Professional Documents

Culture Documents

3 Property H7900 Eng

3 Property H7900 Eng

Uploaded by

Mohit MohataOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Property H7900 Eng

3 Property H7900 Eng

Uploaded by

Mohit MohataCopyright:

Available Formats

PP Homopolymer

SÉETEC H7900

Applications

• Ultra fine denier melt blown non-wovens,typical end use applications including diapers,

sanitary napkins, oil absorbent mats, wipes, wet tissues, masks, air filtration media

and medicals.

Description

• SÉETEC H7900 is a newly developed pellet type melt blown grade made by 5th

generation catalyst and the Spheripol process. Its has a very high melt flow and very

narrow molecular weight distribution, which promotes thread line continuity, reduce

lint, and spins ultra fine denier fibers with high strength vs. conventional flake type

melt blown grade. This polymer is well designed to control and increase the melt flow

rate (between 400 to 1500) by adding the concentrated peroxide master batch into the

polymer during the M/B processing. SEETEC H7900 meets the FDA requirement in

the code of Federal Regulations in 21 CFR 177.1520 for food contact..

Typical properties

Characteristics Test Method Unit Value

Physical(1)

Density ASTM D1505 g/㎤ 0.9

MFR(230℃,2.16Kg) ASTM D1238 g/10min 230

Mechanical(2)

Tensile Strength at Yield ASTM D638(3) Mpa 34

Elongation at Break ASTM D638(3) % >500

Flexural Modulus ASTM D790(4) Mpa 1600

Izod Impact Strength (Notched, 23℃) ASTM D256 J/m 29

Hardness(R-scale) ASTM D785 - 105

Thermal

Vicat Softening point (1kgf) ASTM D1525 ℃ 151

Heat Deflection Temperature (4.6kgf/cm2) ASTM D648 ℃ 110

(1) The properties data in this table are typical values, and not guaranteed specification.

(2) Typical resin property values are measured on a standard compression molded specimens

The actual processing conditions of our products may vary and are beyond our control,

establishing satisfactory performance of the resin for the intended application is the customer's responsibility.

For additional sales, order and technical assistance Revised : 06/12/2015

Head office PO Division, LG Chem Ltd. TS&D TECH Center . Polyolefin

Yeoui-do P.O.Box 672, 21st floor LG Twin Tower, 175, Gajeong-ro,Yuseong-gu, Daejeon, 305-343, Korea.

Yeoui-daero 128, Yeongdeungpo-gu Seoul, Korea. Tel. 82-42-860-8538,8394

Tel. 82-2-3773-3538 Email : dbdefault@lgchem.com

The information contained herein, including, but not limited to, data, statements and typical values, are given in good faith. LG Chem makes no warranty or guarantee, expressed

or implied, (i) that the result described herein will be obtained under end - use conditions, or (ii) as to the effectiveness or safety of any design incorporating LG Chem materials,

products, recommendations or advice. Further, any information contained herein shall not be construed as a part of legally binding offer. Especially, the typical values should be

regarded as reference values only and not as binding minimum values. Each user bear full responsibility for making its own determination as to the suitability of LG Chem's

materials, products, recommendations, or advice for its own particular use. Each user must identify and perform all tests and analyses necessary to assure that its finished

parts incorporating LG Chem material or products will be safe and suitable for use under end - use conditions. The data contained herein can be changed without notice as a

result of the quality improvement of the products."

You might also like

- Crushing - GrindingDocument118 pagesCrushing - GrindingHarrison Antonio Mira NiloNo ratings yet

- Astm C457Document18 pagesAstm C457dinoNo ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- TDS B0155DDocument1 pageTDS B0155DtechnopackishvarlalNo ratings yet

- TDS H019TGDocument2 pagesTDS H019TGkeyurmangnani2015No ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- Tds H110maDocument2 pagesTds H110maShibu MohanNo ratings yet

- TDS HD T9 04052022Document2 pagesTDS HD T9 04052022tiger.patelNo ratings yet

- Opal - Hdpe - 4Document2 pagesOpal - Hdpe - 4Piyush A JoshiNo ratings yet

- TDS H020egDocument2 pagesTDS H020egkeyurmangnani2015No ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- Polysure PP RB02CRDocument1 pagePolysure PP RB02CRPiyush A JoshiNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- TDS - TR144 - Astm (Eng)Document2 pagesTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoNo ratings yet

- b325.b328 Polimaxx 3340HDocument1 pageb325.b328 Polimaxx 3340HdianaNo ratings yet

- Topilene J800Document1 pageTopilene J800KevinGarciaNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- Estane 58202 TPU: Advancing MaterialsDocument2 pagesEstane 58202 TPU: Advancing MaterialsMoisés Antonio Gamboa MartínezNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- PP Homo k1111 DatasheetDocument1 pagePP Homo k1111 Datasheethamdany danyNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- PP Block bc03bsw DatasheetDocument2 pagesPP Block bc03bsw Datasheetphanplastic299No ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polypropylene (PP) : DescriptionDocument1 pagePolypropylene (PP) : DescriptionBanupriya BalasubramanianNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- P O L Y P R O P Y L E N E: Reliance Industries LimitedDocument1 pageP O L Y P R O P Y L E N E: Reliance Industries LimitedSiddheshNo ratings yet

- M6007LDocument1 pageM6007LempacNo ratings yet

- PP Block bc03bs DatasheetDocument1 pagePP Block bc03bs Datasheetphanplastic299No ratings yet

- HD M5306 PDFDocument2 pagesHD M5306 PDFmohamed1303No ratings yet

- HD2200JP Technical Data Sheet 20240208170555Document1 pageHD2200JP Technical Data Sheet 20240208170555phanplastic299No ratings yet

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsarthymanicNo ratings yet

- Im B120MADocument1 pageIm B120MAQUALITY MAYURNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaNo ratings yet

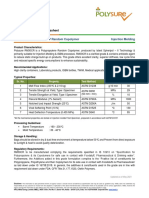

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- TDS F4600Document2 pagesTDS F4600tech.omNo ratings yet

- Pp-Block 2300k DatasheetDocument1 pagePp-Block 2300k Datasheetphanplastic299No ratings yet

- Hdpe r1760 DatasheetDocument1 pageHdpe r1760 Datasheetphanplastic299No ratings yet

- Hdpe SP360Document1 pageHdpe SP360Alejandra Paz San MartínNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- TDS HP740T DaelimDocument1 pageTDS HP740T Daelimbrandon abella gutierrezNo ratings yet

- Hdpe V1160 TDS 20230908Document2 pagesHdpe V1160 TDS 20230908phanplastic299No ratings yet

- Polysure PP RM30CRDocument1 pagePolysure PP RM30CRyansyafNo ratings yet

- Product Sheet Petlin LD N125y - 0Document2 pagesProduct Sheet Petlin LD N125y - 0Manufaktur Sinar JoyoboyoNo ratings yet

- Tds Hp450j EnglishDocument1 pageTds Hp450j EnglishMd Abdul SalamNo ratings yet

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetDocument2 pagesDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyNo ratings yet

- PP RANDOM Lotte - Ranpelen - J590K MI 44Document1 pagePP RANDOM Lotte - Ranpelen - J590K MI 44Luis LOZANONo ratings yet

- ASTM FL7100U Eng 240223Document1 pageASTM FL7100U Eng 240223MERVENo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- Sabic 37MK10Document2 pagesSabic 37MK10Chu ChuNo ratings yet

- PDS M365Document2 pagesPDS M365prabhunmayNo ratings yet

- TDS Engage 8200Document3 pagesTDS Engage 8200afernandezNo ratings yet

- TDS Hpr1018ha AstmDocument2 pagesTDS Hpr1018ha AstmOsamah JoubsenNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

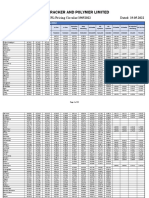

- PE RO Price Circular Wef 18th May 2022Document201 pagesPE RO Price Circular Wef 18th May 2022Mohit MohataNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polymer Price Circular 19.05.2022Document15 pagesPolymer Price Circular 19.05.2022Mohit MohataNo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polypropylene Impact Co Polymer Injection MoldingDocument2 pagesPolypropylene Impact Co Polymer Injection MoldingMohit MohataNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- OPaL Polymers CSA Price Circular - PP Wef 19 May 2022Document6 pagesOPaL Polymers CSA Price Circular - PP Wef 19 May 2022Mohit MohataNo ratings yet

- Linear Low Density Polyethylene: Provisional Technical DatasheetDocument2 pagesLinear Low Density Polyethylene: Provisional Technical DatasheetMohit MohataNo ratings yet

- 26 PP Price Circular Wef 19th May 2022 DomesticDocument13 pages26 PP Price Circular Wef 19th May 2022 DomesticMohit MohataNo ratings yet

- Locational Adjustment 2. Cash Discount (CD) & Early Payment Discount (EPD)Document14 pagesLocational Adjustment 2. Cash Discount (CD) & Early Payment Discount (EPD)Mohit MohataNo ratings yet

- OPaL Polymers DTA Price Circular - PP Wef 19 May 2022Document16 pagesOPaL Polymers DTA Price Circular - PP Wef 19 May 2022Mohit MohataNo ratings yet

- Circular W.E.F 19th May'22Document224 pagesCircular W.E.F 19th May'22Mohit MohataNo ratings yet

- IOC PP Paradip Price List 19 May 2022Document8 pagesIOC PP Paradip Price List 19 May 2022Mohit MohataNo ratings yet

- OPaL Polymers DTA Price Circular - PP Wef 19 May 2022Document8 pagesOPaL Polymers DTA Price Circular - PP Wef 19 May 2022Mohit MohataNo ratings yet

- OPaL Polymers CSA Price Circular - PP Wef 19 May 2022Document4 pagesOPaL Polymers CSA Price Circular - PP Wef 19 May 2022Mohit MohataNo ratings yet

- IOC PP Price List 19 May 2022Document12 pagesIOC PP Price List 19 May 2022Mohit MohataNo ratings yet

- HMTDocument234 pagesHMTkanivelNo ratings yet

- Sample Questions 3Document4 pagesSample Questions 3MA KAYE NICCA DALLUAYNo ratings yet

- BRB Anti Vibration Mounts BRB Anti Vibration Mounts: Technical Characteristics ApplicationsDocument8 pagesBRB Anti Vibration Mounts BRB Anti Vibration Mounts: Technical Characteristics ApplicationsJairo Andres Romero QuirogaNo ratings yet

- GRDSLABDocument15 pagesGRDSLABmjlazo0% (1)

- Clamping: Clamping Forces Dry Cycle TimeDocument1 pageClamping: Clamping Forces Dry Cycle TimeschaNo ratings yet

- TRICHYDocument31 pagesTRICHYArunan MgNo ratings yet

- MST MCQ U1Document8 pagesMST MCQ U1AyrenNo ratings yet

- Process Improvement Study of Preparation of Medicinal Oil From NirgundiDocument8 pagesProcess Improvement Study of Preparation of Medicinal Oil From Nirgundidr_saketram6146100% (2)

- Indian Standard: Cement Paint - Specification (Document18 pagesIndian Standard: Cement Paint - Specification (Frank StephensNo ratings yet

- Drop Melting Point of Petroleum Wax, Including Petrolatum: Standard Test Method ForDocument10 pagesDrop Melting Point of Petroleum Wax, Including Petrolatum: Standard Test Method ForJan BakosNo ratings yet

- A Review Research Progress On Microplastic Pollutants in Aquatic EnvironmentsDocument80 pagesA Review Research Progress On Microplastic Pollutants in Aquatic EnvironmentsPhuping SucharitakulNo ratings yet

- MC DE - EEC Form 4B AEUR Industrial DEsDocument6 pagesMC DE - EEC Form 4B AEUR Industrial DEsJohn Evan Raymund BesidNo ratings yet

- ENERGIRON Direct Reduction Technology - Economical Flexible and Environmentally FriendlyDocument28 pagesENERGIRON Direct Reduction Technology - Economical Flexible and Environmentally FriendlyAgustine Setiawan100% (1)

- Chemical and Thermal Decomposition of Ammonium Sulphate Into Ammonia and Sulphuric AcidDocument3 pagesChemical and Thermal Decomposition of Ammonium Sulphate Into Ammonia and Sulphuric AcidRamona Mihaela VerdesNo ratings yet

- Formula of A Hydrate Lab Student Part 1Document2 pagesFormula of A Hydrate Lab Student Part 1api-234443511No ratings yet

- TDS - en - 480703 Gravihel Vinyl Acrylic Topcoat 301Document3 pagesTDS - en - 480703 Gravihel Vinyl Acrylic Topcoat 301dika2303No ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument22 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsSrini VasanNo ratings yet

- HVAC LifeDocument8 pagesHVAC LifeNadeem QaisarNo ratings yet

- Raw Board Battle Round 2Document4 pagesRaw Board Battle Round 2Maridil Joy IsidroNo ratings yet

- E2209 13Document6 pagesE2209 13diego rodriguez100% (1)

- Astm D512 - 12 - Cloruros en AguaDocument9 pagesAstm D512 - 12 - Cloruros en AguaEliasNo ratings yet

- Review For Final Exam:: SteelsDocument8 pagesReview For Final Exam:: SteelsCKNo ratings yet

- Transformer OilDocument8 pagesTransformer OilMohammad Ibnul HossainNo ratings yet

- (CIDECT DG3) - Design Guide For Rectangular Hollow Section (RHS) Joints Under Predominantly Static LoadingDocument156 pages(CIDECT DG3) - Design Guide For Rectangular Hollow Section (RHS) Joints Under Predominantly Static Loading_at_to_75% (4)

- High Performance RF Antenna Material: FeaturesDocument3 pagesHigh Performance RF Antenna Material: FeaturesDale XiaoNo ratings yet

- A. Distillation of Essential OilDocument4 pagesA. Distillation of Essential OilUrsula BologaNo ratings yet

- Suaval Lorven References - IndiaDocument2 pagesSuaval Lorven References - IndiaMONER MANUSNo ratings yet

- Leachate and Groundwater Quality in Lagos FinalDocument12 pagesLeachate and Groundwater Quality in Lagos FinalLasisi Adedoyin K.S100% (2)