Professional Documents

Culture Documents

Projects

Projects

Uploaded by

Muhammad Shoaib RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Projects

Projects

Uploaded by

Muhammad Shoaib RaoCopyright:

Available Formats

Fluid Dynamics

PIV-laser Based Measurement of Industrial and Biological Fluid Flows

Project description: Particle Image Velocimetry (PIV) is an advanced method for measuring the velocity field in complex flows. http://en.wikipedia.org/wiki/Particle_image_velocimetry It uses a pulsed laser and digital cameras, and digital image processing to extract the velocity field. The UC Mech Eng PIV group built the first PIV system in New Zealand. It is used currently to probe complex fluid mechanic behaviour in mechanically assisted breathing and human arterial bloodflow. The PIV research group has developed advanced methods for rapid fabrication of scaled physical models of complex flow systems. The successful candidate will join the group and work on developing the technique further, developing analysis software (currently written in MATLAB), developing test rigs and making measurements in scale models of human arteries (in work supporting treatment and prevention of stroke and arterial disease), measurements in the human airway with novel assisted ventilation devices, and in supersonic unsteady under expanded jets used in thin film manufacturing processes. Field of study This project suits a graduate in mechanical engineering, chemical engineering or physics.

Aerodynamic Optimisation of the Windflow 500 Blade Theoretical modelling and dynamic simulation of variable fill hydraulic dynamometers. Vibration isolating ambulance stretcher suspension Finite element modelling pavement-induced tyre vibration and noise

Application of Lightweight Metal Foams to Helmet Design

Experimental Heat Transfer and Fluid Dynamics in Unsteady Low-Pressure CVD Reactor

Supervisor Dr. Susan Krumdieck Degree Masters or PhD Project Description An innovative thin film deposition process has been developed. The process uses Chemical Vapor Deposition (CVD) to deposit a very thin layer (<100 mm) of a ceramic material on a metal part or other substrate material. This technology can be used to fabricate Solar Photovoltaic Cells, Fuel Cells, and protective and Thermal Barrier Coatings. It is also being explored for MEMS. The new part of the process is how the precursor chemicals are delivered to the reaction chamber. (This is the Mechanical Engineering part of what sounds a lot like Chemical Engineering) The liquid chemical precursor is sprayed, using an ultrasonic atomizer, into a vacuum chamber in a short pulse. The reactor is then pumped down to vacuum to start the cycle over again. Field of Study Heat Transfer, Heater Design, Design Data, Experimental Process Development.

You might also like

- Mems Report in Iit KanpurDocument24 pagesMems Report in Iit KanpurbillalaxmanNo ratings yet

- Claytronics Research PaperDocument4 pagesClaytronics Research Paperafeascdcz100% (1)

- Show PDFDocument130 pagesShow PDFajith.ganesh2420No ratings yet

- Introduction To MEMSDocument29 pagesIntroduction To MEMSjaimon_cletusNo ratings yet

- New Sensors and Processing ChainFrom EverandNew Sensors and Processing ChainJean-Hugh ThomasNo ratings yet

- Ac 2007-987: Innovative Fluid Mechanics Experiments For Modern Mechanical Engineering ProgramDocument13 pagesAc 2007-987: Innovative Fluid Mechanics Experiments For Modern Mechanical Engineering ProgramharshNo ratings yet

- Fabrication of A Cost-Effective MEMS-based PiezoreDocument13 pagesFabrication of A Cost-Effective MEMS-based PiezoreYoga VyshnaviNo ratings yet

- Editorial Special Topic Issueðparticle Technology Particle Technologyða Driving Force in European Chemical EngineeringDocument2 pagesEditorial Special Topic Issueðparticle Technology Particle Technologyða Driving Force in European Chemical EngineeringMarthaAlbaGuevaraNo ratings yet

- AF7 TecMedDocument8 pagesAF7 TecMedNicolás SilvaNo ratings yet

- VLSI Spin-Offs and Technological Innovation: T.J. TateDocument5 pagesVLSI Spin-Offs and Technological Innovation: T.J. TatePRAVEEN1640No ratings yet

- Design Experiments and Multidisciplinary OptimizatDocument15 pagesDesign Experiments and Multidisciplinary OptimizatmohamedNo ratings yet

- Udroiu 11Document9 pagesUdroiu 11Waqas AleemNo ratings yet

- Mechanics of Advanced Materials Analysis of Properties and Performance by Vadim V. Silberschmidt, Valery P. Matveenko (205pgs)Document205 pagesMechanics of Advanced Materials Analysis of Properties and Performance by Vadim V. Silberschmidt, Valery P. Matveenko (205pgs)Silverio Acuña100% (3)

- Conveyor Image NewDocument14 pagesConveyor Image NewGopuNo ratings yet

- Two Heads Are Better Than One!!: Advances in Process Analytics and Control TechnologyDocument4 pagesTwo Heads Are Better Than One!!: Advances in Process Analytics and Control TechnologyA MahmoodNo ratings yet

- Icp Ms DissertationDocument8 pagesIcp Ms DissertationCollegePapersToBuyMadison100% (1)

- Chemical Engineering Thesis PDFDocument6 pagesChemical Engineering Thesis PDFMonique Carr100% (2)

- Marketable Ideas - Newsletter June 2014Document1 pageMarketable Ideas - Newsletter June 2014erc_websiteNo ratings yet

- A Literature Review On Sampling Techniques in Semiconductor ManufacturingDocument6 pagesA Literature Review On Sampling Techniques in Semiconductor ManufacturingaflskeqjrNo ratings yet

- NANO S&T 2011 Chennai TalkDocument91 pagesNANO S&T 2011 Chennai TalkS.R.SriramNo ratings yet

- ViewDocument2 pagesViewDian LiuNo ratings yet

- Research Paper On StereolithographyDocument7 pagesResearch Paper On Stereolithographyc9q0c0q7100% (1)

- NASA Microelectronics Reliability Physics-Of-Failure Based ModelingDocument216 pagesNASA Microelectronics Reliability Physics-Of-Failure Based Modelinggoldpanr8222100% (2)

- LC Vco ThesisDocument8 pagesLC Vco Thesissarareedannarbor100% (2)

- 2003 Development20of20X-ray20ScannerDocument7 pages2003 Development20of20X-ray20ScannerBABLU TIWARINo ratings yet

- Wind Turbine Nantes 22Document12 pagesWind Turbine Nantes 22didineNo ratings yet

- M.tech Project Thesis PDFDocument7 pagesM.tech Project Thesis PDFcourtneypetersonspringfield100% (2)

- Darvish Darvish Resume Oct2018Document2 pagesDarvish Darvish Resume Oct2018api-409630960No ratings yet

- Hybrid Electronics To Enable Digital India: Swarm Chip ArchitectureDocument3 pagesHybrid Electronics To Enable Digital India: Swarm Chip ArchitectureSANJAYNo ratings yet

- CAMDDocument6 pagesCAMDMeena raniNo ratings yet

- 1st Sem Progess ReportDocument5 pages1st Sem Progess ReportArun JoharNo ratings yet

- Zaharin 2018 IOP Conf. Ser. - Mater. Sci. Eng. 328 012003 PDFDocument8 pagesZaharin 2018 IOP Conf. Ser. - Mater. Sci. Eng. 328 012003 PDFGet SazzidNo ratings yet

- Edz Clusters Young cr38 - enDocument5 pagesEdz Clusters Young cr38 - enJorge Raul JjaramilloNo ratings yet

- Laser Optical Systems EngineerDocument4 pagesLaser Optical Systems Engineerapi-77706403No ratings yet

- Iboc Technology 11574 GNxhMh4Document26 pagesIboc Technology 11574 GNxhMh4Bhavana GummaNo ratings yet

- Latest Research Paper in ElectronicsDocument7 pagesLatest Research Paper in Electronicsafeavbrpd100% (1)

- Earthquake Simulations of Large Scale Structures Using Opensees Software On Grid and High Performance Computing in IndiaDocument4 pagesEarthquake Simulations of Large Scale Structures Using Opensees Software On Grid and High Performance Computing in Indiasofiane9500No ratings yet

- Title: Underwater Camera System For Hull Inspection: Final Year Design Projects of Mechanical Engineering 2011/2012Document26 pagesTitle: Underwater Camera System For Hull Inspection: Final Year Design Projects of Mechanical Engineering 2011/2012inba_1No ratings yet

- Siemens PLM Maha Cs 63828 A8Document6 pagesSiemens PLM Maha Cs 63828 A8S R E E N I V A S A R A 0No ratings yet

- Iboc TechnologyDocument24 pagesIboc TechnologyJishnu KrishnanNo ratings yet

- Micro CT of Ti Investment Casting For Aerospace +++ 1-s2.0-S2214657115000040-2015Document6 pagesMicro CT of Ti Investment Casting For Aerospace +++ 1-s2.0-S2214657115000040-2015ugo_rossiNo ratings yet

- 345 Prakash2014Document17 pages345 Prakash2014xDiego MNo ratings yet

- فاینال ریپورتDocument9 pagesفاینال ریپورتtis_khalili79No ratings yet

- Electronic Hardware Design of Electrical Capacitance Tomography SystemsDocument16 pagesElectronic Hardware Design of Electrical Capacitance Tomography SystemsvineelaNo ratings yet

- 整合式金氧半微機電流速計及其在拍翼之Document135 pages整合式金氧半微機電流速計及其在拍翼之蕭禹恩No ratings yet

- 0960-1317 25 7 075025 PDFDocument14 pages0960-1317 25 7 075025 PDFSankar SaroNo ratings yet

- Overview of MEMS and MicrosystemsDocument43 pagesOverview of MEMS and Microsystemsvigneshwararaja1988No ratings yet

- ME189 Chapter 1Document43 pagesME189 Chapter 1Sindhya JayaramNo ratings yet

- Scheduling of Power GenerationDocument148 pagesScheduling of Power GenerationHeng LayNo ratings yet

- Hbni ThesisDocument5 pagesHbni Thesisjuliekwhlanchorage100% (2)

- List of IC@N Research Projects and Supervisors: School of Electrical & Electronic Engineering (EEE)Document21 pagesList of IC@N Research Projects and Supervisors: School of Electrical & Electronic Engineering (EEE)Ayush VatsalNo ratings yet

- Air Force Portable Device For Retinal ImagingDocument22 pagesAir Force Portable Device For Retinal Imagingjnane2006No ratings yet

- Ije V3 I2Document139 pagesIje V3 I2AI Coordinator - CSC JournalsNo ratings yet

- Research Papers CFDDocument6 pagesResearch Papers CFDh03318kj100% (1)

- 2006-2314: A Nanotechnology Experiment: Design of Low Cost Scanning Tunneling MicroscopesDocument13 pages2006-2314: A Nanotechnology Experiment: Design of Low Cost Scanning Tunneling MicroscopesTapan MajumdarNo ratings yet

- Kaleev 2017 IOP Conf. Ser. Mater. Sci. Eng. 240 012030Document5 pagesKaleev 2017 IOP Conf. Ser. Mater. Sci. Eng. 240 012030gfdczxNo ratings yet

- Proceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsFrom EverandProceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsArild HelsethNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- Glass Waste: Yağmur Dokuzoğlu 3023 10/BDocument10 pagesGlass Waste: Yağmur Dokuzoğlu 3023 10/BYağmur DNo ratings yet

- FDFDSFSDFDocument2 pagesFDFDSFSDFapi-254428474100% (1)

- Table of Fundamental Constants in Theoretical PhysicsDocument1 pageTable of Fundamental Constants in Theoretical PhysicsTunarisNo ratings yet

- DLP Particle Nature of MatterDocument2 pagesDLP Particle Nature of MatterAizelle Taratara0% (1)

- Stereo ChemistryDocument4 pagesStereo ChemistryDORINA MANTUNo ratings yet

- Mechanical EngineeringDocument15 pagesMechanical EngineeringcomandhurstNo ratings yet

- Is Matter Around Us PureDocument31 pagesIs Matter Around Us PureAtul VermaNo ratings yet

- Thermal Performance of Nanofluid Filled Solar Flat Plate CollectorDocument8 pagesThermal Performance of Nanofluid Filled Solar Flat Plate CollectorDriss Miral AchemlalNo ratings yet

- Section 16.4 Force On Current-Carrying Conductor in Magnetic FieldDocument18 pagesSection 16.4 Force On Current-Carrying Conductor in Magnetic Fieldtwy113No ratings yet

- 444 StainlessDocument4 pages444 StainlessSH1961No ratings yet

- Naseeb Scale - Up and Post Approval ChangesDocument32 pagesNaseeb Scale - Up and Post Approval ChangesshivaniNo ratings yet

- Shaker Service CertficateDocument3 pagesShaker Service Certficateአዲስ viewNo ratings yet

- HPLC Columns 186-234Document49 pagesHPLC Columns 186-234Long ManNo ratings yet

- Types of Drag On AircraftDocument20 pagesTypes of Drag On AircraftPramod DhaigudeNo ratings yet

- Lesson PlanDocument4 pagesLesson PlanClenchtone Celiz100% (1)

- AQA AS Physics A Chapter 9 Textbook AnswersDocument4 pagesAQA AS Physics A Chapter 9 Textbook Answerscathylister100% (1)

- BS en 10181-2019Document16 pagesBS en 10181-2019Federico De Martini100% (1)

- Astm D1876 08 2023Document2 pagesAstm D1876 08 2023Michelle LCNo ratings yet

- Solved HT ProblemsDocument34 pagesSolved HT ProblemsRavichandran GNo ratings yet

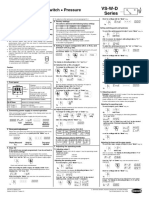

- Manual Vacuostato Vs W DDocument3 pagesManual Vacuostato Vs W DHigor MoraesNo ratings yet

- Mock Test 6 P 2 Bks DDocument22 pagesMock Test 6 P 2 Bks DRare RootNo ratings yet

- DTFS Project 1Document9 pagesDTFS Project 1ridaNo ratings yet

- CAGI ElectHB ch7Document259 pagesCAGI ElectHB ch7Alejandro GilNo ratings yet

- Thermal Denitration of Ammonium Nitrate Solution in A Fluidized-Bed ReactorDocument10 pagesThermal Denitration of Ammonium Nitrate Solution in A Fluidized-Bed ReactorgauravNo ratings yet

- Paten Etanol Kel3 B IDLDocument18 pagesPaten Etanol Kel3 B IDLFazaaNo ratings yet

- 11 1 Colloids SynthesisDocument18 pages11 1 Colloids SynthesisPrashant VermaNo ratings yet

- ECUACIONES 1° (Esmeralda)Document52 pagesECUACIONES 1° (Esmeralda)isaac figueroa alomiaNo ratings yet

- EMD Final Micro ProjectDocument18 pagesEMD Final Micro Projectvedantbakal043No ratings yet

- An Investigation On The Production of Construction Brick With Processed Waste TeaDocument5 pagesAn Investigation On The Production of Construction Brick With Processed Waste TeaTang B. LinNo ratings yet

- Information About Galileo Galilei - A4Document4 pagesInformation About Galileo Galilei - A4johnreybayoguingNo ratings yet