Professional Documents

Culture Documents

Test Report: M. Crystal Ind. Services Corp

Test Report: M. Crystal Ind. Services Corp

Uploaded by

MARKOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Report: M. Crystal Ind. Services Corp

Test Report: M. Crystal Ind. Services Corp

Uploaded by

MARKCopyright:

Available Formats

M. CRYSTAL IND. SERVICES CORP. كريستال المروج للخدمات الصناعية.

م

P.O. BOX 363 – Jubail 31951 ٣١٩٥١الجبيل-٣٦٣ ب.ص

Kingdom of Saudi Arabia المملكة العربية السعودية

Tel.: (03) 362 6994 (٠٣ ) ٣٦٢ ٦٩٩٤هاتف

Mobile: +966 507247271 +٩٦٦٥٠٧٢٤٧٢٧١:جوال

Fax: (03) 362 6998 )٠٣( ٣٦٢ ٦٩٩٨ :فاكس

C.R. 2055005283 ٢٠٥٥٠٠٥٢٨٣ت.س

E-mail: crystalcorp@mcrystal.net crystalcorp@mcrystal.net :بريد

Website: www.mcrystalcorp.com www.mcrystalcorp.com :بريد إلكتروني

TEST REPORT

NO : 4017

DATE : JAN. 24, 2022

P.O. # : 5190003197

COMPANY NAME : National Petroleum Technology Co. ( NESR )

TANK DESCRIPTION : ACID FRAC TANK # 0072

LINING/COATING: ACID FRAC TANK IS LINED WITH FIBER GLASS

MATERIAL (5mm) ON THE INSIDE OF THE STEEL SHELL.

TEST LOCATION : NESR YARD IN HAWIYA

VISUAL TEST: NO DEFECTS FOUND. ACCEPTABLE

HOLIDAY TEST: Elcometer 236, Serial GF91968-14. No Spark Noticed. Acceptable

VOLTAGE USED : 5,000 Volts

EXTERNAL COATING : NOT Applicable

COMMENT: Acid Frac Tank is in Good Condition and can go for Acid Service.

Next Inspection Recommended within 12 months’ time. JAN.23 2023

TANK RESULT : PASSED

CRYSTAL CORP. CLIENT

Tank Name: NESR tank Year: 2019

Tank Type: Frac Useful For: Acid

Tank Capacity: 500bbl Inspected By: Crystal Corp.

Material Used: Fiberglass Date of Inspection: JAN. 23, 2022

ANNUAL ABOVEGROUND STORAGE TANK INSPECTION CHECKLIST

The inspection of this tank was performed by a professional coating inspector from M.

CRYSTAL IND. SERVICES CORP. who has over ten years of experience in the FRP business.

The inspection consisted of the visual observation of the tank’s interior and exterior components

as well as the coating systems. The tank was drained for the duration of the inspection and a

Spark Test was performed in the areas of concern.

INTERNAL & EXTERNAL INSPECTION

Was the containment structure in proper working condition

Yes No N/A

before inspection?

Was the coating in visible satisfactory condition? Yes No N/A

Was the coating of appropriate thickness fit for operation? Yes No N/A

Were there any pinholes or discontinuities detected in the lining? Yes No N/A

Was there any detectable light penetrating the coated steel from

Yes No N/A

anywhere other than the top manways?

Was there any spark detected during the Holiday examination? Yes No N/A

If so, was the spark of right characteristics and reactive nature?* Yes No N/A

Was there any lining missing inside the structure? Yes No N/A

Was there any visible Peeling, Cracking, Crazing, or Blistering Yes No N/A

of the coating?

Was there any evidence of rust or steel degradation inside the Yes No N/A

structure?*

Did the coating appear to have a dry or rough surface? Yes No N/A

Were there any noticeable areas of moisture inside the tank? Yes No N/A

Were there any noticeable areas of moisture outside the tank? Yes No N/A

Was there evidence of external paint failures that could be an Yes No N/A

indication of an internal leaks?

Were there noticeable distortions in the tank shell/head/ bottom

Yes No N/A

such as buckling, denting, or bulging?

Was there evidence of major corrosion of the tank shell /head/

Yes No N/A

bottom that was of worrisome nature?*

Were the internal support columns in good working condition,

Yes No N/A

especially around the edges where the lining is prone to crack?

Was the external steel thickness within satisfactory working

Yes No N/A

conditions?

Was the coating supporting the Manifold in proper working

Yes No N/A

condition?

Were the Manifolds free of Peeling, Cracking, Crazing,

Yes No N/A

Blistering, Corrosion or Pinholes?

Were the manways functional and was the coating supporting

Yes No N/A

them still intact, free of Peeling, Cracking and Corrosion?

Were the external pipes tightly fitted and free of stains,

Yes No N/A

alterations and corrosion?

Were the drainage Pipes/Valves fit for continued service? Yes No N/A

Did the perimeter seams and welding joints appear to be sealed

Yes No N/A

with no evidence of leaking?

CONCLUSION

a) The Storage Tank is fit for work with no defects detected and can begin operation

immediately.

b) The Storage Tank is fit for work but with minor defects detected that are un-harmful to the

scope of work, and can begin operation immediately.

c) The Storage Tank is NOT fit for work with Major defects detected and should be sent for

repair immediately.

Reference *

Rust Grades according to Swedish Standard 055900

A. Steel surface covered completely with adhering mill scale and with little or no rust.

B. Steel surface which has started to rust and from which the mill scale has begun to flake.

C. Steel surface where the mill scale has rusted away or from which it can be scraped with little pitting visible

to the naked eye.

D. Steel surface where the mill scale has rusted away and where pitting is visible to the naked eye.

You might also like

- Car Owner Database - CL 8826460912Document3 pagesCar Owner Database - CL 8826460912mobile number database27% (11)

- HR Defect AlbumDocument27 pagesHR Defect AlbumPrabhakar Kattula33% (3)

- Chemical Hazard Bulletin: Schlumberger Logeco Acid Retarding Agent J683Document1 pageChemical Hazard Bulletin: Schlumberger Logeco Acid Retarding Agent J683MARKNo ratings yet

- Paper No.: Pitting Corrosion Problems of Stainless Steels in A Pta PlantDocument12 pagesPaper No.: Pitting Corrosion Problems of Stainless Steels in A Pta PlantAdrian Galvis100% (1)

- Oracle Risk Management Cloud Financial Reporting Compliance Fundamentals Sample PDFDocument30 pagesOracle Risk Management Cloud Financial Reporting Compliance Fundamentals Sample PDFsw21910No ratings yet

- Wells Fargo Team Member Handbook HB - OnlineDocument279 pagesWells Fargo Team Member Handbook HB - OnlineLisa Stinocher OHanlon100% (2)

- Galvanizing Defects RectificationsDocument28 pagesGalvanizing Defects RectificationslakshanNo ratings yet

- Một số lỗi về mạDocument11 pagesMột số lỗi về mạĐình Khoa PhanNo ratings yet

- Galvanizing Defects RectificationsDocument19 pagesGalvanizing Defects RectificationskumarNo ratings yet

- Coatings For Steel Including Inorganic & OrganicDocument145 pagesCoatings For Steel Including Inorganic & OrganicSphesihle MagubaneNo ratings yet

- XGD 435 Bus - 02 - Interior Seal Plates Quality Inspection Report - 16.05.2022Document4 pagesXGD 435 Bus - 02 - Interior Seal Plates Quality Inspection Report - 16.05.2022MASEDE JOBNo ratings yet

- Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsDocument8 pagesPractical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsIan FletcherNo ratings yet

- Nickel Acetate Seal Makes A Smut - Film On Our Black AnodizeDocument7 pagesNickel Acetate Seal Makes A Smut - Film On Our Black AnodizealipeyNo ratings yet

- HDG Practical GuidelinesDocument7 pagesHDG Practical GuidelinesMantasNo ratings yet

- Galvanizing ChecklistDocument1 pageGalvanizing ChecklistআসিফহাসানখানNo ratings yet

- Silo - Tips - Problem Solving ForumDocument5 pagesSilo - Tips - Problem Solving ForumMax DraggerNo ratings yet

- Mechanical SealsDocument3 pagesMechanical Sealsapi-3848429100% (2)

- Oating Failure Filter For Water TreatmentDocument13 pagesOating Failure Filter For Water TreatmentAmati AntonioNo ratings yet

- Daily Report 27-11-2021Document7 pagesDaily Report 27-11-2021Ahmed MohammedNo ratings yet

- 0 Condition Survey RPTDocument35 pages0 Condition Survey RPTKingEphrem10100% (1)

- Daily Report 25-11-2021Document7 pagesDaily Report 25-11-2021Ahmed MohammedNo ratings yet

- Coating Procedure - Sop 04 Abrasive ControlDocument2 pagesCoating Procedure - Sop 04 Abrasive ControlajimalbaljeetNo ratings yet

- Cyclone QuestionnaireDocument4 pagesCyclone Questionnairemshah222No ratings yet

- 15 Checklist For PlasteringDocument1 page15 Checklist For PlasteringsoorajNo ratings yet

- Casting High Quality C12A: Bradken Energy ProductsDocument37 pagesCasting High Quality C12A: Bradken Energy Productsdelta lab sangliNo ratings yet

- EFDFrequently Asked QuestionsDocument2 pagesEFDFrequently Asked QuestionsLuiz FabianoNo ratings yet

- She 9.5 TravellerDocument11 pagesShe 9.5 TravellerBen WooffNo ratings yet

- Cut StoneDocument7 pagesCut Stonejack.simpson.changNo ratings yet

- GI Defects & Its Repair MethodDocument4 pagesGI Defects & Its Repair MethodmanojbarikjglNo ratings yet

- Paint: Guide To Preparing Hot-Dip Galvanized Steel ForDocument12 pagesPaint: Guide To Preparing Hot-Dip Galvanized Steel ForEidrish ShaikhNo ratings yet

- Failure Tube BoilerDocument8 pagesFailure Tube Boilerberanosh100% (3)

- RESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceDocument11 pagesRESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceLaxit100% (1)

- Evaluation - 2012-256 - Responsive - 4Document74 pagesEvaluation - 2012-256 - Responsive - 4Bob MackinNo ratings yet

- Inspection and Test Plan - Sprinkler System - Rev 01Document7 pagesInspection and Test Plan - Sprinkler System - Rev 01Anonymous ixIhrPM2No ratings yet

- Shielding Vs Non-Shielding CoatingsDocument62 pagesShielding Vs Non-Shielding CoatingsAce AceNo ratings yet

- Derr 2023 009988Document2 pagesDerr 2023 009988Ngwa ElvisNo ratings yet

- Webinar - Concrete Shrinkage MitigationDocument52 pagesWebinar - Concrete Shrinkage MitigationGonzalo OviedoNo ratings yet

- Port 5Document18 pagesPort 5gbsubbuNo ratings yet

- Sika Anchorfix®-3030: Product Data SheetDocument5 pagesSika Anchorfix®-3030: Product Data SheetPramuditha SuraweeraNo ratings yet

- BBA Assessment Report S260461 - CopieDocument15 pagesBBA Assessment Report S260461 - CopiearbiNo ratings yet

- Paint GuideDocument12 pagesPaint GuideLeo RaivoganNo ratings yet

- Boiler Tube Analysis: Reduce Future Boilertube FailuresDocument8 pagesBoiler Tube Analysis: Reduce Future Boilertube FailuresIWE Study MaterialsNo ratings yet

- Boiler Tube AnalysisDocument8 pagesBoiler Tube Analysisparholong100% (1)

- Chlor Rid SlidesDocument47 pagesChlor Rid Slidesmohammed goudaNo ratings yet

- Galvanising InspectionDocument3 pagesGalvanising InspectionannamachaaryaNo ratings yet

- Corrosion Control of Reinforcement Bars (Rebars)Document7 pagesCorrosion Control of Reinforcement Bars (Rebars)Lan LavistoNo ratings yet

- Concessionaire Tuni ROBDocument9 pagesConcessionaire Tuni ROBL N MALVIYA INFRA PROJECTSNo ratings yet

- Strucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKDocument1 pageStrucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKSteelcraft engineeringNo ratings yet

- The Purpose of Pigging: Crude Oil Pipelines CleaningDocument1 pageThe Purpose of Pigging: Crude Oil Pipelines CleaningferdosizadehNo ratings yet

- Dowel Bar KDOTSurvey 1Document3 pagesDowel Bar KDOTSurvey 1faisal dildarNo ratings yet

- Why Do Kraft Recovery Boiler Composite Floor TubesDocument12 pagesWhy Do Kraft Recovery Boiler Composite Floor TubesNarayanan KharthiNo ratings yet

- Es9725 (002) Norma 2 ZincDocument13 pagesEs9725 (002) Norma 2 Zincfernando.zabdiNo ratings yet

- Flow Accelerated Corrosion (FAC) of Deaerator TankDocument1 pageFlow Accelerated Corrosion (FAC) of Deaerator TankAliNo ratings yet

- Met Process and DefectsDocument85 pagesMet Process and DefectsBITS PILANI WILP MTQMNo ratings yet

- How to Select, Equip and Maintain a Cruising Boat. The Series.From EverandHow to Select, Equip and Maintain a Cruising Boat. The Series.Rating: 5 out of 5 stars5/5 (1)

- On the Construction of a Silvered Glass Telescope: Fifteen and a half inches in aperture, and its use in celestial photographyFrom EverandOn the Construction of a Silvered Glass Telescope: Fifteen and a half inches in aperture, and its use in celestial photographyNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Family Handyman Whole House Repair Guide Vol. 2: 300+ Step-by-Step Repairs, Hints and Tips for Today's HomeownersFrom EverandFamily Handyman Whole House Repair Guide Vol. 2: 300+ Step-by-Step Repairs, Hints and Tips for Today's HomeownersFamily HandymanNo ratings yet

- Processing, Properties, and Applications of Glass and Optical MaterialsFrom EverandProcessing, Properties, and Applications of Glass and Optical MaterialsNo ratings yet

- Chemical Hazard Bulletin: Ecolab M290Document1 pageChemical Hazard Bulletin: Ecolab M290MARKNo ratings yet

- 4043 LabelDocument1 page4043 LabelMARKNo ratings yet

- Chemical Hazard Bulletin: Schlumberger Surfactant F112Document1 pageChemical Hazard Bulletin: Schlumberger Surfactant F112MARKNo ratings yet

- 4068 LabelDocument1 page4068 LabelMARK100% (1)

- Health Hazards: CHB 4220 CHB 4220Document1 pageHealth Hazards: CHB 4220 CHB 4220MARKNo ratings yet

- Chemical Hazard Bulletin: Schlumberger Acid Retarding Agent J682Document1 pageChemical Hazard Bulletin: Schlumberger Acid Retarding Agent J682MARKNo ratings yet

- Theta Enterprises, Inc.: Stand-Alone Installation Guide For USB SentinelDocument4 pagesTheta Enterprises, Inc.: Stand-Alone Installation Guide For USB Sentinelatilio martinezNo ratings yet

- 07.08.13-2231 EN Check Push Button ControllerDocument1 page07.08.13-2231 EN Check Push Button ControllerJezrell JaravataNo ratings yet

- Devices Working On Att NetworkDocument13 pagesDevices Working On Att NetworkEthanNo ratings yet

- Long Lead Acid Battery 12v 65ahDocument2 pagesLong Lead Acid Battery 12v 65ahnadeemNo ratings yet

- User Guide BEEP AND PARKDocument9 pagesUser Guide BEEP AND PARKzxsdfNo ratings yet

- Unveil The Mystery of Code Coverage in Low-Power Designs: Achieving Power AwareDocument13 pagesUnveil The Mystery of Code Coverage in Low-Power Designs: Achieving Power AwareNishit GuptaNo ratings yet

- Dms Link 4.0 For Enterprise: Automate Paper-Intensive WorkflowsDocument2 pagesDms Link 4.0 For Enterprise: Automate Paper-Intensive WorkflowsmcrissNo ratings yet

- 01B. Introduction Data Strictures and AlgorithimsDocument331 pages01B. Introduction Data Strictures and Algorithimspiyushbose100% (1)

- Amazon - in - Order 405-4802236-5693166Document1 pageAmazon - in - Order 405-4802236-5693166Madhumitha LNo ratings yet

- HD 973P Parking Lift Manual 5175238 BendPakDocument92 pagesHD 973P Parking Lift Manual 5175238 BendPakHector VertizNo ratings yet

- An Introduction To Cognitive Psychology: Cognition, 8e by Margaret W. MatlinDocument6 pagesAn Introduction To Cognitive Psychology: Cognition, 8e by Margaret W. Matlinhen chNo ratings yet

- Engineering Guide Flex and Rigid Flex PCBsDocument14 pagesEngineering Guide Flex and Rigid Flex PCBsMariano DiazNo ratings yet

- Blowfish AlgorithmDocument11 pagesBlowfish AlgorithmMomtaj Hossain MowNo ratings yet

- SVPWM Vs SPWM Modulation Techniques - Imperix Power ElectronicsDocument1 pageSVPWM Vs SPWM Modulation Techniques - Imperix Power ElectronicsRafael MendozaNo ratings yet

- NRP Undertaking FormDocument1 pageNRP Undertaking FormAlexia JacksonNo ratings yet

- ISO 15531 MANDATE: A Product-Process-Resource Based Approach For Managing Modularity in Production ManagementDocument4 pagesISO 15531 MANDATE: A Product-Process-Resource Based Approach For Managing Modularity in Production ManagementJanven A. GranfonNo ratings yet

- Search in AIDocument55 pagesSearch in AIArijit GhoshNo ratings yet

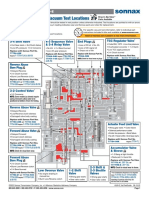

- 4L60-E VacTestGuideDocument4 pages4L60-E VacTestGuideJailton GomesNo ratings yet

- 21RMI56Document74 pages21RMI56Dheeraj100% (1)

- Ase Collision Repair and Refinish Tests: T O Ase S GDocument39 pagesAse Collision Repair and Refinish Tests: T O Ase S GCarlos Calderon GuzmanNo ratings yet

- Module Workshop and TheoryDocument1 pageModule Workshop and TheoryJoshua Allen AjetoNo ratings yet

- Bedienungs-Und Wartungsanleitung: Operating and Maintenance InstructionsDocument17 pagesBedienungs-Und Wartungsanleitung: Operating and Maintenance Instructionsuuur35No ratings yet

- Append Many Files (Dir)Document3 pagesAppend Many Files (Dir)wellawalalasithNo ratings yet

- Jockey Pump Balsam (Grundfosh) PDFDocument11 pagesJockey Pump Balsam (Grundfosh) PDFm khaeronNo ratings yet

- Alarma DS-PHA48-EP - DatasheetDocument4 pagesAlarma DS-PHA48-EP - DatasheetHector Gary Moquete AlcantaraNo ratings yet

- Gopertz Growth Curve, Linear Co-EfficientDocument17 pagesGopertz Growth Curve, Linear Co-EfficientAmal DattaNo ratings yet

- Dynamic Memory AllocationDocument4 pagesDynamic Memory AllocationSunil SuryawanshiNo ratings yet