Professional Documents

Culture Documents

Incident Summary Report II-663369-2018 (6287) (Final) : Technical Safety BC WWW - Technicalsafetybc.ca

Incident Summary Report II-663369-2018 (6287) (Final) : Technical Safety BC WWW - Technicalsafetybc.ca

Uploaded by

Logic EngineeringOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Incident Summary Report II-663369-2018 (6287) (Final) : Technical Safety BC WWW - Technicalsafetybc.ca

Incident Summary Report II-663369-2018 (6287) (Final) : Technical Safety BC WWW - Technicalsafetybc.ca

Uploaded by

Logic EngineeringCopyright:

Available Formats

Incident Summary Report II-663369-2018 (6287) (Final)

Incident Date March 12, 2018

Location Burnaby

Regulated industry

Escalator

sector

SUPPORTING INFORMATION

Qty injuries 0

Injury

Injury

No injuries

description

Impact

Injury rating None

Damage 4 damaged steps, step axial, upper comb plates, up thrust track, hold down

Damag

description track, upper landing plate and stressed step chain.

e

Damage rating Major

Incident rating Major

Escalator steps misaligned and came into contact with the upper landing

Incident overview comb plates, causing a pile up. This is a malfunction that occurs when the

moving components come into contact with the stationary components

Inside an escalator, a pair of chains wraps around two pairs of gears that are

driven by an electric motor. The motor and step chain sit within a metal

structure known as the truss, which extend between the floors served by the

Site, system and

escalator. Within the truss, the escalator houses steps and tracks. At the top

components

of the unit the steps and track are kept aligned by upthrust tracks and hold

down tracks. This allows the conveyer like rotation to travel through the truss

with precise alignment

INVESTIGATION CONCLUSIONS

Licenced contractor failed to provide field mechanics with specifications and

tolerances for the Otis 506 escalators.

Upthrust track was not set to the correct specification which allowed the step

rollers to ride higher or out of alignment prior to entering into the upper

Failure scenario(s)

combplates.

The hold down track was not set to correct specifications, which allowed the

step to rise more than 1mm. The ability for the step to rise lead to the step

and track to come into contact.

Onsite investigation observations:

The proper adjustment for the upthrust track is 1mm. This escalator

the upthrust track was set to 6mm. (5mm above maximum allowance)

Facts and evidence

The hold down track was allowing the steps to rise 4mm. (3mm above

maximum allowance)

Technical Safety BC www.technicalsafetybc.ca

Incident Summary Report II-663369-2018 (6287) (Final)

Through conversation the Field Mechanic made the Safety Officer

aware that he did not have the upthrust track specifications for

allowances. Field Mechanic was not provided the documentation to

maintain those specifications.

Field Mechanic was not trained or checking for these allowances.

It is highly probable that the cause of this pile up was that The upthrust track

and hold down track were not set to proper specifications.

A contributing factor was that the Field mechanic(s) were not aware of the

Causes and

specifications of the upthrust track and the hold down track when doing

contributing factors

regular inspections and clean downs of the internal components of the

escalator.

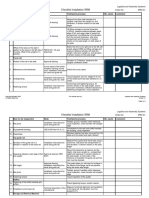

Photos or diagrams (if necessary)

Steps piled up into upper combplates.

Technical Safety BC www.technicalsafetybc.ca

Example of a properly adjusted upthrust track, showing the correct clearance.

Upthrust track as found. This is showing the clearance beyond 1mm.

Technical Safety BC www.technicalsafetybc.ca

Step hold down track and step up lift tab.

This helps keep the step in alignment as it rotates in the upper end.

Proper setting of 1mm clearance being shown here. During incident

it was found at 4mm.

Technical Safety BC www.technicalsafetybc.ca

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Inferno SummaryDocument4 pagesInferno SummaryAva Barrameda67% (3)

- API Inspection GuideDocument14 pagesAPI Inspection Guidesouilah100% (1)

- New Password 3: A Reading and Vocabulary Text: Linda ButlerDocument1 pageNew Password 3: A Reading and Vocabulary Text: Linda ButlerRastko Manojlovic0% (3)

- S4800 Supplementary Notes1 PDFDocument26 pagesS4800 Supplementary Notes1 PDFTanu OhriNo ratings yet

- Lifting-Failure of EquipmentDocument1 pageLifting-Failure of EquipmentRanjan PradhanNo ratings yet

- Too Much Vibration PDFDocument8 pagesToo Much Vibration PDFThanh LuanNo ratings yet

- 11.07.09 Working at Height (TD Repair)Document1 page11.07.09 Working at Height (TD Repair)Hamdi Rafiek100% (1)

- Work at Height Permit FormDocument3 pagesWork at Height Permit FormEbenezer OpuniNo ratings yet

- Vibration ANALYSIS ServiceDocument4 pagesVibration ANALYSIS ServiceRCM Hoc vien100% (2)

- Checklist Installation enDocument4 pagesChecklist Installation enamansaxena9208No ratings yet

- Rig Components: Well DrillingDocument129 pagesRig Components: Well DrillingAfzaalUmairNo ratings yet

- Rig Components: Well DrillingDocument129 pagesRig Components: Well DrillingAfzaalUmairNo ratings yet

- Elevador Challenger E10Document13 pagesElevador Challenger E10Abelardo JoseloNo ratings yet

- Rig Components: We LL Drilling Eng Dana MohammadDocument129 pagesRig Components: We LL Drilling Eng Dana Mohammaddana mohammedNo ratings yet

- Sarens: GroupDocument8 pagesSarens: GroupBobbyNo ratings yet

- Sany SRC 350Document11 pagesSany SRC 350Jorge AlmirallNo ratings yet

- Ed 5622240Document9 pagesEd 5622240Ton marquesNo ratings yet

- Anchor Why Mounts FailDocument2 pagesAnchor Why Mounts FailJua ChaidezNo ratings yet

- Two Post Surface Mounted Lift: I, O & M MDocument15 pagesTwo Post Surface Mounted Lift: I, O & M MhugoDiaz1981No ratings yet

- Emerson - Cooling Tower Vibration Sensors - WirelessDocument8 pagesEmerson - Cooling Tower Vibration Sensors - WirelessCandida MorvinNo ratings yet

- Mastiff Tech Specs Rev BDocument13 pagesMastiff Tech Specs Rev BThem Bui XuanNo ratings yet

- ST60 I&M ManualDocument28 pagesST60 I&M ManualKAMALAKANNAN DURAIRAJNo ratings yet

- Src550 Rough-Terrain Crane 55 Tons Lifting Capacity: Quality Changes The WorldDocument11 pagesSrc550 Rough-Terrain Crane 55 Tons Lifting Capacity: Quality Changes The WorldThet Phyo AungNo ratings yet

- IMW2910 4 Ton Clear Floor Manual Release 2 Post LiftDocument6 pagesIMW2910 4 Ton Clear Floor Manual Release 2 Post LiftLuhanNo ratings yet

- MJ 2635 Eriez Chip Parts Conveyor IOMDocument20 pagesMJ 2635 Eriez Chip Parts Conveyor IOMSuyapa Lainez LainezNo ratings yet

- IMCASF - Dec 16Document4 pagesIMCASF - Dec 16Shivkumar JadhavNo ratings yet

- SWMS Worn Gear DriveDocument6 pagesSWMS Worn Gear DriveMahran MastouriNo ratings yet

- MECA Operations Manual Shuttle Rack System PDFDocument27 pagesMECA Operations Manual Shuttle Rack System PDFHasnain KanchwalaNo ratings yet

- RR RD5700SDocument1 pageRR RD5700ShugoamendozaNo ratings yet

- Product Information Servo-Hydraulic Load Frames - HA SeriesDocument3 pagesProduct Information Servo-Hydraulic Load Frames - HA SeriesAnilNo ratings yet

- SWMS Worn Gear DriveDocument5 pagesSWMS Worn Gear DriveChaima Ben AliNo ratings yet

- Static AsignmentDocument19 pagesStatic AsignmentMuhammad ZackNo ratings yet

- Estudio Fricción PoleasDocument9 pagesEstudio Fricción PoleasSer PicoNo ratings yet

- Assessing Bearing Condition Using CFDocument1 pageAssessing Bearing Condition Using CFBenny LagartoNo ratings yet

- Anexo Grove TMS 700B Tabla de Carga Load Chart - MCST 4A - 4B (v1.1)Document10 pagesAnexo Grove TMS 700B Tabla de Carga Load Chart - MCST 4A - 4B (v1.1)HERSON BORIS RIVERA REFULIONo ratings yet

- In The Name of Allah, The Most Gracious, The Most MercifulDocument53 pagesIn The Name of Allah, The Most Gracious, The Most MercifulHassan UetmecheNo ratings yet

- Unifire XT BoomDocument21 pagesUnifire XT BoomRosa UrquietaNo ratings yet

- Tenaris Conn2 PDFDocument28 pagesTenaris Conn2 PDFDanielNo ratings yet

- Manual Hidraulico Montacargas Yale Gp060rcDocument52 pagesManual Hidraulico Montacargas Yale Gp060rcPepe AlNo ratings yet

- TMS Type IIIDocument2 pagesTMS Type IIIluochen703No ratings yet

- Misalignment - Power-MI: Aug 21, 2023 2:32 PMDocument9 pagesMisalignment - Power-MI: Aug 21, 2023 2:32 PMAnd jazNo ratings yet

- Anti SkewDocument2 pagesAnti SkewvozefjadavNo ratings yet

- A Guide To Shaft AlignmentDocument2 pagesA Guide To Shaft AlignmentAlfredo Ortiz BocanegraNo ratings yet

- VOLVO EC150 LC EC150LC EXCAVATOR Service Repair Manual PDFDocument15 pagesVOLVO EC150 LC EC150LC EXCAVATOR Service Repair Manual PDFfjjsjekdmmeNo ratings yet

- Camshaft Ret 010Document11 pagesCamshaft Ret 010Agus IrawanNo ratings yet

- Working at Height Is One of The Hazardous OccupationsDocument6 pagesWorking at Height Is One of The Hazardous OccupationsHemaNo ratings yet

- MCP200A-07 Issue 9 R2Document5 pagesMCP200A-07 Issue 9 R2TAMILNo ratings yet

- Src550h Rough-Terrain CraneDocument11 pagesSrc550h Rough-Terrain CraneRene Ramos MenesesNo ratings yet

- FINAL OASIS Published ArticleDocument4 pagesFINAL OASIS Published ArticleAbderrahim AbarayNo ratings yet

- Mounting Adjusting Pump UnitDocument2 pagesMounting Adjusting Pump UnitRalf JonesNo ratings yet

- Tilt TowerDocument40 pagesTilt TowervalyoudnNo ratings yet

- 4 Common Coupling Issues and How To Prevent ThemDocument6 pages4 Common Coupling Issues and How To Prevent ThemApple StarkNo ratings yet

- Overhead Crane Manual 10tonDocument71 pagesOverhead Crane Manual 10tonBuddhika MarasinghaNo ratings yet

- LEEA IP1 Step Notes 2 - LEEA - IP1 - 002 - 2012 v1.0000Document13 pagesLEEA IP1 Step Notes 2 - LEEA - IP1 - 002 - 2012 v1.0000aymanNo ratings yet

- 800 Cranes, Rigging and LiftingDocument43 pages800 Cranes, Rigging and LiftingLm Imran100% (5)

- Patterson VibrationAnalysisDocument15 pagesPatterson VibrationAnalysisandres monederoNo ratings yet

- GD Satcom 3.7M Assembly Manual 4096-225Document32 pagesGD Satcom 3.7M Assembly Manual 4096-225jrdmaNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Taxpayer Online Verification: 01-03-2022 20:47:57 Individual Imtiaz HussainDocument1 pageTaxpayer Online Verification: 01-03-2022 20:47:57 Individual Imtiaz HussainLogic EngineeringNo ratings yet

- Starting Guide: 3 PH 400 VAC 2.2 - 45 KW 1 PH 200 VAC 2.2 - 4.0 KWDocument38 pagesStarting Guide: 3 PH 400 VAC 2.2 - 45 KW 1 PH 200 VAC 2.2 - 4.0 KWLogic EngineeringNo ratings yet

- Si47 1971 Frenic Lift Loader Im WebDocument128 pagesSi47 1971 Frenic Lift Loader Im WebLogic EngineeringNo ratings yet

- Sbca Brochure 1Document2 pagesSbca Brochure 1Logic EngineeringNo ratings yet

- Full Chapter The Cambridge Handbook of Intelligence 2Nd Edition Robert J Sternberg PDFDocument53 pagesFull Chapter The Cambridge Handbook of Intelligence 2Nd Edition Robert J Sternberg PDFvicki.harkey877100% (5)

- Lección 7 - Who - Why-Because (WH Questions)Document3 pagesLección 7 - Who - Why-Because (WH Questions)jaime sordoNo ratings yet

- Contoh Formal LetterDocument2 pagesContoh Formal LetterFairos Azmi MarzahNo ratings yet

- Metrics by Vincanne AdamsDocument24 pagesMetrics by Vincanne AdamsDuke University PressNo ratings yet

- Welcome To Anderson Workone. Your Career Starts HereDocument28 pagesWelcome To Anderson Workone. Your Career Starts HereHilary TerryNo ratings yet

- 04 Rodrigo Roa Duterte, Fifth State of The Nation Address, July 27, 2020 - Official Gazette of The Republic of The PhilippinesDocument23 pages04 Rodrigo Roa Duterte, Fifth State of The Nation Address, July 27, 2020 - Official Gazette of The Republic of The PhilippinesJoseph SalazarNo ratings yet

- Helical Pile Behaviour Analysis in Different Soils: January 2009Document11 pagesHelical Pile Behaviour Analysis in Different Soils: January 2009mohamed magdyNo ratings yet

- The African Tribes of Egypt and Israel FinalDocument35 pagesThe African Tribes of Egypt and Israel FinalYared YAHU100% (3)

- Thesis Template University of TorontoDocument5 pagesThesis Template University of Torontoivanirosadobridgeport100% (2)

- Common Ailments LPDocument5 pagesCommon Ailments LPJeyxa Keizz Viernes-Apostol BalanayNo ratings yet

- Nama: Fajar Santoso NPM: 17315043 Kelas: TE17A: N Value For January 2Document6 pagesNama: Fajar Santoso NPM: 17315043 Kelas: TE17A: N Value For January 2Fajar SNo ratings yet

- Chapter 2 Capacity To Buy or SellDocument3 pagesChapter 2 Capacity To Buy or Sellariane marsadaNo ratings yet

- Journal Date Account Titles Debit CreditDocument9 pagesJournal Date Account Titles Debit CreditFrances Monique AlburoNo ratings yet

- Penggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanDocument26 pagesPenggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanII8I40O24 Oktaviana Rinda SariNo ratings yet

- Folding Standards: GeneralDocument9 pagesFolding Standards: GeneralNaadiyah JauharaNo ratings yet

- Define Sales ProcessDocument15 pagesDefine Sales Processwww.GrowthPanel.com100% (5)

- EiE Competency Framework CPHA Annex enDocument25 pagesEiE Competency Framework CPHA Annex enCumar Cadaani100% (1)

- MaleficentDocument7 pagesMaleficentbagasNo ratings yet

- Excavation Backfill For UtilitiesDocument13 pagesExcavation Backfill For UtilitiesGHL AdaroNo ratings yet

- CH06 LoopingDocument44 pagesCH06 LoopingNhemi EstradaNo ratings yet

- The Old Town White Coffee Marketing EssayDocument6 pagesThe Old Town White Coffee Marketing Essayfieya910% (1)

- CPM20CV Data SheetDocument2 pagesCPM20CV Data SheetAndi BondocNo ratings yet

- Dakshina - Kannada - Brochure 2012Document28 pagesDakshina - Kannada - Brochure 2012maheshanischithaNo ratings yet

- J. of Church and State-2010-Payne-jcs - csq102Document16 pagesJ. of Church and State-2010-Payne-jcs - csq102MotricalăMihailNo ratings yet

- The Secret Language of NarcissistsDocument2 pagesThe Secret Language of NarcissistsNIUK67% (3)

- Europapa - Joost KleinDocument4 pagesEuropapa - Joost KleinEvert MostertNo ratings yet

- HDSB Cover Letter1Document1 pageHDSB Cover Letter1api-436059149No ratings yet