Professional Documents

Culture Documents

EI-20-222-M322 Rev. A9339917743744272976

EI-20-222-M322 Rev. A9339917743744272976

Uploaded by

Edwar ZulmiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EI-20-222-M322 Rev. A9339917743744272976

EI-20-222-M322 Rev. A9339917743744272976

Uploaded by

Edwar ZulmiCopyright:

Available Formats

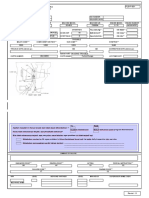

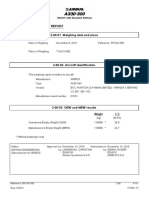

ENGINEERING INSTRUCTION

SUBJECT: DOCUMENT NO:

INSPECTION OF EFB MOUNTING El-20-222-M322

REVISION DATE: REV:

21.Jul.2020

SECTION A: PLANNING INFORMATION

AIRCRAFT REGISTRATION(Tobefilled by Planning):

PART NUMBER AND SERIAL NUMBER (Tobefilled by Planning):

EFFECTIVE DATE:

21.Jul.2020

ATA-CHAPTER:

25(EQUIPMENT/FURNISHINGS)

TYPE OF CHANGE:

EVRI:APRD DATA,NON-OEM,DCAM DOA

MAINTENANCE CLASSIFICATION:

LINE MAINTENANCE

COMPLIANCE:

MANDATORY

TYPE OF MODIFICATION/TASK:

MISCELLANEOUS:

Cabin Layout Change O Yes

Other Pax modification

Inspection

Cl Documentwith hardtime limit

Documentwith repetitive interval

APPROVAL/SIGNATURE:

PREPAREDBY: CHECKEDBY: APPROVEDBY:

= 4

NAME: NUR ELISHA REHAN NAME: RIZAL RAKIP NAME: ANAS MUKRIMIN

LC: NER LC: MSP LC: ANM

DATE: 21 JUL 2020 DATE: 21 JUL 2020 DATE: 21 JUL 2020

FORM NO, TSF1001R06 [1 Jor] «|

produced byAMOS www.swiss-as.com

Gig ENGINEERING INSTRUCTION

SUBJECT: DOCUMENTNO:

INSPECTION OF EFB MOUNTING EI-20-222-M322

REVISION DATE: REV:

21.Jul.2020 A

SECTION A: PLANNING INFORMATION

REVISION HISTORY:

REV DATE DESCRIPTION

A 21.Jul.2020 [NER][MSP][ANM]INITIAL ISSUE

EFFECTIVITY:

Title AIC-TYPE NEW P/N RANGE

A320CEO A320 PIN

S/N RANGES: SERIAL NO FROM SERIAL NO TO INCL/EXCL

MAA001 MAA999 INCLUDED

[TIME REQUIREMENT: DIM-TYPE .| BASE LINE DIMENSION AMOUNT/DATE Tolerance

Interval MT 4 +0D/-0D

[SHOP PLANNING: SHOP/SKILL EST-MAN EST-MANHOUR TOTAL

AVIONICS 1.0 01:00 = 01:00

Title AIC-TYPE NEW P/N RANGE

A320NEO A320N PIN

S/N RANGES: SERIAL NO FROM SERIAL NO TO INCL/EXCL

MAA001 MAA999 INCLUDED

[TIME REQUIREMENT: DiM-TYPE BASELINE DIMENSION AMOUNT/DATE Tolerance

Interval MT 4 +0D/-0D

[SHOP PLANNING: SHOP/SKILL EST-MAN EST-MANHOUR TOTAL

AVIONICS 1.0 01:00 = 01:00

Title AIC-TYPE NEW P/N RANGE

A321NX A321N PIN

S/N RANGES: SERIAL NO FROM SERIAL NO TO INCL/EXCL

MAA001 MAA999 INCLUDED

[TIME REQUIREMENT: DIM-TYPE BASELINE DIMENSION AMOUNT/DATE Tolerance

Interval MT 4 +0D/-0D

[SHOP PLANNING: SHOP/SKILL EST-MAN EST-MANHOUR TOTAL

AVIONICS 1.0 01:00 = 01:00

REFERENCES:

DOC NO DOC-TYPE REVISION REV DATE ISSUED BY

TDS-322-25-102 TDS A 09.Mar.2020 AIRASIA BERHAD

DOCUMENT CLASSIFICATIONS:

TECH FIELD: CABIN INTERIORS

GENERAL: APPLICABLE FOR 9M ONLY

APPROVAL BASIS: CAAM DOA DATA

WORK CLASS: INSPECTION

TEXT

REVISION DETAIL:

Initial issuance.

THRESHOLD ACTION:

Perform as per Section B on the next E-Checkafterinstallation of

El-20-127-N322 and/or El-20-201-N322

[FORM NO. TSF1001R06 [2 [or] 4 |

produced byAMOS www.swiss-as.com

RR. ENGINEERING INSTRUCTION

SUBJECT: DOCUMENT NO:

INSPECTION OF EFB MOUNTING EI-20-222-M322

REVISION DATE: REV:

21.Jul.2020

SECTION A: PLANNING INFORMATION

INTERVAL ACTION:

Perform as per Section B every 4 months.

TERMINATING REQUIREMENT:

Nil.

NOTICE TO DEPARTMENT:

1. Planning: To schedule the El as per threshold and repetitively on

every E-Check.

2. Maintenance: Perform inspection of the EFB mounting components.

3. Technical Records: To perform reporting back upon completion of

the task.

4. Technical Services: To terminate this El once AMP has been revised

to include AMP task 251300-AXM-1.

DESCRIPTION:

The El providesinstruction for a repetitive inspection of the EFB

mounting componentsafter the installation as per El-20-127-N322

and/or El-20-201-N322.

REASON:

The EFB mounting components are required to be inspected at every

E-Checkas stipulated by AirAsia DOA mod package DAS-20-023.

CONCURRENT REQUIREMENT:

The accomplishmentof this El satisfy the requirement of AMP task

251300-AXM-1.

IF ACCOMPLISHED PER PREVIOUS REVISION, MORE WORK NECESSARY:

N/A

SUMMARYOF DATA JUSTIFICATION:

Thetask is carried out i.a.w TDS-322-25-100 approved underAirAsia

DOA DAS-20-023.

EFFECT ON ENVIRONMENTAL CONDITION:

Nil.

LIMITATION:

Nil.

CONTINUED AIRWORTHINESS:

Nil.

PUBLICATION CHANGE:

Nil.

NUMBER OF PAGES IN SECTION B:

2

[FORM No. TSF1001R06 Ls [or[ 4 |

produced byAMOS www.swiss-as.com

Pea ENGINEERING INSTRUCTION

SUBJECT: DOCUMENT NO:

INSPECTION OF EFB MOUNTING EI-20-222-M322

REVISION DATE: REV:

21.Jul.2020

SECTION A: PLANNING INFORMATION

NOTE: The manpower estimates givenin this Instruction(if any) are

based onthe direct labour cost to do the work. These estimates

assumethat the work will be done by experienced personnel, and may

need to be revised upwards to suit circumstances. The estimates do

not include the time to prepare, plan or inspect the work.

Manufacture and procurementofparts andtools, drying times for

paints, sealants, etc., and general administration work are also not

included.

REMARKS

This El serves as a substitution to AMP task 251300-AXM-1 while

waiting for the MAA A320Fam AMP toberevisedto include the AMP task.

This El is no longer required to be performed once the AMP task has

beenincluded in the A320 Family Aircraft Maintenance Programme (AMP).

FORM NO, TSF1001R06 [+ [or] +]

produced byAMOS www.swiss-as.com

ENGINEERING INSTRUCTION

SUBJECT: DOCUMENT NO:

INSPECTION OF EFB MOUNTING

El-20-222-M322

REVISION DATE: REV:

21.Jul.2020

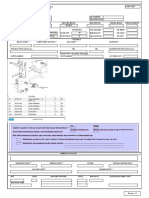

SECTION B: ACCOMPLISHMENTINSTRUCTIONS

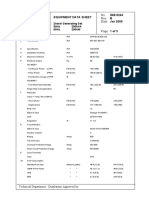

General Visual Inspection of EFB Mounting components

1. Gain access to the Captain and F/O sliding window.

2. Refer to Figure 1. Perform inspection on the front and back of the EFB mounting.

a. Inspect all the plastic parts (Item 1 and 2) to ensure that there is no crack.

b. Check for any missing rubber grommet(Item 3) or screws.

c. Operate the handles(Item 4) to ensure that the spring-loaded mechanism is functional.

d. Operate the knob(Item 5) to ensure that the gripping mechanism is functional.

e. Check the contact between item 1, 6, 7 and 8. Tighten up any loosen screws.

NOTE: The screwsshall be hand-tightened only. DO NOT OVERTIGHTEN.

f. Replace any degrading part that may impair the structural integrity of the mounting.

3. Return the aircraft back to its serviceable condition.

FORM NO. TSF1001R06 | 1 [or] 2 |]

ENGINEERING INSTRUCTION

SUBJECT: DOCUMENTNO:

INSPECTION OF EFB MOUNTING

El-20-222-M322

REVISION DATE: REV:

21.Jul.2020

SECTION B: ACCOMPLISHMENT INSTRUCTIONS

Figure 1: EFB Mounting components- front and back

FORM NO. TSF1001R06

BIEIEN

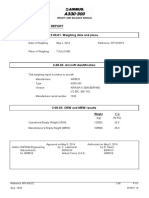

ERI CERTIFICATION SHEET

DOCUMENTNO: REV: A/C REGN: PART NUMBER: SERIAL NUMBER:

: EI-20-222-M322 A o

TYPE OF COMPLIANCE ACTION: PART/SECT. TO BE PERFORMED: TRADE: ZONE: STATION:

U Once Off O Repeat

O First Accomplishment___ Terminating

NOTE: TECHNICALLOG(e.g. MR1, etc):

NDTreport is required for every NDT task.

Raise applicable form for Duplicate Inspection / Require Inspection Item / Critical

Task Inspection and state the control numberofthe form in action taken field.

LAE/AH

RESULTS/FINDINGS:

Sign, Stamp & Date

ACTION TAKEN & CROSS REFERENCES: LAE/AH

Sign, Stamp & Date

CRS STATEMENT:

The work recorded above has been carried out in accordance with the requirements of the Malaysian Civil Aviation Regulations for the time being

9M , : : : : . :

D in force and in that respectthe aircraft/equipment is considered fit for release to service.

Certifies that the work specified except as otherwise specified was carried outin accordance with latest manufacturer's data orother data

o HS accepted by Civil Aviation Authority of Thailand (CAAT) and in respectto that work the aircraft is considered ready for release to service.

Certifies that the work recorded above has beencarried out in accordance with the requirement of CASR forthis time being in force-and in that

D respectto the aircraft / aircraft component is considered fit for release to service.

The work recorded above has been carried out in accordance with the requirementsofthe Philippine Civil Aviation Regulations for the time being

D in force and in that respect theaircraft/equipmentis considered fit for release to service.

The work recorded abovehasbeencarried out in accordancewith the requirements of the Circular for Aircraft Safety of Japan for the time being

oJA, x = = 5 : ‘

in force and in that respectthe aircraft/equipmentis consideredfit for release to service.

vr Certifies that the work specified except as otherwise specified was carried out in accordance with CAR-145 and in respectto that work the

D aircraft/aircraft component is considered ready for release to service

DATE COMPLETED: | TAH/TSN: TACICSN: ACTUAL MANHOUR: ACTUAL MANPOWER: TOTAL ELAPSED TIME:

DESCRIPTION PIN ON SIN ON P/N OFF S/N OFF BATCH NO QTY

USE ADDITIONAL SHEETIF REQUIRED BY MAKING COPY OF THIS PAGE PAGE 0)PA

NOTE: Technical Records to perform Status Reporting of the El/RI in AMOS. EI/RI whichis related to OEM SB, Technical Records to report the SB status

in the OEM webportal.

FORM NO. TSF7008R05

You might also like

- Body Control Module PinoutsDocument10 pagesBody Control Module Pinoutslamping_ap100% (5)

- LGKR - Corfu Approach PlatesDocument45 pagesLGKR - Corfu Approach PlatesJonas50% (2)

- Integrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgDocument34 pagesIntegrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgEdwar ZulmiNo ratings yet

- Integrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgDocument12 pagesIntegrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgEdwar ZulmiNo ratings yet

- Chainsaw: Parts CatalogDocument17 pagesChainsaw: Parts CatalogГоран СтанишићNo ratings yet

- Cold Test Report 3Document1 pageCold Test Report 3Venkitesh PG100% (1)

- Ei N StuffDocument18 pagesEi N StuffMuhammad SyahmiNo ratings yet

- Aza27nov22 CGK Rev01Document26 pagesAza27nov22 CGK Rev01fridianyNo ratings yet

- EI-17-272-A322 Rev A ELDS INSTALLATION SB PDFDocument50 pagesEI-17-272-A322 Rev A ELDS INSTALLATION SB PDFAbhishek Roy100% (1)

- Cycle Time Report WEX018 6020BDocument6 pagesCycle Time Report WEX018 6020BDandung Yunianto123No ratings yet

- Storage Tank F-9026 Stone Column No SC-9026-52Document1 pageStorage Tank F-9026 Stone Column No SC-9026-52engmaar201037No ratings yet

- 02 Terminal BatraiDocument1 page02 Terminal BatraiEbit NurNo ratings yet

- 01 BalbDocument1 page01 BalbEbit NurNo ratings yet

- Ei-16-333-A322 Rev D TSFDocument76 pagesEi-16-333-A322 Rev D TSFJoaninha nvsNo ratings yet

- Tools 200000101261Document15 pagesTools 200000101261Arun SidharthNo ratings yet

- FS-S-000-132Z-0001-00: Field Change SheetDocument1 pageFS-S-000-132Z-0001-00: Field Change SheetNgọc Đức ĐoànNo ratings yet

- SLD MergedDocument14 pagesSLD Mergedkikokiko KarimNo ratings yet

- TSR Drill Mei 2022Document8 pagesTSR Drill Mei 2022Fata KickbalNo ratings yet

- Routine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeDocument3 pagesRoutine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeFL Technics DFPNo ratings yet

- SA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02Document2 pagesSA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02altipatlarNo ratings yet

- Gdu Ga Rev (Vme)Document8 pagesGdu Ga Rev (Vme)bennsavyaalrawafNo ratings yet

- Column FoundationDocument21 pagesColumn Foundationvijay10484No ratings yet

- SACTR-W-2006 Rev 2Document1 pageSACTR-W-2006 Rev 2husnain aliNo ratings yet

- Gdu Vendor Ref List Rev ADocument2 pagesGdu Vendor Ref List Rev AbennsavyaalrawafNo ratings yet

- Mechanical Data Sheet For Nitrogen ReceiverDocument8 pagesMechanical Data Sheet For Nitrogen ReceiversudjonoNo ratings yet

- TSR Drill JuliDocument10 pagesTSR Drill JuliFata KickbalNo ratings yet

- T006S52PDocument12 pagesT006S52PdiegoNo ratings yet

- Dfe-B00-Ele-Dwg-Sld-001 - R0 - Single Line Diagram For MV DistributionDocument1 pageDfe-B00-Ele-Dwg-Sld-001 - R0 - Single Line Diagram For MV DistributionElectrical PCBL Team100% (1)

- F-034 (Piping Dismantling Format)Document1 pageF-034 (Piping Dismantling Format)Rajeev KumarNo ratings yet

- Work Order: VN 23980529 6 - MiscellaneousDocument2 pagesWork Order: VN 23980529 6 - MiscellaneousJohn SmithNo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- MCC PanelDocument9 pagesMCC PanelLokeshTripathi0% (1)

- Flare Scrubber DSDocument8 pagesFlare Scrubber DSsudjonoNo ratings yet

- 0W430191-STR-051 - Squadcheck PipingDocument1 page0W430191-STR-051 - Squadcheck PipingNew BossNo ratings yet

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselDocument4 pages45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalNo ratings yet

- E84 in TN CMBR GVRD NB 0001 502Document35 pagesE84 in TN CMBR GVRD NB 0001 502Balaji SowrirajanNo ratings yet

- On Shot Fan Blade Balancing Leap 1aDocument7 pagesOn Shot Fan Blade Balancing Leap 1aAbhishekprasad royNo ratings yet

- Bsi CCDocument92 pagesBsi CC王马No ratings yet

- Technical Service Report: PT - Pamapersada Nusantara Topb Coal Mining ProjectDocument15 pagesTechnical Service Report: PT - Pamapersada Nusantara Topb Coal Mining ProjectFata KickbalNo ratings yet

- Prolong 1 Month BosDocument5 pagesProlong 1 Month BosAl Fitrah EdisonNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- Iskra DPM MC740 DrawingDocument5 pagesIskra DPM MC740 Drawinghairul hafizNo ratings yet

- Nrs Mod 5 Data Innovation ReportDocument1 pageNrs Mod 5 Data Innovation ReportBrahmananda ChakrabortyNo ratings yet

- A320-ENGINE-1-ON-JB : Work Control CardDocument2 pagesA320-ENGINE-1-ON-JB : Work Control CardFredy BonillaNo ratings yet

- Adobe Scan 3 Aug 2022Document4 pagesAdobe Scan 3 Aug 2022Nitin GhotekarNo ratings yet

- Work Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionDocument2 pagesWork Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionRejoy Baby100% (1)

- TENDERDOCUMENTPDFDocument73 pagesTENDERDOCUMENTPDFNeela lohithaNo ratings yet

- B. Mix Design Manual PDFDocument98 pagesB. Mix Design Manual PDFeddieNo ratings yet

- Mix Design Manual - 1Document98 pagesMix Design Manual - 1Gajendra PandeyNo ratings yet

- Gas Development Project For Unitization of The Jambaran - Tiung Biru FieldDocument1 pageGas Development Project For Unitization of The Jambaran - Tiung Biru FieldBintang AtdiNo ratings yet

- MS DD 3000 HSE FRM 0095 - Synthetic - Sling - Inspection - ChecklistDocument1 pageMS DD 3000 HSE FRM 0095 - Synthetic - Sling - Inspection - ChecklistcrystinNo ratings yet

- Issue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamDocument1 pageIssue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamGanesh YadavNo ratings yet

- 2 Iso 01000 - 1Document10 pages2 Iso 01000 - 1MansourNo ratings yet

- Advance Trim Balance LEAP 1ADocument7 pagesAdvance Trim Balance LEAP 1AAbhishekprasad roy0% (1)

- Gas Development Project For Unitization of The Jambaran - Tiung Biru FieldDocument2 pagesGas Development Project For Unitization of The Jambaran - Tiung Biru FieldBintang AtdiNo ratings yet

- MR Summary & Approval SheetDocument1 pageMR Summary & Approval SheetErin JohnsonNo ratings yet

- G-102-01 (790DBBC) Al-Shahaniya: Qatar Armed ForcesDocument1 pageG-102-01 (790DBBC) Al-Shahaniya: Qatar Armed ForcesAslamNo ratings yet

- Arr PK-GJR 05 August 2020 RonhlpDocument3 pagesArr PK-GJR 05 August 2020 RonhlpDwiky Alif SatriaNo ratings yet

- Ash 13.8 em 411B - AsbuiltDocument25 pagesAsh 13.8 em 411B - AsbuiltMr IlchamNo ratings yet

- WICSDocument3 pagesWICSmohd as shahiddin jafri100% (1)

- 1045-BB1-ME-CAL-001 - A ScopeDocument187 pages1045-BB1-ME-CAL-001 - A ScopeAlfredo Bautista HernándezNo ratings yet

- Priming Pump 02Document3 pagesPriming Pump 02Bayu SaputraNo ratings yet

- Ibnu Rinaldy - Eob Claim Apr 24Document2 pagesIbnu Rinaldy - Eob Claim Apr 24Edwar ZulmiNo ratings yet

- GD Eob Edwar A. Zulmi 19 Apr 24 Qz474 CGK-PNHDocument1 pageGD Eob Edwar A. Zulmi 19 Apr 24 Qz474 CGK-PNHEdwar ZulmiNo ratings yet

- GD Eob Edwar A. Zulmi 26 Apr 24 Qz474 CGK-PNHDocument1 pageGD Eob Edwar A. Zulmi 26 Apr 24 Qz474 CGK-PNHEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00 DefinitionsDocument33 pagesAircraft Weighing Report 2.00 DefinitionsEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Quick Reff Cabin Part A320-March 2020Document30 pagesQuick Reff Cabin Part A320-March 2020Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report Table of Content 2.00 DefinitionsDocument31 pagesAircraft Weighing Report Table of Content 2.00 DefinitionsEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report Table of Content 2.00 DefinitionsDocument32 pagesAircraft Weighing Report Table of Content 2.00 DefinitionsEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document27 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument27 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Integrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgDocument15 pagesIntegrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- General Summary of Highlights: Weight and Balance ManualDocument10 pagesGeneral Summary of Highlights: Weight and Balance ManualEdwar ZulmiNo ratings yet

- Weight and Balance Manual: Reference: Xax A330-300 Fleet WBM Issue Date: 09 Feb 17Document6 pagesWeight and Balance Manual: Reference: Xax A330-300 Fleet WBM Issue Date: 09 Feb 17Edwar ZulmiNo ratings yet

- Aircraft Weighing ReportsDocument31 pagesAircraft Weighing ReportsEdwar ZulmiNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument21 pagesAlert Operators Transmission - Aot: Customer Services DirectorateEdwar ZulmiNo ratings yet

- AOT-A32N016-19 Rev 00Document13 pagesAOT-A32N016-19 Rev 00Edwar ZulmiNo ratings yet

- Saej 135 V 001Document5 pagesSaej 135 V 001BonnerNo ratings yet

- Repuesto Transmision 962gIIDocument6 pagesRepuesto Transmision 962gIIWilliams ArayaNo ratings yet

- Ukv TRD 2.6 Squawk Codes and TranspondersDocument2 pagesUkv TRD 2.6 Squawk Codes and TranspondersAlvinNo ratings yet

- F-082 Chief Engineer's Night Order BookDocument2 pagesF-082 Chief Engineer's Night Order BookFlorin Burugiu83% (6)

- Realistic Airplane Manual by Inkompetent 2018-04-04Document75 pagesRealistic Airplane Manual by Inkompetent 2018-04-04Francisco EstradaNo ratings yet

- Catalog Mobile-20171019084122 PDFDocument21 pagesCatalog Mobile-20171019084122 PDFedy wiranata100% (1)

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- Design Basis Report - DraftDocument9 pagesDesign Basis Report - Draftabhi0912No ratings yet

- Cumberland Piazza Heritage StatementDocument17 pagesCumberland Piazza Heritage Statementray_smith1099No ratings yet

- Peugeot 2000 HandbookDocument260 pagesPeugeot 2000 HandbookAshenafi WegayehuNo ratings yet

- D50 60 70S-5 (Sb1100e05)Document377 pagesD50 60 70S-5 (Sb1100e05)goxmadNo ratings yet

- Keep It Clean Wiring Pro51dDocument12 pagesKeep It Clean Wiring Pro51dDrewsomeNo ratings yet

- Benghazi Detailed Design PresentationDocument76 pagesBenghazi Detailed Design PresentationRana El abaniNo ratings yet

- 5604 Traveller - (15mm Deck Plans) Laboratory ShipDocument9 pages5604 Traveller - (15mm Deck Plans) Laboratory ShipZakys Backinblack100% (2)

- 04 Diagrama Hidraulico-NeumaticoDocument100 pages04 Diagrama Hidraulico-NeumaticoLc NoéNo ratings yet

- Parcel InformationDocument1 pageParcel InformationArnau Bataller RuizNo ratings yet

- ATA07Document68 pagesATA07N ANo ratings yet

- Braking System: KE (1/2) (W/G) (U - V) (1/2) M (U - V)Document11 pagesBraking System: KE (1/2) (W/G) (U - V) (1/2) M (U - V)Mathew ScariaNo ratings yet

- The Hunting (Hawksmoor Sam)Document300 pagesThe Hunting (Hawksmoor Sam)afrinaroosNo ratings yet

- Whitetopping - A Case Study From BangaloreDocument6 pagesWhitetopping - A Case Study From BangaloreRam KumarNo ratings yet

- Mother Touch Group of Schools (MTGS) Transport PolicyDocument2 pagesMother Touch Group of Schools (MTGS) Transport PolicyTsitsi Abigail100% (1)

- Lbu Equipment ListDocument70 pagesLbu Equipment Listcapayam ayamcapNo ratings yet

- Mr366megane2 AutomatDocument113 pagesMr366megane2 AutomatAli ALiNo ratings yet

- 5156 - High Mast LightDocument23 pages5156 - High Mast LightPEER ZAKIR HUSSAINNo ratings yet

- 200 KVA DC9 Spec SheetsDocument3 pages200 KVA DC9 Spec SheetsMateen YounasNo ratings yet

- Nigeria Aerodrome Approach ChartsDocument260 pagesNigeria Aerodrome Approach ChartsDumo CharlesNo ratings yet

- Annual Report - 2020 21 Kamarajar PortDocument140 pagesAnnual Report - 2020 21 Kamarajar PortSherin ShihabudeenNo ratings yet