Professional Documents

Culture Documents

Refineries and The Environment

Refineries and The Environment

Uploaded by

Anh Bui TuanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refineries and The Environment

Refineries and The Environment

Uploaded by

Anh Bui TuanCopyright:

Available Formats

REFINERIES AND THE ENVIRONMENT

Air, water and land can all be affected by refinery operations. Refineries are well aware of their responsibility to the community and employ a variety of processes to safeguard the environment. The processes described below are those used by the Shell refinery at Geelong in Victoria, but all refineries employ similar techniques in managing the environmental aspects of refining. AIR Preserving air quality around a refinery involves controlling the following emissions:

y y y y

Sulphurdoxides hydrocarbon vapours smoke smells

Sulphur enters the refinery in crude oil feed. Gippsland and most other Australian crude oils have a lowsulphur content but other crude's may contain up to 5 per cent sulphur. To deal with this refineries incorporate a sulphur recovery unit which operates on the principles described above. Many of the products used in a refinery produce hydrocarbon vapours. The escape of vapours to atmosphere are prevented by various means. Floating roofs are installed in tanks to prevent evaporation and so that there is no space for vapour to gather in the tanks. Where floating roofs cannot be used, the vapours from the tanks are collected in a vapour recovery system and absorbed back into the product stream. In addition, pumps and valves are routinely checked for vapour emissions and repaired if a leakage is found. Smoke is formed when the burning mixture contains insufficient oxygen or is not sufficiently mixed. Modern furnace control systems prevent this from happening during normal operation. Smells are the most difficult emission to control and the easiest to detect. Refinery smells are generally associated with compounds containing sulphur, where even tiny losses are sufficient to cause a noticeable odour. WATER Aqueous effluent's consist of cooling water, surface water and process water. The majority of the water discharged from the refinery has been used for cooling the various process streams. The cooling water does not actually come into contact with the process material and so has very little contamination. The cooling water passes through large "interceptors" which separate any oil from minute leaks etc., prior to discharge. The cooling water system at Geelong Refinery is a once-through system with no recirculation.

Rainwater falling on the refinery site must be treated before discharge to ensure no oily material washed off process equipment leaves the refinery. This is done first by passing the water through smaller "plant oil catchers", which each treat rainwater from separate areas on the site, and then all the streams pass to large "interceptors" similar to those used for cooling water. The rainwater from the production areas is further treated in a Dissolved Air Flotation (DAF) unit. This unit cleans the water by using a flocculation agent to collect any remaining particles or oil droplets and floating the resulting flock to the surface with millions of tiny air bubbles. At the surface the flock is skimmed off and the clean water discharged. Process water has actually come into contact with the process streams and so can contain significant contamination. This water is treated in the "sour water treater" where the contaminants (mostly ammonia and hydrogen sulphide) are removed and then recovered or destroyed in a downstream plant. The process water, when treated in this way, can be reused in parts of the refinery and discharged through the process area rainwater treatment system and the DAF unit. Any treated process water that is not reused is discharged as Trade Waste to the sewerage system. This trade waste also includes the effluent from the refinery sewage treatment plant and a portion of treated water from the DAF unit. As most refineries import and export many feed materials and products by ship, the refinery and harbour authorities are prepared for spillage from the ship or pier. In the event of such a spill, equipment is always on standby at the refinery and it is supported by the facilities of the Australian Marine Oil Spill Centre at Geelong, Victoria. LAND The refinery safeguards the land environment by ensuring the appropriate disposal of all wastes. Within the refinery, all hydrocarbon wastes are recycled through the refinery slops system. This system consists of a network of collection pipes and a series of dewatering tanks. The recovered hydrocarbon is reprocessed through the distillation units. Wastes that cannot be reprocessed are either recycled to manufacturers (e.g. some spent catalysts can be reprocessed), disposed of in EPA-approved facilities off-site, or chemically treated on-site to form inert materials which can be disposed to land-fill within the refinery. Waste movements within the refinery require a "Process liquid, Sludge and Solid waste disposal permit". Wastes that go off-site must have an EPA "Waste Transport Permit".

You might also like

- Petroleum Refinery HSE ManualDocument11 pagesPetroleum Refinery HSE ManualFarrukh TouheedNo ratings yet

- h2 Dew PointDocument4 pagesh2 Dew Pointgeddam0610882592% (13)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- VWS Westgarth Specialises in The Turnkey Design and Build of Water Treatment Plants For Upstream Oil and Gas MarketsDocument4 pagesVWS Westgarth Specialises in The Turnkey Design and Build of Water Treatment Plants For Upstream Oil and Gas Marketskay50No ratings yet

- Objectives TypesDocument24 pagesObjectives TypesLouis Alfred MendrosNo ratings yet

- Petroleum Refineries Waste Water - AssignmentDocument29 pagesPetroleum Refineries Waste Water - AssignmentIastra100% (2)

- Etp Process - RefineryDocument3 pagesEtp Process - Refinerysumit gulatiNo ratings yet

- WWT in RefineryDocument32 pagesWWT in RefineryGodwin100% (1)

- Dialogue - Acd. Uriarte Jr.Document22 pagesDialogue - Acd. Uriarte Jr.John Dave WilsonNo ratings yet

- Environmental Impact Analysis 233Document10 pagesEnvironmental Impact Analysis 233Kayla CoxNo ratings yet

- Ibp1868 12Document8 pagesIbp1868 12Marcelo Varejão CasarinNo ratings yet

- Finals Marpower Reviewer MroomsDocument22 pagesFinals Marpower Reviewer MroomsBerbaño, Jan JoshuaNo ratings yet

- Brochure Producedwater Sorbwater For WEBDocument12 pagesBrochure Producedwater Sorbwater For WEBManvendra SinghNo ratings yet

- CairnDocument5 pagesCairnsamcat2009No ratings yet

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Document9 pagesThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationNo ratings yet

- Discuss The Pure Dry Waste Oil Recovery System On Board The ShipDocument3 pagesDiscuss The Pure Dry Waste Oil Recovery System On Board The ShipSwarg VibhaNo ratings yet

- Applications: Reverse Osmosis Is A Separation Process That Uses Pressure To Force A Solvent Through ADocument4 pagesApplications: Reverse Osmosis Is A Separation Process That Uses Pressure To Force A Solvent Through AGoutam GiriNo ratings yet

- Rocla Oil Grease SeparatorsDocument12 pagesRocla Oil Grease Separatorsmoloko masemolaNo ratings yet

- Crude Oil DesaltingDocument14 pagesCrude Oil DesaltingDucViking100% (1)

- 03 04 Petroleum Waste Water Desalter Case StudyDocument6 pages03 04 Petroleum Waste Water Desalter Case StudyivandavidmtNo ratings yet

- Alderley PWT BrochureDocument8 pagesAlderley PWT BrochurechirinoslaaNo ratings yet

- Sour Water Treatment UnitDocument16 pagesSour Water Treatment Unitpkgarg_iitkgp100% (2)

- RayterDocument4 pagesRayterLTE002No ratings yet

- Radiator Repair Facility Pollution Prevention: Regulations, Regulations, Regulations! RecyclingDocument5 pagesRadiator Repair Facility Pollution Prevention: Regulations, Regulations, Regulations! RecyclingdionymackNo ratings yet

- Gas Dehydrators LessonsDocument20 pagesGas Dehydrators LessonsBinarga SatriaNo ratings yet

- SWS Paper FinalA4Document17 pagesSWS Paper FinalA4faisalmuradNo ratings yet

- EN - Water For Upstream Oil & Gas Industry - Degrémont IndustryDocument6 pagesEN - Water For Upstream Oil & Gas Industry - Degrémont IndustryDegrémont IndustryNo ratings yet

- Water and Wastewater Management Oil Refining IndustryDocument62 pagesWater and Wastewater Management Oil Refining IndustryAle SanzNo ratings yet

- 750 0015Document6 pages750 0015Mohamed ZaghloulNo ratings yet

- Removing Oil From Water With Organoclays: Cleaning WastewaterDocument2 pagesRemoving Oil From Water With Organoclays: Cleaning WastewaterCarlos LiraNo ratings yet

- Produced Water Treatment & Recycling-Oil & Gas Fields 4.25.2024Document59 pagesProduced Water Treatment & Recycling-Oil & Gas Fields 4.25.2024magdielbeheiriNo ratings yet

- The Ohsol PresentationDocument53 pagesThe Ohsol PresentationArsalan QadirNo ratings yet

- LT - Leaflet - Oil & Gas - Rev02Document6 pagesLT - Leaflet - Oil & Gas - Rev02Mouayed ZeadanNo ratings yet

- Idrabel Tank CleaningDocument8 pagesIdrabel Tank CleaningMuTe JameeLa BimbimShopNo ratings yet

- API - Intro To Oil and Gas ProductionDocument10 pagesAPI - Intro To Oil and Gas Productionfoobar2016No ratings yet

- EPE Donaldson Purify and Pressure FiltersDocument132 pagesEPE Donaldson Purify and Pressure FiltersJamin SmtpngNo ratings yet

- Guide To Refinery ProcessDocument131 pagesGuide To Refinery Processvazzoleralex6884100% (2)

- Leading The Way Through Health, Safety & EnvironmentDocument20 pagesLeading The Way Through Health, Safety & EnvironmentNEHANo ratings yet

- OBM Imagenes SLBDocument19 pagesOBM Imagenes SLBLenis CeronNo ratings yet

- Oil TreatDocument3 pagesOil TreatfarhanNo ratings yet

- Zero LiquidDocument6 pagesZero LiquidEr Govind Singh ChauhanNo ratings yet

- Westfalia Separator Seaprotectsolutions 997 1131 040Document28 pagesWestfalia Separator Seaprotectsolutions 997 1131 040ronald_edinsonNo ratings yet

- Fundamentals of Refining and Petrochemicals ProcessesDocument263 pagesFundamentals of Refining and Petrochemicals ProcessesneocentricgeniusNo ratings yet

- Oil Refinery Water OverviewDocument5 pagesOil Refinery Water OverviewAshwini BunkarNo ratings yet

- Reliance - Wastewater TreatmentDocument4 pagesReliance - Wastewater Treatmentarini_aristia_sNo ratings yet

- Oily Water TreatmentDocument9 pagesOily Water TreatmentaamikiNo ratings yet

- Car WashingDocument51 pagesCar WashingShiv Anand0% (1)

- Oil Water SeparatorDocument3 pagesOil Water SeparatorPanagiotis MouzenidisNo ratings yet

- CHE 586 Lecture 2Document18 pagesCHE 586 Lecture 2Charles ObiefunaNo ratings yet

- 1c Process Operation SystemDocument20 pages1c Process Operation SystemrubensNo ratings yet

- Oil & Gas SeperationDocument34 pagesOil & Gas Seperationassatpute100% (2)

- Prevention: Cutting DryersDocument5 pagesPrevention: Cutting DryersAljay ImperialNo ratings yet

- One Kind of Evaporator Is A Kind of Radiator Coil Used in A Closed Compressor Driven Circulation of A Liquid CoolantDocument1 pageOne Kind of Evaporator Is A Kind of Radiator Coil Used in A Closed Compressor Driven Circulation of A Liquid CoolantfikaduNo ratings yet

- Problems Occurring in De-Salter Plant of Crude Oil and Its SolutionDocument6 pagesProblems Occurring in De-Salter Plant of Crude Oil and Its Solutionmustafa abdulhameedNo ratings yet

- Water Treatment PlantDocument12 pagesWater Treatment PlantkukucuckooNo ratings yet

- Surface FacilitiesDocument20 pagesSurface Facilitiesheriku_mulyaNo ratings yet

- Rising Film EvaporatorsDocument10 pagesRising Film EvaporatorsPelin Yazgan BirgiNo ratings yet

- Process Intensification in Industrial Wastewater Treatment FinalDocument10 pagesProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasNo ratings yet

- PTRT 1301 CH7 Managing Oil and Gas ProductionDocument24 pagesPTRT 1301 CH7 Managing Oil and Gas ProductionMohammed adelNo ratings yet

- Outlining Seatwork and QuizDocument4 pagesOutlining Seatwork and QuizJyra DoloirasNo ratings yet

- Slaughter House: Initial Environmental Examination (Iee) ChecklistDocument15 pagesSlaughter House: Initial Environmental Examination (Iee) ChecklistavieNo ratings yet

- CPTM 3.5 Environment and Natural ResourcesDocument24 pagesCPTM 3.5 Environment and Natural ResourcesMario SantosNo ratings yet

- CH16 EditedDocument11 pagesCH16 EditedInmeNo ratings yet

- Environment Policy and Management of Dhaka CityDocument13 pagesEnvironment Policy and Management of Dhaka CityDidar Hossain ToqeeNo ratings yet

- Biomedical Waste Disposal Report FinalDocument31 pagesBiomedical Waste Disposal Report FinalMayur Madhukar MankarNo ratings yet

- Environmental Pollution: by Mrs. Vaibhavi ApteDocument71 pagesEnvironmental Pollution: by Mrs. Vaibhavi ApteNOT AkulNo ratings yet

- Project On Water ScarcityDocument22 pagesProject On Water ScarcityGaurav100% (1)

- Gasland DebunkedDocument2 pagesGasland DebunkedNathan BenefieldNo ratings yet

- List of Special Areas Under Marpol and Particularly Sensitive Sea AreasDocument6 pagesList of Special Areas Under Marpol and Particularly Sensitive Sea AreasAdil AhmedNo ratings yet

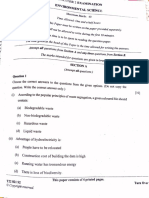

- Evs Question Paper Class 10 Sem 2, 2022-2023Document4 pagesEvs Question Paper Class 10 Sem 2, 2022-2023Bidisha DeyNo ratings yet

- Bin Collection Calendar - North Lanarkshire CouncilDocument1 pageBin Collection Calendar - North Lanarkshire CouncilMark DavisNo ratings yet

- Enviormental Protection in PakistanDocument2 pagesEnviormental Protection in PakistanMuhammad Nouman KhanNo ratings yet

- Earth Day We Care Acrostic Poem 2015Document1 pageEarth Day We Care Acrostic Poem 2015api-2133684440% (1)

- Pollution Prevention Action Plan AprilDocument2 pagesPollution Prevention Action Plan AprilApril Reyes Perez100% (2)

- ENVE 100-Introduction To Environmental EngineeringDocument6 pagesENVE 100-Introduction To Environmental EngineeringclaudioNo ratings yet

- PPT-6-Air PollutionDocument26 pagesPPT-6-Air Pollutionjk kbjbNo ratings yet

- KelloggsDocument3 pagesKelloggsrohini jhaNo ratings yet

- Basura Ko Garbo KoDocument3 pagesBasura Ko Garbo KoAnnaliza Rivera CantujaNo ratings yet

- EnvironmentDocument37 pagesEnvironmentanicktumuNo ratings yet

- Protecting The Environment Is The Most Important Problem Facing The World Today (Protejarea Mediului Este Cea Mai Imporanta Problema Cu Care Se Confrunta Lumea in Ziua de Azi)Document1 pageProtecting The Environment Is The Most Important Problem Facing The World Today (Protejarea Mediului Este Cea Mai Imporanta Problema Cu Care Se Confrunta Lumea in Ziua de Azi)Ana-Maria CiobotaruNo ratings yet

- EV201 RESEARCH ESSAY 1 (s11166003)Document7 pagesEV201 RESEARCH ESSAY 1 (s11166003)Rolland JohnNo ratings yet

- Waste Management of SheillarocoDocument4 pagesWaste Management of SheillarocoSheilla De Felix RocoNo ratings yet

- HWM Unit-2 PDFDocument68 pagesHWM Unit-2 PDFSuresh KannaNo ratings yet

- Awesome 3 Progress Test Unit 2Document5 pagesAwesome 3 Progress Test Unit 2santycz1978No ratings yet

- PRinciples of The EnvironmentDocument12 pagesPRinciples of The EnvironmentALMONIA, GEZZIEL GANIRNo ratings yet

- Who Owns Our TrashDocument7 pagesWho Owns Our TrashBogdan BerenghiaNo ratings yet

- 'Save Our Planet' SpeechDocument2 pages'Save Our Planet' SpeechShabrina Rahma SantosoNo ratings yet

- Final SpeechSpeech Clean & Green PakistanDocument2 pagesFinal SpeechSpeech Clean & Green PakistanDEPUTY DEO MALE DEPALPUR100% (3)

- Dispersion Model of Methane (CH4) and Carbondioxide (CO2) Emissions From Punggur Landfill BatamDocument6 pagesDispersion Model of Methane (CH4) and Carbondioxide (CO2) Emissions From Punggur Landfill BatamSilitmunyukNo ratings yet