Professional Documents

Culture Documents

Procedure For Control of Bottling Line 01 Process: 1.purpose

Procedure For Control of Bottling Line 01 Process: 1.purpose

Uploaded by

Cao CườngOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Control of Bottling Line 01 Process: 1.purpose

Procedure For Control of Bottling Line 01 Process: 1.purpose

Uploaded by

Cao CườngCopyright:

Available Formats

PROCEDURE FOR CONTROL OF BOTTLING LINE

01 PROCESS

1.PURPOSE

To ensure to pack beer in bottles according to the specified requirements and using the available

equipment.

2. SCOPE

Object: Tiger Pint (330ml)

Responsibilities: Packaging section; Packaging Team Leader (PTL)

3. REFERENCE DOCUMENTS

Doc.# Document title

ISO 9001:2015 Clause 8

ISO 22000:2005 Clause 7

HVB_VT. BRE.PR.00.00.04 Procedure for control of monitoring and measuring devices

HVB_VT.BRE. PR.01.01.02 Procedure for control of documents and data

HVB_VT. BRE.PR.00.00.02 Procedure for control of inspection & test status

HVB_VT. BRE.PR.00.00.06 Procedure for control of non-conforming outputs and handling of potentially

unsafe product

HVB_VT. BRE.PR.00.00.01 Procedure for control of identification and traceability

HVB_VT.WHS.RE.02.02.01 Transfer empty bottle & crate to PKG

HVB_VT.TEC.WI.05.01.** Work instruction for quality control at packaging

HVB_VT.TEC.SD.20.03.02 Packaging cleaning frequency

HVB_VT. WHS.PR.00.01.02 Procedure for FG receive from production

HVB_VT. WHS.PR.00.04.01 Procedure for receive Raw, General & Packaging Materials

HVB_VT.PPA.WI.01.**.** Bottling line work instruction

Qualass v5.1 Sale quality

4. DEFINITION

Good Transfer Note (GTN)

Pasteurizing Unit (PU)

Internal Transfer Note (ITN)

Empties Returnable (ER): empty crates, empty bottles, wooden pallets and empty kegs

Empty Bottle Inspector (EBI)

Filling Height Inspector (FHI)

Caustic Inspection (CI)

Full Crate Inspector (FCI)

Technological Controller (TC)

Logistics Executive – Planning (LE-P)

Packaging Operators (PO)

Brewing Operators (BO)

Packaging Team Leader (PTL)

Packaging coordinator (PC)

5. Description:

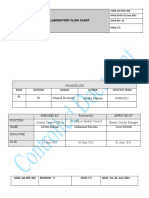

5.1: Flow chart:

Doc No.: HVB_VT.PPA.PR.01.00.00 UNCONTROLED COPY FOR PRINTING

Author: LTDKha_PS Page: 1/5

Issue: 2

Approver: NQMinh_PTL

Eff. Date: 12-May-2017

PROCEDURE FOR CONTROL OF BOTTLING LINE

01 PROCESS

Responsibility Activities Documents/Forms

Receive weekly PLN.RE.01.03.05

Packaging Section packaging schedule

PTL

Review

capability

Packaging Section Receive pallet of new or returnable bottle, HVB_VT.WHS.RE.02.02.01

packaging materials

HVB_VT.PPA.RE.01.04.01

Preparation and Test HVB_VT.PPA.RE.01.05.01

PO, BO before production HVB_VT.PPA.RE.01.07.03

HVB_VT.PPA.WI.01.**.**

Qualass v5.1

It is OK?

Packaging Section

HVB_VT.PPA.RE.01.01.02

Manual DEPALLETIZER: unloads the HVB_VT.PPA.RE.01.01.03

crates of empty bottles from pallets onto HVB_VT.TEC.RE.02.04.01

PO, Casual crate conveyors to transfer to Unpacker

worker

HVB_VT.PPA.RE.01.01.01

UNPACKER: takes empty bottles out HVB_VT.PPA.WI.01.01.**

of crates & put them onto bottle

PO conveyor to transfer to Washer

HVB_VT.TEC.RE.02.04.01

WASHER: bottles are CRATE WASHER: HVB_VT.PPA.RE.01.04.01

washed (external & Cleans plastic crates HVB_VT.PPA.WI.01.02.**

internal) with hot by warm water and HVB_VT.PPA.WI.01.04.**

caustic, then rinsed transferred onto the HVB_VT.TEC.WI.05.01.01

PO with water crate conveyor to the

Packer

EBI: checks if bottles are good HVB_VT.PPA.RE.01.05.01

for filling (Inspections: Too HVB_VT.PPA.WI.01.05.**

high, too low, color, side wall, HVB_VT.TEC.WI.05.01.03

base, scuffing, chip finish,

water residue, caustic residue)

PO

bottle

Dirty

Good for

chipped, cracked bottles

next

Rejected foreign,

step?

PO CAUSTIC INSPECTION: HVB_VT.PPA.RE.01.07.05

check bottle are good for HVB_VT.TEC.WI.05.01.03

filling (caustic residue)

A

PO

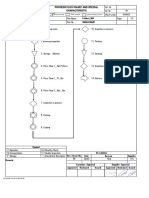

Doc No.: HVB_VT.PPA.PR.01.00.00 UNCONTROLED COPY FOR PRINTING

Author: LTDKha_PS Page: 2/5

Issue: 2

Approver: NQMinh_PTL

Eff. Date: 12-May-2017

PROCEDURE FOR CONTROL OF BOTTLING LINE

01 PROCESS

Responsibility Activities Documents/Forms

A

Qualass v5.1

Rejected by hand 24

Good empty bottles from CI

PO for to infeed filler

HVB_VT.PPA.RE.01.07.01

FILLER AND HVB_VT.PPA.RE.01.07.02

CROWNER: fills bottles HVB_VT.PPA.RE.01.07.03

with beer, then seal the HVB_VT.PPA.RE.01.07.04

PO HVB_VT.PPA.RE.01.07.05

bottles with crown corks

HVB_VT.PPA.WI.01.07.**

HVB_VT.TEC.WI.05.01.05/06/07

FHI: checks crown Check: OE of 1st & last bottle,

cork on bottles and Crimp allowance, Foreign gas, HVB_VT.PPA.RE.01.07.05

PO filling height of CO2 content, O2 content, taste test, HVB_VT.PPA.WI.01.08.**

bottles Filling content HVB_VT. TEC.WI.05.01.11/18

Qualass v5.1

NotGood

Trouble shooting

Good Reject bottles No OK?

? loss crown cork

PO and under filled

Stop production

PASTEURISER: bottles Discuss with TC

are heated up at 60-62oC

HVB_VT.PPA.RE.01.07.01

PO to pasteurize beer

HVB_VT.PPA.WI.01.09.**

PC

HVB_VT.TEC.WI.05.01.08

PU

contro

l no

LABELLER & CODER: Bottles are glued with HVB_VT.PPA.RE.01.10.01

foil, neck, body and back labels. HVB_VT.PPA.RE.01.10.02

PO - The Tiger bottles are coded on the back label HVB_VT.PPA.WI.01.10.**

with date / time for product traceability. HVB_VT.PPA.WI.01.12.**

- Bottles are checked missing labels. Non conform

PU reject

Rejected loss

B

label or loss code

TAPTONE

Checking Destroy leaked & too

B high pressure bottles

Responsibility Activities Documents/Forms

Doc No.: HVB_VT.PPA.PR.01.00.00 UNCONTROLED COPY FOR PRINTING

Author: LTDKha_PS Page: 3/5

Issue: 2

Approver: NQMinh_PTL

Eff. Date: 12-May-2017

PROCEDURE FOR CONTROL OF BOTTLING LINE

01 PROCESS

C B

HVB_VT.PPA.RE.01.10.01

PO HVB_VT.PPA.RE.01.10.02

HVB_VT.PPA.WI.01.11.**

Reject bottles loss

FHI: checks crown cork& under

crown cork, filled

HVB_VT.PPA.RE.01.10.01

under fill HVB_VT.PPA.RE.01.10.02

HVB_VT.PPA.WI.01.13.**

PO HVB_VT.TEC.WI.05.01.10

Destroy bottles

TAP TONE: Checks leak bottles, crown without crown

cork deform, damage neck bottle. HVB_VT.PPA.RE.01.10.01

cork& leaked

PO HVB_VT.PPA.RE.01.10.02

bottles

HVB_VT.PPA.WI.01.14.**

WAX: make smooth for old bottles HVB_VT.PPA.RE.01.01.01

PO Insert bottles HVB_VT.PPA.WI.01.15.**

HVB_VT.PPA.RE.01.00.02

PACKER: packs bottles into plastic crates HVB_VT.PPA.RE.01.00.03

HVB_VT.TEC.WI.05.01.09

PO

Crat Not full

Crate

e is is

full? full?

Casual Casual Full HVB_VT .PPA.RE.01.01.01

worker

MANUAL PALLETIZER: Arrangenment Non conform

onto the pallets by woker Reject

HVB_VT.WHS.PR.00.01.02

PO, Forklift

Transfer for storage in the finished product

store (Full store) in the warehouse

PC HVB_VT .PPA.RE.01.00.04

Make report

Packaging Section

Maintain

records

5.1.2. NOTE:

1) Bottle production is done according to the Weekly Packaging Schedule by PTL ensures the availability of

man-power to comply with the Packaging schedule. In case the Packaging schedule cannot be achieved,

PTL and LE_P issue a revised packaging schedule. Refer to PLN.RE.01.03.05 Packaging weekly schedule

PC:

Ensure that the right amount and type of Packaging materials are requested and supplied to comply with the

schedule. Refer to PLN.RE.01.03.05 Packaging weekly schedule

Check that beer with specified requirements is delivered to the packaging line. Refer to

HVB_VT.BRW.RE.01.05.06 (Bright beer record)

Ensure that non conform product is put on hold according to the Process of control of non conforming

product HVB_VT.BRE.PR.00.00.06 (Procedure for control of non-conforming outputs and handling of

potentially unsafe product)

Ensure that all finished product is inspected & tested according to HVB_VT.BRE.PR.00.00.02 (Process of

Inspection Test and Test Status)

Doc No.: HVB_VT.PPA.PR.01.00.00 UNCONTROLED COPY FOR PRINTING

Author: LTDKha_PS Page: 4/5

Issue: 2

Approver: NQMinh_PTL

Eff. Date: 12-May-2017

PROCEDURE FOR CONTROL OF BOTTLING LINE

01 PROCESS

Ensure that the daily finished product is sent to the Warehouse by signing on the

HVB_VT.PPA.RE.01.00.03. Refer to HVB_VT. WHS.PR.00.01.02 (Procedure for FG receive from

production)

Make “Daily performance report” (according to the form HVB_VT.PPA.RE.01.00.04), PC record and signs

then send to PTL every day

POs are responsible for the operation of the machine at its location according to

HVB_VT. PPA.WI.01.**.** ,

HVB Packaging Technological Parameters – Bottling line (HVB_VT.TEC.SD.20.02.01)

PTL is responsible for all parameters of machines which were listed in. These parameters approved by TC,

kept & followed up by PC

PCs ensure that all these parameters are checked by POs during operation. In case out of norm, POs take

actions as described in Trouble shooting instruction bottling Line

For changing these parameters (or hard ware modification), requester raises in the “MOC module” of

Paperless system. This form approved by TC, PTL

PTL is informed through PLE & EM for the planned maintenance and ensures with PC continuing process

capacity.

6. RECORDS:

Doc.Nr Document title

PLN.RE.01.03.05 Weekly Packaging Schedule

HVB_VT .PPA.RE.01.01.01 Unpacker-packer daily record

HVB_VT.TEC.RE.02.04.01 Quality control sheet of return empty bottle and pallets

HVB_VT.PPA.RE.01.01.02 Loss empty bottle in crate, loss crate in pallet record

HVB_VT.PPA.RE.01.01.03 New empty bottles for production

HVB_VT.PPA.RE.01.04.01 Bottle washer- Crate washer daily record

HVB_VT.PPA.RE.01.05.01 EBI quality checklist- Daily record

HVB_VT.PPA.RE.01.07.01 Bottle filler daily record

HVB_VT.PPA.RE.01.07.02 Bottle line downtime record

HVB_VT.PPA.RE.01.07.03 Bottle filler CIP caustic & sterilization record

HVB_VT.PPA.RE.01.07.04 Packaging crown details

HVB_VT.PPA.RE.01.07.05 Filler-Crowner-FHI quality check

HVB_VT.PPA.RE.01.10.01 Labeler-FHI- Taptone -Wax daily record

HVB_VT.PPA.RE.01.10.02 FHI -Coder- Taptone - Labeller - Wax quality checklist

HVB_VT.TEC.RE.02.04.01 Quality control sheet of return empty bottle and pallets

HVB_VT.PPA.RE.01.00.02 Bottling line production materials request

HVB_VT.PPA.RE.01.00.03 Bottling line production output

HVB_VT.PPA.RE.01.00.04 Bottling line report

7. ANNEX

N/A

Doc No.: HVB_VT.PPA.PR.01.00.00 UNCONTROLED COPY FOR PRINTING

Author: LTDKha_PS Page: 5/5

Issue: 2

Approver: NQMinh_PTL

Eff. Date: 12-May-2017

You might also like

- 02 Cleaning Validation of Double Cone Blender CLV 02Document2 pages02 Cleaning Validation of Double Cone Blender CLV 02Ravi Yadav67% (3)

- Partners in Reduce, Reuse and RecycleDocument27 pagesPartners in Reduce, Reuse and RecycleRana RashidNo ratings yet

- 1 1 An Overview of Communication Skills in EnglishDocument11 pages1 1 An Overview of Communication Skills in EnglishBARIBOR SHADRACH100% (7)

- Nde Map & Nde Procedure (Sudah Di Revisi)Document4 pagesNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangNo ratings yet

- Chemicals Loading ProcedureDocument8 pagesChemicals Loading ProcedureGRANIERNo ratings yet

- Laboratory Flow Chart: Change LogDocument3 pagesLaboratory Flow Chart: Change LogSreelakshmi RakeshNo ratings yet

- Bottle Unpacker Kr66030 Operation: 4. ScopeDocument5 pagesBottle Unpacker Kr66030 Operation: 4. ScopeCao CườngNo ratings yet

- MNT 031-02 Sewage Treatment PlantDocument2 pagesMNT 031-02 Sewage Treatment PlantAniket kopateNo ratings yet

- Annex 1 - Icrc Aql - Hygienic ParcelDocument23 pagesAnnex 1 - Icrc Aql - Hygienic ParcelMamdouhNo ratings yet

- Material Controller ProcedureDocument10 pagesMaterial Controller ProcedureAmos FiestaNo ratings yet

- Img 0004Document3 pagesImg 0004Shruti BhatiaNo ratings yet

- SOP On Transferring Finished Products To Finished Goods StoresDocument3 pagesSOP On Transferring Finished Products To Finished Goods StoresRainMan7567% (3)

- Process Flow - Cabinet - WNDocument1 pageProcess Flow - Cabinet - WNแต่ก่อน เสี่ยหำ เดี๋ยวนี้ ป๋าหำNo ratings yet

- Batch Manufacturing Record: Wellborne Pharmachem & BiologicalsDocument23 pagesBatch Manufacturing Record: Wellborne Pharmachem & BiologicalsMohammed Zubair100% (2)

- Section 1.2 - CDPNL - CHEMICAL AUDIT OPERATING PROCEDUREDocument5 pagesSection 1.2 - CDPNL - CHEMICAL AUDIT OPERATING PROCEDURECHRISTOPHER WEALTHNo ratings yet

- 04 Cleaning Validation of Empty Capsule Loader 04Document2 pages04 Cleaning Validation of Empty Capsule Loader 04Ravi YadavNo ratings yet

- Warehouse ProcedureDocument5 pagesWarehouse ProcedureMavic MediavilloNo ratings yet

- 26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)Document20 pages26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)bangunNo ratings yet

- 26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)Document20 pages26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)bangunNo ratings yet

- Sop For Membrane Filtration UnitDocument4 pagesSop For Membrane Filtration UnitMusyoka Urbanus100% (1)

- Standard Operating Procedure (Haematology) : R. K. Life Services Private LimitedDocument61 pagesStandard Operating Procedure (Haematology) : R. K. Life Services Private LimitedAniruddha ChatterjeeNo ratings yet

- Control Sample DestructionDocument3 pagesControl Sample DestructionJai MurugeshNo ratings yet

- 2018 Assessment Tool BSFDocument24 pages2018 Assessment Tool BSFRugay LaboratoryNo ratings yet

- RO Plant DMAHCL Plant Pass DONE...Document4 pagesRO Plant DMAHCL Plant Pass DONE...Yashwant WaghmareNo ratings yet

- Receiving Material Procedure (Done) (Sudah Direvisi)Document8 pagesReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangNo ratings yet

- Lab Qa Compliance VerificationDocument18 pagesLab Qa Compliance Verificationrobit SiddikiNo ratings yet

- Process Flow - Cabinet - WCDocument1 pageProcess Flow - Cabinet - WCแต่ก่อน เสี่ยหำ เดี๋ยวนี้ ป๋าหำNo ratings yet

- Empty Carton Inspection SOPDocument4 pagesEmpty Carton Inspection SOPFaysalNo ratings yet

- 2Document5 pages2Girish PsNo ratings yet

- JM-SOP-08 SOP For Carrying Out Physical Inventory of Store ItemDocument2 pagesJM-SOP-08 SOP For Carrying Out Physical Inventory of Store ItemKishan MauryaNo ratings yet

- Bio-Burden Test Procedure.: Revital Healthcare (Epz) LTDDocument5 pagesBio-Burden Test Procedure.: Revital Healthcare (Epz) LTDMusyoka UrbanusNo ratings yet

- SP-WHS-01 Receiving and Storage of Items - Rev 1 - 09022019Document2 pagesSP-WHS-01 Receiving and Storage of Items - Rev 1 - 09022019rbjennmortzzNo ratings yet

- STP SopDocument4 pagesSTP SopYashwant WaghmareNo ratings yet

- SOP - Product RecallDocument7 pagesSOP - Product Recallkitek100% (1)

- Inspection Report: Material Inspected This VisitDocument25 pagesInspection Report: Material Inspected This VisitFrancis Astorga AriasNo ratings yet

- PROSEDUR PRESSURIZED - Without compressor-TEST BIOGAS FLARE SYSTEMDocument6 pagesPROSEDUR PRESSURIZED - Without compressor-TEST BIOGAS FLARE SYSTEMMuh ArnoldNo ratings yet

- Incoming VTM Material Inspection Procedure - RevisedDocument6 pagesIncoming VTM Material Inspection Procedure - RevisedMusyoka Urbanus100% (1)

- Nit 2800 3 PDFDocument7 pagesNit 2800 3 PDFAnonymous uXdS9Y7No ratings yet

- Label Control (1)Document3 pagesLabel Control (1)Sanjay yadavNo ratings yet

- Whousekeeping SOPDocument3 pagesWhousekeeping SOPMohamed SelimNo ratings yet

- 01 Cleaning Validation of Vibratory Sifter CLV 01Document2 pages01 Cleaning Validation of Vibratory Sifter CLV 01Ravi YadavNo ratings yet

- (Ocp-05) Prevention of Lub Oilgrease Spillage at Unloading PointDocument1 page(Ocp-05) Prevention of Lub Oilgrease Spillage at Unloading PointAnkit SharmaNo ratings yet

- Hassi Bir Rekaiz Field Development Phase1Document5 pagesHassi Bir Rekaiz Field Development Phase1ahmed.njahNo ratings yet

- Ed GoodsDocument2 pagesEd GoodsMohamed SelimNo ratings yet

- Hed GoodsDocument2 pagesHed GoodsMohamed SelimNo ratings yet

- Conservation of WaterDocument2 pagesConservation of Wateranoushia alviNo ratings yet

- RL-GO-OP-DD-003-004 - Processing A Pre-Alert ProcedureDocument13 pagesRL-GO-OP-DD-003-004 - Processing A Pre-Alert ProcedurecasandraassanahNo ratings yet

- Packing List & Delivery NoteDocument1 pagePacking List & Delivery NoteAbdul Ridwan Guntur MaulanaNo ratings yet

- PHPL (B) - LTHE-PL-PRO-19 Rev 1-Pipe BookDocument5 pagesPHPL (B) - LTHE-PL-PRO-19 Rev 1-Pipe BookFrancis DhanarajNo ratings yet

- Procedure Bit Sharpener MachineDocument21 pagesProcedure Bit Sharpener MachineAnthony ObaraNo ratings yet

- BX 5 Door Latch Cylinder Replacements TO17357Document4 pagesBX 5 Door Latch Cylinder Replacements TO17357mohamed hamedNo ratings yet

- BMR SuspensionsDocument16 pagesBMR SuspensionsMohammed Zubair50% (2)

- BD100IR0002 - 0 HIPPS Valves Technical and Budgeting EstimatesDocument32 pagesBD100IR0002 - 0 HIPPS Valves Technical and Budgeting EstimatesDucNo ratings yet

- XXXXXXXXXXXXXXXXXXXXXXXXXXXX Process Validation Protocol (Capsule)Document25 pagesXXXXXXXXXXXXXXXXXXXXXXXXXXXX Process Validation Protocol (Capsule)Navdeep ChaudharyNo ratings yet

- Ceftriaxone 1g InjectionDocument40 pagesCeftriaxone 1g InjectionNazia KabirNo ratings yet

- Flexibag (Discharge Port)Document1 pageFlexibag (Discharge Port)waqiuddinNo ratings yet

- BX Elevator Lock Tab Washer TO17311Document5 pagesBX Elevator Lock Tab Washer TO17311mohamed hamed100% (1)

- BIL-TFR-026Document1 pageBIL-TFR-026Mutlu CivlanNo ratings yet

- Nitrogen Tank SM1 Checklist - Controlled PDFDocument3 pagesNitrogen Tank SM1 Checklist - Controlled PDFMaxim Kanibetov50% (2)

- 9-2. RO Plant DMAHCL Plant Pass DONE...Document4 pages9-2. RO Plant DMAHCL Plant Pass DONE...Yashwant WaghmareNo ratings yet

- QO™ Load Centers - PK6FLDocument1 pageQO™ Load Centers - PK6FLLeví StrataNo ratings yet

- Kabayanihan Service Coopeative Newsdate MarchDocument9 pagesKabayanihan Service Coopeative Newsdate MarchEveNo ratings yet

- (LIT) LS90 LS110 LS160 BrochureDocument20 pages(LIT) LS90 LS110 LS160 BrochureJuan Carlos Reinhold Niembro SuchowitzkiNo ratings yet

- Cheat Sheet PDFDocument1 pageCheat Sheet PDFGonçalo RaçõesNo ratings yet

- BodasurudabixDocument3 pagesBodasurudabixtom.quang6112No ratings yet

- NEPCon-CoC-Annual-Volume Summary-template-Nov17Document12 pagesNEPCon-CoC-Annual-Volume Summary-template-Nov17abraham alonso subiria cuetoNo ratings yet

- 99 Ways To Be A Better MusicianDocument14 pages99 Ways To Be A Better Musiciangunter_wepplerNo ratings yet

- Reflection of Truth - OutlineDocument2 pagesReflection of Truth - OutlineRaphael Clark Christian RarangNo ratings yet

- Test - Project Management Chapter 2 - QuizletDocument5 pagesTest - Project Management Chapter 2 - Quizletahmed mahmoudNo ratings yet

- Petroleum & Petrochemicals Test Method Capabilities: Intertek Caleb Brett 1Document18 pagesPetroleum & Petrochemicals Test Method Capabilities: Intertek Caleb Brett 1Eng-sadeq HesseinNo ratings yet

- Final Report - BFRDocument49 pagesFinal Report - BFRpuneeth hNo ratings yet

- Customer Service AssignmentDocument2 pagesCustomer Service AssignmentJoe Kau Zi YaoNo ratings yet

- Confessions of Some High Ranking 1Document111 pagesConfessions of Some High Ranking 1Habilian AssociationNo ratings yet

- 2 Functional AnalysisDocument17 pages2 Functional AnalysisnidhiNo ratings yet

- Properties of Bio-Based PolyurethaneDocument200 pagesProperties of Bio-Based PolyurethaneMust BoujaataNo ratings yet

- Engineering Mathematics Questions and Answers - Laplace Transform by Properties - 1Document9 pagesEngineering Mathematics Questions and Answers - Laplace Transform by Properties - 1RAHUL SOLANKENo ratings yet

- Chi-Square and Related DistributionDocument7 pagesChi-Square and Related DistributionMohammedseid AhmedinNo ratings yet

- Google Glass PresentationDocument25 pagesGoogle Glass PresentationVenu Kinng100% (1)

- Eta Line 150-250Document32 pagesEta Line 150-250tafseerahmadNo ratings yet

- PandasDocument1,349 pagesPandasMichael GemminkNo ratings yet

- Negor q3 Genbio2 Slkweek3 V2.finalDocument22 pagesNegor q3 Genbio2 Slkweek3 V2.finaljenicahazelmagahisNo ratings yet

- Premium Year 8 Spring Higher 2021Document12 pagesPremium Year 8 Spring Higher 2021siminicNo ratings yet

- Math108a - Fall - 2013 - Lecture5 - Linear IndependenceDocument7 pagesMath108a - Fall - 2013 - Lecture5 - Linear IndependenceArunmozhliNo ratings yet

- Specification of Combine HarvesterDocument18 pagesSpecification of Combine HarvesterImpang KichuNo ratings yet

- A Project Proposal of Online Enrollment in WmsuDocument9 pagesA Project Proposal of Online Enrollment in WmsuClairole Marie Quilantang100% (2)

- 2020 Wddty February 2020Document84 pages2020 Wddty February 2020San RajNo ratings yet

- Pathway To English Peminatan 3 Bab 3Document9 pagesPathway To English Peminatan 3 Bab 3Agung PrasetyoNo ratings yet

- Confined Space Hazards AwarenessDocument27 pagesConfined Space Hazards AwarenessNoor Fadilah Printis100% (1)

- 8602 1 PDFDocument14 pages8602 1 PDFwajiha0% (2)