PC 400Anton MaleNo ratings yet

- PS-EN203+ZX470LC-5G+vs+PC400LC-8(For+Russia)Document4 pagesPS-EN203+ZX470LC-5G+vs+PC400LC-8(For+Russia)Nguyễn ĐạtNo ratings yet

- SY35 Vs Competition - V2Document4 pagesSY35 Vs Competition - V2Raj Kumar V RNo ratings yet

- FireBall Oil Pump SpecificationsDocument1 pageFireBall Oil Pump SpecificationsInstruktur MesinNo ratings yet

- The Ready To Go Range: The 8 Series. What Do You Tow?Document8 pagesThe Ready To Go Range: The 8 Series. What Do You Tow?Mohamad NasserNo ratings yet

- XE230C BrochureDocument4 pagesXE230C Brochureecoritesh144No ratings yet

- C-10 & C-12 Industrial Engine BDLDocument18 pagesC-10 & C-12 Industrial Engine BDLblueseatxNo ratings yet

- Datasheet 3 RTGM 1018150 D 1T1 1T2 1T1 L 5,400.0Document2 pagesDatasheet 3 RTGM 1018150 D 1T1 1T2 1T1 L 5,400.0Edson PulaskiNo ratings yet

- MTX Series Spec PageDocument2 pagesMTX Series Spec PageService AgroMONDONo ratings yet

- Bucket Selection Guide Supplemental SpecificationsDocument6 pagesBucket Selection Guide Supplemental SpecificationsJhon MenesesNo ratings yet

- LoaderDocument6 pagesLoaderSefa yıldızNo ratings yet

- CPS 185 KD T4F Compressor Flyer 71414 V2 tcm332-3538870Document2 pagesCPS 185 KD T4F Compressor Flyer 71414 V2 tcm332-3538870jamalhabbas742No ratings yet

- STTT Walkaround GuideDocument4 pagesSTTT Walkaround GuideMohammad Fikri Aditya RamadhanNo ratings yet

- Cargador Frontal Hl760-9 HyundaiDocument6 pagesCargador Frontal Hl760-9 Hyundaiuriel zavala hernandezNo ratings yet

- Brosur Engine MarineDocument21 pagesBrosur Engine MarineChulunk04No ratings yet

- Bucket Selection Guide Supplemental SpecificationsDocument6 pagesBucket Selection Guide Supplemental SpecificationsJosue Juaniquina LucanaNo ratings yet

- Td-Hiab T-Hiduo 029-En-Eu - 150402Document8 pagesTd-Hiab T-Hiduo 029-En-Eu - 150402DavidNo ratings yet

- RenaultSport Clio 200 Raider October 2011Document2 pagesRenaultSport Clio 200 Raider October 2011BreoNo ratings yet

- Ficha Tecnica CF Hyundai HL757 7 PDFDocument6 pagesFicha Tecnica CF Hyundai HL757 7 PDFanmec20No ratings yet

- Cat - 950H - 962H - Compettive Bulletin - TEJB9281Document25 pagesCat - 950H - 962H - Compettive Bulletin - TEJB9281Airthon Najar100% (1)

- Bucket Selection Guide Supplemental SpecificationsDocument6 pagesBucket Selection Guide Supplemental SpecificationsRiski KurniawanNo ratings yet

- Datasheet 3 RTGM 1223120 E 1T1 1T2 1T1 L 5,400.0Document2 pagesDatasheet 3 RTGM 1223120 E 1T1 1T2 1T1 L 5,400.0Edson PulaskiNo ratings yet

- AE20/BE20: SeriesDocument7 pagesAE20/BE20: SeriesPatricio Acuña0% (1)

- Guia Práctica de Interpretacià N de La Resolucià N SRT 9002015 Protocolo de Medicià N de Puesta A TierraDocument2 pagesGuia Práctica de Interpretacià N de La Resolucià N SRT 9002015 Protocolo de Medicià N de Puesta A TierraSergio Fabian VasicekNo ratings yet

- Rotator Baltrotors GR105DBDocument3 pagesRotator Baltrotors GR105DBAnonymous 80HAPYsoNo ratings yet

- Guia Mecanica Compresor Aire Ir Rs30iDocument9 pagesGuia Mecanica Compresor Aire Ir Rs30iAndy acevedoNo ratings yet

- 9 Aluminum Gear PumpDocument10 pages9 Aluminum Gear PumpEddy OrtegaNo ratings yet

- CE ENG HL770-9S AUG2018 Rev.7 WebDocument6 pagesCE ENG HL770-9S AUG2018 Rev.7 Webmaikaru86No ratings yet

- Bucket Selection Guide Supplemental SpecificationsDocument6 pagesBucket Selection Guide Supplemental Specificationsanon_485665212No ratings yet

- Specifications: Heel OaderDocument4 pagesSpecifications: Heel OaderMat Pole LapriNo ratings yet

- 4245 Aa DC 1362502004 Is00Document1 page4245 Aa DC 1362502004 Is00Tayyab AchakzaiNo ratings yet

- RTN 900 Product Family PosterDocument1 pageRTN 900 Product Family PosterAung Aung OoNo ratings yet

- TC - Rak - (18-50) Peb - Web - en (TC - Erp-Peb 00.0) (05.14)Document38 pagesTC - Rak - (18-50) Peb - Web - en (TC - Erp-Peb 00.0) (05.14)Paweł PszczółkowskiNo ratings yet

- Cargador Frontal Hl770-9 HyundaiDocument6 pagesCargador Frontal Hl770-9 Hyundaiuriel zavala hernandezNo ratings yet

- MHilux Tech SpecDocument3 pagesMHilux Tech SpecKesh DursunNo ratings yet

- Specifications BMW X6 Xdrive30d Xdrive40d 04 2012Document2 pagesSpecifications BMW X6 Xdrive30d Xdrive40d 04 2012Alex AlxNo ratings yet

- 5.13 7 8 Lobes 5.7 StagesDocument1 page5.13 7 8 Lobes 5.7 StagesLeonardo BarriosNo ratings yet

- Bosch Split Highwall - Climate Line 5000i ENDocument2 pagesBosch Split Highwall - Climate Line 5000i ENMannu KiruiNo ratings yet

- Climate Line 5000i en KeDocument2 pagesClimate Line 5000i en Kezaheer Zafar KhanNo ratings yet

- 4-3/4" LBTB: - Mud Lubricated Bearing PackDocument3 pages4-3/4" LBTB: - Mud Lubricated Bearing PackGina Vanessa Quintero CruzNo ratings yet

- JCB Vibromax - Compaction Equipment Reversible Plate Compactor Vmp18LDocument2 pagesJCB Vibromax - Compaction Equipment Reversible Plate Compactor Vmp18LskirmantasNo ratings yet

- Kubota Produktinfo U30 3ALPHA2Document5 pagesKubota Produktinfo U30 3ALPHA2MarkiyanNo ratings yet

- Bobcat Skid Steer LoadersDocument8 pagesBobcat Skid Steer LoadersSa DzNo ratings yet

- TD-TDUO013-EN-EU 151110 Original 74705Document8 pagesTD-TDUO013-EN-EU 151110 Original 74705pawel.jasinski00No ratings yet

- Liugong Global Product PosterDocument2 pagesLiugong Global Product PosterSandeep Kumar100% (2)

- T8 EnglishDocument12 pagesT8 Englishgustavo puentes hidalgoNo ratings yet

- Well Program Summary 2Document18 pagesWell Program Summary 2Samuel Arevalo0% (1)

- Butterworth-Heinemann - Civil Jet Aircraft Design - Engine Data File - CFMI and IAEDocument2 pagesButterworth-Heinemann - Civil Jet Aircraft Design - Engine Data File - CFMI and IAEAlrino Dwi PrasetyoNo ratings yet

- Bucket Selection Guide Supplemental SpecificationsDocument6 pagesBucket Selection Guide Supplemental Specificationshadi_kurniawan000No ratings yet

- The DVB-H Handbook: The Functioning and Planning of Mobile TVFrom EverandThe DVB-H Handbook: The Functioning and Planning of Mobile TVNo ratings yet

- FX30DDocument2 pagesFX30Dhaiccdk6No ratings yet

- Ex25 2,35 2,45 2, Hanixs&b800Document1 pageEx25 2,35 2,45 2, Hanixs&b800haiccdk6No ratings yet

- 534B BrochureDocument6 pages534B Brochurehaiccdk6No ratings yet

- EX55-135UR 60-200-5 Sliding ArmDocument1 pageEX55-135UR 60-200-5 Sliding Armhaiccdk6No ratings yet

- EX25Document4 pagesEX25haiccdk6No ratings yet

- S-100/S-105 Specifications: Self-Propelled Telescopic BoomDocument1 pageS-100/S-105 Specifications: Self-Propelled Telescopic Boomhaiccdk6No ratings yet

- EX55UR-3 JPDocument7 pagesEX55UR-3 JPhaiccdk6No ratings yet

- 534C 9Document4 pages534C 9haiccdk6No ratings yet

- FK145W enDocument6 pagesFK145W enhaiccdk6No ratings yet

- L1F6F60-10U enDocument3 pagesL1F6F60-10U enhaiccdk6No ratings yet

- 30BHD Series FourDocument6 pages30BHD Series Fourhaiccdk6No ratings yet

- 544DDocument2 pages544Dhaiccdk6No ratings yet

- L245F 1976 enDocument38 pagesL245F 1976 enhaiccdk6No ratings yet

- Short Radius: WT HP BKT CapDocument16 pagesShort Radius: WT HP BKT Caphaiccdk6No ratings yet

- BW600 950 1 - JPDocument6 pagesBW600 950 1 - JPhaiccdk6No ratings yet

- Ä) (Ónê Lã Îè°Xêjêó) Óääê, ΰÄh °nêvõêvì°Document4 pagesÄ) (Ónê Lã Îè°Xêjêó) Óääê, ΰÄh °nêvõêvì°haiccdk6No ratings yet

- Short Radius: WT HP BKT CapDocument16 pagesShort Radius: WT HP BKT Caphaiccdk6No ratings yet

- EX12Document4 pagesEX12haiccdk6No ratings yet

- L 506 - L 510 The Stereoloaders .: Stereo StereoDocument15 pagesL 506 - L 510 The Stereoloaders .: Stereo Stereohaiccdk6No ratings yet

- BW284 BrochureDocument4 pagesBW284 Brochurehaiccdk6No ratings yet

- Wheel Loaders L 550 - L 580: New GenerationDocument28 pagesWheel Loaders L 550 - L 580: New Generationhaiccdk6No ratings yet

- D275AX-5E0 2018 JPDocument7 pagesD275AX-5E0 2018 JPhaiccdk6No ratings yet

- ZW250 enDocument11 pagesZW250 enhaiccdk6No ratings yet

- New 7 Series: Bucket Selection Guide Supplemental SpecificationsDocument6 pagesNew 7 Series: Bucket Selection Guide Supplemental Specificationshaiccdk6No ratings yet

- 70SR 80CS EZprintDocument20 pages70SR 80CS EZprinthaiccdk6No ratings yet

- Power Source: Back To Kobelco ExcavatorsDocument3 pagesPower Source: Back To Kobelco Excavatorshaiccdk6No ratings yet

- Short Radius: WT HP BKT CapDocument2 pagesShort Radius: WT HP BKT Caphaiccdk6No ratings yet

- CCH500 2Document7 pagesCCH500 2haiccdk6No ratings yet

- (N) Xääê L° Óîê-Ê / °nnh° °óxêvõêþ'Document8 pages(N) Xääê L° Óîê-Ê / °nnh° °óxêvõêþ'haiccdk6No ratings yet

- Filedate - 858download Ebook Shigleys Mechanical Engineering Design 11Th Ed PDF Full Chapter PDFDocument67 pagesFiledate - 858download Ebook Shigleys Mechanical Engineering Design 11Th Ed PDF Full Chapter PDFjeremy.collins128100% (37)

- ZIP R3i R3 REPAIR MANUALDocument141 pagesZIP R3i R3 REPAIR MANUALRaul ArroyoNo ratings yet

- System OperationDocument82 pagesSystem OperationAntonio MejicanosNo ratings yet

- Monster 900S (2001)Document103 pagesMonster 900S (2001)Yuri FabresNo ratings yet

- Sinnis Terrain 125 Motorcycle Owner's Manual PDFDocument68 pagesSinnis Terrain 125 Motorcycle Owner's Manual PDFMVPNo ratings yet

- FS1800 - Enplr1Document45 pagesFS1800 - Enplr1ncflatfenderNo ratings yet

- Ford of Europe Special Service Tools Since 2003Document8 pagesFord of Europe Special Service Tools Since 2003Ricardo BolañosNo ratings yet

- Power+Take-Off+ (PTO) Eng 13 1858382Document22 pagesPower+Take-Off+ (PTO) Eng 13 1858382james100% (1)

- 6hp19 26 PDFDocument92 pages6hp19 26 PDFВиталий Черненко100% (9)

- Komatsu D375Document24 pagesKomatsu D375Bambang Cliquers50% (2)

- Instructions AND Parts Manual: Modular Drive SystemDocument55 pagesInstructions AND Parts Manual: Modular Drive SystemMarcos Ribeiro100% (1)

- English - Car AnatomyDocument4 pagesEnglish - Car Anatomyabdulfetahabdi32No ratings yet

- Eaton 14" and 15.5" Heavy-Duty Manual Adjust Clutch CLMT1351 US-ENDocument2 pagesEaton 14" and 15.5" Heavy-Duty Manual Adjust Clutch CLMT1351 US-ENwayne fountainNo ratings yet

- Ashcroft ZF4HP22Document15 pagesAshcroft ZF4HP22Felipe Mercado SandyNo ratings yet

- At8603 TTWDocument5 pagesAt8603 TTWManiKjNo ratings yet

- Model MT-70H: Parts and Operation ManualDocument44 pagesModel MT-70H: Parts and Operation ManualRui FerreiraNo ratings yet

- Daytona T595 Et Speed Triple T509 Manuel Propriétaire ANGLAISDocument81 pagesDaytona T595 Et Speed Triple T509 Manuel Propriétaire ANGLAISTriumphadonfNo ratings yet

- 13-58 HD MOD-B 6-DegreeDocument57 pages13-58 HD MOD-B 6-Degreenardo_ing100% (1)

- Covered & Claim by Warranty SmartDocument8 pagesCovered & Claim by Warranty SmartDestinyz ChanNo ratings yet

- Acknowledgement: Mechanical DesignDocument72 pagesAcknowledgement: Mechanical DesignEyob KetemaNo ratings yet

- F&G Series EURO 5Document6,078 pagesF&G Series EURO 5Whet Crisostomo50% (2)

- Owner's Manual: Snow ThrowerDocument49 pagesOwner's Manual: Snow ThrowerGaryNo ratings yet