Professional Documents

Culture Documents

Environmental Control Unit and Pressurization System Review: 10Th Stage Overview

Environmental Control Unit and Pressurization System Review: 10Th Stage Overview

Uploaded by

romixrayzenCopyright:

Available Formats

You might also like

- KA B200 - B200GT - 250 PL21 Pilot Training ManualDocument490 pagesKA B200 - B200GT - 250 PL21 Pilot Training ManualKarl Hering100% (2)

- B737 Question BankDocument111 pagesB737 Question BankMohit Bhartia98% (41)

- CAAB QB For ATR 72-500 Green Jul-18Document43 pagesCAAB QB For ATR 72-500 Green Jul-18কবীরবিপু75% (4)

- B737 Question BankDocument111 pagesB737 Question BankFathan Hiliry100% (4)

- B777 Quick ReferenceDocument76 pagesB777 Quick ReferenceDang Xuan Tien94% (32)

- Citation Mustang Pilot Training ManualDocument457 pagesCitation Mustang Pilot Training ManualGerman Rebollar100% (4)

- B747-400 Quick Study Review PDFDocument39 pagesB747-400 Quick Study Review PDFnzcruiser100% (3)

- B747-400 Quick Study Review PDFDocument39 pagesB747-400 Quick Study Review PDFnzcruiser100% (3)

- Smart Cockpit System Questions - FlattenedDocument85 pagesSmart Cockpit System Questions - FlattenedBarut Brkk100% (4)

- B737ng Systems Question BankDocument121 pagesB737ng Systems Question Banksebastien80% (10)

- B737-Pneumatic Systems SummaryDocument5 pagesB737-Pneumatic Systems SummaryEtienne Gerber100% (2)

- B767 Air ConditioningDocument5 pagesB767 Air ConditioningGustavo Avila Rodriguez67% (3)

- Bombardier CRJ 200-Environmental Control System PDFDocument39 pagesBombardier CRJ 200-Environmental Control System PDFmamon113No ratings yet

- Hydraulics A320Document101 pagesHydraulics A320KamalVirk100% (7)

- Flight Controls ReviewDocument8 pagesFlight Controls ReviewromixrayzenNo ratings yet

- SkySim MD11 FLTTECHDocument34 pagesSkySim MD11 FLTTECHMarco Lima100% (1)

- Gulfstream III: Operating HandbookDocument148 pagesGulfstream III: Operating HandbookSantiago Hidalgo100% (2)

- Phenom300 QuestionBankDocument18 pagesPhenom300 QuestionBankPaul Kostukovsky100% (2)

- Pratt & Whitney JT8DDocument41 pagesPratt & Whitney JT8DJhon 117100% (5)

- A320 Family Notes 1Document103 pagesA320 Family Notes 1antynccbzersdrodiz100% (1)

- B767 Equipment CoolingDocument3 pagesB767 Equipment CoolingGustavo Avila Rodriguez0% (1)

- A320 Limitations & QuestionsDocument15 pagesA320 Limitations & Questionsbrent everittNo ratings yet

- B777 Air SystemsDocument0 pagesB777 Air SystemsJOUO20009167No ratings yet

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- Airbus 320 Lights and SwitchesDocument1,320 pagesAirbus 320 Lights and SwitchesUros Miladinovic100% (1)

- Auxiliary Power Unit (Apu) Systems ReviewDocument5 pagesAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)

- B767 PneumaticsDocument6 pagesB767 PneumaticsGustavo Avila Rodriguez100% (5)

- 36 PneumaticDocument6 pages36 PneumaticĐoàn Hồng NgọcNo ratings yet

- Phase 4 (1 MAC 22)Document4 pagesPhase 4 (1 MAC 22)AzurianiNo ratings yet

- Ata 21 Air ConditioningDocument9 pagesAta 21 Air Conditioninggreatest everNo ratings yet

- ARMS Handout NG To MAX Rev 01Document46 pagesARMS Handout NG To MAX Rev 01swayam1495No ratings yet

- 2.air SystemsDocument14 pages2.air Systemsshameem aktharNo ratings yet

- ATA 21 AirCon Day 2Document10 pagesATA 21 AirCon Day 2Muhammed YaseenNo ratings yet

- 36 - TopicsDocument14 pages36 - TopicsMohamad MagdyNo ratings yet

- Mil Mi-8 Startup Manual and ChecklistDocument13 pagesMil Mi-8 Startup Manual and ChecklistOscar Alfonso100% (2)

- Boeing 777: Your Result Is 78%. You The Test!Document5 pagesBoeing 777: Your Result Is 78%. You The Test!Wasim AkhterNo ratings yet

- B737-800 PneumaticsDocument5 pagesB737-800 PneumaticsReynaldo100% (2)

- Air - Pneumatic, Air Conditioning, PressurizationDocument8 pagesAir - Pneumatic, Air Conditioning, Pressurizationamasis66No ratings yet

- Ata 36Document11 pagesAta 36jontis jasoliyaNo ratings yet

- Cessna 182 Pilots Operating Handbook (1966)Document31 pagesCessna 182 Pilots Operating Handbook (1966)Gustavo Adolfo Términe100% (1)

- VP-9 2P Study Bible: "Rick James" VersionDocument8 pagesVP-9 2P Study Bible: "Rick James" VersionpepeNo ratings yet

- Acf DifferencesDocument71 pagesAcf DifferencesMorrisNo ratings yet

- خلاصه ارباس ٣٢٠Document23 pagesخلاصه ارباس ٣٢٠Reza MaserratNo ratings yet

- Teaching PPDocument3 pagesTeaching PPH LATKNo ratings yet

- Atr72 Air PDFDocument34 pagesAtr72 Air PDFEhsan Ul HaqueNo ratings yet

- B737NG Air SystemsDocument10 pagesB737NG Air SystemsMohamood Salman SiddiquiNo ratings yet

- Pneumatics Exam Part 2Document1 pagePneumatics Exam Part 2Amiel Simon AureNo ratings yet

- On The GroundDocument3 pagesOn The Groundroyalairmaroc737No ratings yet

- AIRCO QuizDocument6 pagesAIRCO Quizluc madou0% (1)

- Dornier 328jet PneumaticDocument14 pagesDornier 328jet PneumaticEmily Armstrong100% (1)

- Cl605 PneumaticDocument12 pagesCl605 PneumaticMirko Novakovic100% (1)

- Section 3 (Emergency Procedures)Document75 pagesSection 3 (Emergency Procedures)Jung SunhoNo ratings yet

- 06 Abnormal Procedures 737 678900 v14Document17 pages06 Abnormal Procedures 737 678900 v14JavierNo ratings yet

- Pneumatic System: IsolationDocument6 pagesPneumatic System: IsolationGirish SreeneebusNo ratings yet

- Dc9 Normal Checklist, Expanded.: Obs - Only For Flightsim - ObsDocument26 pagesDc9 Normal Checklist, Expanded.: Obs - Only For Flightsim - ObsRichard LundNo ratings yet

- Q400 Presentation - APUDocument9 pagesQ400 Presentation - APUTom100% (1)

- MD90 Differences ResumenDocument8 pagesMD90 Differences ResumenSamuli SutinenNo ratings yet

- B1900 NOTES Page 21-40Document20 pagesB1900 NOTES Page 21-40Hayden CourtneyNo ratings yet

- Notes About A320 FCTM by Iman Jafarian and MJ - AzadiDocument47 pagesNotes About A320 FCTM by Iman Jafarian and MJ - Azadimohammad javad AzadiNo ratings yet

- Normal Procedures c172Document5 pagesNormal Procedures c172Vinicius LinsNo ratings yet

- AUTO FAIL or Unscheduled Pressurization ChangeDocument10 pagesAUTO FAIL or Unscheduled Pressurization ChangeДамир УзенбаевNo ratings yet

- Construction of The Ai-9V EngineDocument8 pagesConstruction of The Ai-9V EngineYosif NorendoNo ratings yet

- DC6 NORMAL PROCEDURES For PMDGDocument8 pagesDC6 NORMAL PROCEDURES For PMDGGilberto FonsecaNo ratings yet

- Ice and Rain CH 30: Training Manual B767-3S2F CH 30-00Document39 pagesIce and Rain CH 30: Training Manual B767-3S2F CH 30-00Elijah Paul Merto100% (3)

- Systems Atpl PDFDocument111 pagesSystems Atpl PDFMay Be100% (1)

- Air Conditioning and Pressurisation 1Document147 pagesAir Conditioning and Pressurisation 1Ricardo Jose Navarro Pacheco100% (1)

- Ata 28Document6 pagesAta 28phonesavanh.dod1989No ratings yet

- 737 Air Systems SummaryDocument10 pages737 Air Systems SummaryAhmed RefNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- MC 10230573 0001Document27 pagesMC 10230573 0001romixrayzenNo ratings yet

- MC 10214482 0001Document8 pagesMC 10214482 0001romixrayzenNo ratings yet

- 05 Диагностика неисправностейDocument12 pages05 Диагностика неисправностейromixrayzenNo ratings yet

- Link2000 DecisionTree 2012 12bDocument1 pageLink2000 DecisionTree 2012 12bromixrayzenNo ratings yet

- SA3644SWDocument2 pagesSA3644SWromixrayzenNo ratings yet

- Active Service Bulletins With Instructions For Continued AirworthinessDocument1 pageActive Service Bulletins With Instructions For Continued AirworthinessromixrayzenNo ratings yet

- Data Link Services Workshop Brussels 17june2014Document47 pagesData Link Services Workshop Brussels 17june2014romixrayzenNo ratings yet

- 02 Техническое описаниеDocument20 pages02 Техническое описаниеromixrayzenNo ratings yet

- AW600 23 2387 - Rev4Document7 pagesAW600 23 2387 - Rev4romixrayzenNo ratings yet

- csp-023 I0r0Document18 pagescsp-023 I0r0romixrayzenNo ratings yet

- csp-015 I0r0Document20 pagescsp-015 I0r0romixrayzenNo ratings yet

- Landing Gear and Brakes ReviewDocument8 pagesLanding Gear and Brakes ReviewromixrayzenNo ratings yet

- Flight Instruments Review: Pitot-Static SystemDocument5 pagesFlight Instruments Review: Pitot-Static SystemromixrayzenNo ratings yet

- Auxiliary Power Unit (Apu) Systems ReviewDocument5 pagesAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)

- Fire Protection Review: Fire Detection and ExtinguishingDocument7 pagesFire Protection Review: Fire Detection and ExtinguishingromixrayzenNo ratings yet

- Fdap P13 PDFDocument52 pagesFdap P13 PDFiespartaNo ratings yet

- 49 Apu PDFDocument68 pages49 Apu PDFAaron Harvey50% (2)

- Helicopter Division, BangaloreDocument1 pageHelicopter Division, Bangaloregoten25No ratings yet

- Chapter 49 Part 1Document11 pagesChapter 49 Part 1Frank JansenNo ratings yet

- Airbus Prologue ManualDocument98 pagesAirbus Prologue Manualdannyells_danielsNo ratings yet

- B737CL Fire ProtectionDocument17 pagesB737CL Fire ProtectionDan StroescuNo ratings yet

- AIRBUS A318/A319: Systems GuideDocument67 pagesAIRBUS A318/A319: Systems GuideJavier Pérez DelgadoNo ratings yet

- EP3EDocument25 pagesEP3Edagger21100% (1)

- Airbus A320 Overhead Panel PresentationDocument10 pagesAirbus A320 Overhead Panel PresentationSurya Oka Setyawan67% (3)

- Airbus ATA36Document56 pagesAirbus ATA36phonesavanh.dod1989No ratings yet

- Flysimware's FALCON 50 MANUAL V2.2Document46 pagesFlysimware's FALCON 50 MANUAL V2.2Leonardo SantanaNo ratings yet

- 737 Check ListDocument7 pages737 Check ListGuillermo Pinzón AmayaNo ratings yet

- B 737 - CL - Ata 38 - B1.1Document47 pagesB 737 - CL - Ata 38 - B1.1Vasili RafaelyanNo ratings yet

- 12 Ice RainDocument10 pages12 Ice RainBlueSkyMaster100% (2)

- B737-200 L3 ATA 21 Air ConditioningDocument230 pagesB737-200 L3 ATA 21 Air ConditioningBelisario Sergio Llacchas rodasNo ratings yet

- 407 Crov CH21Document106 pages407 Crov CH21edsel jose diaz sarmientoNo ratings yet

- ATA 44 - Cabin Systems (Mike Tooley)Document17 pagesATA 44 - Cabin Systems (Mike Tooley)Anees Ek100% (1)

- PDF N Fcom Gia TF N Eu 20121113 DSC 21Document116 pagesPDF N Fcom Gia TF N Eu 20121113 DSC 21Nigel AmartaNo ratings yet

- Aircraft Anti-Icing Systems: Presented byDocument13 pagesAircraft Anti-Icing Systems: Presented bynandheswaraNo ratings yet

- Bae - e Sil - 21 146 RJ 536 1Document27 pagesBae - e Sil - 21 146 RJ 536 1alpenadler100% (2)

Environmental Control Unit and Pressurization System Review: 10Th Stage Overview

Environmental Control Unit and Pressurization System Review: 10Th Stage Overview

Uploaded by

romixrayzenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Control Unit and Pressurization System Review: 10Th Stage Overview

Environmental Control Unit and Pressurization System Review: 10Th Stage Overview

Uploaded by

romixrayzenCopyright:

Available Formats

The CRJ200 Quicknotes Study Guide

ENVIRONMENTAL CONTROL

UNIT AND PRESSURIZATION

SYSTEM REVIEW

The Environmental

Control System (ECS)

provides temperature

regulated

conditioned air for the

flight and passenger

compartments by using

two airconditioning

units or packages

(PACKs). Cooling air is

supplied to the

electronic equipment and

cockpit displays. The cargo

compartment can be

ventilated or air-

conditioned (optional).

Aircraft pressurization is

accomplished by regulating

the overboard

discharge of conditioned

air through two outflow

safety valves.

• 7TH STAGE – Labyrinth Seals (Air / Oil Seals) – Oil seal pressurization and sump pump

• 10TH STAGE – Engine Start, Air Conditioning, Pressurization, Avionics Cooling (370°C, 170

psi)

• 14TH STAGE – Thrust Reverse, Wing/Cowl Anti-ice (510°C, 215 psi)

10TH STAGE OVERVIEW

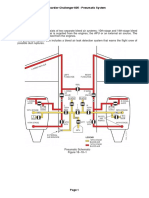

METHODS OF OBTAINING 10TH MANIFOLD AIR

• HUFFER BOTTLE

–– DO NOT USE air conditioning if using a bottle – only use for engine start

–– Air flows through packs

–– For BOTTLE start – 95% of the time will get NO STRTR CUTOUT (not enough air to

close ATS), press STOP to disengage starter

• Engines or APU

Copyright © 2009 www.flycrj.com PAGE 62

The CRJ200 Quicknotes Study Guide

–– Air flows through the packs

–– Output pressure is based on N2 speed

–– APU BLEED ⇒ 260°C, 50 psi

• Low Pressure (LP) GROUND AIR

–– Air BYPASSES packs

–– Conditioned air directly into passenger cabin and flight compartment

• Ram Air

–– Air bypasses packs

–– Ram air directly into passenger cabin and flight compartment

–– Ram air inlet up on tail

–– Will not DEPRESSURIZE aircraft by open this valve – a check valve inhibits air from

escaping from the HIGHER pressure INSIDE cabin to the LOWER pressure outside the

airplane

–– Air will only enter once the pressures INSIDE and OUTSIDE HAVE EQUILIBRATED

BLEED VALVE FAILURES

• 10th Stage SOV fails CLOSED –

–– Allows for anti-icing with 14th if 10th SOV’s fail

–– Need both pneumatic pressure and DC electrical to power valve OPEN

• 14th Stage SOV fails OPEN –

–– Allows for anti-icing and thrust reverse if 14th SOV’s fail

10th STAGE BLEED VALVE CLOSURE

• ENGINE START SEQUENCE COMPLETE

• ENGINE SHUT DOWN – FAILS CLOSED

• ENGINE FIRE SWITCH PUSHED

• PACK OVERTEMP OR PACK OVERPRESSURE

• 10th STAGE SWITCHES SELECTED CLOSED

PACKS

• No valve representation on synoptic page – pack outline indicates pack status

–– White – PRSOV is CLOSED

–– Green – PRSOV is OPEN

• Two flow rates

–– Normal pressure – Both packs operating – 30 psi

–– High pressure – Single pack operations – 41 psi

OUTFLOW VALVES

• 10th stage air is run through a jet pump to provide VACUUM to run outflow valves

• If suction is lost, outflow valves fail safe CLOSED

10th STAGE ISOLATION VALVE

• Separates left and right bleed air

Copyright © 2009 www.flycrj.com PAGE 63

The CRJ200 Quicknotes Study Guide

• Permits APU to supply RIGHT pack

• Allows start air to flow to right engine

• 10TH ISOL switchlight – OPEN – 10TH stage bleed air isolation valve is OPEN

APU LCV

• Selected to FULLY OPEN or FULLY CLOSED by the APU LCV switchlight

• In operation, valve is MODULATED to provide priority to ELECTRICAL LOADS

• APU check valve (NOT SHOWN ON ECS PAGE – would be located above LCV)

–– Prevents engine bleed air from backing into APU

–– Prioritizes ENGINE BLEED over APU BLEED

–– The APU-ECU INTERLOCK serves as a back up to the check valve (based on SWITCH

POSITION)

• APU LCV fails CLOSED

• “APU BLEED ON” caution – Extracting bleed air ABOVE 15,000’ MSL (AMBER flow line

on ECS page)

• When OPEN – supplies bleed air to the LEFT pack

• OPENS to provide air for engine starts

• APU LCV switchlight – FAIL – Indicates that the APU LCV is not in the commanded

position

• APU LCV switchlight – OPEN – Indicates the APU pneumatic duct is connected to the

10TH stage bleed air manifold

APU-ECU INTERLOCK

• BASED ON SWITCH POSITION ONLY

• Back-up protection for backpressure into APU

• APU-ECU INTERLOCK PROTECTION IS NOT ACTIVE DURING ENGINE

START

–– During engine start – the 10th SOV’s are OPEN at the same time as the APU LCV

–– 70% N2 limitation on engine number 2 start – 10TH could back flow into APU if > 70%

N2 on operating engine

–– APU LCV will only OPEN during engine start as long as the 10th bleed switches are

PRESSED OUT

• If APU LCV selected OPEN and:

–– If ISOL CLOSED and L 10th SOV OPEN – APU LCV will CLOSE

AUTOMATICALLY

• If APU LCV selected OPEN and:

–– If ISOL OPEN – either L or R 10th SOV OPEN will cause APU LCV to CLOSE

automatically

ENGINE START SEQUENCE

1. Push START button – Air Turbine Starter (ATS) valve OPENS on engine that is being

started

Copyright © 2009 www.flycrj.com PAGE 64

The CRJ200 Quicknotes Study Guide

2. ALL 10th stage valves OPEN (L 10th SOV, R 10th SOV, and 10th STAGE ISOL) and

APU LCV if using APU for engine start

3. PRSOV’s close (Pressure Regulating SOV)

4. Check valve on NON-OPERATING engine keeps 10th stage bleed air from entering

engine

5. Ignition ON (IGNITION A (B) advisory message on status page)

6. 55% N2 – ENGINE START CUTOUT – Air Turbine Starter (ATS) CLOSES

7. If ATS doesn’t cut out at 55% N2 – “NO STRTR CUTOUT” caution – Press STOP,

this CLOSES ATS 10th STAGE on ECS SYNOPTIC PAGE (Note: L (R) ENGINE START

advisory will still be displayed and L (R) Start pushbutton will remain lit.)

SYSTEM MONITORING

• L 10th DUCT or R 10th DUCT Warning Messages – Sensors detect a BLEED AIR LEAK

–– L or R 10th DUCT FAIL lights illuminate on BLEED AIR panel

–– Light extinguishes when the failure is isolated or the duct cools below a predetermined

value

–– “BLEED AIR DUCT” Aural warning

• 10th stage leak detection achieved through a DUAL heat detection loop

• 14th stage leak detection achieved through a SINGLE heat detection loop

• Bleed air duct leak in the JETPIPE/PYLON area – “JETPIPE OVERHEAT” aural warning

Copyright © 2009 www.flycrj.com PAGE 65

The CRJ200 Quicknotes Study Guide

AIR CONDITIONING

RAM AIR

• Heat exchanger cooling for packs

• Airflow for un-pressurized flight with both packs inoperative

• Supplies LEFT distribution duct and BYPASSES the packs

PACKS

• Located in the AFT EQUIPMENT BAY

• Left pack supplies COCKPIT (70%) and additional air to CABIN (30%)

• Right pack supplies CABIN (70%) and additional air to COCKPIT (70%)

• PRSOV (Pressure Regulating SOV) – Outline of pack indicates status of pack operation

• PRSOV CLOSES AUTOMATICALLY with a pack OVERTEMP (88°C) or

OVERPRESSURE (53 psi)

• PACK OVERTEMP

–– L PACK HI TEMP – If Left engine is running – PRSOV, L 10TH SOV, 10TH ISOL

VALVE automatically CLOSE

–– Bleed air supply shut down to the pack – system isolates itself

• PACK OVERPRESSURE

–– The pack will isolate itself just like an OVERTEMP

• PACK SWITCHLIGHT

–– FAULT – OVERPRESSURE between heat exchanger and compressor of pack

–– FAULT – OVERTEMPERATURE – High temperature detected in pack outlet

–– OFF – Associated PRSOV is CLOSED

TEMPERATURE CONTROL

• Dual temperature control valves

• MANUAL TEMP CONTROL (1.7 – 71°C)

–– Press in MAN switchlights – STATUS message

–– Toggle UP or DOWN to control temp – spring loaded to center position

–– DO NOT press and hold toggle until you reach desired output temp – can OVERTEMP

or freeze the pack

–– DO NOT operate in manual to a negative temperature

–– Manual mode < 3°C ⇒Can FREEZE pack water separator

–– AUTO mode (14.5 – 28°C) will not freeze a pack

AVIONICS COOLING

• Cooled from either conditioned air supply to the cockpit or from re-circulated air from the

cabin/cockpit

• DISPLAY FANS:

–– Three fans

–– NORM: FLIGHT = FAN 1, GND = FAN 2,

–– GND ALTERNATE = FAN 1

Copyright © 2009 www.flycrj.com PAGE 66

The CRJ200 Quicknotes Study Guide

–– FLIGHT ALTERNATE = FAN 2

–– First two fans use FILTERED AIR

–– Third fan (Standby) is a backup using UNFILTERED AIR

• ARINC FANS consist of two (2) fans with same setup as DISPLAY FANS

• Flight deck exhaust air is discharged into the under floor avionics equipment bay

• “DISPLAY COOL” caution – Low airflow in cockpit display duct

• “ARINC COOL” caution – Low airflow in ARINC chassis supply duct

• On the ground – Vent cooling exhaust overboard

• In the air – Cooling exhaust dumped through inboard exhaust shutoff valve to the aft under

floor area and expelled through the outflow valves

CARGO COMPARTMENT

• Fans provide ventilation and temperature control

FAN POSITIONS

• FAN – Provides recirculation of cabin exhaust air and heater is NOT energized

• OFF – Fan and heater are OFF

• COND AIR – Provides mix of cabin exhaust air and fresh conditioned air. Heater is energized.

PRESSURIZATION

• Dual CABIN PRESSURE CONTROLLERS

–– Independent operation (If both FAIL – ISOBARIC hold mode)

–– One operates at all times (If 1 fails – automatic switchover should occur)

–– Pre-pressurizes to -150’ on takeoff

–– Equalizes cabin for ground operation

–– Limits climb and descent rates

–– AUTO ELECTRO-PNEUMATIC OPERATION

–– To SWITCH CONTROLLERS, PUSH SWITCH TWICE (Sequence PRESS CONT

1 -> MANUAL -> PRESS CONT 2 -> MANUAL -> PRESS CONT1) OR LAND

ONCE (Switches after 3 minutes W-ON-W)

• Dual OUTFLOW VALVES

–– Electrically controlled and pneumatically operated

–– Outflow regulates cabin pressure

–– Cabin altitude limiter – 14,250’ ± 750’

–– Max Diff – 8.7 psi

–– AUTO MODE

• Responds to ELECTRICAL SIGNALS from pressure controller

• Left is MASTER – Right is SLAVE

–– MANUAL MODE

• Respond to pneumatic inputs via manual regulators

Copyright © 2009 www.flycrj.com PAGE 67

The CRJ200 Quicknotes Study Guide

• Right is MASTER – Left is SLAVE

• Cabin Pressure Acquisition Module (CPAM)

–– Monitors information from cabin pressure controllers (CPC)

–– Displays pressurization information on EICAS

–– 8,500’ cabin altitude - CABIN ALT caution message

–– 10,000’ cabin altitude - CABIN ALT warning message and an aural alert “CABIN

PRESSURE”

–– 14,000’ ± 500’ - AUTO deployment of Oxygen masks if cabin altitude reaches

–– 10,000’ – if SEAT BELT sign is selected to AUTO, the NO SMOKING/FASTEN SEAT

BELT sign is illuminated

–– CPAM FAILURE

• Standby controller will assume CPAM duties of communicating with DCU

• LOSE AUTO DEPLOYMENT OF OXYGEN MASKS AND NO SMK/SEAT

BELT SIGN ILLUMINATION

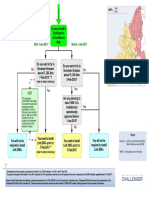

• Pressurization Control And Modes

–– Pressurization Control Switchlight

• FAULT – ILLUMINATES WHEN THERE IS A FAILURE IN BOTH

PRESSURE CONTROLLERS

• MAN – PRESSED ONCE TO SELECT MANUAL MODE

–– Automatic Modes Of Operation

• GROUND – Outflow valves commanded FULLY OPEN

• PRE-PRESSURIZATION – Outflow valves close to pressurize the cabin to -150’ on

takeoff

• T/O ABORT – TL retarded – Returns to field elevation at 500 fpm then fully opens

• FLIGHT ABORT – The logic criterion for flight abort is:

1. Descent of 1000’ within 10 minutes of take-off and/or

2. Aircraft did not reach flight elevation 6000’ above take-off field before descent

• CLIMB – Typically limited to 500 fpm but will vary slightly with rate of climb and

landing elevation

• CRUISE – Assigned cruise altitude – when reached – descent mode armed

• DESCENT – Typically 300 fpm until 150’ below landing field elevation but may vary

if descent rate high

• LANDING – W-ON-W – Cabin climbs at 500 fpm to field elevation then outflow

valves fully open

• TOUCH-AND-GO – LANDING MODE to PRE-PRESSURIZTION MODE

–– NEVER USE MANUAL UNLESS QRH DIRECTS YOU TO

MANUAL MODE

• Information shown on ECS pages, PRI pages, and STATUS pages

• TO INCREASE CABIN ALTITUDE – MUST DECREASE CABIN PRESSURE (LET

Copyright © 2009 www.flycrj.com PAGE 68

The CRJ200 Quicknotes Study Guide

AIR OUT – CABIN CLIMBS)

• TO DECREASE CABIN ALTITUDE – MUST INCREASE CABIN PRESSURE

(FORCE AIR IN – CABIN DESCENDS)

• Two (2) vacuum lines directly connect MAN ALT and MAN RATE knobs to OUTFLOW

VALVES

• Pilots are manually metering amount of vacuum pressure applied to the outflow valves

• Rates are 50 fpm ⇒ 3000 fpm ± 1000 fpm

CRJ700 SYSTEM DIFFERENCES

• The CRJ700 uses re-circulated air in addition to conditioned air for air-conditioning

• Air Conditioning System Controllers (ACSC) are used instead of temperature controllers

• The ACSC monitors bleed duct pressure and bleed requirements to determine the suitable

engine bleed source

–– Normally the 6th-stage bleed air supplies the manifold

–– If N2 rpm is low or pneumatic demand is high the 10th stage bleed air supplies the

manifold

• High Pressure Valve (HPV) opens

• ECS synoptic page displays actual and selected cockpit and passenger cabin temperatures

• Single pack operations to max FL310 vs. FL250

• Aft Cargo Bay Conditioned Air - No electric fan

• Single, common bleed air system for ECS and Anti-ice

• Engine bleeds:

–– 6th or 10th stage bleeds vs. 10th and 14th

–– Pressure-regulated to 45 ± 3 psi

–– When the engines are the source of bleed air - no synoptic page indication identifies which

compressor bleed port is supplying bleed air

• Engine bleed valves (same valves depicted on ECS and Anti-Ice synoptic pages)

–– Pressure-Regulating shutoff valves (PRSOV)

–– Regulates engine bleed air pressure to 45 ± 3 psi

–– Commanded open or closed by the associated ACSC

–– Selectable at the BLEED AIR control panel

–– Electro-pneumatic - (Fail safe closed)

• Bleed Air selection is automatically controlled by the ACSC’s in AUTO mode

• Manual selection is available at the BLEED AIR control panel

• Bleed Switching - AUTOMATIC

–– On ground, when APU rpm stabilized:

• ACSC communicates with the APU ECU to open the APU LCV

• When APU LCV opens, the ACSC opens the ISOL valve to allow APU to supply

both sides of the common manifold

• On the ground, APU LCV has bleed priority over the engines

–– Climb Thrust/After T/O Check

Copyright © 2009 www.flycrj.com PAGE 69

The CRJ200 Quicknotes Study Guide

• Transfer of bleeds from APU to engines happens when all of the following conditions

are met:

–– Landing gear is up

–– Flaps are equal to or less than 200

–– Thrust levers are retarded from the takeoff detent

–– Bleed transfer takes approximately 20 seconds to complete

–– Approach

• Transfer of bleeds from engines to APU happens automatically when the approach bit

is set:

–– Flaps are >20 or

–– Landing gear is down

• Bleeds – MANUAL MODE

–– Two step procedure

–– QRH directed

–– Preset the switches in the “box” - Select MANUAL

–– BLEED MISCONFIG caution message appears when:

• Bleed air panel switches are not configured properly

• Manual selected with both engines as the source and the ISOL valve open

• Manual selected with APU as the source and wing or cowls selected on

–– Message is to advise the pilot that the APU is not the normal source for anti-icing

–– If the APU is the bleed air source and wing anti-ice is selected ON:

• APU LCV remains open to provide air-conditioning and pressurization

• Wing anti-icing is not available - Wing anti-icing valves remain closed

• ISOLATION VALVE is displayed on the ECS and ANTI-ICE synoptic pages and is not

considered an anti-icing component

• APU LCV

–– In AUTO, ACSC commands the APU LCV closed when:

1. The engines are supplying the manifold

2. Either the wing and/or cowl or anti-ice is selected to ON

• Conditioned Air enters the cabin at the ceiling, sidewalls and PSU gaspers and exhausted at

floor level

• Air from the left RECIRC FAN ventilates the cargo bay when the intake and exhaust valves are

open

• If the left RECIRC FAN fails or is selected OFF, conditioned air from the mixing manifold is

fed to the aft cargo bay

• Forward cargo bay is not ventilated or air conditioned

• Two methods of cooling are provided to the EFIS and EICAS CRTs:

–– NORM mode:

• Ground fan is the primary source of filtered cooling air on ground

• Flight fan is the primary source of filtered cooling air in flight

–– Standby mode:

• Both fans are de-energized

Copyright © 2009 www.flycrj.com PAGE 70

The CRJ200 Quicknotes Study Guide

• Flight deck conditioned air is used for cooling

• Avionics bay equipment is cooled by ambient air

• Avionics exhaust fans are used to evacuate air from avionics bay, and CRT display exhaust duct

• 2 fans automatically controlled by W-ON-W or manually selected at control panel

• Ram Air Valve SOV provides ram air to the right side of mixing manifold

• Mixing manifold supplies ram air to both compartments

• Pressurization operates similar to the CRJ200 but uses different components

• CABIN PRESS Control Panel (CPCP) microprocessor replaces the CPAM and commands the

ground valve open after landing

• Ground valve is open during most phases of ground operations, closed when the passenger and

galley doors are closed, and assists in de-pressurizing the aircraft 60 seconds after landing

• Two cabin pressure controllers (same as CRJ200)

• One outflow valve with triple redundancy DC motors mounted on the aft pressure bulkhead

beneath the aft cargo bay floor

–– Two DC motors on the outflow valve respond to commands from the CPCs in AUTO

mode

–– One motor associated with each CPC

–– Same automatic switchover of CPC on landing

–– A third DC motor is used to electrically control the outflow valve in manual mode

–– Same manual mode procedures as the CRJ200 (QRH procedure)

• Two pneumatically operated safety valves provide over-pressure (8.6 ± 1 psid) and negative

pressure relief (-0.5 psid)

Copyright © 2009 www.flycrj.com PAGE 71

You might also like

- KA B200 - B200GT - 250 PL21 Pilot Training ManualDocument490 pagesKA B200 - B200GT - 250 PL21 Pilot Training ManualKarl Hering100% (2)

- B737 Question BankDocument111 pagesB737 Question BankMohit Bhartia98% (41)

- CAAB QB For ATR 72-500 Green Jul-18Document43 pagesCAAB QB For ATR 72-500 Green Jul-18কবীরবিপু75% (4)

- B737 Question BankDocument111 pagesB737 Question BankFathan Hiliry100% (4)

- B777 Quick ReferenceDocument76 pagesB777 Quick ReferenceDang Xuan Tien94% (32)

- Citation Mustang Pilot Training ManualDocument457 pagesCitation Mustang Pilot Training ManualGerman Rebollar100% (4)

- B747-400 Quick Study Review PDFDocument39 pagesB747-400 Quick Study Review PDFnzcruiser100% (3)

- B747-400 Quick Study Review PDFDocument39 pagesB747-400 Quick Study Review PDFnzcruiser100% (3)

- Smart Cockpit System Questions - FlattenedDocument85 pagesSmart Cockpit System Questions - FlattenedBarut Brkk100% (4)

- B737ng Systems Question BankDocument121 pagesB737ng Systems Question Banksebastien80% (10)

- B737-Pneumatic Systems SummaryDocument5 pagesB737-Pneumatic Systems SummaryEtienne Gerber100% (2)

- B767 Air ConditioningDocument5 pagesB767 Air ConditioningGustavo Avila Rodriguez67% (3)

- Bombardier CRJ 200-Environmental Control System PDFDocument39 pagesBombardier CRJ 200-Environmental Control System PDFmamon113No ratings yet

- Hydraulics A320Document101 pagesHydraulics A320KamalVirk100% (7)

- Flight Controls ReviewDocument8 pagesFlight Controls ReviewromixrayzenNo ratings yet

- SkySim MD11 FLTTECHDocument34 pagesSkySim MD11 FLTTECHMarco Lima100% (1)

- Gulfstream III: Operating HandbookDocument148 pagesGulfstream III: Operating HandbookSantiago Hidalgo100% (2)

- Phenom300 QuestionBankDocument18 pagesPhenom300 QuestionBankPaul Kostukovsky100% (2)

- Pratt & Whitney JT8DDocument41 pagesPratt & Whitney JT8DJhon 117100% (5)

- A320 Family Notes 1Document103 pagesA320 Family Notes 1antynccbzersdrodiz100% (1)

- B767 Equipment CoolingDocument3 pagesB767 Equipment CoolingGustavo Avila Rodriguez0% (1)

- A320 Limitations & QuestionsDocument15 pagesA320 Limitations & Questionsbrent everittNo ratings yet

- B777 Air SystemsDocument0 pagesB777 Air SystemsJOUO20009167No ratings yet

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- Airbus 320 Lights and SwitchesDocument1,320 pagesAirbus 320 Lights and SwitchesUros Miladinovic100% (1)

- Auxiliary Power Unit (Apu) Systems ReviewDocument5 pagesAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)

- B767 PneumaticsDocument6 pagesB767 PneumaticsGustavo Avila Rodriguez100% (5)

- 36 PneumaticDocument6 pages36 PneumaticĐoàn Hồng NgọcNo ratings yet

- Phase 4 (1 MAC 22)Document4 pagesPhase 4 (1 MAC 22)AzurianiNo ratings yet

- Ata 21 Air ConditioningDocument9 pagesAta 21 Air Conditioninggreatest everNo ratings yet

- ARMS Handout NG To MAX Rev 01Document46 pagesARMS Handout NG To MAX Rev 01swayam1495No ratings yet

- 2.air SystemsDocument14 pages2.air Systemsshameem aktharNo ratings yet

- ATA 21 AirCon Day 2Document10 pagesATA 21 AirCon Day 2Muhammed YaseenNo ratings yet

- 36 - TopicsDocument14 pages36 - TopicsMohamad MagdyNo ratings yet

- Mil Mi-8 Startup Manual and ChecklistDocument13 pagesMil Mi-8 Startup Manual and ChecklistOscar Alfonso100% (2)

- Boeing 777: Your Result Is 78%. You The Test!Document5 pagesBoeing 777: Your Result Is 78%. You The Test!Wasim AkhterNo ratings yet

- B737-800 PneumaticsDocument5 pagesB737-800 PneumaticsReynaldo100% (2)

- Air - Pneumatic, Air Conditioning, PressurizationDocument8 pagesAir - Pneumatic, Air Conditioning, Pressurizationamasis66No ratings yet

- Ata 36Document11 pagesAta 36jontis jasoliyaNo ratings yet

- Cessna 182 Pilots Operating Handbook (1966)Document31 pagesCessna 182 Pilots Operating Handbook (1966)Gustavo Adolfo Términe100% (1)

- VP-9 2P Study Bible: "Rick James" VersionDocument8 pagesVP-9 2P Study Bible: "Rick James" VersionpepeNo ratings yet

- Acf DifferencesDocument71 pagesAcf DifferencesMorrisNo ratings yet

- خلاصه ارباس ٣٢٠Document23 pagesخلاصه ارباس ٣٢٠Reza MaserratNo ratings yet

- Teaching PPDocument3 pagesTeaching PPH LATKNo ratings yet

- Atr72 Air PDFDocument34 pagesAtr72 Air PDFEhsan Ul HaqueNo ratings yet

- B737NG Air SystemsDocument10 pagesB737NG Air SystemsMohamood Salman SiddiquiNo ratings yet

- Pneumatics Exam Part 2Document1 pagePneumatics Exam Part 2Amiel Simon AureNo ratings yet

- On The GroundDocument3 pagesOn The Groundroyalairmaroc737No ratings yet

- AIRCO QuizDocument6 pagesAIRCO Quizluc madou0% (1)

- Dornier 328jet PneumaticDocument14 pagesDornier 328jet PneumaticEmily Armstrong100% (1)

- Cl605 PneumaticDocument12 pagesCl605 PneumaticMirko Novakovic100% (1)

- Section 3 (Emergency Procedures)Document75 pagesSection 3 (Emergency Procedures)Jung SunhoNo ratings yet

- 06 Abnormal Procedures 737 678900 v14Document17 pages06 Abnormal Procedures 737 678900 v14JavierNo ratings yet

- Pneumatic System: IsolationDocument6 pagesPneumatic System: IsolationGirish SreeneebusNo ratings yet

- Dc9 Normal Checklist, Expanded.: Obs - Only For Flightsim - ObsDocument26 pagesDc9 Normal Checklist, Expanded.: Obs - Only For Flightsim - ObsRichard LundNo ratings yet

- Q400 Presentation - APUDocument9 pagesQ400 Presentation - APUTom100% (1)

- MD90 Differences ResumenDocument8 pagesMD90 Differences ResumenSamuli SutinenNo ratings yet

- B1900 NOTES Page 21-40Document20 pagesB1900 NOTES Page 21-40Hayden CourtneyNo ratings yet

- Notes About A320 FCTM by Iman Jafarian and MJ - AzadiDocument47 pagesNotes About A320 FCTM by Iman Jafarian and MJ - Azadimohammad javad AzadiNo ratings yet

- Normal Procedures c172Document5 pagesNormal Procedures c172Vinicius LinsNo ratings yet

- AUTO FAIL or Unscheduled Pressurization ChangeDocument10 pagesAUTO FAIL or Unscheduled Pressurization ChangeДамир УзенбаевNo ratings yet

- Construction of The Ai-9V EngineDocument8 pagesConstruction of The Ai-9V EngineYosif NorendoNo ratings yet

- DC6 NORMAL PROCEDURES For PMDGDocument8 pagesDC6 NORMAL PROCEDURES For PMDGGilberto FonsecaNo ratings yet

- Ice and Rain CH 30: Training Manual B767-3S2F CH 30-00Document39 pagesIce and Rain CH 30: Training Manual B767-3S2F CH 30-00Elijah Paul Merto100% (3)

- Systems Atpl PDFDocument111 pagesSystems Atpl PDFMay Be100% (1)

- Air Conditioning and Pressurisation 1Document147 pagesAir Conditioning and Pressurisation 1Ricardo Jose Navarro Pacheco100% (1)

- Ata 28Document6 pagesAta 28phonesavanh.dod1989No ratings yet

- 737 Air Systems SummaryDocument10 pages737 Air Systems SummaryAhmed RefNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- MC 10230573 0001Document27 pagesMC 10230573 0001romixrayzenNo ratings yet

- MC 10214482 0001Document8 pagesMC 10214482 0001romixrayzenNo ratings yet

- 05 Диагностика неисправностейDocument12 pages05 Диагностика неисправностейromixrayzenNo ratings yet

- Link2000 DecisionTree 2012 12bDocument1 pageLink2000 DecisionTree 2012 12bromixrayzenNo ratings yet

- SA3644SWDocument2 pagesSA3644SWromixrayzenNo ratings yet

- Active Service Bulletins With Instructions For Continued AirworthinessDocument1 pageActive Service Bulletins With Instructions For Continued AirworthinessromixrayzenNo ratings yet

- Data Link Services Workshop Brussels 17june2014Document47 pagesData Link Services Workshop Brussels 17june2014romixrayzenNo ratings yet

- 02 Техническое описаниеDocument20 pages02 Техническое описаниеromixrayzenNo ratings yet

- AW600 23 2387 - Rev4Document7 pagesAW600 23 2387 - Rev4romixrayzenNo ratings yet

- csp-023 I0r0Document18 pagescsp-023 I0r0romixrayzenNo ratings yet

- csp-015 I0r0Document20 pagescsp-015 I0r0romixrayzenNo ratings yet

- Landing Gear and Brakes ReviewDocument8 pagesLanding Gear and Brakes ReviewromixrayzenNo ratings yet

- Flight Instruments Review: Pitot-Static SystemDocument5 pagesFlight Instruments Review: Pitot-Static SystemromixrayzenNo ratings yet

- Auxiliary Power Unit (Apu) Systems ReviewDocument5 pagesAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)

- Fire Protection Review: Fire Detection and ExtinguishingDocument7 pagesFire Protection Review: Fire Detection and ExtinguishingromixrayzenNo ratings yet

- Fdap P13 PDFDocument52 pagesFdap P13 PDFiespartaNo ratings yet

- 49 Apu PDFDocument68 pages49 Apu PDFAaron Harvey50% (2)

- Helicopter Division, BangaloreDocument1 pageHelicopter Division, Bangaloregoten25No ratings yet

- Chapter 49 Part 1Document11 pagesChapter 49 Part 1Frank JansenNo ratings yet

- Airbus Prologue ManualDocument98 pagesAirbus Prologue Manualdannyells_danielsNo ratings yet

- B737CL Fire ProtectionDocument17 pagesB737CL Fire ProtectionDan StroescuNo ratings yet

- AIRBUS A318/A319: Systems GuideDocument67 pagesAIRBUS A318/A319: Systems GuideJavier Pérez DelgadoNo ratings yet

- EP3EDocument25 pagesEP3Edagger21100% (1)

- Airbus A320 Overhead Panel PresentationDocument10 pagesAirbus A320 Overhead Panel PresentationSurya Oka Setyawan67% (3)

- Airbus ATA36Document56 pagesAirbus ATA36phonesavanh.dod1989No ratings yet

- Flysimware's FALCON 50 MANUAL V2.2Document46 pagesFlysimware's FALCON 50 MANUAL V2.2Leonardo SantanaNo ratings yet

- 737 Check ListDocument7 pages737 Check ListGuillermo Pinzón AmayaNo ratings yet

- B 737 - CL - Ata 38 - B1.1Document47 pagesB 737 - CL - Ata 38 - B1.1Vasili RafaelyanNo ratings yet

- 12 Ice RainDocument10 pages12 Ice RainBlueSkyMaster100% (2)

- B737-200 L3 ATA 21 Air ConditioningDocument230 pagesB737-200 L3 ATA 21 Air ConditioningBelisario Sergio Llacchas rodasNo ratings yet

- 407 Crov CH21Document106 pages407 Crov CH21edsel jose diaz sarmientoNo ratings yet

- ATA 44 - Cabin Systems (Mike Tooley)Document17 pagesATA 44 - Cabin Systems (Mike Tooley)Anees Ek100% (1)

- PDF N Fcom Gia TF N Eu 20121113 DSC 21Document116 pagesPDF N Fcom Gia TF N Eu 20121113 DSC 21Nigel AmartaNo ratings yet

- Aircraft Anti-Icing Systems: Presented byDocument13 pagesAircraft Anti-Icing Systems: Presented bynandheswaraNo ratings yet

- Bae - e Sil - 21 146 RJ 536 1Document27 pagesBae - e Sil - 21 146 RJ 536 1alpenadler100% (2)