Professional Documents

Culture Documents

FDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010

FDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010

Uploaded by

Fazalrahman RangCopyright:

Available Formats

You might also like

- Smells - Like - Teen - Spirit Robert Glasper InspiredDocument1 pageSmells - Like - Teen - Spirit Robert Glasper Inspiredléo Geller50% (4)

- Clarinet ScalesDocument1 pageClarinet ScaleslucasNo ratings yet

- Clarinet Scales PDFDocument1 pageClarinet Scales PDFGiza_RozarioNo ratings yet

- Bracing Supplement Document: GIB Bracing Design NotesDocument22 pagesBracing Supplement Document: GIB Bracing Design NotesJimuel MejicaNo ratings yet

- WallSystems PDFDocument26 pagesWallSystems PDFEiz Zu DeenNo ratings yet

- Of Cantilever Retaining Wall (C-I-P) 1 2 400-010: Description: Revision Last Sheet IndexDocument2 pagesOf Cantilever Retaining Wall (C-I-P) 1 2 400-010: Description: Revision Last Sheet Indexammarsteel68No ratings yet

- Bushology: IndexDocument13 pagesBushology: IndexVictor C. HeimNo ratings yet

- Ave Maria For Saxophone Quartet - PartsDocument6 pagesAve Maria For Saxophone Quartet - PartsMarcos JNo ratings yet

- Azucar-Alto SaxDocument2 pagesAzucar-Alto SaxMauricio BautistaNo ratings yet

- Chasing Cars-Lead SheetDocument1 pageChasing Cars-Lead SheetjonatancuevasNo ratings yet

- Party at Ground Zero - Lead SheetDocument6 pagesParty at Ground Zero - Lead SheetZakriya Bashir-HillNo ratings yet

- Autumn Leaves V.3: G-D A - E B F CDocument2 pagesAutumn Leaves V.3: G-D A - E B F CAnonymous jWF9PmNo ratings yet

- Clarinet ScalesDocument1 pageClarinet ScaleslucasNo ratings yet

- Clarinet Scales PDFDocument1 pageClarinet Scales PDFGiza_Rozario100% (1)

- Clarinet ScalesDocument1 pageClarinet ScalesAshes AMWNo ratings yet

- Eamco DMJ RS SD 004Document1 pageEamco DMJ RS SD 004libin513No ratings yet

- BasieDocument2 pagesBasieKarotakos KarotakosNo ratings yet

- MC Ph01 p04 06a01 Dea DWG Ind 506190 B SPF 19 External KitchensDocument1 pageMC Ph01 p04 06a01 Dea DWG Ind 506190 B SPF 19 External Kitchensm abdullahNo ratings yet

- Ayat RevisedDocument1 pageAyat RevisedLelisa TarekegnNo ratings yet

- 560 000 ST S 001 - 1 PDFDocument1 page560 000 ST S 001 - 1 PDFJohan Carranza AlvarezNo ratings yet

- Road CrossingDocument5 pagesRoad CrossingMahata PriyabrataNo ratings yet

- O Christmas Tree (Bossa Nova) - PianoDocument2 pagesO Christmas Tree (Bossa Nova) - PianosharmahridhNo ratings yet

- Front Elevation Rear Elevation: Cyrus Construction Development GroupDocument1 pageFront Elevation Rear Elevation: Cyrus Construction Development GroupCyrus RivasNo ratings yet

- Tan CercaDocument2 pagesTan CercaCarlos RodriguezNo ratings yet

- 40G/43G Technical Poster: Section Overhead Line Overhead High-Order Path Overhead Low-Order Path OverheadDocument2 pages40G/43G Technical Poster: Section Overhead Line Overhead High-Order Path Overhead Low-Order Path Overheadchuang xuNo ratings yet

- Et Tu Danses Danses danses-SCOREDocument2 pagesEt Tu Danses Danses danses-SCOREOakbeanNo ratings yet

- Aus Meines Herzens Grunde - CoroDocument1 pageAus Meines Herzens Grunde - Corojoel S escobarNo ratings yet

- KjljklllijDocument2 pagesKjljklllijGiorgos PantazopoulosNo ratings yet

- Denah Mobile ScaffoldingDocument1 pageDenah Mobile ScaffoldingBayu BiroeNo ratings yet

- Denah Mobile Scaffolding PDFDocument1 pageDenah Mobile Scaffolding PDFBayu BiroeNo ratings yet

- Sma SMB SMCDocument1 pageSma SMB SMCDwi Sakti PutraNo ratings yet

- Hardened Ground Racks: Carburized Ground Racks, The Highest Performance Ever in The KHK Rack Series!Document1 pageHardened Ground Racks: Carburized Ground Racks, The Highest Performance Ever in The KHK Rack Series!Azis Fajar RiyadiNo ratings yet

- Danzon TranscripcíonDocument2 pagesDanzon TranscripcíonCristian MarroquínNo ratings yet

- Danzon Transcripcíon 2Document4 pagesDanzon Transcripcíon 2Cristian MarroquínNo ratings yet

- Sharp Cef171a A5x504g240 Power SCHDocument1 pageSharp Cef171a A5x504g240 Power SCHAlex Urbina SanchezNo ratings yet

- Planta Ba A: Plano de ConstruccionDocument1 pagePlanta Ba A: Plano de ConstruccionJarin Hasbel Alcala CastroNo ratings yet

- Proposed Soccer Field: Side Elevation Side ElevationDocument1 pageProposed Soccer Field: Side Elevation Side ElevationanzaniNo ratings yet

- Buster Rides AgainDocument1 pageBuster Rides AgainRo BertNo ratings yet

- Bags Groove - Piano PartDocument1 pageBags Groove - Piano Partbyron0% (1)

- Reckless - Love, Sheet Music, 7 PagesDocument7 pagesReckless - Love, Sheet Music, 7 PagesMora PierreNo ratings yet

- Reckless Love: Written by Cory Asbury Arranged For TLC Emerge Youth 166 Pre-Verse/Post-ChorusDocument7 pagesReckless Love: Written by Cory Asbury Arranged For TLC Emerge Youth 166 Pre-Verse/Post-ChorusPierreNo ratings yet

- Adagio Cantabile Opus 13 No. 8 For Woodwind QuartetDocument2 pagesAdagio Cantabile Opus 13 No. 8 For Woodwind QuartetCompañia de Maria -antiguas alumnas-No ratings yet

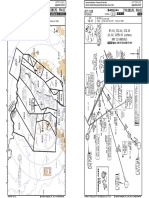

- LFST/SXB Strasbourg, France LFST/SXB Strasbourg, France: Rwy 23 Arrivals Epl 6V, GTQ 6U, GTQ 6V Lul 6V, Lupen 6VDocument11 pagesLFST/SXB Strasbourg, France LFST/SXB Strasbourg, France: Rwy 23 Arrivals Epl 6V, GTQ 6U, GTQ 6V Lul 6V, Lupen 6VboobaNo ratings yet

- 5 - Ruže Z JuhuDocument6 pages5 - Ruže Z JuhusvitajNo ratings yet

- Make Me Smile: Q 130 RockDocument4 pagesMake Me Smile: Q 130 RockDominic BertucciNo ratings yet

- 22f00200 Plans 3Document9 pages22f00200 Plans 3Serge Guevarra ParochaNo ratings yet

- labor handbook for HDDocument2 pageslabor handbook for HDbradfordlanham89No ratings yet

- Watermalon Man The Headhunters Version EbDocument1 pageWatermalon Man The Headhunters Version EbAlexander StefaniNo ratings yet

- Dragon Ball Z Sax PDFDocument1 pageDragon Ball Z Sax PDFmabekNo ratings yet

- Dragon Ball Z SaxDocument1 pageDragon Ball Z SaxmabekNo ratings yet

- Mazeej Wadih El Safi: PercussionDocument2 pagesMazeej Wadih El Safi: PercussionlucasakrNo ratings yet

- Bees ScoreDocument6 pagesBees ScoreCalvin HG LipetzkyNo ratings yet

- Alhamdulillah A3 HidrostaticDocument1 pageAlhamdulillah A3 HidrostaticIzzu FaturNo ratings yet

- Snakes 1Document1 pageSnakes 1Ron KubisNo ratings yet

- Stainless Steel Bevel Gears: Spur Gears Spur GearsDocument1 pageStainless Steel Bevel Gears: Spur Gears Spur Gearsdenizbademci31No ratings yet

- Roca Eterna - D - 130bpm - CompletaDocument4 pagesRoca Eterna - D - 130bpm - CompletaVICTOR EMANUEL CHACON AGUILARNo ratings yet

- Major Scales TrumpetDocument2 pagesMajor Scales TrumpetMaousspeaceNo ratings yet

- PURITAS RGB UsermanualDocument2 pagesPURITAS RGB UsermanualMadolfsNo ratings yet

- Segunda Obra Score General HOW GREAT THOU ART PDFDocument2 pagesSegunda Obra Score General HOW GREAT THOU ART PDFJ AndrésNo ratings yet

- Manhole Line: Rord N837-1: PLRN RND ProfileDocument1 pageManhole Line: Rord N837-1: PLRN RND ProfileVorn Ra VuthNo ratings yet

- Cop DESIGN FOR SAFETY EXTERNAL MAINTENANCEDocument31 pagesCop DESIGN FOR SAFETY EXTERNAL MAINTENANCEchong pak limNo ratings yet

- Technical ReportDocument31 pagesTechnical ReportCalin AlexandruNo ratings yet

- Unit 1 Ece For QuiklrnDocument37 pagesUnit 1 Ece For QuiklrnVINE TUBENo ratings yet

- Technical Catalog PWS, PWW - English VersionDocument24 pagesTechnical Catalog PWS, PWW - English VersionAndra FancialiNo ratings yet

- HATIM Concrete Industries LTDDocument33 pagesHATIM Concrete Industries LTDNaimur RahamanNo ratings yet

- Hybrid Wood and Steel Details-Builder's GuideDocument12 pagesHybrid Wood and Steel Details-Builder's GuideKeysha ApriliaNo ratings yet

- Balaji.E: Curriculum VitaeDocument5 pagesBalaji.E: Curriculum VitaeEngr Balaji100% (1)

- Conservatory Foundations.Document12 pagesConservatory Foundations.Phillipe LysNo ratings yet

- Assignment 2Document31 pagesAssignment 2S.m. MoniruzzamanNo ratings yet

- Evanston, IL Code of OrdinancesDocument16 pagesEvanston, IL Code of OrdinancesOdiseo BasquasaNo ratings yet

- Masonry Su PDFDocument32 pagesMasonry Su PDFDanusha EgodawatteNo ratings yet

- PDCB - GC RFQ PDFDocument272 pagesPDCB - GC RFQ PDFAlexandru Simion CosmaNo ratings yet

- PD 1096 National Building Code - Revised Implementing Rules and Regulations Rule 1-3Document22 pagesPD 1096 National Building Code - Revised Implementing Rules and Regulations Rule 1-3Clive Aaron GuanzonNo ratings yet

- Ba 281838 001Document1 pageBa 281838 001salmanNo ratings yet

- Curtain Wall System From Technal - Geode-BrochureDocument38 pagesCurtain Wall System From Technal - Geode-BrochurebatteekhNo ratings yet

- "Planning of G+2 Commercial Building Using Autocad": Siddharth Institute of Engineering & Technology, PutturDocument13 pages"Planning of G+2 Commercial Building Using Autocad": Siddharth Institute of Engineering & Technology, PutturNeeharikaNo ratings yet

- Door Schedule Window Schedule: Label D1 D2 D3 D4 D5 Label W1 W2 V1Document1 pageDoor Schedule Window Schedule: Label D1 D2 D3 D4 D5 Label W1 W2 V1Brian Masogoyi NNo ratings yet

- Heradesign InstallationDocument12 pagesHeradesign InstallationshanNo ratings yet

- BCA 96 Guide Amdt 12Document495 pagesBCA 96 Guide Amdt 12phanthanhsiNo ratings yet

- Builder's Guide To Continuous Insulation: P B, P.E - J L, P .D., P.EDocument76 pagesBuilder's Guide To Continuous Insulation: P B, P.E - J L, P .D., P.EMangga88dNo ratings yet

- DAP Amorim Isolamentos ICB en 06-10-2016Document21 pagesDAP Amorim Isolamentos ICB en 06-10-2016Paulo UtargNo ratings yet

- Vision Government SolutionsDocument5 pagesVision Government Solutionsnihadawad1964No ratings yet

- 1954 August - School at Hunstanton, Norfolk, by Alison and Peter Smithson - Buildings - Architectural ReviewDocument9 pages1954 August - School at Hunstanton, Norfolk, by Alison and Peter Smithson - Buildings - Architectural ReviewSomeonealreadygotthatusername.No ratings yet

- Trafalgar Fyreflex S55776e3992ae6Document14 pagesTrafalgar Fyreflex S55776e3992ae6cliveNo ratings yet

- ATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlyDocument8 pagesATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlycuanicochorielynjuviNo ratings yet

- Tall Building - CGDCR - Preliminary - ModificationDocument16 pagesTall Building - CGDCR - Preliminary - ModificationBhavikNo ratings yet

- Comparative Analysis of Creating Traditional Quantity Takeoff Method and Using BIM ToolDocument5 pagesComparative Analysis of Creating Traditional Quantity Takeoff Method and Using BIM ToolKhusnul KhotimahNo ratings yet

- Safwan Portfolio 2023Document21 pagesSafwan Portfolio 2023SafwanNo ratings yet

- Requirements For Design Thesis SubmissionDocument5 pagesRequirements For Design Thesis SubmissionHaleema SadiyaNo ratings yet

FDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010

FDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010

Uploaded by

Fazalrahman RangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010

FDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010

Uploaded by

Fazalrahman RangCopyright:

Available Formats

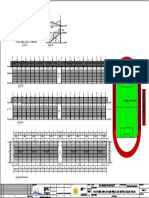

Bars G2 (evenly spaced) Backfill

Bars F

4" Min.

Bars A (F.S.) Front Face

of Wall

Bars A (paired with Bars J)

Wall Cover

(Typ.)

H eight Bars G2 (evenly

H eight

spaced)

Bars F (N.S.) Slope

NOTE:

Bkwall

See Plans for Retaining Wall Data

Bars J & K

Bars K (F.S.)

Dsoil

(1’-0" Min.) Const. Jt.

L Bars H

toe

Bars M (N.S.) Bars J (F.S.) Footing Cover (Typ.)

D

D

A

key

key

Bars Z (N.S.)

*D

*D

Bars G1

dgn

Bars H Bars G1

\d\projects\standards\structures\current\ready4release\2014BOOK\06010-1of2.

L *L Footing Cover (bottom only)

Bars Z toe key

(Showing Near Side) (Showing Far Side)

Bars M (paired with Bars F)

L

VIEW A-A foot

(Shear key shown dashed)

* Shear Key is required only when

specified in the Plans.

TYPICAL SECTION

NOTES

DESIGN SPECIFICATIONS:

Design according to FDOT Structures Manual (current edition).

REINFORCING STEEL BENDING DIAGRAMS

TRAFFIC RAILINGS OR PARAPETS:

Total Length

If there is a Traffic Railing or Parapet on the wall, align Wall Joints with V-Grooves, and Wall Expansion Joints

with Barrier Open Joints.

1’-0" Lap Splice (Typ.)

FOUNDATION: Prepare the soil below the footing in accordance with the requirements for spread footings in Specification

Section 455.

PAYMENT: BARS G1

All Retaining Wall costs, including all miscellaneous costs, shall be paid for at the unit contract price for

C:

either Class II, III or IV Concrete (Retaining Walls) (CY) and Reinforcing Steel (Retaining Walls) (lbs.).

Retaining Wall quantities shall not include concrete nor reinforcing steel for Traffic Railing, Parapet or Junction Slab. 1

A

Slope

sm 970re

Bkwall

A

90

50 PM

B B

56:

6:

BARS J & K BARS M

NOTE:

All bar dimensions are out-to-out

6/24/2013

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

C-I-P CANTILEVER RETAINING WALL

01/01/11 DESIGN STANDARDS 6010 1of 2

**Wall joint spacing 25 ft. maximum and

5’ minimum. At minimum, every fourth

Wall Joint

wall joint to be an expansion joint.

**Wall Joint Spacing »¿˘" V-Groove across top and (required at footing step)

See Plans for actual wall joint spacing

front face of wall at joint (Typ.).

and expansion joint location.

Extend V-Groove down back of wall

Const. Joint permitted

to 6" min. below ground. Top of Footing

(keyway not required)

(see ’V-Groove Detail’)

)

-0" M ax.

45 (Typ.)

D

Vstep

A A

2’

1’-0"

(

Ground Line

D

V-GROOVE DETAIL

Bars R Optional Shear Key

Top of Footing (paired with

Level (Typ.) Bars G1)

3" PVC Drain Pipe at DETAIL A

10 ft. max. spacing (Typ.) See ’Detail A’

At Contractor’s option,

See ’Typical Backfill Detail’

Suface Treatments may

terminate 6" below ground line

Traffic Railing (Index No. 420,

Front Face »¿ Wall

32" F-Shape shown, see Plans

FRONT ELEVATION Stem Offset

for Traffic Railing type) of Wall

1 b" »¿˘" V-Groove (T

Top of Coping

» ¿

Junction Slab (See Stem as constructed (see ’V-Groove Detail’)

Vertical Line

4"

Top of Index Series 6100) Bars D @ 1’-0"

Front Face

"

CIP Wall of Wall (Max. spacing)

9

»

Varies

4"

dgn

Stem Offset (in.) = H(Ft.)/16

\d\projects\standards\structures\current\ready4release\2014BOOK\06010-2of2.

H eight Varies

*3b "

H

Front Face

of Wall

4

"

M

n

i

Bars D

V

.

a

»¿

r

(field bend)

Varies

ie

»¿

s

9"

STEM OFFSET VALUES SECTION A-A TYPICAL CORNER JOINT DETAIL

( for H < 20 Ft.) WALL JOINT DETAIL

TRAFFIC RAILING/JUNCTION SLAB DETAIL »¿ Wall

Front Face

(32" F-Shape Shown, other Traffic Railings similar)

of Wall 1 b"

(for 32" F-Shape Traffic Railing (as shown), see Index No. 420;

Slope backfill layers transversely

» ¿

for 32" Vertical Shape Traffic Railing, see Index No. 423; b" Preformed Joint Filler

and longitudinally as necessary

for 42" Vertical Shape Traffic Railing, see Index No. 422) Bars D @ 1’-0"

to drain and prevent ponding

(Max. spacing)

4"

during backfilling.

Front Face of Wall »¿

*3b "

See Roadway Plans for

drainage requirement

3" PVC Drain Pipe. Slope down »

»

b" from back to front of wall

Plastic sleeve

Varies

and extend b" beyond both

front face and back face of wall.

C:

Attach Type D-5 (of Index No. 199) Geotextile fabric,

9"

1’-0" wide and full height of fill, to the back of wall

with an adhesive approved by the Engineer.

SECTION A-A

RD960DM

1" Cl. Limits of Excavation

EXPANSION JOINT DETAIL

Final Groundline.

Drain shall be continuous 1.5’ x 1.5’ clean,

11 AM

Inside ends of weep holes broken stone or gravel, graded and placed

* Key to stop at top of footing and 6" from top of wall. Joint

shall be covered with 1.0 to allow free drainage. Place Type D-3 (of

27:

across footing and top of wall to be a straight line.

Index No. 199) geotextile fabric, around

9:

square foot of galvanized

»¿mesh with ˘" open the perimeter to prevent fill from washing out.

TYPICAL BACKFILL DETAIL

7/1/2013

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

C-I-P CANTILEVER RETAINING WALL

01/01/11 DESIGN STANDARDS 6010 2 of 2

GENERAL NOTES

:1 s

1 ie

r

1. Gravity walls constructed as extensions of reinforced

a

ESTIMATED QUANTITIES FOR WALL

V

Bars B concrete retaining walls, except walls of proprietary

8"

.

e

x

p

(Typ.)

lo

a

designs, shall have the same face texture and finish

M

PER LINEAR FOOT OF WALL

S

WEEP as the reinforced concrete retaining wall.

3"

»¿˘" Cha HEIGHT HOLES

»¿ ˘" V- CLASS NS CONCRETE (CY) REINF. 2. Concrete for Gravity Wall shall be Class NS per Section 347.

(Typ.) (FT.) & DRAIN Concrete for Scheme 3 Junction Slab and Traffic Railing shall

STEEL

6"

General Note 5)

SCHEME SCHEME SCHEME REQD.

Joint Seal, see

(LB.) be Class II per Section 346, unless otherwise specified in

3" Cl.

1 2 3

the plans.

3. Reinforcing steel shall meet the requirements of Specification

-0"

1’ 0.08 0.11 (0.20*) 0.03 3 (4*) No

Section 931 (Grade 40 or 60) and be provided at the max.

1’

Joint Seal

2’ 0.14 0.20 (0.32*) 0.09 4 (5*) No

spacings shown. Smooth or Deformed Welded Wire Reinforcement

3" Cl.

)

Typ.

M ax.

)

W all Joints equally spaced

-0" M ax.

4b" 3’ 0.22 0.32 (0.47*) 0.29 5 (6*) Yes (WWR) may be substituted on an equal area basis. Do not increase

9"

bar/wire spacing for Grade 60 reinforcing steel or WWR.

(

Varies

(

4’ 0.32 0.47 (0.65*) 0.43 6 (7*) Yes

)

3" Cl.

, 5’M in.

Bar A 4. When required, for adjunct guiderail see the plans,

Bars A (Typ.)

(Typ.) 5’ 0.43 0.65 (0.85*) 0.60 7 (8*) Yes Index No. 870 or 880 as appropriate. For adjunct Type B

Keyway

5’

-6" sp.

12

Bars B @

Bar B fence see Index No. 802.

H eight (

5. Joint seal to be two layers of 30# smooth roofing paper

30’M ax.

ESTIMATED QUANTITIES NOTES:

or Type D-5 geotextile fabric in accordance with Index

1’

8" Varies 6"

) No. 199. Mop all contact surfaces of concrete and roofing

p. For Scheme 3 Junction Slab and Traffic Railing see the

Ground Ty

( paper or geotextile fabric with cut-back asphalt. Stop

referenced Design Standards for estimated quantities.

Surface Bars A &

(

roofing paper or geotextile fabric 6" below top of wall).

M ax.

» ¿

General Note 5)

Joint Seal, see

B @ 1’-6"

9"

» »¿ » 6. Provide a continuous 1’x1’ clean gravel or crushed rock

1" Cl. * Quantity for 2’-0" Toe Depth in Scheme 2.

Ctrs. (Max.) drain for wall heights 3 ft. and higher. Wrap drainage layer

Weep

-0"

as shown, with Type D-3 geotextile fabric in accordance

Hole

with Index No. 199. Provide 8"x8" galvanized mesh with

1’

Depth)

Varies

»¿ ˘" openings, at the inside end of the PVC Drain P

Drainage Layer

Toe

Provide 2" PVC Drain Pipe (Sch. 40) at 10 ft. max.

One layer And PVC Drain

(

4b"

(

spacing (When Drainage Layer required). Locate minimum

of 30# Smooth (See Note 6)

2’-0" clear of wall joints.

Roofing Paper

7. Cost of reinforcing steel, face texture, finish, joint seal,

or gray preformed 6" Cl. (– 2" Prepare Foundation Per drain pipes, drainage layer, galvanized mesh and geotextile

plastic bond Tolerance) Spec. 455 (Spread Footings) fabric to be included in the Contract Unit Price for Concrete

breaker (Typ.)

dgn

Class NS, Gravity Wall. Cost of concrete for Junction Slab in

\d\projects\standards\structures\current\ready4release\2014BOOK\06011-1of1.

Scheme 3, to be included in Contract Unit Price for Concrete

KEYWAY & WALL JOINT DETAIL

TYPICAL SECTION Traffic Railing Barrier With Junction Slab. Adjunct railings or

(TOP VIEW)

fences to be paid for separately.

BILL OF REINFORCING STEEL

MARK SIZE LENGTH

A 4 As Reqd.

Edge of paved shoulder B 4 As Reqd.

1:1b < Slopes = 1:1 3’-6" Min. Offset or face of curb Traffic Railing (Index No. 420,

1:6 < Slopes = 1:1b 32" F-Shape shown, see Plans

Edge of paved shoulder 3’-6" = Offset < 7’-3"

or face of curb

for Traffic Railing type) BAR BENDING DIAGRAM

Slopes = 1:6 3’-6" = Offset < 6’-6"

1:6 < Slopes = 1:1b 7’-3" Min. offset 3b"

Scheme 3

Live Load Limit Scheme 1 & 2

Slopes = 1:6 6’-6" Min. offset

Live Load Limit

1

-0"

Soil Reinforcement

"

See General Wall Joint spacing - 4"

H eight + Toe Depth - 9"

R

H eight + Toe Depth - 2’

.

Note 4 when required Junction Slab (See (29’-8" Max.)

See General (See Plans) Index Series 6100)

Note 4

C:

BAR A

)

Slopes up Slopes up

5’M ax.

H eight

to Max. 1:1 to Max. 1:1

RD960DM

1’-0" Min. to SHW

)

9

5’M ax.

5’M ax.

H eight

H eight

(Except for slopes 1’-0" Min. to SHW

(

1’-0" For Slopes = 1:1b for Wall Height = 2’-0" 12

steeper than 1:2

2’-0" For Slopes > 1:1b 2’-0" Min. to SHW

with wall heights > 3’, 5 9

(

then 2’-0" Min.) for Wall Height > 2’-0"

13 AM

12 1’-0" Min. 12

to SHW NOTES:

27:

1. All bar dimensions are BAR B

9:

out to out.

1’-0" 1’-0" For Wall Height = 2’-0"

2. Lap splices for Bars A

SCHEME 1 SCHEME 2 2’-0" For Wall Height > 2’-0" SCHEME 3

must be a minimum of 1’-6".

7/1/2013

(No Traffic Loading Effects) (With Traffic Loading or Slopes > 1:1b) (With Traffic Railing)

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

C-I-P GRAVITY WALL

07/01/13 DESIGN STANDARDS 6011 1of 1

C-I-P Traffic Railing

NOTES

SPECIFICATIONS:

C-I-P Junction Slab

1. General Specifications: 9. For concrete facing panel surface treatment, see Wall Control Drawings. Top of Shoulder or

(See Index Series

The Florida Department of Transportation "Standard Specifications for Road Extend surface treatment a minimum of 6" below final ground line. Coping Elevation Roadway Pavement

6100)

and Bridge Construction", Current Edition and Supplements as Amended. 10. Drive piles located within the soil volume prior to construction of the

2. Design Specifications: retaining wall, unless a method to protect the structure, acceptable to both

a. Florida Department of Transportation (FDOT) "Structures Design Guidelines", the Engineer and Wall Company, is proposed and approved in writing. The Concrete Coping

Current Edition. portion of piles or drilled shafts extensions within the soil volume will be

b. American Association of State Highway and Transportation Officials (AASHTO) wrapped with polyethylene sheeting in accordance with Specification

"LRFD Bridge Design Specifications", Current Edition. Section 459.

Soil Reinforcement (Typ.)

c. AASHTO-AGC-ARTBA Task Force 27 (Ground Modification Techniques), 11. A structural extension of the connection of the retaining wall panel to soil

"Insitu Soil Improvement Techniques", January 1990. reinforcement will be used whenever necessary to avoid cutting or excessive

skewing (greater than 15) of the soil reinforcement around obstructions Surface treatment when

DESIGN CRITERIA: (i.e., piles, pipes, manholes, drop inlets, etc.). required (See Construction

1. Design is based on the assumption that the material contained within the 12. Steps in leveling pads will occur at MSE Wall panel interfaces. Panels will not Note 9) Limits of

reinforced soil volume, methods of construction and quality of prefabricated cantilever more than 2" past the end of the upper tier leveling pad. Soil Volume

materials are in accordance with Specification Section 548 and Chapter 3 13. The top of the leveling pad or footing will be 2’-0" minimum below final 1’-0" Min.

4’-0" Min.

of the FDOT Structures Design Guidelines. ground line.

2. It is the responsibility of the Engineer of Record to determine that the 14. Top of leveling pad elevations shown in the Wall Control Drawings are maximum

Proposed Final

maximum factored bearing pressure shown for the wall does not exceed elevations. The constructed leveling pad elevations may be deeper based on

Ground Line

the factored bearing resistance of the foundation for that specific wall location. the panel layout shown in the shop drawings.

3. The Wall Company is responsible for internal stability of the wall. External 15. The height of panels in the bottom course of MSE Walls must not be less

stability design, including foundation and slope stability, is the responsibility than half the height of a standard panel.

of the Engineer of Record. 16. Work this Index with Index 6100 & 6200 Series.

Top of

4. If there are manholes and/ or drop inlets present, design and analysis for both

Leveling Pad

internal and external stability shall be considered. SHOP DRAWING REQUIREMENTS:

2’-0" Min. Elevation

See Specification Section 548 for shop drawing requirements.

Interior Face of

SOIL PARAMETERS:

Concrete Leveling Pad Concrete Facing Panels

1. See Wall Control Drawings for soil characteristics of foundation material to be

used in the design of the wall system.

2. The Contractor will provide soil design parameters for backfill material based TYPICAL MSE RETAINING WALL SECTION

on the actual soil characteristics utilized at the site. WITH A TRAFFIC RAILING

dgn

\d\projects\standards\structures\current\ready4release\2014BOOK\06020-1of1.

(Showing Limits of the Reinforced Soil Volume)

MATERIALS:

1. Concrete Class: See Wall Control Drawings.

2. See Specification Section 548 for material requirements.

3. For additional material requirements see the Wall Company’s General Notes.

10’-0" min. C.I.P. Coping 12’-0" min. Precast Coping/Traffic Railing

CONSTRUCTION:

1. Walls will be constructed in accordance with Specification Section 548 and

the Wall Company’s instructions. 12" 2’-0" 6"

2. For location and alignment of retaining walls, see Wall Control Drawings. Coping

Top of Coping

3. If present, consider in design and analysis and locate manholes and drop Transition

inlets as shown on wall elevations.

FDOT MSE RETAINING WALL CLASSIFICATION TABLE

4. Refer to Wall Control Drawings of individual walls for minimum reinforcement

strip/mesh length, factored bearing resistance’s, minimum wall embedment Durability Requirements Other Allowable FDOT Wall Types

Precast

Coping

Coping

P.

-0"

-3"

and anticipated long term and differential settlements.

I.

Applicable Concrete Concrete Pozzolan Soil

2’

2’

C.

5. The Contractor is responsible for controlling water during storm events as

needed during construction. FDOT Wall Cover Class Additions? Reinforcement 2A 2B 2C 2D 2E 2F

6. It is the Contractor’s responsibility to determine the location of any Type * (in.) for Panels ** Type

guardrail posts behind retaining wall panels. Prior to placement of the top

layer of soil reinforcement, individual reinforcing strips/mesh may be Type 2A 2 II No Metal

3"

skewed (15 maximum) to avoid the post locations if authorized by b" Preformed

Type 2B 2 IV No Metal

the Engineer. No cutting of soil reinforcement is allowed unless shown Joint Filler

on Shop Drawings and approved by the Engineer. Any damage done to Provide Supplemental Type 2C 3 IV No Metal

C:

the soil reinforcement due to installation of the guardrail will be repaired #4 Bar with 3" concrete Type 2D 3 IV Yes Metal

by the Contractor at the Contractor’s expense. Repair method will be cover

approved by the Engineer. Type 2E 3 IV No Plastic

7. If existing or future structures, pipes, foundations or guardrail posts Type 2F 3 IV Yes Plastic

RD960DM

within the reinforced soil volume interfere with the normal placement of ELEVATION VIEW OF

soil reinforcement and specific directions have not been provided on the * See Data Table in Contract Plans.

COPING HEIGHT TRANSITION

plans, the Contractor will notify the Engineer to determine what course ** Silica fume, metakaolin or ultrafine fly ash.

of action shall be taken.

(Railing Not Shown For Clarity)

8. The Contractor is responsible for gradually displacing upper layer(s) of

18 AM

soil reinforcement downward (15 maximum from horizontal) to avoid

27:

cutting soil reinforcement and conflicts with paving and subgrade preparation.

9:

The Contractor’s attention is directed especially to situations where roadway

superelevation and/or soil mixing are anticipated.

7/1/2013

GENERAL NOTES AND DETAILS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

PERMANENT MSE RETAINING WALL SYSTEMS

07/01/13 DESIGN STANDARDS 6020 1of 1

NOTES

SPECIFICATIONS:

1. General Specifications:

The Florida Department of Transportation "Standard Specifications for

Road and Bridge Construction", Current Edition and Supplements as

Amended.

Secondary Reinforcement

2. Design Specifications:

Top of Wall as required

a. Florida Department of Transportation (FDOT) "Structures Design

Guidelines", Current Edition.

b. American Association of State Highway and Transportation Officials

(AASHTO) "LRFD Bridge Design Specifications", Current Edition. Primary Reinforcement

c. AASHTO-AGC-ARTBA Task Force 27 (Ground Modification Techniques),

"Insitu Soil Improvement Techniques", January 1990.

Reinforced

Fill

DESIGN CRITERIA:

1. Design is based on the assumption that the material contained within the

reinforced soil volume, methods of construction and quality of prefabricated

Geotextile Wrap

materials are in accordance with Specification Section 548 and FDOT

Structures Design Guidelines Section 3.13.2. Wire Facing

Limits of

2. It is the responsibility of the Engineer to determine that the factored or Basket

Soil Volume

bearing pressure shown for the wall does not exceed the factored

bearing resistance of the foundation for that specific wall location.

3. The Wall Company is responsible for internal stability of the wall. External

stability design, including foundation and slope stability, is the responsibility

of the Engineer.

4"-0" Min.

4. If present, consider in design and analysis and locate manholes and drop

inlets as shown on wall elevations.

1"-0" Min.

SOIL PARAMETERS: Foundation Soil

1. See wall control drawings for soil characteristics of foundation material

to be used in the design of the wall system. The Contractor must provide Soil Reinforcement Length

soil design parameters for backfill material based on the actual soil

dgn

characteristics utilized at the site. Provide the values of unit weight,

\d\projects\standards\structures\current\ready4release\2014BOOK\06030-1of1.

cohesion and internal friction angle in the Shop Drawings. TYPICAL RETAINING WALL SECTION

(Showing Limits of the Reinforced Soil Volume)

MATERIALS:

1. Provide soil reinforcement in accordance with Specification Section 548.

2. For additional material notes, see Wall Company General Notes.

CONSTRUCTION:

1. Walls must be constructed in accordance with Specification Section 548 and

the Wall Company’s instructions.

2. For location and alignment of retaining walls, see Wall Control Drawings. Varies (See Index No. 414

2’-0" Min. and Wall Control Drawings)

3. Refer to Plan and Elevation sheets of individual walls for minimum

reinforcement strip/mesh length, factored bearing resistance’s, minimum

wall embedment and anticipated long term and differential settlements.

Type K Temporary

4. If existing or future structures, pipes, foundations or guardrail posts within

Traffic Railing

the reinforced soil volume interfere with the normal placement of soil

Dropoff (See Index No. 414

reinforcement and specific directions have not been provided on the

for Details)

plans, the Contractor must notify the Engineer to determine what course

of action should be taken.

5. The Contractor is responsible for gradually deflecting upper layer(s) of

soil reinforcement downward (15 maximum from horizontal) to avoid

cutting soil reinforcement and conflicts with paving and subgrade

45

preparation. The Contractor’s attention is directed especially to

situations where roadway superelevation and/or soil mixing are Front Face of

C:

anticipated. Temporary

Retaining Wall

sm 970re

10 PM

TEMPORARY TRAFFIC RAILING

52:

PLACEMENT DETAIL

3:

6/24/2013

GENERAL NOTES AND DETAILS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

TEMPORARY MSE RETAINING WALL SYSTEMS

01/01/11 DESIGN STANDARDS 6030 1of 1

Bulkhead Cap

SHEET PILE DESIGN CRITERIA AND NOTES

(See Bulkhead Plans

for actual Cap outline)

DESCRIPTION:

This Design Standard includes details for five types of piles with two thicknesses.

Types "B1", "B2", "C1" and "C2" piles (corner piles) are of reinforced concrete construction, and Type "A" is of

prestressed concrete construction. The piles shall be manufactured, cured and installed in accordance with

the requirements of the contract documents.

)

-0"

M in.

1’

MATERIALS: (for materials not listed refer to the Specifications)

(

Compacted Fill

CONCRETE

Class: V (Special) for slightly and moderately aggressive environments

V (Special w/ Silica Fume) for extremely aggressive environment

Unit weight: 150 pcf

Plastic Filter Fabric Modulus of Elasticity: Based on the use of Florida limerock concrete

(Continuous) Sheet pile

REINFORCING STEEL

ASTM A615 Grade 60

PRESTRESSING STEEL

Existing Ground ASTM A416 Grade 270 (Low-Relaxation Strand)

(Mud Line)

CROSS REFERENCES: DESIGN PARAMETERS:

For Dimensions L and X see Sheet Type "A"

Pile Wall Data Table in Structures Plans. Concrete Compressive Strength at release of prestressing: 4000 psi minimum

-8"

Uniform compression after prestressing losses: 1000 psi minimum

1’

Pick-up, Storage and Transportation: 0.0 psi tension with 1.5 times pile self weight

Types "B1", "B2", "C1" & "C2"

Bottom of Dim. X

Pick-up, Storage and Transportation: Minimum compressive strength f’ci = 4000 psi required.

and Filter Fabric

ENVIRONMENT:

The pile designs are applicable to all Environments.

SECTION THRU BULKHEAD

dgn

PLASTIC FILTER FABRIC:

(Showing Plastic Filter Fabric)

\d\projects\standards\structures\current\ready4release\2014BOOK\06040-1of4.

The plastic filter fabric shall extend to the bottom of the "X" dimension.

PILE PICK-UP AND HANDLING:

Grout (Typ.) (See Specifications) Type "A"

Pick-up of pile may be either a single point pick-up or a two point pick-up as shown below.

~

Types "B1", "B2", "C1" & "C2"

2’-6"

Two point pick-up for lifting out of forms & two point support for storage & transportation.

Type "A" (Typ.)

Single point pick-up for installation only.

PILE FIT-UP:

90

~

The 2’-6" Sheet Pile dimension is nominal. This dimension may be shortened by the Manufacturer up to b" to

allow for Sheet Pile fit-up in its final position. Minimum Sheet Pile width is 2’-5b". No changes shall be made

to the tongues or grooves.

Type "A"

Type "A"

Type "C1" Type "A" Type "B1" or "B2"

Starter Pile Plastic Filter Fabric

or "C2"

DETAIL "A"

(Cap and Anchoring System Not Shown)

(Section Taken Above Dimension X)

NOTE: Detail "A" shows a Part-Plan View of an assumed bulkhead.

See Bulkhead plans for actual Plan View.

C:

1’-3"

»¿ Pile and

Starter Pile

2 Point Pick-up, Tie Down and Support Points Single Point

sm 970re

Pick-up

0.21 L 0.58 L 0.21 L

il r

"

o

12 PM

s

o pi ’-3

e

l

1

n ca

P

52:

r

e

y

3:

1’-3" L

T

DETAIL "A"

C

(Section Taken Below Dimension X) PILE STORAGE AND TRANSPORTATION SUPPORT DETAILS

Type "C2" Shown, Type "B2" Shown,

6/24/2013

Type "C1" Opposite Hand Type "B1" Opposite Hand

NOTES AND DETAILS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

PRECAST CONCRETE SHEET PILE WALL

07/01/12 DESIGN STANDARDS 6040 1of 4

L

BAR BENDING DIAGRAMS

4" (Typ.)

11" X

(Typ.)

Slope only on the tongue side

10"

DIMENSION A

(Typ.)

A Prestressed

2 ~ Bars A B S1 1’-11 "

Strands

M in. Lap)

S2 1’-9b "

-3"

S3 2’-2"

)

11"

Typ.

Pick-up Strand(S)

A

1’

Varies S4 1’-6 "

(

1

Bars Bars

(

S5 1’-10 "

’-

0

S1 S2

"

S6 11"

45

"

Bar S5 S7 1’-7 "

-0

Bar S4

BAR A

1’

DIMENSION B

T=10 in. 4"

B B T=12 in. 6"

7"

B

A 2-PIECE 1-PIECE

BAR S

4b " 6 sp. @ 4" Spaced at 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for

Bars S

NOTES:

1. Intermediate Prestress Strands not shown in Elevations and Sections.

TYPICAL PILE 2. All bar dimensions are out-to-out.

3. Bars A are #5 and Bars S are #4.

SHEET PILE DIMENSIONS

L 4. At the Contractor’s option Bars S may be fabricated as a two piece bar

T(in.) 10 12 as shown in the Bar Bending Diagram.

Y(in.) » » 5. The Contractor may use Deformed Welded Wire Reinforcement meeting

11" X the requirements of Specification Section 931 in lieu of Bars A and

Z(in.) 3 4

dgn

(Typ.) Bars S if the wire size and spacing provide the same area of

\d\projects\standards\structures\current\ready4release\2014BOOK\06040-2of4.

reinforcing steel per foot as the Bars shown.

10"

6. For Dimensions L and X see Sheet Pile Data Table in Structures Plans.

(Typ.)

C Prestressed

2" Cover

2" Cover

2 ~ Bars A B T T T

2" Cover

Strands

See Detail "D" See Detail "E" See Detail "D"

2 "

11"

2 "

)

Typ.

Pick-up

Strand(S)

(

Bars Bars

S3 S2 Bars A Bars A

Strands)

Strands)

Strands)

D

D

"

-6"

-6"

Bar S7

n sp. @

n sp. @

n sp. @

Bars S1 Bars S2 Bars S3

-6"

-0

2’

2’

Bar S6 3" Cover 3" Cover 3" Cover

1’

2’

(

(

(

(Typ.) (Typ.) (Typ.)

Bars A

2 "

Cover

7"

Cover

2 ~ Bars A

Cover

B

C

2"

2"

2"

4b " 6 sp. @ 4" Spaced at 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for

SECTION A-A SECTION B-B SECTION C-C

Bars S

STARTER PILE Y 3 " Y Z 4" Z

C:

b" 2 " b" b" 3" b"

Wall STRAND DIA. MAXIMUM D TOTAL # OF SECTION * STRESS

n

Thickness (in.) L (in.) STRANDS MODULUS (in.‡) (psi)

sm 970re

T=10 in. 0.5 28’-0" 6 3 14 500 1150

2"

0.6 27’-0" 4 5 10 500 1160

2 "

T=12 in. 0.5 31’-0" 7 2 16 720 1100

14 PM

0.6 30’-0" 5 4 12 720 1160

52:

3:

* Unit Prestress after losses.

DETAIL "D" DETAIL "E"

(Typical Tongue) (Typical Groove)

6/24/2013

TYPE "A" STANDARD SECTION

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

PRECAST CONCRETE SHEET PILE WALL

07/01/13 DESIGN STANDARDS 6040 2 of 4

See Detail "D"

L

Bars A1

11" Slope is to Bars A2

Bars A1

this point 11" 2’-2" X 7" Bars A2

Bars A3

Bars A3 Bars A3

T C B Bars A2 Bars A1 Bars A3

A Bars A4

Bars A4 Bars A3

Bars A4

Bars S1

Slope only on Bars A4

Bars A4

1’

tongue side

-3

Bars A4 Bars S2

Bars A4

"

Bars A4

S2 S1 Bars A4

Bars A4

Bars A4

4"

Pick-up Strand(s) Bars A4

3" Cover

Bars S3 (Typ.) See Detail "D" 3" Cover

(Typ.)

"

Bars S4

-3

SECTION A-A SECTION B-B

1’

T

bT

T

C B Bars A4 A bT

10" Y

» ¿

b"

VIEW C-C Y

2

2"

4 " 6 sp. @ 4" Spaced @ 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for "

b" SHEET PILE DIMENSIONS

Bars S

ELEVATION T (in.) 10 12

r

2"

ve

(TYPE "B1" PILE SHOWN, TYPE "B2" PILE OPPOSITE HAND)

Y (in.) 3 4

Co

Z (in.) 3 4

BAR BENDING DIAGRAMS

Bars A2 Bars S

dgn

\d\projects\standards\structures\current\ready4release\2014BOOK\06040-3of4.

STIRRUP DIMENSIONS (T = 10") STIRRUP DIMENSIONS (T = 12")

Bars A1 or A4

BAR MARK R1 R2 R3 R4 R5 R6 R7 R8 BAR MARK R1 R2 R3 R4 R5 R6 R7 R8

2

S1 11 " 9 " 1’-6b " 2b " 5" 4 " 5b " 4 " S1 11b " 10" 1’-6" 3b " 7" 4 " 5 " 6"

Co

2"

"

ve

S2 1’-1b " 9 " 1’-8 " 2b " 4b " 5b " 5 " 4 " S2 1’-1 " 10" 1’-8 " 3b " 6b " 5 " 5 " 6"

r

30 30

S3 11 " 8" 1’-6" 1 " 5" 4b " 4b " 5" S3 11b " »¿ 1’-5 " 2" 7" 4 " 4b " 7 "

b"

S4 11 " 4 " 1’-1 " 1 " 5" 3 " 2b " 6 " S4 11b " 4" 1’-1 " 2 " 7" 3 " 2b " 8 "

3"

b" Z

S1 11b " 8" 1’-4" 4" 5b " 6b " 8" 4" S1 1’-0" 8b " 1’-3 " 5 " 7b " 6 " 8b " 5 "

4"

S2 1’-1 " 8" 1’-5 " 4" 4b " 7b " 8" 4" S2 1’-2 " 8b " 1’-5b " 5 " 6b " 7 " 8b " 5 " Z bT

45 45

S3 11b " 6 " 1’-4" 2 " 5b " 6 " 6 " 5b " S3 1’-0" 7" 1’-4" 3" 7b " 6 " 7" 7 " bT

T

S4 11b " 3b " 1’-0" 3" 5b " 5" 3b " 7" S4 1’-0" 3b " 11 " 3 " 7b " 5" 3b " 9"

S1 1’-0" 6" 1’-0 " 5 " 6" 7 " 10 " 3" S1 1’-0b " 6 " 11 " 7" 8" 6 " 10 " 4"

S2 1’-2" 6" 1’-2 " 5 " 4 " 8 " 10b " 3" S2 1’-2 " 6 " 1’-2" 7" 6 " 8" 10 " 4" DETAIL "D"

60 60

3 "

(TYPE "B1" PILE SHOWN, TYPE "B2" PILE OPPOSITE HAND)

S3 1’-0" 4 " 1’-1b " 6" 8" 8 " 5 " S3 1’-0b " 5" 1’-1b " 4" 8" 8" 9" 7"

S4 1’-0" 2b " 10" 4b " 6" 5 " 4" 7b " S4 1’-0b " 2b " 9b " 5b " 8" 5b " 4 " 9 "

NOTES:

1. This drawing includes details for precast concrete corner piles for 10"

C:

)

Typ.

and 12" thick sheet pile systems. The details apply equally to both thicknesses.

Typ.

R5 R6 R5 R6

4"

R5 R6

4"

2. The bar configurations shown in Sections A-A and B-B shall be used for

(

angles between 15 and 75. For angles not shown, the reinforcing bar

sm 970re

dimensions may be interpolated or extrapolated from the stirrup dimensions shown.

R1

R1

3. All bar dimensions are out-to-out.

R1

Varies

R3

R3

4. Bars A are #8 and Bars S are #4.

R3

5. Values for Stirrup Dimensions are shown for equal to 30, 45 & 60 only.

6. At the Contractor’s option Bars S may be fabricated as a 2 piece bar with

16 PM

R2

R2

R2

a minimum lap length of 1’-6", as shown in Bar Bending Diagrams.

45

R4

7. If Type "B1" or "B2" pile is used as a Starter Pile show tongue on both sides of pile

R4

52:

1

’-

R4

3:

0

" from Dim. X down. Show dimensions for Bars S2, S3 & S4 in shop drawings.

R7 R8 R7 R8 8. If tongue must be on the opposite side from that shown all dimensions and Bars A,

R7 R8 BAR A2

S2, S3 and S4 will be the same but opposite hand.

9. For Dimensions L, X and Angle , see Sheet Pile Data Table in Structures Plans.

6/24/2013

1 - PIECE 2 - PIECE BARS S3 & S4

BARS S1 & S2 TYPE "B1" AND "B2" - VARIABLE ANGLE CORNER PILE

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

PRECAST CONCRETE SHEET PILE WALL

07/01/12 DESIGN STANDARDS 6040 3 of 4

L

For 10" Pile

For 12" Pile

1’-4" 10 " 2’-2" X

This A4 bar ends See

T

here if T=12"

)

Section C-C

Typ.

Bars A1

C B 2 ~ Bars A2

2"

10" T S2 T

D Bar A4 A

(

Bars S3 (Typ.) Bars A1 3" Cover

* Bar A4 * Bar A4

Bars S1 Bar A5

Bar A5

-8"

-9"

Bars S5 Bars A2

-8"

-9"

** Bar A4

** Bar A4

1’

1’

Bars S4 Bar A6

1’

1’

T

T

Pick-up Bar A6

Strand(s)

Bars A5 Bars A3 7" Bars A3 Bars A3

3" 2" (Typ.)

1’-8" D A

(Typ.) C B 3" Cover

See Section C-C

For 10" Pile

For 12" Pile

1’-9"

Bars S2 Bars S1

1’-8" For 10" Pile

END VIEW 1’-9" For 12" Pile

4" 6 sp. @ 4" Spaced @ 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for

SECTION A-A SECTION B-B

Bars S

ELEVATION

(TYPE "C1" PILE SHOWN, TYPE "C2" PILE OPPOSITE HAND) * This Bar A4 shall be 1’-2" shorter than other A4 bars for T = 12".

Bars A2

** This Bar A4 (not shown in elevation) is included only if T = 12".

Bar A4 BAR BENDING DIAGRAMS

Bar S2

Y 3 " Y

Bar S3 R3

dgn

R2

Bar A5 STIRRUP DIMENSIONS

\d\projects\standards\structures\current\ready4release\2014BOOK\06040-4of4.

b" 2 " b"

R2

Bar S4 T (in.) BAR MARK R1 R2 R3

Bars

Bar S5 S1 7" 5 " 7"

R1

A3

2"

2"

4"

S2 7" 8" 4 "

10 S3 6 " 7 " 4 "

Bar A6

4"

*Bar A4 S4 5b " 6b " 4 "

S5 4 " 5 " 4 "

4b "A2 & A6

Bar A5 Bars A2 90 STIRRUPS S

-3"

-3"

S1 9" 4 " 9"

1’

1’

** Bar A4

2b " A4

0" A5

3b "A3

S2 9" 7" 6 "

SECTION D-D (T=10") 1’-2" Varies

b"

Bars A3

12 S3 8 " 6 "

Z

6 "

Bars S2

Bars A2

Bar A6 S4 7b " 5b " 6 "

45

4"

3"

T

1

S5 6 " 4 " 6 " - (Bars A2 only)

’

0

"

5"

6"

BARS A

b"

Bar A4

Bar S2

Z

For 10" Pile

For 12" Pile

Bar S3

Bar A5

»¿ Bul Note: All Bar dimensions are out-to-out.

2 " SHEET PILE DIMENSIONS

C:

For 10" Pile 1’-3" 5" Bar S4 T (in.) 10 12 NOTES:

For 12" Pile 1’-3" 6" Bar A4 Bar S5 1. All bar dimensions are out-to-out.

Bars

Y (in.) 3 4

2. Bars A are #8 and Bars S are #4.

A3

Z (in.) 3 4 3. This drawing includes information for precast Corner Piles for 10" and 12"

sm 970re

thick Sheet Pile systems. The details apply to both thicknesses but the bar

SECTION C-C (T=10" or 12") Bar A6

configurations change slightly according to the thickness values used.

4. If Type "C1" or "C2" pile is used as a Starter Pile show tongue on both sides of

pile from Dim. X down. Show dimensions for Bars S2, S3, S4 & S5 in

18 PM

shop drawings.

5. If tongue must be on opposite side (Groove Side) from that shown,

52:

all dimensions and reinforcement shall follow the corresponding Tongue

3:

or Groove side.

SECTION D-D (T=12") 6. For Dimensions L and X see Sheet Pile Data Table in Structures Plans.

6/24/2013

TYPE "C1" AND "C2" - RIGHT ANGLE CORNER PILE

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

PRECAST CONCRETE SHEET PILE WALL

07/01/12 DESIGN STANDARDS 6040 4 of 4

» b " Open Joint

Dim. A

0"Mi n)

.

» b " Open Joint 1

l (0-

’

"Typc

ia

0-

’0

Spacn

ig~ 3

nJon

it Bars 4B (follows top of 2" Min. Cover (Typ.)

b"Ope

Top of C-I-P Retaining Wall Panel) (Typ.)

Drainage Ditch when

Bars 4A (follows Coping required (See Wall Control

Bars 4U1 @ 1’-6" Max. Slope of C-I-P Bars 4U1

Drawings for details)

sp. (lap with Dowel Coping)

A

" Chamfer Bars 4A

Bars 4D) (Typ.) (Typ.)

Varies

Dowel Bars 4D (1’-3" Max.,

2" Min.)

-0"

(Typ.) (See

2’

Note 2)

Bars 4B shown as ( )

Top of Retaining

Wall Panel (Typ.) Dowel Bars 4D

(See Note 2)

6"

Clearance

Bottom of Varies

C-I-P Coping Retaining Wall Panel

Retaining Wall (See Wall Company

Panels (Typ.) Drawings for Details)

Smooth or Textured Face of Panel

A

PRECAST AND C-I-P COPING NOTES:

1. Provide Class II concrete for slightly aggressive environments

SECTION A-A

or Class IV for moderately or extremely aggressive environments.

C-I-P COPING - PARTIAL ELEVATION VIEW Panel width

2. Dowel Bars 4D extend 1’-0" above the top of retaining C-I-P COPING

dgn

Dim. A

+ 6"

wall panel. Field cut as necessary to maintain 2" minimum

\d\projects\standards\structures\current\ready4release\2014BOOK\06100-1of2.

Panel width

cover. See Wall Company Drawings for number and spacing

Dim. B

+ 1’-0" Min.

of Dowel Bars 4D.

3. Payment for Dowel Bars 4D, Buildup Concrete and Coping will

be made under Retaining Wall System (Permanent).

» b " Open Joint Dim. B

2" Min. Cover (Typ.)

» b " Open Joint Drainage Ditch when

n.) Top of Retaining

5

g(’-0"Mi required (See Wall

stCopn

i

alPreca Wall Panel (Typ.)

0"Typc

i Control Drawings

10-

’

Top of C-I-P Bars 4U2

Bars 4A for details)

2" Cover

Buildup Concrete (Typ.)

B

)

" Chamfer (Typ.)

-0" M ax.

Top of Precast

Coping

Varies

2" Cover

1’

Min.

(

-0"

2’

-3"

C-I-P Buildup Concrete

1’

(1’-0" Max.)

Provide 3b " x 3b " preservative

treated timber blocking @ 5’ Max.

Bars 4U2 @ Spacing for gaps > 1"

C:

1’-4" sp. (Typ.)

Varies (1’-3" Max., Dowel Bars 4D

Bars 4A

Clearance "

2" Min.) (See Note 2)

Dowel Bars 4D (Typ.) Varies

Bottom of " Std.

(See Note 1) 6" 6"

sm 970re

Precast Coping (

b " Min. ~ 2b " Max.)

Min. Min.

Retaining Wall

Retaining Wall Panel

Panels (Typ.)

Smooth or Textured Face of Panel (See Wall Company

B

Drawings for Details)

20 PM

52:

3:

SECTION B-B

PRECAST COPING - PARTIAL ELEVATION VIEW PRECAST COPING

6/24/2013

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

MSE WALL COPING (PRECAST OR C-I-P)

07/01/13 DESIGN STANDARDS 6100 1of 2

REINFORCING STEEL BENDING DIAGRAMS - PRECAST AND C-I-P COPINGS Dim. B

BILL OF REINFORCING STEEL REINFORCING STEEL NOTES: 2" Min. Cover (Typ.)

1. All bar dimensions in the bending diagrams are out to out. Drainage Ditch when

LENGTH (L) LENGTH (L) 2. All reinforcing steel at the open joints will have a 2" minimum cover. required (See Wall

MARK SIZE

##S or M ## E 3. Bars 4A may be continuous or spliced at the construction joints. Lap splices for Bars 4A will Bars 4U2 Control Drawings

Bars 4A

be a minimum of 1’-8". for details)

3

A 4 AS REQD. AS REQD. 4" Chamfer (Typ.) (Typ.)

4. The Contractor may use Welded Wire Reinforcement (WWR) when approved by the Engineer.

WWR must consist of Deformed wire meeting the requirements of Specification Section 931.

B 4 AS REQD. AS REQD.

Recess Varies

Varies (L)

D 4 2’-0" 2’-0" ## S = Slightly Aggressive (1’-3" Max., 2" Min.)

-0"

M = Moderately Aggressive

U1 4 Panel width + 4" Panel width + 4" E = Extremely Aggressive

2’

U2 4 Dim. B - 4" Dim. B - 4"

Varies Dowel Bars 4D

7" M in.

Varies

(See Note 2, Sheet 1)

U3 4 Dim. C - 4" Dim. C - 6" (L) (L)

Varies

Ground

4A Length as Required (L)

Line 6" 6"

-0"

L)

-8"

-8"

Min.

2’

-0" M in.

(

1’

4B Length as Required (L) (Match

1’

Precast

Field cut as

Dimensions)

2’

required to maintain

2" minimum cover Retaining Wall Panel

BARS 4A & 4B DOWEL BAR 4D BAR 4U1 BAR 4U2 BAR 4U3 Leveling Pad for (See Wall Company

MSE Wall Shown Drawings for Details)

C-I-P COPING USED WITH PRECAST COPING

Note: When precast coping units do not fit the entire length of the retaining

wall, use this similar C-I-P coping for short portions between precast

coping units. This C-I-P coping may also be used for vertical copings.

dgn

\d\projects\standards\structures\current\ready4release\2014BOOK\06100-2of2.

Field bend Bars 4A

to maintain minimum Dim. C

* For Slightly and Moderately

cover for Extremely Aggressive environments

Aggressive Environments Top of Coping

Top of Retaining

* 2" Cover (Top & Sides)

Wall End Panel ** For Extremely Aggressive

** 3" Cover (Top & Sides)

environments.

C 3

Begin or End 4" Chamfer (Typ.)

Bars 4B

Bars 4B (Horizontal) (Field

Spacing

Retaining Wall

cut as required to maintain

minimum cover)

Bars 4A (follows Slope

Panel width

of C-I-P Coping Enclosure) Dim. B

Bars 4A (Typ.) + 1’-0" Min.

Panel width

Bottom of Coping Dim. C

+ 6"

-6" M ax.

Eq. sp. @

Varies

Retaining Wall End Panel

Edge of C-I-P Bars 4B shown

(See Wall Company

1’

Coping Enclosure as ( ) (Typ.)

Drawings for details)

Bars 4U3

-0" M in.

Bars 4U3 @ 1’-6"

C:

Edge of Retaining

Max. sp. (Typ.)

Wall End Panel

6"

2’

sm 970re

412"

Bars 4B (Horizontal) C

4" Cover Leveling Pad for

(Bottom) MSE Wall Shown

22 PM

3" Min. Overlap

Varies SECTION C-C

52:

3:

C-I-P COPING ENCLOSURE DETAIL

6/24/2013

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014

REVISION NO. NO.

MSE WALL COPING (PRECAST OR C-I-P)

07/01/13 DESIGN STANDARDS 6100 2 of 2

5’-4" (Typ.) ~ Additional 8"

(See Note 1) Bars 3D @ 8" sp. (42" F-Shape)

1" Dowel Load Transfer (Shown Dashed)

Devices (See Typical Sections Top of

for details) Bars 5B2

Junction Slab b" V-Groove (See 2" Cover Expansion Joint (See

Bars 3D Bars 5C @ 8" sp. 1" Dowel Load

Bars 4A @ "Expansion Joint Detail"

4 ~ Bars 5F (Shown Dashed) Note 7 & Detail "A") Sides (Typ.) (Typ.) Transfer Devices

4" (Typ.) this sheet and Detail "A")

(Top of Slab)

Approved metal (Required only

or fiber cap when Junction

Bars 3D

Slab is skewed)

(Typ. at

Expansion

Joints)

Bottom of "

Lap Splice

Junction Slab

-0" M in.

3"

" Preformed Expansion Approach Slab 3s

p.

@

(See Note 12) 6"

Joint Filler

2’

Gutter Line

1’-0" 1’-0"

»¿ Expansion

Bars 4L @ 8" sp.

(Typ.)

EXPANSION JOINT DETAIL

(Junction Slab expansion joints are to coincide Field cut reinforcing as required Bars 5V2 (Typ.) Coping

" Open Joint Bars 5S Bars 5B1

with " open joints in Traffic Railing) 3" to maintain minimum cover (Typ.)

in Precast Coping

Spacing Bars 5V2 8" Spacing (Typ.) (See Note 9)

CROSS REFERENCE: For Detail "A", see Sheet 2. 2" Cover @

2" Cover @ Expansion Joints

b " V-Groove Spacing 30’-0" Max. (See Note 7)

Open Joints

» " Open Joint in Precast

dgn

Begin or End Retaining Wall »¿˘" Expansion Joint Spacing ~ 30’-0" Min. (32" F-Shape), 60’-0" Min. (42" F-Shape), 90’-0" Max. (See Not

Coping and C-I-P Traffic

\d\projects\standards\structures\current\ready4release\2014BOOK\06110-1of6.

and Precast or C-I-P Coping

Railing to coincide with "

" Open Joint PARTIAL PLAN VIEW FOR F-SHAPE TRAFFIC RAILING Expansion Joint in Junction

Slab.

(Skewed Approach Slab Shown, Perpendicular Approach Slab Similar)

(Precast Coping Shown, C-I-P Coping Similar) (Traffic Railing not Shown for Clarity)

JUNCTION SLAB NOTES: ny(

l 5-

’0"Min)

.

»¿ ˘" Open Jo ecastCo pn

igO

10-

’0"Typc

ial Pr

1. When a 42" F-Shape Traffic Railing is used with precast copings, provide Bars 3D @ 8" spacing Precast Coping and Seci

tons*

l

iing& Copn

ig

Top of ecastTraffc Ra

i

between Bars 5C within 6’-0" of Expansion Joints. Precast Traffic Railing 12-

’0"Minmu

i m Pr

Traffic

2. Construct the Junction Slab level transversely and expansion joints plumb; do not construct the junction

Railing Top of Precast Coping

slab or C-I-P coping perpendicular to the roadway surface. Slip forming of Coping and/or junction slab

is not permitted.

Traffic Railing

3. Provide Class II concrete for slightly aggressive environments or Class IV for moderate or extremely Mortar Plug

Varies

aggressive environments. (See Note 5)

2" Cover M in.

Top of C-I-P

4. Dowel Load Transfer Devices will be ASTM A 36 smooth round bar and hot-dip

Buildup Concrete

galvanized in accordance with Specification Section 962. Install Dowel Load Transfer Devices in accordance

)

9" M ax.

with Specification Section 350.

Top of Retaining

Varies

»¿5. Construct ˘" Expansion Joints in junction slabs and C-I-P copings plumb and perpendicular or radial to

Wall Panel (Typ.)

3"

Gutter Line. Provide at 90’-0" maximum intervals as shown. Provide 3"x3" Mortar plugs in open joints at the

base of traffic railings to contain runoff.

Precast

Coping

-3"

6. Provide and install Preformed Expansion Joint Filler in accordance with Specification Section 932.

7. Construct b" V-Grooves in junction slabs and C-I-P copings plumb and provide at 30’-0" maximum intervals as

2’

C:

»¿ shown. Space V-Grooves equally between ˘" Expansion Joints and/or Begin or End Junction Slab. V-Gr

locations are to coincide with V-Groove locations in the Traffic Railing.

8. Shoulder or Roadway Pavement is required on top of the junction slab for its entire length on the traffic

side of the Traffic Railing. See Typical Sections on Sheet Nos. 2 and 3 for details.

sm 970re

Clearance

9. Spacing shown is along the Gutter Line. Varies

10. On MSE Walls provide, Dowel Bars 4D and extend to 7" above the top of retaining wall panel. Field cut as Bottom of Dowels 4D (Typ.)

necessary to maintain 2" minimum cover to the top of the buildup concrete. See Wall Company Drawings for Precast Coping (See Note 9)

number and spacing of Dowel Bars 4D.

24 PM

11. Work this Index with the following:

Index No. 420 - Traffic Railing - (32" F-Shape)

52:

Retaining Wall (MSE Shown,

Index No. 425 - Traffic Railing - (42" F-Shape).

3:

Other Types Similar) (Typ.)

12. The following Indexes contain details of the intersection of the retaining wall at approach slabs: PARTIAL ELEVATION VIEW

Index No. 20900 - Approach Slabs (Flexible Pavement Approaches)

(Precast Coping and Junction Slab Reinforcing not Shown for Clarity) * C-I-P End Section must

Index No. 20910 - Approach Slabs (Rigid Pavement Approaches)

6/24/2013

(Precast Coping Shown, C-I-P Coping Similar) be = 12’-0".

F-SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014 WALL COPING WITH TRAFFIC RAILING/JUNCTION

REVISION NO. NO.

07/01/13 DESIGN STANDARDS SLAB 6110 1of 6

1

6’-6 2"

1’-2b " (32" F-Shape) 3 1

5’-0" 5" 8 4" 2 2"

1’-5" (42" F-Shape)

Cover

(C-I-P Junction Slab)

»¿

Bars 4N @ 8" sp.

2"

Top of Precast Coping »¿1˘" C-I-P F-Sh (Tied to Bars 5P)

312"

»¿3˘" Precast 32" F-S

Traffic Bars 5C @ 8" sp. Bars 5P

-0"

4 "

Railing (Tied to alternate Bars 4A)

714"

@ 8" sp.

Precast Traffic Railing

Min. Embed. (32" F-Shape)

1’

(See Note 1, Sheet 1 for

-0" M in. Length)

Min. Embed. (42" F-Shape) Bars 5S

-10"

Bars 5S (Field Bent) Coping

Bars 3D) (Typ.)

312"

1’

6"

8"

1" Dowel Load 2"Co

-8"

Bars 5V Construction ver

114"

Transfer Devices at

2’

(Rotated) Joint Permitted

3" 4 2"

214"

expansion joints (Typ.)

for C-I-P 10 114"

1

"R

Bars 4A @ 4" sp. Sections*

12’

End Stirrup Bar 5V Shoulder or Roadway

Precast Coping 2" Cover (Top) Bars 5V2

7"

(Bars 5V2 may be Pavement (Full depth

4"

@ 8" sp. 3

(

3 4"

8"

substituted) asphalt or See Note 3) Sl

ope Vari

es Top of

3

1

(

Se Coping

3"

e Note1)

Bars 5S

PARTIAL END VIEW OF TRAFFIC RAILING END

3

TRANSITION FOR GUARDRAIL ATTACHMENT

4"

3 4"

812"

Precast Coping)

(Showing Bars 5V and Bars 5S) (See Note 2)

-0"

2" Cover

(Precast Coping Shown, C-I-P Coping Similar)

1’

-0"

6"

-3"

1’

NOTE: See Index No. 420 and Index No. 425, Detail "A" for details. 3" Cover

6"

Bars 4L @ 8" sp.

2’

-114"

6"

Utility Conduit

(

permitted

Bars 5B2 @ 1’-0" sp. (Typ.)

1’

» ¿

ESTIMATED QUANTITIES FOR PRECAST COPING Slope Permitted (See Note 8)

dgn

\d\projects\standards\structures\current\ready4release\2014BOOK\06110-2of6.

Two Layers 30Lb. Roofing Felt

ITEM UNIT QUANTITY Varies (2" min.)

2" Min. Cover

Spacing Bars 5B1

Optional widening & extension for Precast Coping (See Note 6) 514"

Concrete (Precast Coping Only) CY/LF 0.083

Retaining Wall (Type Varies)

C-I-P Buildup Concrete

Dowel Bars 4D (MSE Walls only) (MSE Walls only)

Concrete (Precast Barrier & Coping) CY/LF 0.169 6"

Spacing 1" 1’-3" 3 sp. @ 1’-0" = 3’-0" Spacing 6"

Concrete (C-I-P Junction Slab) CY/LF 0.185 Dowels Bars 5S

»¿ »

b" Min. ~ 2b" Max. Gap (See Note 7) Smooth or Textured

Reinforcing Steel (Precast Coping & Traffic

LB/LF 52.67 Face of Wall

Railing) 3" 4 sp. @ 1’-0" = 4’-0" (5B2) 2 sp. @ 1’-0"– (5B1) 3"

Spacing

Bars 5B

Reinforcing Steel (C-I-P Junction Slab) (Typ.) LB/LF 12.52

TYPICAL SECTION THRU PRECAST* 32" F-SHAPE

Additional Reinf. @ Expansion Joints (Dowels) LB 21.36 TRAFFIC RAILING AND COPING WITH C-I-P JUNCTION SLAB

* C-I-P Traffic Railing and Coping Sections using precast dimensions

(The above concrete quantities are based on a max. superelevation of 6.25%

and reinforcement are permitted at End Sections, Drainage Inlets and

and a 32" F-Shape Traffic Railing.

Light Pole Pedestals if slip forming is not used.

NOTES:

1. Match Cross Slope of Travel Lane or Shoulder.

»¿2. The 3˘" dimension corresponds to a maximum superelevation of 6.

C:

For steeper superelevations increase this dimension to match roadway superelevation.

3. For Rigid Pavement (Concrete), Junction Slab may be thickened to match finish grade.

b " V-Groove (Typ.) b " V-Groove (Typ.)

4. Minimum length of Junction Slab between expansion joints is 30’-0".

5. At the Contractor’s option, mechanical couplers may be used to splice reinforcing.

sm 970re

Complete details, including reinforcement lengths are required in the Shop Drawings.

Provide mechanical couplers in accordance with Specification Section 415. Mechanical

»¿˘" Preformed Expan »¿˘" Preformed Expan

Joint Filler Joint Filler couplers shall develop 125% of the bar yield strength.

6. Contractor to maintain stability of precast coping/traffic railing prior to junction slab

completion. In the Shop Drawings, show reinforcement for optional extension required

26 PM

for stability, shipping and handling. Maintain 2" minimum concrete cover.

C-I-P COPING

52:

7. When the air gap between the precast coping extension and retaining wall exceeds 2b",

3:

PRECAST COPING fill gap with full depth Expanded Polystyrene to provide a maximum 2b" air gap.

8. Angle varies ~ 0 min., 20 max.

DETAIL "A"

6/24/2013

(Showing Locations of b " V-Grooves and " Preformed Expansion Joint Filler)

F-SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014 WALL COPING WITH TRAFFIC RAILING/JUNCTION

REVISION NO. NO.

07/01/13 DESIGN STANDARDS SLAB 6110 2 of 6

REINFORCING STEEL BENDING DIAGRAMS 6’-6b" (32" F-Shape)

3’-9"

6’-9" (42" F-Shape) »¿

BILL OF REINFORCING STEEL

5’-0" 5" 1034" b" (32" F-Shape)

8"

LENGTH (C-I-P Junction Slab) »¿1’- (42" F-Shape)

Cover

»¿

Spacing Bars 5S (32" F-Shape)

MARK SIZE PRECAST COPING

2"

Shoulder or Roadway

COPING & Spacing Bars 8S1 (42" F-Shape)

BARS 4L Pavement (Full depth

3b "

3b "

32" F-SHAPE C-I-P Precast

asphalt or See Note 3)

32" F-Shape)

42" F-Shape)

6 " (32" F-Shape) Bars 5P

-0"

A 4 5’-7" 8’-0" 5’-7"

(42" F-Shape) @ 8" sp.

8b "

8b "

9" Bars 4A or for Precast Coping

1’

C-I-P Traffic Railing

3"

32" F-Shape)

42" F-Shape)

(32" F-Shape) Bars 5C @ 8" sp. (See Note 1,

-0" M in. Length)

B1 5 11’-6" N/A 9’-6" Bars 5S

(42" F-Shape) »¿ Sheet 1 for Bars 3D)

or 8S1 (Typ.)

B2 5 AS REQD. AS REQD. AS REQD.

1" Dowel Load

2" 3 4"

» ¿

3"Co

-10" (

ve

-8" (

r

114"

1

Transfer Devices at

C 5 4’-8" N/A 4’-8"

expansion joints (Typ.)

3b " 9"

2’

114"

1’

10

32" F-Shape)

42" F-Shape)

-8" (

-6" (

Construction "R

3" 4

D 3 4’-8" N/A 4’-8"

Bars 4A @ 4" sp. Joint Reqd.

30’

2’

3’

F 5 4’-8" 4’-8" 4’-8" 2" Cover (Top)

Bars 5V2

7"

(

@ 8" sp.

134"

8"

8"

L 4 4’-5" 4’-5" 4’-5" Sl

ope Vari

es

Top of

134"

3"

(

See Note1)

-5" (

-3" (

Bars 5S Coping

N 4 2’-6" N/A N/A

C-I-P or Precast Coping)

» ¿

2’

3’

4"

P 5 5’-7" 5’-7" 5’-7"

4"

3

2" Cover

3

-0"

8

S 5 11’-6" AS REQD. 9’-6" See Note 8

1’

-0"

S1 8 N/A AS REQD. 9’-6"

-3"

6"

1’

3" Cover

6"

1

5 2"

2’

V2 5 5’-10" 5’-10" 5’-10"

"

Bars 4L @ 8" sp.

Varies

1’-

6"

1˘

Smooth STIRRUP BAR 5P

)

Two layers 30Lb. Roofing Felt

2" m in.

1" Dowel 2’-0" 2’-0" 2’-0"

(1’-

Bars 5B2 @ 1’-0" sp. (Typ.)

»¿

Bar

dgn

5b "

»¿

Expanded Polystyrene (b" Side) (for C-I-P only)

(

9’-6" (Precast Coping only),

\d\projects\standards\structures\current\ready4release\2014BOOK\06110-3of6.

5B1 11’-6" (Precast Traffic Railing) Contractor’s

Optional widening & extension for Precast Coping (See Note 6)

5B2 Length as Required option

"

9

Retaining Wall (Type Varies)

5C Precast Coping ~ 4’-8" (See Note 7) 512" (C-I-P) Spacing Bars

b" Min. ~ 2b" Max. Gap (See Note 7) 5B1 ~ Precast,

514" (Precast)

)

3D Precast ~ 4’-8" (See Sheet 1, Note 1) 45

2’-0" F Spacing 1" 1’-3" 3 sp. @ 1’-0" = 3’-0" Spacing 6" 6" 5B2 ~ C-I-P Coping

)

"

F

2

5F 4’-8"

32" F-Shape)

42" F-Shape)

Dowels

(3

Bars 5S

"

Smooth or Texture

2

"

(4

-2

Precast Coping, ~ 11’-6" (with Face of Wall

"

’

3" 4 sp. @ 1’-0" = 4’-0" 2 sp. @ 1’-0"– 3"

-5

Spacing

1

5S 32" F-Shape), 9’-6" (Coping Only) Optional Keyway

’

1

Bars 5B2

8S1 C-I-P Coping ~ Length as Required Construction Joint Permitted

1" DOWEL TYPICAL SECTION THRU C-I-P TRAFFIC RAILING

-8b " (

-1b " (

WITH C-I-P JUNCTION SLAB AND C-I-P COPING Buildup for

BARS 5B, 5C, 5F & 5S 5" 5430’

(PRECAST COPING SIMILAR WITH C-I-P BUILDUP) stepped MSE

-1b "

2’

3’

g~ Wall Panels

tCopin

s

M ax.

Preca

M in.

1"

5& 6) (0" min.,

412"

6"

e

2"

Not

1’

9"(See

3-

’ NOTES: »¿11˘" m

" 45

10"

’-2

pn

ig ~6

C-I-P Co 1. Match Cross Slope of Travel Lane or Shoulder. Coping

412"

»¿2. The 3˘" dimension corresponds to a maximum superelevation of 6. Expanded

For steeper superelevations increase this dimension to match roadway Polystyrene (b")

-10"

10" (32" F-Shape)

superelevation. 6"

86 1’-0b" (42" F-Shape)

1’

6" 3. For Rigid Pavement (Concrete), Junction Slab may be thickened to match

finish grade. BUILDUP FOR STEPPED MSE WALL PANELS

C:

4. Minimum length of Junction Slab between expansion joints is 30’-0" for AND C-I-P COPING

BAR 4A STIRRUP BAR 4N STIRRUP BAR 5V2

32" F-Shape or 60’-0" for 42" F-Shape.

REINFORCING STEEL NOTES: 5. See Index No. 420 & 425 for additional Traffic Railing Details. ESTIMATED QUANTITIES FOR C-I-P COPING

1. All bar dimensions in the bending diagrams are out to out. 6. Contractor to maintain stability of precast coping prior to junction

sm 970re

ITEM UNIT QUANTITY

2. All reinforcing steel at expansion and open joints will have a 2" minimum cover. slab completion. In the Shop Drawings, show reinforcement for

3. Lap splices for Bars 5B & 5S will be a minimum of 2’-0". optional extension required for stability, shipping and handling.

Concrete (Traffic Railing not Included) CY/LF 0.268

4. For Precast Copings only, lap splice Bars 4A with Bars 5C. Lap splices will be a minimum of 2’-0". Maintain 2" minimum concrete cover.

5. The Contractor may use either full length Bars 4A or lap splice with Bars 5C at alternate Bars 4A 7. When the air gap between the precast coping extension and retaining

Reinforcing Steel (Typical) excluding

28 PM

for C-I-P Copings. wall exceeds 2b", fill gap with full depth Expanded Polystyrene to

LB/LF 30.89

6. Dimension shown is for lap splice option. For mechanical coupler option, this dimension is 1’-4b" provide a maximum 2b" air gap. Bars 5V2 and 5S (Typ.)

52:

(32" F-Shape) or 1’-7" (42" F-Shape). 8. Angle varies ~ 0 min., 20 max.

3:

Additional Reinf. @ Expansion Joint

7. Dimension shown is for lap splice option. For mechanical coupler option, this dimension is 4’-8". LB/LF 21.36

(Dowels)

8. The Contractor may use Welded Wire Reinforcement (WWR) when approved by the Engineer. WWR

must consist of deformed wire meeting the requirements of Specification Section 931.

6/24/2013

(The above concrete quantities are based on a max. superelevation

9. Contractor may use a single #5 stirrup in lieu of two bars for 5P and 5V2.

of 6.25%, beneath a 32" F-Shape Traffic Railing on an MSE Wall).

F-SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014 WALL COPING WITH TRAFFIC RAILING/JUNCTION

REVISION NO. NO.

07/01/13 DESIGN STANDARDS SLAB 6110 3 of 6

Bars 5C @ 8" sp. b" V-Groove

4 ~ Bars 5F 3" Expansion Joint (See Expansion

2" Cover (Tie to Bars 4A) 4L Bars @ (See Detail "A" 1" Dowel Load

(Top of Slab) 3s

p.

@ Joint Detail & Detail "A")

6" Bars 5B2 Sides (Typ.) (Typ.) 8" sp. (Typ.) & Note 7, Sheet 1) Transfer Devices

(Required only

when Junction

Slab is skewed)

Field cut reinforcement

as required to maintain

minimum concrete

cover (Typ.)

-0" M in.

Lap Splice

Approach Slab

(See Note 12

Sheet 1)

2’

Begin or End Skew Bars 7P1 & Bars 4L @ 8" (Typ.) Bars 7P1 & 4V1 (Typ.) Bars 5B1

Gutter Line Coping Line Bars 7P1 &

Approach Slab 4V1 as required Bars 4A @ 4" (Typ.)

4V1 (Typ.)

dgn

" Open Jt. 5’-0" End Post Varies 2’-6" (Typ.) 5’-0" Interior Post (Typ.) 2’-6" (Typ.) Varies ~ 5’-0" (Typ.) 5’-0" End Post 5’-0" End Post

\d\projects\standards\structures\current\ready4release\2014BOOK\06110-4of6.

(2’-6" Min., 5’-0" Max.) (2’-6" Min., 5’-0" Max.) @ Expansion Joint @ Expansion Joint

2" Cover @

» " Open Joint in Precast

b" V-Groove Spacing ~ 30’-0" Max. (See Note 7, Sheet 1) Open Joints

Coping and C-I-P Traffic

Railing to coincide with "

»¿˘" Expansion Joint Spacing ~ 30’-0" Min., 90’-0" Max. (See Note 5, Shee

Expansion Joint in Junction

Slab.

PLAN VIEW

(Skewed Approach Slab shown, Perpendicular Approach Slab similar) CROSS REFERENCES:

(Precast Coping shown, C-I-P Coping similar) 1. For Detail "A" see Sheet 2.

(Traffic Railing reinforcement not shown, except for Bars 7P1 & 4V1) 2. For "Expansion Joint Detail" see Sheet 1.

3. For "Junction Slab Notes" see Sheet 1.

Bars 5C @ 8" sp. Bars 5C @ 8" sp.

Bars 5B2 (Tie to Bars 4A) (Typ.) (Tie to Bars 4A) (Typ.) Bars 5B2

Guardrail

Gutter Line Gutter Line

4b " Taper

(Typ.)

C:

Face of Curb

Bars 4L (Typ.) Bars 4A (Typ.)

Begin or End

sm 970re

Retaining Wall

Coping and Bars 7P1 & 4V1 (Typ.) Bars 5B1 Bars 4L Bars 4P5 (Typ.) Bars 7P1 & 4V1 (Typ.) Bars 4R3 (Typ.)

Traffic Railing Bars 4A

3’-0" Taper Varies (12’-6" Min.) 3’-0" Taper Coping Line 2’-6" (Typ.) 5’-0" Interior Post (Typ.) 2’-6" (Typ.) Coping Line

(Inside Face) (Inside Face)

30 PM

PARTIAL PLAN VIEW OF GUARDRAIL TRANSITION AT BEGIN OR END RETAINING WALL PARTIAL PLAN VIEW OF COPING WITH CURB

52:

3:

(Precast Coping shown, C-I-P Coping similar) (Precast Coping shown, C-I-P Coping similar)

(Traffic Railing reinforcement not shown, except for Bars 7P1 & 4V1) (Traffic Railing reinforcement not shown, except for Bars 4P5, 4R3, 7P1 & 4V1)

6/24/2013

CORRAL SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FDOT 2014 WALL COPING WITH TRAFFIC RAILING/JUNCTION

REVISION NO. NO.

01/01/12 DESIGN STANDARDS SLAB 6110 4 of 6

»¿ Interior Post (C 1

6 4"–

rs4A) Joint permitted in rail) P1 & 4V1

i oa

et t

lernate Ba Spacn

ig Bars7

4 " paced@ 8–(

" T 5sp.

Bars7P1 & 4V1 s 5sp.

11 " 5–

"

5 " @ 4" Curb)

nst

iion @ 4" acn

ig Bars4P5 (

GuardralT

i ra 2sp. Sp

8"

7-

’3 " 6-

’6–

"

u-BoltSpacing –

" 2sp. "

6-

’3" Thr 5 @ 8

Guardrail Thrie Beam 1-