Professional Documents

Culture Documents

Presentation Preheater Fan Selection

Presentation Preheater Fan Selection

Uploaded by

lightsonsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presentation Preheater Fan Selection

Presentation Preheater Fan Selection

Uploaded by

lightsonsCopyright:

Available Formats

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

General parameters Installation conditions

Inlet Density (section Inlet pressure Static

Fluid density

0) Ducted inlet Yes

Tolerance class Class 1 Inlet box Yes

Volume at actual Fluid velocity at inlet 20.0 m/s

Flow units

conditions

Outlet pressure Static

Dust concentration at

Dust concentration units Ducted outlet Yes

actual conditions

Outlet pelican diffuser No

Outlet diffuser Yes

Diffuser velocity at max. flow 20.0 m/s

Performance control Speed

Loads description

Design temperature 400.0 °C

Heat coefficient ratio 1.4

Design load number 1

Fan elevation 430 m

Load number 1 2

Designation Design Operating

Inlet flow 186.40 m3/s 153.20 m3/s

Inlet density 0.602 kg/m3 0.615 kg/m3

Inlet temperature 292.0 °C 292.0 °C

Inlet pressure -7,110 Pa -5,100 Pa

Outlet pressure -200 Pa -200 Pa

Inlet dust rate 37.00 g/m3 38.00 g/m3

Version: 1.7.5 Page 1/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Aerodynamic preselection

Impeller width Double

Rotating speed (1) 970 tr/min

Rotating speed (2) 960 tr/min

Groups

Backward curves blades

Version: 1.7.5 Page 2/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Aerodynamic computation Air performance results

Aerodynamic family number 96 Aerodynamic family HF 5S TDR

Impeller type Shortened Blade type curved

Nominal fan size 3,120.0 mm Impeller type double inlet

Rotating speed of the fan 960 tr/min Calculated size 3,120.0 mm

Casing Standard Delta coefficient at the best efficiency

0.466

for the design load

Minimum delta coefficient for

running in parallele for the design 0.275

load

Maximum fan efficiency for the design

83.4 %

load

Calculated impeller diameter 2,880.0 mm

Pressure at no flow and 20 °C 14,098 Pa

Absorbed power at no flow and 20

1,022 kW

°C

Maximum tip speed at operating

160.2 m/s

temperature

Calculated tip speed 144.8 m/s

Computed area at inlet box 6.8620 m2

Computed area at inlet cone 8.3716 m2

Computed area at casing outlet 3.3189 m2

Mesured area at section 0 0.0000 m2

Mesured area at section 1 0.0000 m2

Mesured area at section 2 0.0000 m2

Mesured area at section 3 0.0000 m2

Length of oulet diffuser 4,957.9 mm

Outlet area of outlet diffuser 8.8728 m2

Inlet area of connecting piece 9.3200 m2

Outlet area of inlet connection piece 6.8620 m2

Length of inlet connection piece 423.4 mm

Version: 1.7.5 Page 3/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Air performance results for each load

Version: 1.7.5 Page 4/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Load 1 2

Total pressure at system inlet -6,990 Pa -5,017 Pa

Total pressure at fan inlet -6,997 Pa -5,022 Pa

Total pressure at fan outlet 142 Pa 39 Pa

Total pressure at system outlet -73 Pa -111 Pa

Static pressure at system inlet -7,110 Pa -5,100 Pa

Static pressure at fan inlet -7,219 Pa -5,175 Pa

Static pressure at fan outlet -766 Pa -595 Pa

Static pressure at system outlet -200 Pa -200 Pa

Dynamic pressure at system inlet 120 Pa 83 Pa

Dynamic pressure at fan inlet 222 Pa 153 Pa

Dynamic pressure at fan outlet 908 Pa 635 Pa

Dynamic pressure system outlet 126 Pa 89 Pa

Volumic flow at system inlet 186.40 m3/s 153.20 m3/s

Volumic flow at fan inlet 186.56 m3/s 153.29 m3/s

Volumic flow at fan outlet 178.21 m3/s 148.44 m3/s

Volumic flow at system outlet 177.46 m3/s 148.00 m3/s

Density at system inlet 0.602 kg/m3 0.615 kg/m3

Density at fan inlet 0.601 kg/m3 0.615 kg/m3

Density at fan outlet 0.630 kg/m3 0.635 kg/m3

Density at system outlet 0.632 kg/m3 0.637 kg/m3

Temperature at fan outlet 305.5 °C 301.5 °C

Calculated pressure 7,139 Pa 5,061 Pa

Average volumetric flow 182.29 m3/s 150.83 m3/s

Mass flow 112.21 kg/s 94.22 kg/s

Average density 0.616 kg/m3 0.625 kg/m3

Absorbed power at operating temperature 1,570 kW 920 kW

Absorbed power at 20°C 3,028 kW 1,774 kW

Absorbed power at at operating temperature including dust load 1,665 kW 976 kW

Fan efficiency 82.9 % 83.0 %

Static fan efficiency 72.3 % 72.5 %

Delta coefficient at the operating point 0.517 0.513

Mu coefficient at the operating point 0.553 0.556

Tau coefficient at the operating point 0.345 0.344

Minimum delta coefficient 0.25 0.25

Maximum delta coefficient 0.846 0.846

Calculated speed 960 tr/min 801 tr/min

Calculated speed for basic size 886 tr/min 739 tr/min

Inlet regulation device angle 90.0 ° 90.0 °

Loss at inlet connection piece 7 Pa 5 Pa

Outlet diffuser pressure loss 215 Pa 151 Pa

Tolerance on flow ±2.5% 0%

Tolerance on pressure ±2.5% 0%

Tolerance on power +3% +2%

Tolerance on efficiency -2% -2%

Version: 1.7.5 Page 5/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

kW

2,000 90

1

Absorbed power with dust

1,500

90

1,000 2

500

0

0 50 100 150 200 250

m3/s

System inlet flow

Pa

8,000

Difference in system static pressures

7,000 1

6,000

5,000 2

4,000

3,000

2,000

90

90

1,000

0

0 50 100 150 200 250

m3/s

System inlet flow

Curves correspond to the following conditions at inlet

Specific weight 0.602 kg/m3

Temperature 292.0 °C

Static pressure -7,110 Pa

Version: 1.7.5 Page 6/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Sound

Inlet spectrum results

Spectrum analysis (Hz) dB(lin)

Spectrum description Global (dBA) 63 125 250 500 1000 2000 4000 8000

PWL at inlet 115 111 115 115 112 110 107 103 98

Outlet spectrum results

Spectrum analysis (Hz) dB(lin)

Spectrum description Global (dBA) 63 125 250 500 1000 2000 4000 8000

PWL in duct at outlet 119 124 124 122 116 115 104 99 89

Casing noise

Calculation according to NFS 31-021 Lpc

Distance between the measurement point and the reference surface: d 1,000.0 mm

Casing insulation

Attenuation levels Technicaldatabase

Type of Casing insulation A

Casing insulation thickness in mm unit 150

Type A: Ordinary thermal insulation

Casing acoustic results

Inlet and outlet ducted

Version: 1.7.5 Page 7/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Spectrum analysis (Hz) dB(lin)

Global

Spectrum description 63 125 250 500 1000 2000 4000 8000

(dBA)

PWL casing 110 108 110 110 107 105 102 97 91

SPL casing (NFS 31.021) without acoustic

90 87 89 89 86 84 81 76 70

insulation

PWL casing with acoustic insulation 98 101 104 103 94 88 82 79 73

SPL casing (NFS 31.021) with acoustic

77 80 83 82 73 67 61 58 52

insulation

Version: 1.7.5 Page 8/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

S 355 JOWP / S 355

Material group

K2G3 / S 690 QL 1

Overspeed at design temperature 990 tr/min

Wear liners on impeller Yes

Without hard

Type of the wear liners

surfacing

Wear liners on blades 25%

basic sheet material S 690 QL 1

basic sheet thickness 5.0 mm

Specified continuous operating

400.0 °C

temperature

Casual maximum temperature 450.0 °C

Operation time (% of full operation

2.0 %

time) 3TD8A

Impellers preselection results

Selected solution 111

Solution number 111 112 113 122 123

Blades with Blades with Blades with Blades with Blades with

Type of the blade welded welded welded welded welded

reinforcement reinforcement reinforcement reinforcement reinforcement

Material of the blade S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 10.0 mm 10.0 mm 10.0 mm 10.0 mm 10.0 mm

Thickness n°2 20.0 mm 20.0 mm 20.0 mm 20.0 mm 20.0 mm

28.32 28.32 28.32 28.32 28.32

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

25% without 25% without 25% without 25% without 25% without

Protection blades with wear liners hard hard hard hard hard

surfacing surfacing surfacing surfacing surfacing

Blades mass 736 kg 736 kg 736 kg 736 kg 736 kg

Type of the shroud One thickness One thickness One thickness One thickness One thickness

Material of the shroud S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 15.0 mm 15.0 mm 15.0 mm 20.0 mm 20.0 mm

20.51 20.51 20.51 19.25 19.25

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

Shroud stiffener Nothing Nothing Nothing Nothing Nothing

Shroud mass 1,453 kg 1,453 kg 1,453 kg 1,938 kg 1,938 kg

Backplate type Bolted Bolted Bolted Bolted Bolted

Material of the backplate S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 25.0 mm 30.0 mm 35.0 mm 30.0 mm 35.0 mm

21.54 20.36 19.51 20.36 19.51

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

Version: 1.7.5 Page 9/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

28.91 28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

Estimated bolting diameter 1,120.0 mm 1,030.0 mm 950.0 mm 1,060.0 mm 970.0 mm

Backplate mass 1,114 kg 1,337 kg 1,560 kg 1,337 kg 1,560 kg

Welding class C C C C C

Impeller mass 3,487 kg 3,710 kg 3,933 kg 4,195 kg 4,417 kg

Solution number 133 211 212 213 223

Blades with Blades with Blades with Blades with Blades with

Type of the blade welded welded welded welded welded

reinforcement reinforcement reinforcement reinforcement reinforcement

Material of the blade S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 10.0 mm 12.0 mm 12.0 mm 12.0 mm 12.0 mm

Thickness n°2 20.0 mm 16.0 mm 16.0 mm 16.0 mm 16.0 mm

28.32 28.44 28.44 28.44 28.44

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

25% without 25% without 25% without 25% without 25% without

Protection blades with wear liners hard hard hard hard hard

surfacing surfacing surfacing surfacing surfacing

Blades mass 736 kg 785 kg 785 kg 785 kg 785 kg

Type of the shroud One thickness One thickness One thickness One thickness One thickness

Material of the shroud S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 25.0 mm 15.0 mm 15.0 mm 15.0 mm 20.0 mm

18.49 21.44 21.44 21.44 19.94

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

Shroud stiffener Nothing Nothing Nothing Nothing Nothing

Shroud mass 2,422 kg 1,453 kg 1,453 kg 1,453 kg 1,938 kg

Backplate type Bolted Bolted Bolted Bolted Bolted

Material of the backplate S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 35.0 mm 20.0 mm 25.0 mm 30.0 mm 30.0 mm

19.51 23.13 21.39 20.24 20.24

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2 daN/mm2

Estimated bolting diameter 990.0 mm 1,220.0 mm 1,120.0 mm 1,030.0 mm 1,060.0 mm

Backplate mass 1,560 kg 891 kg 1,114 kg 1,337 kg 1,337 kg

Welding class C C C C C

Impeller mass 4,902 kg 3,314 kg 3,536 kg 3,759 kg 4,244 kg

Version: 1.7.5 Page 10/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Solution number 311 312 313 323

Single Single Single Single

Type of the blade thickness thickness thickness thickness

Blades Blades Blades Blades

Material of the blade S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 15.0 mm 15.0 mm 15.0 mm 15.0 mm

Thickness n°2 0.0 mm 0.0 mm 0.0 mm 0.0 mm

25.19 25.19 25.19 25.19

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2

25% without 25% without 25% without 25% without

Protection blades with wear liners hard hard hard hard

surfacing surfacing surfacing surfacing

Blades mass 920 kg 920 kg 920 kg 920 kg

Type of the shroud One thickness One thickness One thickness One thickness

Material of the shroud S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 15.0 mm 15.0 mm 15.0 mm 20.0 mm

22.83 22.83 22.83 20.99

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2

Shroud stiffener Nothing Nothing Nothing Nothing

Shroud mass 1,453 kg 1,453 kg 1,453 kg 1,938 kg

Backplate type Bolted Bolted Bolted Bolted

Material of the backplate S 690 QL 1 S 690 QL 1 S 690 QL 1 S 690 QL 1

Thickness n°1 20.0 mm 25.0 mm 30.0 mm 30.0 mm

23.78 21.91 20.67 20.67

Calculated stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2

28.91 28.91 28.91 28.91

Allowed stress

daN/mm2 daN/mm2 daN/mm2 daN/mm2

Estimated bolting diameter 1,220.0 mm 1,130.0 mm 1,040.0 mm 1,060.0 mm

Backplate mass 891 kg 1,114 kg 1,337 kg 1,337 kg

Welding class C C C C

Impeller mass 3,449 kg 3,671 kg 3,894 kg 4,379 kg

Version: 1.7.5 Page 11/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Impeller + Hub Impeller + Hub results

Calculation conditions Blades

Rotation viewed from motor side Clockwise Material of blades S 690 QL 1

Motor power for calculation 1,831 kW Calculated stress in the blades 28.32 daN/mm2

Minimum welding class imposed A Allowable stress of the blade

28.91 daN/mm2

material

Impeller

Blade with welded Backplate

Type of the blades

reinforcement Material of the backplate S 690 QL 1

Thickness n°1 10.0 mm Cut out on disc Yes

Thickness n°2 20.0 mm Calculated stress in the backplate 22.66 daN/mm2

Backplate type Bolted Allowable stress of the backplate

28.91 daN/mm2

Thickness n°1 25.0 mm material

Shroud type Single thickness

Thickness n°1 12.0 mm Shroud

Thickness of the inlet ring 12.0 mm Material of the shroud S 690 QL 1

Struts Not required Calculated stress in the shroud 21.75 daN/mm2

Strengthening rings + struts Not required Allowed stress of the shroud material 28.91 daN/mm2

Thickness of the inlet ring or bulb 12.0 mm

Presence of shroud extension No

Impeller

Impeller welding class C

Mass of impeller without hub 3,056 kg

Center of gravity of impeller without

0.0 mm

hub

Inertia of impeller without hub 4,014.72 kg.m2

Paint area of impeller 50.1443 m2

Version: 1.7.5 Page 12/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Hub Hub

Fabricated hub material Automatic Hub type Fabricated

Shaft diameter in front of the hub 530.0 mm 25 CrMo 4 / 13 CrMo

Material of the hub

Imposed bolts number 44 4,5

Imposed number of bolting diameter Two External diameter of the hub 1,500.0 mm

Rotating speed lower Bolting diameter n°1 1,310.0 mm

Balancing can be performed at

than the nominal one Number of holes n°1 22

Diameter of holes n°1 48.0 mm

Bolting diameter n°2 1,120.0 mm

Number of holes n°2 22

Diameter of holes n°2 48.0 mm

Minimum tightening torque 4,308 N.m

Maximum tightening torque 4,350 N.m

42 CrMo4 (NFE

Bolts material

29043-10269)

Allowed stress for bolts 38.91 daN/mm2

Bolts length 160.0 mm

Weight 1,998 kg

Center of gravity of Hub -42.5 mm

Hub inertia 426.37 kg.m2

Aera to be lined 5.3092 m2

Impeller + Hub

Impeller + hub mass 5,054 kg

Impeller+hub center of gravity -16.8 mm

Impeller + hub inertia 4,441.09 kg.m2

Area to be painted on impeller+hub 55.4535 m2

Diametrical frequency / rotating

1.622

frequency

Umbrella frequency / rotating

8.256

frequency

Version: 1.7.5 Page 13/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Shaft + Bearings Shaft + Bearings results

Shaft Shaft

Shaft material Automatic Shaft type Stepped

Designation of shaft material 25 CrMo 4

Vibratory risk Shaft diameter at the impeller level 530.0 mm

Vibratory risk Automatic Shaft diameter at the bearings level 240.0 mm

Minimum required first critical speed Shaft diameter at driving level 200.0 mm

1.4

coefficient Bearing centerline distance 4,966.0 mm

Total shaft length 5,782.0 mm

Shaft mass 6,710 kg

Area to be lined 8.2686 m2

Minimum required first critical speed

1.4

coefficient

Calculated critical speed ratio 1.411

Cooling wheel

Cooling wheel Yes

Number of wheel 2

Designation tr nø 992/340

Material A S5UZ Y 20

Cooling impeller mass 20 kg

Seal

Technopal Cover

Shaft seal type plate (fitted on

springs)

Shaft seal width 48.0 mm

Bearings Bearings

Bearing type Roller Bearing housing designation sofn 248 t

Rolling bearing trademark SKF Bearing designation 22248 cc/w33-c3

Specified bearing housing trademark SKF Maximum speed for oil lubrication 1,320 tr/min

Bearing lubrication Oil Radial load on bearing 1 75,552 N

Type of bearing bore Cylindrical Radial load on bearing 2 86,595 N

Material of bearing housing Steel Calculated axial load 1,034 N

Minimum bearing life time 100 x1000 h Calculated free bearing life 798 x1000 h

Calculated bearing life 459 x1000 h

Bearing housing mass 485 kg

Total bearing mass 84 kg

Coupling/Transmissions Coupling/Transmissions

Imposed shaft end diameter for the Coupling designation RUPEX RWN 560

Automatic

motor Total mass coupling 300 kg

Version: 1.7.5 Page 14/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Drive type Rubber plots

Forced coupling trademark RUPEX RWN type

Tailor-made Shaft + Bearings

Forced minimun bearing nominal Total rotor mass 12,270 kg

200.0 mm

diameter Total rotor inertia (MR²) 4,634.62 kg.m2

Version: 1.7.5 Page 15/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Stator Stator results

Inlet Cone Inlet Cone

Inlet cone material Automatic Number of inlet cones 2

Split inlet cone No Inlet cone material S 235 JR G2

Inlet cone calculated thickness 6.0 mm

Reinforced inlet cone No

Extension on inlet throat Yes

Aera ti be lined of the inlet cone 29.0085 m2

Casing + Inlet Box Casing

Housing angle Unknown Calculated thickness of casing side

10.0 mm

Box orientation Unknown plate

Extrapressure (to be added to the Calculated thickness of casing scroll

0 Pa 8.0 mm

previous one) plate

Material of the casing Automatic Plate thickness of wear liners on

5.0 mm

casing scroll plate

Forced material of the casing stiffeners Automatic

Forced thickness of the insulation Automatic

Inlet Box

Scroll wearplate liners Yes

Inlet box exists Yes

Side plates liners No

Number of boxes 2

Calculated thickness of inlet box

10.0 mm

side plate

Calculated thickness of inlet box

10.0 mm

scroll plate

Stiffeners

Designation of casing stiffener

S 235 JR G2

material

Casing stiffening pitch 840.0 mm

Designation of casing stiffeners 150x150x15

Designation of casing stiffening flat

fer plat 120x15

bar

Casing + Inlet Box

Insulation thickness 100.0 mm

Casing + inlet box(es) width 3,850.0 mm

Fan height axis for an orientation

2,496.0 mm

equal to 0°

Designation of casing (+ inlet

S 235 JR G2

box(es)) plates material

Mass of casing (+ inlet box(es))

8,383 kg

plates

Total stiffener ring mass for Inlet

73 kg

cone(s)

Mass of fan inlet and outlet flanges 514 kg

Version: 1.7.5 Page 16/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Mass of casing split bars 1,263 kg

Total mass of stiffeners 3,042 kg

Mass of casing wear liners 1,125 kg

Total casing mass 14,399 kg

Total inlet cone(s) mass 567 kg

Internal area painted area of casing

105.4236 m2

(+ inlet box(es))

External area of casing (+ inlet

138.7094 m2

box(es))

Ground fixing Pedestal support

Method of mounting to foundation Isolator mounting Pedestal under bearing 1 code Separated pedestal

Motor fixed on an independant base Material of pedestal under bearing 1 S 235 JR G2

Yes

frame Pedestal mass n°1 597 kg

Area to be machined of the pedestal

0.4320 m2

n°1

Area to be painted for pedestal under

2.5735 m2

bearing 1

Pedestal under bearing 2 code Separated pedestal

Material of pedestal under bearing 2 S 235 JR G2

Pedestal mass n°2 597 kg

Area to be machined of the pedestal

0.4320 m2

n°2

Area to be painted for pedestal under

2.5735 m2

bearing 2

Whole area to be machined for

0.8640 m2

pedestal under bearing

Total mass of pedestal plates 1,193 kg

Base frame

Baseframe length 8,233.0 mm

Frame overall width 4,724.0 mm

Isolator mounting channel

UAP 300x100

designation

Material of baseframe S 235 JR G2

Total number of fixing bolts for frame 19

Fixing bolts diameter for fan to

30.0 mm

isolator mounting

Total number of anchor bolts for

70

isolator mounting to concrete

Anchor bolts diameter for isolator

27.0 mm

mounting to concrete

Frame total mass 1,589 kg

Area to be painted 33.5117 m2

Version: 1.7.5 Page 17/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Control Control results

Inlet control Inlet damper

Inlet control device Inlet damper Number of inlet dampers 2

forced material of damper Automatic Designation of inlet damper material S 235 JR G2

Number of blades 8

Resisting torque to operate one inlet

1,966 N.m

damper

Operating force for one inlet damper 13,904 N

Mass of one inlet damper 1,520 kg

Internal area to be lined for one inlet

15.7178 m2

damper

External area to be lined for one inlet

11.4958 m2

damper

Inlet actuator

Mounting type Throttle-rod

Fan results

Fan

Fan total mass 34,047 kg

Diffusor results

Material S 235 JR G2

Thickness 8.0 mm

Area to be lined 133.9004 m2

Mass 5,158 kg

Version: 1.7.5 Page 18/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Motor Motor results

Motor

Motor mass 8,700 kg

Version: 1.7.5 Page 19/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Technical limits

The calculated number of bolts is greater than the maximum allowed number

Shaft diameter is too big with regards to inlet throat diameter

Fabricated hub flange is not manufactured from standard sheets

A shrink fit assembly is required between hub and shaft - The shaft with integrated flange shoud be better

A shrink fit assembly, between hub and shaft, is compulsory (The shaft with integrated flange may be better)

In a case of variable speed driving, a tosional analysis is compulsory

Shaft diameter is too big with regards to inlet throat diameter

The bending critical speed ration is lower than 1.5

Fan designed with fitted bearing span taking into account the box orientation

Version: 1.7.5 Page 20/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

Technical conditions

Air performance

Inlet connecting piece : converging

Pressure losses are calculated at different loads with a pressure loss coefficient

The minimum required motor power at operating temperature is equal to 1831 kW taking into account the dust content

The motor must also take into account the gas temperature at starting and the starting time

The fan should be started with inlet vanes or dampers closed.

Sound

Tolerances : overall octive band +/- 3 dB, spectrum +/- 5 dB

The fan sound powers levels do not take into account the motor noise

The values of the acoustic pressures levels do not take into account the external emissions (background noise already

existing where the fan is located, local reflection)

The calculated sound pressures levels according NFS 31-021 do not take into account the motor noise

Impeller + Hub

Welding according standards NF EN 288-3 and ASME section 9

Welders qualification according standards NF EN 287-1 and 2 and ASME section 9

Unless otherwise specified, the rotor is designed for continuous operation or cyclic operation with a maximum of 5000

starts

For a fan operating at variable speed, the number of large amplitude speed variations (greater or equal to 50% of

maximum speed)is limited to 5000

The rotor balancing is performed according standard ISO DIN 1940-1 quality 6.3

Blade stress calculation is done assuming a welded blade reinforcement on backplate side, with a thickness equal to the

blade thickness, and a width equal to 20% of the blade width. Any deviation from this technology must be analysed.

Shaft + Bearings + Stator

The coupling saftey factor is equal to 1.5 (ratio maximum design torque to motor torque at operating speed)

The coupling is designed for continuous operation with a variable speed motor. The harmonic torques of the driving

device must be reduced to minimum values

The brands and designations of some composents (bearings, couplings, actuators, etc) are given for reference only and

may be changed at the final design stage

Unless otherwise specified in the offer, pelican or other types of diffusors are not included in the scope of supply

Version: 1.7.5 Page 21/22 Printed by: Subramany

For internal use only

Preheater Fan

M/s. Vasavadatta Cement Our ref.

Study ID: 25956 Report printed: Apr 2, 2005

FAN DESCRIPTION Type:HF 5S TDR Design temperature:400.9 °C Arrangement:3TD8A

Nominal diameter:3,120.0 mm Special diameter:2,880.0 mm Rotating nominal speed:960 tr/min Rotating maxi speed:990 tr/min

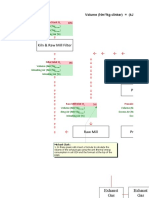

Arrangement 3TD8A

5,782

4,966

3,890

)

50

(5

844 2,162 844

6

24

4,

2,

06

5

)

(0

2

68

1,

53

5

1,

(0

)

655

1,

(300)

84

1

3,033 2,507 2,878 2,878

Not to scale drawing - Preliminary dimensions - Inlet and outlet position not fixed

Version: 1.7.5 Page 22/22 Printed by: Subramany

You might also like

- Chapter2 SolutionsDocument75 pagesChapter2 SolutionsHongyi Frank Liang86% (14)

- Fan Engineering Fundamentals PDFDocument34 pagesFan Engineering Fundamentals PDFKevin Malde100% (2)

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Kiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DDocument1 pageKiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DMohamed SelimNo ratings yet

- Comparison Chart Id Fan: New 25.1 Lacs EachDocument6 pagesComparison Chart Id Fan: New 25.1 Lacs EachJKKNo ratings yet

- Thermal Energy Management NewDocument39 pagesThermal Energy Management NewRamachandrarao MaddaliNo ratings yet

- Identification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsDocument13 pagesIdentification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsAngel CarvajalNo ratings yet

- Manual Testo-510Document7 pagesManual Testo-510roberto saenzNo ratings yet

- 007.heat Balance - New - 25072023hoDocument30 pages007.heat Balance - New - 25072023hoGauranka MoranNo ratings yet

- PH Fan Flow CalculationDocument2 pagesPH Fan Flow CalculationVisnu Sankar100% (1)

- Sieve Analysis GraphDocument6 pagesSieve Analysis GraphRoa Mae JulatonNo ratings yet

- Crash Stop Sample Raw MillDocument14 pagesCrash Stop Sample Raw MillAbhishekNo ratings yet

- Raw Mill (All Time in Hours) : Planed - Down Un - P - Down P - DT ReasonDocument4 pagesRaw Mill (All Time in Hours) : Planed - Down Un - P - Down P - DT ReasonMahla Raj KumarNo ratings yet

- Performance of Fans After at Various Plants: RetrofittingDocument19 pagesPerformance of Fans After at Various Plants: RetrofittingmkpqNo ratings yet

- Operational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionDocument6 pagesOperational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionJoshua JordanNo ratings yet

- Condition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Document6 pagesCondition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Shandi Hasnul FarizalNo ratings yet

- Fuel & Energy Comparison Between B/E & Air LiftDocument1 pageFuel & Energy Comparison Between B/E & Air LiftAbul Qasim QasimNo ratings yet

- Date Who Comments: File: Tromp Curve - Eng v3 DateDocument14 pagesDate Who Comments: File: Tromp Curve - Eng v3 DateThaigroup CementNo ratings yet

- Loss On Ignition (LOI) (CO2 From Calcination)Document5 pagesLoss On Ignition (LOI) (CO2 From Calcination)Tenzin WangchukNo ratings yet

- Specific Stoichiometric - Combustion Air CalculationDocument2 pagesSpecific Stoichiometric - Combustion Air CalculationVijay BhanNo ratings yet

- Tromp Curve v2Document4 pagesTromp Curve v2safwat hassanNo ratings yet

- L-2 Fans 21.11.11Document5 pagesL-2 Fans 21.11.11Aaron HortonNo ratings yet

- Burner AlignmentDocument1 pageBurner Alignmenthmaza shakeelNo ratings yet

- Chiller Comparative Technical ComparativeDocument5 pagesChiller Comparative Technical ComparativeShariq KhawajaNo ratings yet

- 1 - Gas Liquid Contact-HumidityDocument8 pages1 - Gas Liquid Contact-HumidityAriana ReligiosoNo ratings yet

- Alternative Fuel Requirements SolutionsDocument3 pagesAlternative Fuel Requirements SolutionsIrfan AhmedNo ratings yet

- How To Remove Scrap Materials From A Ball Mill CircuitDocument5 pagesHow To Remove Scrap Materials From A Ball Mill Circuitsafwat hassanNo ratings yet

- Mar-16 S.No. Date Time Reason Start Stop Stoppage: Cement Mill Downtime Analysis ReportDocument6 pagesMar-16 S.No. Date Time Reason Start Stop Stoppage: Cement Mill Downtime Analysis ReportVinod Kumar VermaNo ratings yet

- Clinker Cooler Queching Best PracticeDocument1 pageClinker Cooler Queching Best PracticeShukor AzNo ratings yet

- APTI413 PP Ch10Document69 pagesAPTI413 PP Ch10Stefanos DiamantisNo ratings yet

- EAU-1,19000 CFM at 75 MM StaticDocument1 pageEAU-1,19000 CFM at 75 MM StaticdesignhvacNo ratings yet

- Cross-Bar CoolerDocument8 pagesCross-Bar CoolernaikNo ratings yet

- Fuel Energy Euqivalence PDFDocument1 pageFuel Energy Euqivalence PDFruhul010% (1)

- AFR TT 2013 - Preliminary Program Rev 2Document1 pageAFR TT 2013 - Preliminary Program Rev 2Safrin SangiaNo ratings yet

- MAGOTTEAUX Power CALC 13.10.2015Document3 pagesMAGOTTEAUX Power CALC 13.10.2015Muhammad Arsalan TariqNo ratings yet

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- 2 - Polytrack Cooler HydDocument168 pages2 - Polytrack Cooler Hydruchikaporwal2018No ratings yet

- Kiln Inlet Section Casting Procedure LafargeDocument8 pagesKiln Inlet Section Casting Procedure LafargeKhaled BOUALINo ratings yet

- AFR Material Quality 18-Jul-2012Document2 pagesAFR Material Quality 18-Jul-2012Safrin SangiaNo ratings yet

- Finish Grinding Ball Mill Interlocks-V0.0Document5 pagesFinish Grinding Ball Mill Interlocks-V0.0Junaid MazharNo ratings yet

- Process Control IEEE Eml RDocument40 pagesProcess Control IEEE Eml RFran JimenezNo ratings yet

- 1-1 VRM Overview TableDocument1 page1-1 VRM Overview Tableniladri.jagatyNo ratings yet

- Instrumental Beer's Law Deviations: Linear Least-Squares Fit To Calibration CurveDocument11 pagesInstrumental Beer's Law Deviations: Linear Least-Squares Fit To Calibration CurveBùi Hắc Hải100% (1)

- COOLER MANUAL 2 (Process)Document112 pagesCOOLER MANUAL 2 (Process)YhaneNo ratings yet

- Fad Calculations: in CFM 180.9286Document1 pageFad Calculations: in CFM 180.9286Durjoy ChakrabortyNo ratings yet

- Physical VarificationDocument6 pagesPhysical VarificationSudheer NairNo ratings yet

- Fan Build Up ControlDocument2 pagesFan Build Up ControlSafrin SangiaNo ratings yet

- Pyro System - Control Loops V0.0Document2 pagesPyro System - Control Loops V0.0Junaid MazharNo ratings yet

- 3 SOP For Cleaning of Clinker Cooler DischargeDocument3 pages3 SOP For Cleaning of Clinker Cooler DischargekakaNo ratings yet

- Comparison of Bricks SpecificationsDocument1 pageComparison of Bricks SpecificationsSaji KumarNo ratings yet

- Pyroprocessing: Dr. Ari Diana SusantiDocument27 pagesPyroprocessing: Dr. Ari Diana SusantiTitan Titanovsky KoraagNo ratings yet

- Quality and Formulae 4Document1 pageQuality and Formulae 4zane truesdaleNo ratings yet

- Air Bean Clinker Cooler RDocument1 pageAir Bean Clinker Cooler RChe IsmailNo ratings yet

- Kristal / Mineral Sat Kode K1 K2 K3 K4Document13 pagesKristal / Mineral Sat Kode K1 K2 K3 K4TIRIANTONo ratings yet

- PR RFR P07-31 How To Perform TrialsDocument3 pagesPR RFR P07-31 How To Perform TrialsJuan Nacimba NacimbaNo ratings yet

- Flow Conversion To Normal Meter Cube Per HourDocument2 pagesFlow Conversion To Normal Meter Cube Per HourIrfan AhmedNo ratings yet

- Mills Circulating Load Limestone Blaine (CMB)Document11 pagesMills Circulating Load Limestone Blaine (CMB)Mohamed ZayedNo ratings yet

- High Air To Cloth Ratio Bag FilterDocument2 pagesHigh Air To Cloth Ratio Bag Filterayaskant751001No ratings yet

- Calculation For Boiler (Chan May)Document2 pagesCalculation For Boiler (Chan May)kaspersky2009No ratings yet

- HOD-P & QC Work BookDocument6 pagesHOD-P & QC Work BookvinodsnNo ratings yet

- Horno - QuemadorDocument13 pagesHorno - QuemadorRoberto Alanez EncinasNo ratings yet

- Installation Conditions: Fan DescriptionDocument6 pagesInstallation Conditions: Fan DescriptionkingNo ratings yet

- CBDD Standard Paint Spec (With SW Data)Document5 pagesCBDD Standard Paint Spec (With SW Data)lightsonsNo ratings yet

- CBDD Quality Control Check PlanDocument3 pagesCBDD Quality Control Check PlanlightsonsNo ratings yet

- CBDD QAQC Manual (Rev G-2010Document18 pagesCBDD QAQC Manual (Rev G-2010lightsonsNo ratings yet

- XXXXX - PCM - 001with BWE Contact DetailsDocument8 pagesXXXXX - PCM - 001with BWE Contact DetailslightsonsNo ratings yet

- Reverse OsmosisDocument37 pagesReverse OsmosislightsonsNo ratings yet

- Deliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00Document13 pagesDeliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00lightsonsNo ratings yet

- Selection PresentationDocument15 pagesSelection PresentationlightsonsNo ratings yet

- Role of Erection EngDocument15 pagesRole of Erection Englightsons100% (1)

- Piping Engineering NotesDocument46 pagesPiping Engineering Noteslightsons100% (1)

- Piping Design ConsiderationDocument46 pagesPiping Design ConsiderationlightsonsNo ratings yet

- Pipe BranchingsDocument12 pagesPipe BranchingslightsonsNo ratings yet

- 2097-1-G-G0-028 Air & Gas System - Rev 00Document15 pages2097-1-G-G0-028 Air & Gas System - Rev 00lightsonsNo ratings yet

- 2097-1-G-G0-030 - AH Wash.&fire Figh.Document9 pages2097-1-G-G0-030 - AH Wash.&fire Figh.lightsonsNo ratings yet

- 2097-1-G-G0-027 LDO and HFO System - Rev 00Document12 pages2097-1-G-G0-027 LDO and HFO System - Rev 00lightsonsNo ratings yet

- 2097-1-G-G0-034 COAL PREPARATION & FIRING SYSTEM - Rev 00Document15 pages2097-1-G-G0-034 COAL PREPARATION & FIRING SYSTEM - Rev 00lightsonsNo ratings yet

- 2097-1-G-G0-033 - Aux. Steam SystemDocument6 pages2097-1-G-G0-033 - Aux. Steam SystemlightsonsNo ratings yet

- Valve SpecificationDocument7 pagesValve SpecificationlightsonsNo ratings yet

- E - Rolling Bearing CagesDocument20 pagesE - Rolling Bearing CageslightsonsNo ratings yet

- Boiler High Pressure Chemical Dosing System Functional Description 2097-1-G-G0-031Document7 pagesBoiler High Pressure Chemical Dosing System Functional Description 2097-1-G-G0-031lightsonsNo ratings yet

- I - Fits and ToleranceDocument17 pagesI - Fits and TolerancelightsonsNo ratings yet

- G - Rolling Bearing LubricationDocument40 pagesG - Rolling Bearing Lubricationlightsons100% (1)

- F - Rolling Bearing Storage and HandlingDocument13 pagesF - Rolling Bearing Storage and HandlinglightsonsNo ratings yet

- Boiler Alkali BoiloutDocument5 pagesBoiler Alkali BoiloutlightsonsNo ratings yet

- Fuzzy LogicDocument29 pagesFuzzy LogiclightsonsNo ratings yet

- 2 X 30 MW Boiler For DPL (Unit 1 & 2) PpilDocument2 pages2 X 30 MW Boiler For DPL (Unit 1 & 2) PpillightsonsNo ratings yet

- Parametric Design of A Waste To Energy PDocument3 pagesParametric Design of A Waste To Energy PlightsonsNo ratings yet

- A Guide To The Design of An Effective Low Pressure VAV Air Distribution SystemDocument11 pagesA Guide To The Design of An Effective Low Pressure VAV Air Distribution SystemAbdul RaheemNo ratings yet

- 39 Space Air DistributionDocument25 pages39 Space Air DistributionPRASAD326100% (3)

- SAD Steam Atomising Desuperheater-Installation Maintenance ManualDocument20 pagesSAD Steam Atomising Desuperheater-Installation Maintenance ManualparykoochakNo ratings yet

- Square Cone Diffusers SCD / SCD As / Ascd Series: Performance Data - 12 X 12 / 300 X 300 Face SizeDocument2 pagesSquare Cone Diffusers SCD / SCD As / Ascd Series: Performance Data - 12 X 12 / 300 X 300 Face SizesuhasNo ratings yet

- Technical Specification of GrillsDocument1 pageTechnical Specification of GrillsmishtinilNo ratings yet

- University of Mauritius Faculty of Engineering Mechanical & Production Engineering DepartmentDocument5 pagesUniversity of Mauritius Faculty of Engineering Mechanical & Production Engineering DepartmenthansleyNo ratings yet

- Renewable Energy: F. Sorribes-Palmer, A. Sanz-Andres, L. Ayuso, R. Sant, S. FranchiniDocument14 pagesRenewable Energy: F. Sorribes-Palmer, A. Sanz-Andres, L. Ayuso, R. Sant, S. FranchiniNitesh Kumar PatelNo ratings yet

- 17 Velometer Series 6000 PDFDocument70 pages17 Velometer Series 6000 PDFCrawClawNo ratings yet

- High Air Flow Linear Slot Diffusers: Characteristics ApplicationsDocument58 pagesHigh Air Flow Linear Slot Diffusers: Characteristics ApplicationsMireille AttardNo ratings yet

- Diffuser DetailsDocument21 pagesDiffuser DetailsMuzaffar AlamNo ratings yet

- Diffuser (Thermodynamics) - Wikipedia PDFDocument9 pagesDiffuser (Thermodynamics) - Wikipedia PDFvarshaNo ratings yet

- Static Pressure FansDocument35 pagesStatic Pressure FansarifkhadeerNo ratings yet

- Halton Vario Solution Brochure 2014Document11 pagesHalton Vario Solution Brochure 2014Marko KorenićNo ratings yet

- VT BrochureV6-Aug17 PDFDocument83 pagesVT BrochureV6-Aug17 PDFResi Air OrdersNo ratings yet

- Head Loss Consideration in Ducts As Per ServicesDocument3 pagesHead Loss Consideration in Ducts As Per ServicesdasmechNo ratings yet

- RTI Titus CatalogueDocument20 pagesRTI Titus CatalogueSrikanth TagoreNo ratings yet

- Mass and Energy Analysis of Control Volumes: Thermodynamics: An Engineering Approach, 6 EditionDocument20 pagesMass and Energy Analysis of Control Volumes: Thermodynamics: An Engineering Approach, 6 EditionAhmad SiddiqNo ratings yet

- Price - What Is Inlet Effect - Diffuser SelectionsDocument27 pagesPrice - What Is Inlet Effect - Diffuser SelectionssabotaaageNo ratings yet

- 23 3700 - Air Outlets and Inlets PDFDocument8 pages23 3700 - Air Outlets and Inlets PDFMohamed FawzyNo ratings yet

- Catalogo Difusores MetalaireDocument337 pagesCatalogo Difusores Metalairejosebolis50% (2)

- Exercicios Ch04 FundamentalsEngineeringThermodynamics7e PDFDocument23 pagesExercicios Ch04 FundamentalsEngineeringThermodynamics7e PDFTimotius AnggaraNo ratings yet

- Chapter 5 Mass and Energy Analysis of Open SystemsDocument28 pagesChapter 5 Mass and Energy Analysis of Open Systemsrustam effendyNo ratings yet

- RCP Symbols PDFDocument11 pagesRCP Symbols PDFAngela MaeNo ratings yet

- Lindab Magicad Plugin For Dimcomfort, Dimsilencer and LindqstDocument13 pagesLindab Magicad Plugin For Dimcomfort, Dimsilencer and Lindqstu_florinNo ratings yet

- VAV Diffuser ThermallyDocument7 pagesVAV Diffuser ThermallyToan Ho DacNo ratings yet

- USAF Test Pilot School Performance Phase Textbook Volume1Document1,083 pagesUSAF Test Pilot School Performance Phase Textbook Volume1David Russo100% (4)

- HCPL-43 3-4-2013Document72 pagesHCPL-43 3-4-2013barber bobNo ratings yet

- TROX Quick - Selection PDFDocument48 pagesTROX Quick - Selection PDFxkokarcaxNo ratings yet