Professional Documents

Culture Documents

Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

Uploaded by

Kukuh YuonoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

Uploaded by

Kukuh YuonoCopyright:

Available Formats

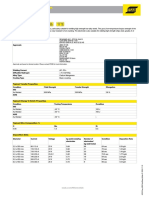

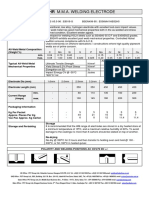

COVERED (STICK) ELECTRODES (SMAW)

LOW ALLOY ELECTRODES

OK 48.08

PE

4G

OK 48.08 is an LMA electrode with very good mechanical properties suitable for demanding applications, such as

offshore. The weld metal contains approximately 1% Ni for high impact values down to -40°C. The coating is of the latest

LMA type for optimum resistance to porosity and hydrogen cracking. OK 48.08 is CTOD tested.

Classifications: SFA/AWS A5.5:E7018-G, EN ISO 2560-A:E 46 5 1Ni B 32 H5

Approvals: CE EN 13479, ABS 3Y H5, DNV 4Y40 H5, GL 4Y H5, RS 4Y H5, DB 10.039.31,

VdTÜV 05778, LR 4Y40m H5, NAKS/HAKC 2.5-5.0 mm

Approvals are based on factory location. Please contact ESAB for more information.

Welding Current: AC, DC +(-)

Diffusible Hydrogen: <5.0 ml/100g

Alloy Type: 0.9% Ni

Coating Type: Lime Basic

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

ISO

As welded 540 MPa 630 MPa 26 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

ISO

As welded -50 °C 115 J

As welded -60 °C 90 J

Typical Weld Metal Analysis %

C Mn Si Ni Cr Mo

0.06 1.2 0.35 0.95 0.02 0.001

Deposition Data

Diameter Current Voltage kg weld metal/ Number of Fusion time Deposition

kg electrodes electrodes/kg per electrode rate 90% I max

weld metal at 90% I max

2.0 x 300 mm 55-80 A 22 V 0.57 135.1 42 s 0.60 kg/h

2.5 x 350 mm 75-110 A 27 V 0.57 88 41 s 1.0 kg/h

3.2 x 350 mm 110-150 A 22 V 0.62 42.3 66 s 1.30 kg/h

3.2 x 450 mm 110-150 A 22 V 0.66 30.0 85 s 1.40 kg/h

4.0 x 450 mm 150-200 A 22 V 0.69 20.3 90 s 2.00 kg/h

5.0 x 450 mm 190-275 A 23 V 0.69 14.0 85 s 3.00 kg/h

1-18 esab.com

You might also like

- The Clear Skin Diet by Nina Nelson PDFDocument370 pagesThe Clear Skin Diet by Nina Nelson PDFmia agustina60% (10)

- 5 - Corporate Governance AmendedDocument24 pages5 - Corporate Governance AmendednurhoneyzNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Ok 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 MpaDocument1 pageOk 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 Mpamitesh prajapatiNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Informationw elhaj abdallaNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- ESABDocument1 pageESABXQNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136No ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodestarun kaushalNo ratings yet

- WeartrodDocument1 pageWeartrodBhavik PatelNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Aristo Rod 55Document1 pageAristo Rod 55joao guilhermeNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesMohammad AdilNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Purus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresDocument1 pagePurus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresYudhveer GrewalNo ratings yet

- Electrode E8018 DetailsDocument1 pageElectrode E8018 DetailskapsarcNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- OK Tigrod 316LDocument1 pageOK Tigrod 316Laxisd47No ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- EN 14700: E Z Fe1: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageEN 14700: E Z Fe1: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesKARLNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- OK Tigrod 13.32Document1 pageOK Tigrod 13.32Paulo CorreiaNo ratings yet

- Industrial Relays of Small Dimensions: Contact DataDocument10 pagesIndustrial Relays of Small Dimensions: Contact DataTarek KhafagaNo ratings yet

- Industrial Relays of Small Dimensions: Contact DataDocument10 pagesIndustrial Relays of Small Dimensions: Contact DatalancenglotNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- Wire Wound Fixed Resistors: FeaturesDocument7 pagesWire Wound Fixed Resistors: FeaturesteoilcaNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Ok 78.16Document1 pageOk 78.16Mario IntikNo ratings yet

- Pinnacle Alloys E9018-M Code and Specification DataDocument2 pagesPinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- May 13, 2019 National and Local Elections: Official BallotDocument2 pagesMay 13, 2019 National and Local Elections: Official BallotStephany Faye Batas AguilarNo ratings yet

- FortiManager Best Practices GuideDocument23 pagesFortiManager Best Practices GuideIzi Rider100% (1)

- Grade 6 - e A Tire Tracks Lesson 4Document3 pagesGrade 6 - e A Tire Tracks Lesson 4api-283081427No ratings yet

- Mid Term QP Puc I Key AnswerDocument4 pagesMid Term QP Puc I Key AnswerDinakara KeshavNo ratings yet

- 2021 AP Exam Administration Scoring Guidelines - AP English Literature and CompositionDocument13 pages2021 AP Exam Administration Scoring Guidelines - AP English Literature and CompositionNicole SchifflerNo ratings yet

- UCD Otolayrngology GuideDocument95 pagesUCD Otolayrngology GuideJames EllisNo ratings yet

- Types of Containers PDFDocument17 pagesTypes of Containers PDFJorge Alegre100% (1)

- FINAL TERM P.E.H. 12 Demonstrate Proper Etiquette and Safety in The Use of Facilities and Equipment For Dance ActivitiesDocument3 pagesFINAL TERM P.E.H. 12 Demonstrate Proper Etiquette and Safety in The Use of Facilities and Equipment For Dance Activitiesrandolf wassigNo ratings yet

- Discourse Society - The Ideological Construction of Solidarity in Translation ComentariesDocument31 pagesDiscourse Society - The Ideological Construction of Solidarity in Translation ComentariesThiago OliveiraNo ratings yet

- Source Rock Identification by IsotopeDocument11 pagesSource Rock Identification by IsotopeNdeye Khady NdiayeNo ratings yet

- Sociology Module B1 2017Document3 pagesSociology Module B1 2017Aerielle CanoNo ratings yet

- Paris Pompidou Building-SaurabhDocument8 pagesParis Pompidou Building-SaurabhVipin Kumar SharmaNo ratings yet

- IBM UML 2.0 Advanced NotationsDocument21 pagesIBM UML 2.0 Advanced NotationsKeerthana SubramanianNo ratings yet

- Colour Magazine - London 1Document103 pagesColour Magazine - London 1iccang arsenal100% (1)

- Chanakya National Law University: Project of Law of History On "Property Rights of Women in Modern India "Document20 pagesChanakya National Law University: Project of Law of History On "Property Rights of Women in Modern India "Vibhuti SharmaNo ratings yet

- LAB 2 EmbeddedDocument21 pagesLAB 2 EmbeddedLeonelNo ratings yet

- J Appl Environ Biol Sci 56S62-682015 PDFDocument8 pagesJ Appl Environ Biol Sci 56S62-682015 PDFSepti Lidya sariNo ratings yet

- What Is Chlorinated Polyvinyl Chloride (CPVC) - CorzanDocument8 pagesWhat Is Chlorinated Polyvinyl Chloride (CPVC) - CorzanmrpalmistNo ratings yet

- P1-E (7-09) - Personnel InductionDocument4 pagesP1-E (7-09) - Personnel InductionDhotNo ratings yet

- Module 8 Teachers As Curriculum LeadersDocument13 pagesModule 8 Teachers As Curriculum Leadersreyma paner100% (1)

- Mga Bilang 1-100 Tagalog With Symbol and PronunciationDocument2 pagesMga Bilang 1-100 Tagalog With Symbol and PronunciationJanice Tañedo PancipaneNo ratings yet

- Psaj Prep Xii - 202324Document5 pagesPsaj Prep Xii - 202324Anto NdesoNo ratings yet

- Arch AddDocument96 pagesArch AddDeepak RDNo ratings yet

- Enzymes Are Always: Compressed Notes Chapter 4: Biocatalysis Sb025Document7 pagesEnzymes Are Always: Compressed Notes Chapter 4: Biocatalysis Sb025LIM ZHI SHUENNo ratings yet

- 96Document1 page96hiteshsachaniNo ratings yet

- Entertainment Weekly - February 19, 2016Document120 pagesEntertainment Weekly - February 19, 2016Prateek Herpersad100% (1)

- Sample Welingkar Welike ProjectDocument17 pagesSample Welingkar Welike Projectashfaq shaikhNo ratings yet

- Alternative Energy SourcesDocument12 pagesAlternative Energy SourcesArodis GomezNo ratings yet