Professional Documents

Culture Documents

EML2322L-Design Process

EML2322L-Design Process

Uploaded by

Benjie flor CalayegCopyright:

Available Formats

You might also like

- The Rich Get Richer and The Poor Get PrisonDocument1 pageThe Rich Get Richer and The Poor Get PrisonGunasundaryChandramohanNo ratings yet

- Full Download Engineering Design 5th Edition Dieter Solutions ManualDocument15 pagesFull Download Engineering Design 5th Edition Dieter Solutions Manualaminamuckenfuss804uk100% (32)

- Drone CurriculumDocument9 pagesDrone CurriculumMarvellousNo ratings yet

- Answer Scheme - Tutorial 1 BMMA 1323 Engineering DesignDocument8 pagesAnswer Scheme - Tutorial 1 BMMA 1323 Engineering DesignI-zad MJNo ratings yet

- Method Statement Stone ColumnDocument10 pagesMethod Statement Stone ColumnSantosh ZunjarNo ratings yet

- Commercial RefrigerationDocument11 pagesCommercial RefrigerationBenjie flor CalayegNo ratings yet

- Prophecies in Islam & Prophet Muhammad - A.aliDocument82 pagesProphecies in Islam & Prophet Muhammad - A.aliZaky MuzaffarNo ratings yet

- Bearing Failure Analysis by Using 8 D ReportDocument7 pagesBearing Failure Analysis by Using 8 D Reportyash prajapatiNo ratings yet

- GSO-1909-2009-E - Requirements For Handling of Ready To Eat FoodsDocument12 pagesGSO-1909-2009-E - Requirements For Handling of Ready To Eat FoodsANSAR100% (1)

- EML2322L Design ProcessDocument14 pagesEML2322L Design ProcessLalo MtzNo ratings yet

- Machine Design Project PPT - NewDocument43 pagesMachine Design Project PPT - NewAdugna GosaNo ratings yet

- Fundamentos Diseño 2022-2Document43 pagesFundamentos Diseño 2022-2Diego MoyaNo ratings yet

- PDD 2 Concept GenerationDocument33 pagesPDD 2 Concept Generationkushal pramanickNo ratings yet

- Textbook - Unit 1 - Engineering DesignDocument13 pagesTextbook - Unit 1 - Engineering DesignThuy TranNo ratings yet

- 3 - Need Analysis and Problem DefinitionDocument23 pages3 - Need Analysis and Problem Definition6yhtzjm5gbNo ratings yet

- Week 2 Principle Mechanical Design PDFDocument45 pagesWeek 2 Principle Mechanical Design PDFWatcharakorn Viva la VidaNo ratings yet

- Engineering Exploration: First Year Engineering (All) 2018-19 Maharashtra Institute of Technology AurangabadDocument66 pagesEngineering Exploration: First Year Engineering (All) 2018-19 Maharashtra Institute of Technology Aurangabadatharva gaikwadNo ratings yet

- Engr400 DesignprocessDocument3 pagesEngr400 Designprocessnishantu_2255705@gmail.comNo ratings yet

- Dome 1Document35 pagesDome 1harikg21No ratings yet

- Dme - Mod 1Document36 pagesDme - Mod 1Linto Varghese100% (1)

- The Design Process: HNC in Engineering-Engineering Design Edexcel Unit: Engineering Design (NQF L4)Document14 pagesThe Design Process: HNC in Engineering-Engineering Design Edexcel Unit: Engineering Design (NQF L4)Joom Chico LocoNo ratings yet

- CHAP1 - Product Design Theory and MethodologyDocument34 pagesCHAP1 - Product Design Theory and Methodologykhalil alhatabNo ratings yet

- Need Analysis and Problem DefinitionDocument23 pagesNeed Analysis and Problem Definitionb hari prasadNo ratings yet

- Lecture 5. The Design ProcessDocument6 pagesLecture 5. The Design ProcessIngrid Nicoleta SterpuNo ratings yet

- Problem Formulation and Case Studies: College of EngineeringDocument34 pagesProblem Formulation and Case Studies: College of EngineeringmmNo ratings yet

- MMD101 ModelAnswerDocument6 pagesMMD101 ModelAnswerVishal JangirNo ratings yet

- DME NotesDocument133 pagesDME NotesNeeraj S GNo ratings yet

- Design ProcessDocument32 pagesDesign Processkhan janNo ratings yet

- LECTURE 2 The Design Process - Sem 1 - 2022 - 2023Document35 pagesLECTURE 2 The Design Process - Sem 1 - 2022 - 2023Idham NasrulNo ratings yet

- Introduction To Machine Design 2021 - July 28Document23 pagesIntroduction To Machine Design 2021 - July 28BaslielNo ratings yet

- 07 Design Drawing and SafetyDocument12 pages07 Design Drawing and SafetySafikul HossainNo ratings yet

- BAH 1 Module 10 in AB Machinery and MechanizationDocument6 pagesBAH 1 Module 10 in AB Machinery and MechanizationDistor, Jane F.No ratings yet

- An Overview of Chemical Process Design EngineeringDocument8 pagesAn Overview of Chemical Process Design EngineeringAzri RazakNo ratings yet

- 02-Introduction To Engineering Design ProcessDocument14 pages02-Introduction To Engineering Design Processyaseen jobaNo ratings yet

- Engineering Design - DetailDocument44 pagesEngineering Design - DetailYogi FahleviNo ratings yet

- 0002 - OM SESSION 2 (Chapter 4 - Process Design & Chapter 5 - Innovation & Design in Services & Products)Document49 pages0002 - OM SESSION 2 (Chapter 4 - Process Design & Chapter 5 - Innovation & Design in Services & Products)Tú Anh NguyễnNo ratings yet

- Ingeniería Mecánica M1T1Document7 pagesIngeniería Mecánica M1T1Shahin AkterNo ratings yet

- 1100 T2 13-4 Lect2 DesignDocument44 pages1100 T2 13-4 Lect2 DesignarulmuruguNo ratings yet

- The Product Design Process What Is Design?Document14 pagesThe Product Design Process What Is Design?michsantosNo ratings yet

- LECTURE NOTES ON Design For ManufacturinDocument63 pagesLECTURE NOTES ON Design For Manufacturinmmk.mech59No ratings yet

- HETT207 Lecture Notes - Unit 2Document63 pagesHETT207 Lecture Notes - Unit 2Joshua DomaNo ratings yet

- Paper3509 515Document7 pagesPaper3509 515Anak SehatNo ratings yet

- Module 3. Individual Assignment: Case Study Proyect: What Is BYD's Current Product Flow Process?Document2 pagesModule 3. Individual Assignment: Case Study Proyect: What Is BYD's Current Product Flow Process?Carina LopezNo ratings yet

- Lec 3Document34 pagesLec 3Ebrahem ShabanaNo ratings yet

- Lecture No. 5 - Dr. Raja Rizwan Hussain Course Ge 105 Introduction To Engineering DesignDocument23 pagesLecture No. 5 - Dr. Raja Rizwan Hussain Course Ge 105 Introduction To Engineering DesignLuân NguyễnNo ratings yet

- Lecture 5Document25 pagesLecture 5mnooNo ratings yet

- Manufacturing Process Selection in Engineering Design. Part 1: The Role of Process SelectionDocument11 pagesManufacturing Process Selection in Engineering Design. Part 1: The Role of Process SelectionAnggi FirmansyahNo ratings yet

- Chapter 3: The Design Process & The Role of CAD: Emd4M2A Emd4M7BDocument59 pagesChapter 3: The Design Process & The Role of CAD: Emd4M2A Emd4M7BfaqhrulNo ratings yet

- Kolej Matrikulasi Kejuruteraan Kedah EB025 SEMESTER 2, SESSION 2022/2023 Assignment: Design Project (Key Chain)Document6 pagesKolej Matrikulasi Kejuruteraan Kedah EB025 SEMESTER 2, SESSION 2022/2023 Assignment: Design Project (Key Chain)VEENOM 0204No ratings yet

- Crystal: Methods and Spiral Lifecycle ModelDocument23 pagesCrystal: Methods and Spiral Lifecycle Modelsax_loverNo ratings yet

- Index 2Document3 pagesIndex 2jithuclt87No ratings yet

- 4-شابتر 5 PDFDocument28 pages4-شابتر 5 PDFnola shNo ratings yet

- Root Cause Analysis - ShaininapproachDocument6 pagesRoot Cause Analysis - ShaininapproachRaghavendra KalyanNo ratings yet

- CH 4Document48 pagesCH 4shiferawNo ratings yet

- PAPERRSBDocument5 pagesPAPERRSBvishal.khalane9No ratings yet

- Electric Discharge Machining EDM by Varun AroraDocument20 pagesElectric Discharge Machining EDM by Varun AroraVarun AroraNo ratings yet

- Materi 7 Concept GenerationDocument30 pagesMateri 7 Concept Generationrachmat nursalamNo ratings yet

- Cutting Tool DesignDocument17 pagesCutting Tool DesignHazrat BelalNo ratings yet

- Unit 4: Introduction To Engineering Design: Engr. Roman M. Richard, MengDocument17 pagesUnit 4: Introduction To Engineering Design: Engr. Roman M. Richard, MengRoman MarcosNo ratings yet

- IT and Business Systems SolutionsDocument4 pagesIT and Business Systems SolutionsMichael GrafNo ratings yet

- Machine DesignDocument10 pagesMachine DesignRahul RahNo ratings yet

- Sciencedirect: in Pursuit of Personalization DesignDocument5 pagesSciencedirect: in Pursuit of Personalization Designvincent BarreauNo ratings yet

- Mechanical Design BasicsDocument17 pagesMechanical Design BasicshrproxNo ratings yet

- ME8691 Computer Aided Design and Manufacturing Notes 1Document79 pagesME8691 Computer Aided Design and Manufacturing Notes 1ARUMUGA NAINARNo ratings yet

- Product DesignDocument27 pagesProduct DesignrubensNo ratings yet

- BeltDocument3 pagesBeltBenjie flor CalayegNo ratings yet

- Statics of Rigid BodiesDocument89 pagesStatics of Rigid BodiesBenjie flor CalayegNo ratings yet

- Marc Kevin B. GonzalesDocument4 pagesMarc Kevin B. GonzalesBenjie flor CalayegNo ratings yet

- Chapter 11 Managing The Marketing FunctionDocument9 pagesChapter 11 Managing The Marketing FunctionBenjie flor CalayegNo ratings yet

- HEAT TRANSFER - Problem SetDocument3 pagesHEAT TRANSFER - Problem SetBenjie flor CalayegNo ratings yet

- Distribution System Components: Figure 31-Pressure TanksDocument6 pagesDistribution System Components: Figure 31-Pressure TanksBenjie flor CalayegNo ratings yet

- COMBUSTIONDocument9 pagesCOMBUSTIONBenjie flor CalayegNo ratings yet

- Machine Design CompletepdfDocument219 pagesMachine Design CompletepdfBenjie flor CalayegNo ratings yet

- Activity 1Document2 pagesActivity 1Benjie flor CalayegNo ratings yet

- Basic Thermodynamics: Module OrientationDocument12 pagesBasic Thermodynamics: Module OrientationBenjie flor CalayegNo ratings yet

- ME6513 Metrology and Measurements LabDocument81 pagesME6513 Metrology and Measurements LabBenjie flor CalayegNo ratings yet

- Material ManualDocument40 pagesMaterial ManualBenjie flor CalayegNo ratings yet

- Mechanical Engineering Laboratory ManualDocument134 pagesMechanical Engineering Laboratory ManualBenjie flor CalayegNo ratings yet

- Evaluate: Direction: Kindly Solve The FollowingDocument4 pagesEvaluate: Direction: Kindly Solve The FollowingBenjie flor CalayegNo ratings yet

- Workshop - and - Machine - Shop ManualDocument96 pagesWorkshop - and - Machine - Shop ManualBenjie flor CalayegNo ratings yet

- Brightpancar Catalog PDFDocument125 pagesBrightpancar Catalog PDFBobby RajNo ratings yet

- Determination of Chromium VI Concentration Via Absorption Spectroscopy ExperimentDocument12 pagesDetermination of Chromium VI Concentration Via Absorption Spectroscopy ExperimentHani ZahraNo ratings yet

- AP3456 Mathematics & Physics PDFDocument319 pagesAP3456 Mathematics & Physics PDFLaxmi Krishnadas0% (1)

- BB FiberOpticCommandmentsDocument4 pagesBB FiberOpticCommandmentsDand LongNo ratings yet

- Concept MappingDocument2 pagesConcept MappingSarah DeNo ratings yet

- Notes:: Dialog Plant Services Sdn. BHDDocument1 pageNotes:: Dialog Plant Services Sdn. BHDTengku ZhafriNo ratings yet

- AND8331/D Quasi-Resonant Current-Mode Controller For High - Power Ac-Dc AdaptersDocument16 pagesAND8331/D Quasi-Resonant Current-Mode Controller For High - Power Ac-Dc AdaptersLucía MitchellNo ratings yet

- 2exam LogisticsDocument6 pages2exam LogisticsJessica LaguatanNo ratings yet

- Development of Instructional Materials Based SETSDocument12 pagesDevelopment of Instructional Materials Based SETSInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Module 4 ResearchDocument9 pagesModule 4 ResearchJegg AsisNo ratings yet

- 13.n-p-n TransistorDocument4 pages13.n-p-n TransistorkirtiNo ratings yet

- Biology HL Student GuideDocument134 pagesBiology HL Student GuideYesenia JassoNo ratings yet

- All About Zookeeper and ClickHouse KeeperDocument45 pagesAll About Zookeeper and ClickHouse KeeperomyeudaihiepNo ratings yet

- IPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalDocument5 pagesIPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalOswaldo MontenegroNo ratings yet

- D Dy DT Q K DyDocument20 pagesD Dy DT Q K DyMohammed Al-OdatNo ratings yet

- Unit-7: Iot SecurityDocument21 pagesUnit-7: Iot SecuritySAMPANo ratings yet

- TEM ManualDocument6 pagesTEM ManualmcsteiNo ratings yet

- Detailed Lesson Plan in MAPE7 ART, Fourth QuarterDocument9 pagesDetailed Lesson Plan in MAPE7 ART, Fourth QuarterLolita Reynolds100% (1)

- Ebook Diversity and Society Race Ethnicity and Gender 4Th Edition Healey Test Bank Full Chapter PDFDocument36 pagesEbook Diversity and Society Race Ethnicity and Gender 4Th Edition Healey Test Bank Full Chapter PDFalmiraelysia3n4y8100% (12)

- Short Keys f1-f12Document2 pagesShort Keys f1-f12Farhan Khan NiaZiNo ratings yet

- 56ef945cea29b 1312621 SampleDocument16 pages56ef945cea29b 1312621 SamplepanditrulesNo ratings yet

- Flow ControlDocument87 pagesFlow Controlibrahim_nfsNo ratings yet

- Some Remarks On Fuzzy N-Normed SpacesDocument7 pagesSome Remarks On Fuzzy N-Normed SpacesRyanEliasNo ratings yet

- Net Metering SopDocument34 pagesNet Metering Sopساحر حسینNo ratings yet

- SIKA Marine 2016Document164 pagesSIKA Marine 2016pcatruongNo ratings yet

EML2322L-Design Process

EML2322L-Design Process

Uploaded by

Benjie flor CalayegOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EML2322L-Design Process

EML2322L-Design Process

Uploaded by

Benjie flor CalayegCopyright:

Available Formats

Introduction to the Design Process

Accreditation Board for Engineering and Technology (ABET)

Definition of Design

Engineering design is the process of devising a system,

component, or process to meet desired needs.

It is a decision-making process (often iterative), in which the

engineering sciences and mathematics are applied to convert

resources optimally to meet a stated objective.

Among the fundamental elements of the design process are the

establishment of objectives and criteria, synthesis, analysis,

construction, testing and evaluation.

Introduction to the Design Process 1

Joseph Shigley (Mechanical Engineering Design)

Definition of Design

Mechanical design means the design of components and

systems of a mechanical nature—machines, products, structures,

devices and instruments.

For the most part mechanical design uses mathematics,

materials, and the engineering-mechanics sciences.

Additionally, it uses engineering graphics and the ability to

communicate verbally to clearly express your ideas.

Mechanical engineering design includes all mechanical design,

but it is a broader study because it includes all the disciplines of

mechanical engineering, such as the thermal fluids and heat

transfer sciences too.

Aside from the fundamental sciences which are required, the

first studies in mechanical engineering design are in

mechanical design, and that is the approach taken in this course.

Introduction to the Design Process 2

Steps of the Design Process

1. Recognize the Need

The first step is to establish the ultimate purpose of the project.

Often, this is in the form of a general statement of the client’s

dissatisfaction with a current situation.

example – “There is too much damage to bumpers in low-speed

collisions.”

This is a general statement that does not comment on the design

approach to the problem. It does not say that the bumper should

be stronger or more flexible.

Recognition and phrasing of the need are often very creative acts

because the need may only be a sensing that something is not

right. For this reason, sensitive people are generally more

creative.

example – the need to do something about a food packaging

machine may be indicated by the noise level, variation in

package weights, or by slight but perceptible variations in the

quality of the packaging.

Introduction to the Design Process 3

2. Problem Definition Recognize the Need

This is one of the most critical

steps of the design process. Problem Definition

There is an iteration between the

definition of the problem and the recognition of need. Often the

true problem is not what it first seems.

The problem definition is more specific than recognizing the

need. For instance, if the need is for cleaner air, the problem

might be that of reducing the dust discharge from power-plant

stacks, or reducing the quantity of irritants from automotive

exhausts, or means for quickly extinguishing forest fires.

The problem definition must include all the specifications for

the thing that is to be designed. Anything which limits the

designer’s freedom of choice is a specification.

It is imperative to write a formal problem statement which

expresses what the design is to accomplish

include:

objectives and goals

(musts, must nots; wants, don't wants)

constraints

criteria used to evaluate the design

Example: Mobile Vehicle

Design a vehicle which can maneuver in an indoor

environment. The vehicle will be operated via remote control

and must be able to:

Introduction to the Design Process 4

1) Travel up to a speed of 7 ft/sec on a flat, horizontal, dry,

bare concrete surface.

2) Climb 5” high stairs at speeds up to 2 ft/sec.

3) Carry a payload of at least 20 lbs.

4) Fit through doorways.

5) Cross obstacles up to 20" high and up to 24" across

within 20 seconds.

6) Climb a slope of up to 30 degrees and cross side slopes

up to 20 degrees.

7) Rotate with zero turning radius.

8) Travel in any direction.

9) Total vehicle weight should be less than 275 lbs.

Design considerations (in no particular order)

strength cost flexibility

reliability safety control

thermal properties weight stiffness

corrosion life surface finish

wear noise lubrication

friction styling maintenance

ergonomics shape volume

utility size liability

manufacturability speed feedrate

ectetera

Note: Design considerations in bold might be pertinent

to the design project in EML2322L.

Introduction to the Design Process 5

3. Gathering of Information

Recognize the Need

Often, either no information is

easily found, or there is an

abundance of information Problem Definition

Never-ending process for the

best design engineers Gathering of Information

Info sources:

textbooks

trade journals & magazines

technical reports from government sponsored R&D

company catalogs, web pages and technical personnel

handbooks

company reports

patents

people

Problems in gathering information:

LAZINESS

Where to find it?

How to get it?

How accurate & credible is the information?

How should the information be interpreted for my needs?

When do I have enough information?

What decisions result from the information?

PLAGIARISM (integrity = giving others credit for their ideas)

Introduction to the Design Process 6

4. Concept Generation Recognize the Need

This is the most creative part of

the design process.

Problem Definition

Store ideas in a design notebook.

Some approaches to concept

generation: Gathering of Information

- adaptation

a solution of a Concept Generation

problem in one field

is applied to a similar problem in another field

(wine press → printing press → pistol grip)

- analogy

obstacle avoidance similar to potential fields

- area thinking

improve an existing product by concentrating on

one of its important characteristics (cost,

performance, function, appearance, safety, etc.)

- brainstorming

group of people who are familiar with the general

nature of the problem;

everyone says what comes to mind

rules: (1) no judgements; (2) the more

unconventional the better; (3) the more ideas the

better

- involvement

visualize yourself as being part of the mechanism

Introduction to the Design Process 7

- functional synthesis

divide the system into subunits

describe each subunit by a complete list of

functional requirements

list all the ways the functional requirements of each

subunit can be realized

study all combinations of partial solutions

Can Opener

Part Function Realization

Subunit 1 1. Separate metal 1. Shearing

2. Tearing

3. Fatigue

4. Melting

5. Drawing thin

6. Chemical erosion

Subunit 2 1. Apply power 1. Hand

2. Electric motor

3. Hot wire

4. Hydraulic motor

5. Flame

6. Chemical reaction

7. Mechanical vibration

8. Laser

2. Position 1. Bring can to opener

2. Bring opener to can

3. Have opener built on can

Introduction to the Design Process 8

- try inversion

try reversing the ordering of things; i.e. an

inversion is produced with an electric motor by

holding the rotor stationary and permitting the field

windings to rotate

- change the normal position and character of things

if it operates horizontally, try operating it vertically.

If it’s round, try making it square. For example,

doors hinged at top or bottom, a horizontal drill

press, etc.

- talk it over

If the designer has followed these suggestions thus

far, he/she is now quite familiar with the problem.

Many solutions have been found but none are quite

satisfying. Having worked to this point, the

designer’s mind is in a receptive condition and will

instantly recognize a solution. The problem is to

bridge a gap between two groups of ideas—to make

an association of ideas. It is generally conceded

that this association occurs by pure chance. This

event is most likely to occur when the problem is

being discussed with another person or group of

persons.

Introduction to the Design Process 9

Recognize the Need

5. Concept Selection

form decision matrix to unbiasedly Problem Definition

evaluate different ideas based on a

weighted set of objectives the

design team decides are important Gathering of Information

for the solving the problem

Concept Generation

Concept Selection

Introduction to the Design Process 10

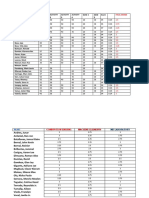

Decision matrix for the design of a crane hook

CRANE HOOK Welded Plates Riveted Plates Cast Hook

Weighting

Objective Parameter Mag. Score Value Mag. Score Value Mag. Score Value

Factor

Material Cost 0.10 $ 2500 8.8 0.9 2500 8.8 0.9 2200 10.0 1.0

Manufacturing Cost 0.20 $ 1500 8.0 1.6 1200 10.0 2.0 2400 5.0 1.0

Manufacturing Time 0.10 hours 40 6.3 0.6 25 10.0 1.0 50 5.0 0.5

Durability 0.15 experience great 10 1.5 good 8 1.2 good 8 1.2

Reliability 0.30 experience good 8 2.4 great 10 3.0 okay 6 1.8

Repairability 0.15 experience good 8 1.2 great 10 1.5 fair 4 0.6

Overall value 8.2 9.6 6.1

mbraddock

2015-01-20 20:29:51

2014-09-09

2014-01-21

2013-01-22

2012-09-09 20:30:16

20:30:18

08:13:13

20:30:25

08:32:15

07:44:41

08:03:25

Qualitative Score Assignments: --------------------------------------------

great 10 Begin

Next,

The

Magnitude

Score

Value

Note

When

Always

Overall

These

If twoevaluation

parameter

how

assign

concepts

by

is

creating

arevalue

highlight

simply

the

selecting

this

the

isrelative

weighting

the

is

design

score

evaluation

column

matrix

receive

the

simply

the

assigned

the

weighing

comparison

design

assignments

concept

contains

objectives

the

factors

lists

magnitudes

matrices,

value

sumthe

concept

factor

based

one

units

ofoffor

all

good 8 which

on

(or

col

each

the

times

receives

al

whi

the

ofwucays

"good",

mn

qual

val

hparameters)

how

direcei

obj

u

fferent

the

assi

e

ifor

tati

are

evcomputations

cti

vimportant

ge

score

they

each

es

vnhal

e,

important

magnitudes.

assessments

the

fthe

whether

the

for

MUST

design

for

concept

highest

each

score

a

eachparticular

for

both

quantitative

concept

objective.

for

of

For

overall

the

with

objective

inthe

each

receive

the

example

design

the

riveted

or

value,

design

There

best

idea.

or

is to

if

okay 6 concepts

are

In

qualitative.

the

conceptual

plate

magnitude

as

concept.

evaluation

scores

this

this

overall

manufacturing

quantitative

idea

example,

is

of the under

8.because

matrix.

success

adesign.

Ifscore

design

youparameters

evaluation.

there

The

are

time

of

itof

which

is

10

are

able

the

purpose

estimated

assessment

and three

design.

was

to(i.e.

use

more

is

ideas

cost,

ato

In

this example

time,

under

(magnitude)

require

linear

proven

use

closely logic

speed,

relationship

consideration

to

distinguish

twice to

meet rationalize

for

weight,

reliability

astheone

muchto

between

selected

concept

for

etc.)

compute

time

has

which

theand the

design

to

aisscore

score

scores

highest

twice of

is

fair 4 weighting

qualitative

a

as

manufacture.

for

objectives

most

of crane

10

much

theappropriate

and other

hook:

asafactor

at

objectives

score

another,

concepts.

the

Itwelding

isbecause

highest

for

important

of 9, each

that

(i.e.

plates

In

then

level.

concept

this

ifreliability,

conceptual

the

to

add use

crane

poor 2 hook fails,

repairability,

together,

would

linear

comparison

design.

another ratios

receive

Ifqualitative

riveting

twocargo

like

the

controllability,

concepts

half

cast

this

will

plates

the

score

to

hook

bescore.

compute

receive

destroyed

together

assessment

possessed

etc.).

Thethe oror

people

Quantitative

casting

"best"

score

the

magnitudes

to this

lowest assignments.

magnitude

table,

can

metal material

be

of

objectives

such

to"great",

killed.

form

always

ascost,"very

All

the

they

can

weighting

therefore

receives

hook.

good:

be

MUST9"the

CRANE PHOTO CLICK HERE FOR THE SAME EXAMPLE WITH

CRANE HOOK PHOTO PRINTABLE (AS OPPOSED TO DIGITAL) COMMENTS

BAD DAY AT WORK FOR CRANE OPERATOR PHOTO

Introduction to the Design 1

6. Communication of the Design

Recognize the Need

The purpose of the design is to

satisfy the needs of the client. Problem Definition

Designer must provide oral

presentations and written design

reports. Gathering of Information

Continuous communication is

important in order to avoid

surprises. Concept Generation

Many great designs and inventions

have been lost simply because the

originator was unable or unwilling Concept Selection

to explain his/her accomplishments

to others.

Communication

There are only 3 forms of

communication available to us: written, oral and graphical.

The successful engineer will be technically competent and

versatile in all three. Competency only comes from practice.

Ability in writing can be acquired by writing letters, reports,

memos, and papers. It doesn’t matter whether the articles are

published or reviewed—the practice is the important thing.

Ability in speaking can be obtained in educational, fraternal,

civic, church and professional activities. To acquire drawing

ability, pencil sketching should be employed to illustrate

every idea possible. CAD work should complement this,

not replace it.

Importance of sketches, drawings, visual aids, computer

graphics and models in the communications process.

Introduction to the Design 1

7. Detailed Design and Analysis

The principal goal of your Recognize the Need

engineering studies is to enable

you to create mathematical

models which accurately simulate Problem Definition

the real physical world.

All real physical systems are Gathering of Information

complex. Creating a

mathematical model of the system

means we are simplifying the

Concept Generation

system to the point that it can be

analyzed. The terms rigid body

and concentrated force are

Concept Selection

examples. The rule in making

such assumptions, is that, in

creating the model, the model

Communication

must be meaningful—i.e. a good

and appropriate model given the

design constraints involved.

Detailed Design and Analysis

The nature of the problem, its

economics, the computational facilities available and the

ability and working time of the engineer, all play a key role in

the formulation of the model.

The designer’s time investment typically increases

exponentially with regard to model accuracy.

Introduction to the Design 1

8. Prototype Development and Testing

Recognize the Need

Initial exposure in EML2322 lab

and design project.

Problem Definition

9. Manufacturing

Gathering of Information

Initial exposure in EML4321

course. Concept Generation

10. Life Cycle Maintenance Concept Selection

Learned from experience and

industry standards. Communication

Detailed Design and Analysis

Prototype and Testing

Manufacturing

Life Cycle Maintenance

Introduction to the Design 1

You might also like

- The Rich Get Richer and The Poor Get PrisonDocument1 pageThe Rich Get Richer and The Poor Get PrisonGunasundaryChandramohanNo ratings yet

- Full Download Engineering Design 5th Edition Dieter Solutions ManualDocument15 pagesFull Download Engineering Design 5th Edition Dieter Solutions Manualaminamuckenfuss804uk100% (32)

- Drone CurriculumDocument9 pagesDrone CurriculumMarvellousNo ratings yet

- Answer Scheme - Tutorial 1 BMMA 1323 Engineering DesignDocument8 pagesAnswer Scheme - Tutorial 1 BMMA 1323 Engineering DesignI-zad MJNo ratings yet

- Method Statement Stone ColumnDocument10 pagesMethod Statement Stone ColumnSantosh ZunjarNo ratings yet

- Commercial RefrigerationDocument11 pagesCommercial RefrigerationBenjie flor CalayegNo ratings yet

- Prophecies in Islam & Prophet Muhammad - A.aliDocument82 pagesProphecies in Islam & Prophet Muhammad - A.aliZaky MuzaffarNo ratings yet

- Bearing Failure Analysis by Using 8 D ReportDocument7 pagesBearing Failure Analysis by Using 8 D Reportyash prajapatiNo ratings yet

- GSO-1909-2009-E - Requirements For Handling of Ready To Eat FoodsDocument12 pagesGSO-1909-2009-E - Requirements For Handling of Ready To Eat FoodsANSAR100% (1)

- EML2322L Design ProcessDocument14 pagesEML2322L Design ProcessLalo MtzNo ratings yet

- Machine Design Project PPT - NewDocument43 pagesMachine Design Project PPT - NewAdugna GosaNo ratings yet

- Fundamentos Diseño 2022-2Document43 pagesFundamentos Diseño 2022-2Diego MoyaNo ratings yet

- PDD 2 Concept GenerationDocument33 pagesPDD 2 Concept Generationkushal pramanickNo ratings yet

- Textbook - Unit 1 - Engineering DesignDocument13 pagesTextbook - Unit 1 - Engineering DesignThuy TranNo ratings yet

- 3 - Need Analysis and Problem DefinitionDocument23 pages3 - Need Analysis and Problem Definition6yhtzjm5gbNo ratings yet

- Week 2 Principle Mechanical Design PDFDocument45 pagesWeek 2 Principle Mechanical Design PDFWatcharakorn Viva la VidaNo ratings yet

- Engineering Exploration: First Year Engineering (All) 2018-19 Maharashtra Institute of Technology AurangabadDocument66 pagesEngineering Exploration: First Year Engineering (All) 2018-19 Maharashtra Institute of Technology Aurangabadatharva gaikwadNo ratings yet

- Engr400 DesignprocessDocument3 pagesEngr400 Designprocessnishantu_2255705@gmail.comNo ratings yet

- Dome 1Document35 pagesDome 1harikg21No ratings yet

- Dme - Mod 1Document36 pagesDme - Mod 1Linto Varghese100% (1)

- The Design Process: HNC in Engineering-Engineering Design Edexcel Unit: Engineering Design (NQF L4)Document14 pagesThe Design Process: HNC in Engineering-Engineering Design Edexcel Unit: Engineering Design (NQF L4)Joom Chico LocoNo ratings yet

- CHAP1 - Product Design Theory and MethodologyDocument34 pagesCHAP1 - Product Design Theory and Methodologykhalil alhatabNo ratings yet

- Need Analysis and Problem DefinitionDocument23 pagesNeed Analysis and Problem Definitionb hari prasadNo ratings yet

- Lecture 5. The Design ProcessDocument6 pagesLecture 5. The Design ProcessIngrid Nicoleta SterpuNo ratings yet

- Problem Formulation and Case Studies: College of EngineeringDocument34 pagesProblem Formulation and Case Studies: College of EngineeringmmNo ratings yet

- MMD101 ModelAnswerDocument6 pagesMMD101 ModelAnswerVishal JangirNo ratings yet

- DME NotesDocument133 pagesDME NotesNeeraj S GNo ratings yet

- Design ProcessDocument32 pagesDesign Processkhan janNo ratings yet

- LECTURE 2 The Design Process - Sem 1 - 2022 - 2023Document35 pagesLECTURE 2 The Design Process - Sem 1 - 2022 - 2023Idham NasrulNo ratings yet

- Introduction To Machine Design 2021 - July 28Document23 pagesIntroduction To Machine Design 2021 - July 28BaslielNo ratings yet

- 07 Design Drawing and SafetyDocument12 pages07 Design Drawing and SafetySafikul HossainNo ratings yet

- BAH 1 Module 10 in AB Machinery and MechanizationDocument6 pagesBAH 1 Module 10 in AB Machinery and MechanizationDistor, Jane F.No ratings yet

- An Overview of Chemical Process Design EngineeringDocument8 pagesAn Overview of Chemical Process Design EngineeringAzri RazakNo ratings yet

- 02-Introduction To Engineering Design ProcessDocument14 pages02-Introduction To Engineering Design Processyaseen jobaNo ratings yet

- Engineering Design - DetailDocument44 pagesEngineering Design - DetailYogi FahleviNo ratings yet

- 0002 - OM SESSION 2 (Chapter 4 - Process Design & Chapter 5 - Innovation & Design in Services & Products)Document49 pages0002 - OM SESSION 2 (Chapter 4 - Process Design & Chapter 5 - Innovation & Design in Services & Products)Tú Anh NguyễnNo ratings yet

- Ingeniería Mecánica M1T1Document7 pagesIngeniería Mecánica M1T1Shahin AkterNo ratings yet

- 1100 T2 13-4 Lect2 DesignDocument44 pages1100 T2 13-4 Lect2 DesignarulmuruguNo ratings yet

- The Product Design Process What Is Design?Document14 pagesThe Product Design Process What Is Design?michsantosNo ratings yet

- LECTURE NOTES ON Design For ManufacturinDocument63 pagesLECTURE NOTES ON Design For Manufacturinmmk.mech59No ratings yet

- HETT207 Lecture Notes - Unit 2Document63 pagesHETT207 Lecture Notes - Unit 2Joshua DomaNo ratings yet

- Paper3509 515Document7 pagesPaper3509 515Anak SehatNo ratings yet

- Module 3. Individual Assignment: Case Study Proyect: What Is BYD's Current Product Flow Process?Document2 pagesModule 3. Individual Assignment: Case Study Proyect: What Is BYD's Current Product Flow Process?Carina LopezNo ratings yet

- Lec 3Document34 pagesLec 3Ebrahem ShabanaNo ratings yet

- Lecture No. 5 - Dr. Raja Rizwan Hussain Course Ge 105 Introduction To Engineering DesignDocument23 pagesLecture No. 5 - Dr. Raja Rizwan Hussain Course Ge 105 Introduction To Engineering DesignLuân NguyễnNo ratings yet

- Lecture 5Document25 pagesLecture 5mnooNo ratings yet

- Manufacturing Process Selection in Engineering Design. Part 1: The Role of Process SelectionDocument11 pagesManufacturing Process Selection in Engineering Design. Part 1: The Role of Process SelectionAnggi FirmansyahNo ratings yet

- Chapter 3: The Design Process & The Role of CAD: Emd4M2A Emd4M7BDocument59 pagesChapter 3: The Design Process & The Role of CAD: Emd4M2A Emd4M7BfaqhrulNo ratings yet

- Kolej Matrikulasi Kejuruteraan Kedah EB025 SEMESTER 2, SESSION 2022/2023 Assignment: Design Project (Key Chain)Document6 pagesKolej Matrikulasi Kejuruteraan Kedah EB025 SEMESTER 2, SESSION 2022/2023 Assignment: Design Project (Key Chain)VEENOM 0204No ratings yet

- Crystal: Methods and Spiral Lifecycle ModelDocument23 pagesCrystal: Methods and Spiral Lifecycle Modelsax_loverNo ratings yet

- Index 2Document3 pagesIndex 2jithuclt87No ratings yet

- 4-شابتر 5 PDFDocument28 pages4-شابتر 5 PDFnola shNo ratings yet

- Root Cause Analysis - ShaininapproachDocument6 pagesRoot Cause Analysis - ShaininapproachRaghavendra KalyanNo ratings yet

- CH 4Document48 pagesCH 4shiferawNo ratings yet

- PAPERRSBDocument5 pagesPAPERRSBvishal.khalane9No ratings yet

- Electric Discharge Machining EDM by Varun AroraDocument20 pagesElectric Discharge Machining EDM by Varun AroraVarun AroraNo ratings yet

- Materi 7 Concept GenerationDocument30 pagesMateri 7 Concept Generationrachmat nursalamNo ratings yet

- Cutting Tool DesignDocument17 pagesCutting Tool DesignHazrat BelalNo ratings yet

- Unit 4: Introduction To Engineering Design: Engr. Roman M. Richard, MengDocument17 pagesUnit 4: Introduction To Engineering Design: Engr. Roman M. Richard, MengRoman MarcosNo ratings yet

- IT and Business Systems SolutionsDocument4 pagesIT and Business Systems SolutionsMichael GrafNo ratings yet

- Machine DesignDocument10 pagesMachine DesignRahul RahNo ratings yet

- Sciencedirect: in Pursuit of Personalization DesignDocument5 pagesSciencedirect: in Pursuit of Personalization Designvincent BarreauNo ratings yet

- Mechanical Design BasicsDocument17 pagesMechanical Design BasicshrproxNo ratings yet

- ME8691 Computer Aided Design and Manufacturing Notes 1Document79 pagesME8691 Computer Aided Design and Manufacturing Notes 1ARUMUGA NAINARNo ratings yet

- Product DesignDocument27 pagesProduct DesignrubensNo ratings yet

- BeltDocument3 pagesBeltBenjie flor CalayegNo ratings yet

- Statics of Rigid BodiesDocument89 pagesStatics of Rigid BodiesBenjie flor CalayegNo ratings yet

- Marc Kevin B. GonzalesDocument4 pagesMarc Kevin B. GonzalesBenjie flor CalayegNo ratings yet

- Chapter 11 Managing The Marketing FunctionDocument9 pagesChapter 11 Managing The Marketing FunctionBenjie flor CalayegNo ratings yet

- HEAT TRANSFER - Problem SetDocument3 pagesHEAT TRANSFER - Problem SetBenjie flor CalayegNo ratings yet

- Distribution System Components: Figure 31-Pressure TanksDocument6 pagesDistribution System Components: Figure 31-Pressure TanksBenjie flor CalayegNo ratings yet

- COMBUSTIONDocument9 pagesCOMBUSTIONBenjie flor CalayegNo ratings yet

- Machine Design CompletepdfDocument219 pagesMachine Design CompletepdfBenjie flor CalayegNo ratings yet

- Activity 1Document2 pagesActivity 1Benjie flor CalayegNo ratings yet

- Basic Thermodynamics: Module OrientationDocument12 pagesBasic Thermodynamics: Module OrientationBenjie flor CalayegNo ratings yet

- ME6513 Metrology and Measurements LabDocument81 pagesME6513 Metrology and Measurements LabBenjie flor CalayegNo ratings yet

- Material ManualDocument40 pagesMaterial ManualBenjie flor CalayegNo ratings yet

- Mechanical Engineering Laboratory ManualDocument134 pagesMechanical Engineering Laboratory ManualBenjie flor CalayegNo ratings yet

- Evaluate: Direction: Kindly Solve The FollowingDocument4 pagesEvaluate: Direction: Kindly Solve The FollowingBenjie flor CalayegNo ratings yet

- Workshop - and - Machine - Shop ManualDocument96 pagesWorkshop - and - Machine - Shop ManualBenjie flor CalayegNo ratings yet

- Brightpancar Catalog PDFDocument125 pagesBrightpancar Catalog PDFBobby RajNo ratings yet

- Determination of Chromium VI Concentration Via Absorption Spectroscopy ExperimentDocument12 pagesDetermination of Chromium VI Concentration Via Absorption Spectroscopy ExperimentHani ZahraNo ratings yet

- AP3456 Mathematics & Physics PDFDocument319 pagesAP3456 Mathematics & Physics PDFLaxmi Krishnadas0% (1)

- BB FiberOpticCommandmentsDocument4 pagesBB FiberOpticCommandmentsDand LongNo ratings yet

- Concept MappingDocument2 pagesConcept MappingSarah DeNo ratings yet

- Notes:: Dialog Plant Services Sdn. BHDDocument1 pageNotes:: Dialog Plant Services Sdn. BHDTengku ZhafriNo ratings yet

- AND8331/D Quasi-Resonant Current-Mode Controller For High - Power Ac-Dc AdaptersDocument16 pagesAND8331/D Quasi-Resonant Current-Mode Controller For High - Power Ac-Dc AdaptersLucía MitchellNo ratings yet

- 2exam LogisticsDocument6 pages2exam LogisticsJessica LaguatanNo ratings yet

- Development of Instructional Materials Based SETSDocument12 pagesDevelopment of Instructional Materials Based SETSInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Module 4 ResearchDocument9 pagesModule 4 ResearchJegg AsisNo ratings yet

- 13.n-p-n TransistorDocument4 pages13.n-p-n TransistorkirtiNo ratings yet

- Biology HL Student GuideDocument134 pagesBiology HL Student GuideYesenia JassoNo ratings yet

- All About Zookeeper and ClickHouse KeeperDocument45 pagesAll About Zookeeper and ClickHouse KeeperomyeudaihiepNo ratings yet

- IPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalDocument5 pagesIPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalOswaldo MontenegroNo ratings yet

- D Dy DT Q K DyDocument20 pagesD Dy DT Q K DyMohammed Al-OdatNo ratings yet

- Unit-7: Iot SecurityDocument21 pagesUnit-7: Iot SecuritySAMPANo ratings yet

- TEM ManualDocument6 pagesTEM ManualmcsteiNo ratings yet

- Detailed Lesson Plan in MAPE7 ART, Fourth QuarterDocument9 pagesDetailed Lesson Plan in MAPE7 ART, Fourth QuarterLolita Reynolds100% (1)

- Ebook Diversity and Society Race Ethnicity and Gender 4Th Edition Healey Test Bank Full Chapter PDFDocument36 pagesEbook Diversity and Society Race Ethnicity and Gender 4Th Edition Healey Test Bank Full Chapter PDFalmiraelysia3n4y8100% (12)

- Short Keys f1-f12Document2 pagesShort Keys f1-f12Farhan Khan NiaZiNo ratings yet

- 56ef945cea29b 1312621 SampleDocument16 pages56ef945cea29b 1312621 SamplepanditrulesNo ratings yet

- Flow ControlDocument87 pagesFlow Controlibrahim_nfsNo ratings yet

- Some Remarks On Fuzzy N-Normed SpacesDocument7 pagesSome Remarks On Fuzzy N-Normed SpacesRyanEliasNo ratings yet

- Net Metering SopDocument34 pagesNet Metering Sopساحر حسینNo ratings yet

- SIKA Marine 2016Document164 pagesSIKA Marine 2016pcatruongNo ratings yet