Professional Documents

Culture Documents

Deisgn of Machine Elements (MTE2202 - 2)

Deisgn of Machine Elements (MTE2202 - 2)

Uploaded by

MeghaCopyright:

Available Formats

You might also like

- Aprilia Scarabeo 500 20052006 EN PDFDocument138 pagesAprilia Scarabeo 500 20052006 EN PDFTomDee0% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- ME-6503 Design of Machine Elements - 16 MarksDocument12 pagesME-6503 Design of Machine Elements - 16 MarksMadhu MithaNo ratings yet

- Dme Model QuestionDocument2 pagesDme Model QuestiondharaniventhanNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- B.Tech Mechatronics DOM SupplyDocument4 pagesB.Tech Mechatronics DOM SupplyMakesh KrishnaNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Assignment No-01 MEPC-301Document6 pagesAssignment No-01 MEPC-301SANDEEP BUDANIANo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Question Bank: Module 1:design For Static StrengthDocument22 pagesQuestion Bank: Module 1:design For Static Strengthcrazy hjNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- Dme 2Document6 pagesDme 2NITHISH KUMAR M SNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Dme Model QPDocument3 pagesDme Model QPCody LeeNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- 107503MEDocument7 pages107503MEPrathamNo ratings yet

- 21 ME63 Set 1&2Document7 pages21 ME63 Set 1&2prathapkumar2403No ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- Code: 13A03505: (Mechanical Engineering)Document2 pagesCode: 13A03505: (Mechanical Engineering)MrHEMAMAHEHNo ratings yet

- DMM 1 Assignment Questions FinalDocument2 pagesDMM 1 Assignment Questions FinalSrimanthula SrikanthNo ratings yet

- Design of Machine ElementDocument11 pagesDesign of Machine ElementVenkat RajaNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- Docs MEDMMIAssignments2013 PDFDocument13 pagesDocs MEDMMIAssignments2013 PDFHafiz Mahar28No ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Design of Machine Elements Question Paper SampleDocument6 pagesDesign of Machine Elements Question Paper SampleK V SATHEESHKUMAR MECHNo ratings yet

- 9A03504 Design of Machine Elements 21Document8 pages9A03504 Design of Machine Elements 21slv_prasaadNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.lavanya babuNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- DMM-1 MID-2 Assignment QuestionsDocument3 pagesDMM-1 MID-2 Assignment Questionsuppada AnilNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- Question Paper Code:: Reg. NoDocument3 pagesQuestion Paper Code:: Reg. NoSURESH KUMAR APNo ratings yet

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 pagesB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- MD ConventionalDocument8 pagesMD ConventionalBipin KumarNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Home-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsFrom EverandHome-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Linear Control Theory (MTE 2203) RCSDocument4 pagesLinear Control Theory (MTE 2203) RCSMeghaNo ratings yet

- Linear Control Theory (MTE 2203) RCS RDocument4 pagesLinear Control Theory (MTE 2203) RCS RMeghaNo ratings yet

- Linear Control Theory (MTE - 2203 - 1)Document4 pagesLinear Control Theory (MTE - 2203 - 1)MeghaNo ratings yet

- Linear Control Theory (MTE - 2203 - 2)Document3 pagesLinear Control Theory (MTE - 2203 - 2)MeghaNo ratings yet

- Gpa en ManualDocument38 pagesGpa en ManualmecmachoNo ratings yet

- Stuff BoxDocument12 pagesStuff BoxHamed GeramiNo ratings yet

- Manual de Parte GenieDocument202 pagesManual de Parte Geniejulio cesarNo ratings yet

- Vento Engine Parts For RX8Document8 pagesVento Engine Parts For RX8Jose Roberto AstiviaNo ratings yet

- How To Disassemble & Take Apart ANY Laptop in 8 Easy StepsDocument18 pagesHow To Disassemble & Take Apart ANY Laptop in 8 Easy StepsSkyNo ratings yet

- 070-251 SM - 2007 - 01 Service Manual TDSH & GDSHDocument12 pages070-251 SM - 2007 - 01 Service Manual TDSH & GDSHAlexNo ratings yet

- ME6503-Design of Machine Elements PDFDocument15 pagesME6503-Design of Machine Elements PDFkarthikNo ratings yet

- Rock DrillDocument75 pagesRock DrillElber Luis Chavez BarriosNo ratings yet

- Padeye PATIDocument43 pagesPadeye PATIbayu_23RNo ratings yet

- Civil Work Specification Part 44Document10 pagesCivil Work Specification Part 44AM MANo ratings yet

- Tronxy X3 Assemble Guide V.03Document30 pagesTronxy X3 Assemble Guide V.03everestoNo ratings yet

- Ryobi 3200PFADocument304 pagesRyobi 3200PFAmayol55No ratings yet

- MD Class Test 1Document5 pagesMD Class Test 1Sambit Das0% (1)

- TK Trunnion Mounted Ball Valves Brochure PDFDocument32 pagesTK Trunnion Mounted Ball Valves Brochure PDFAcid HadiNo ratings yet

- 28 - HitakaDocument11 pages28 - HitakaKha PhucNo ratings yet

- Spare Part List HGX4 465-4Document6 pagesSpare Part List HGX4 465-4zied touilNo ratings yet

- Ch2100x Rev 8 Parts Manual New Side Conveyors Design AddedsmallDocument230 pagesCh2100x Rev 8 Parts Manual New Side Conveyors Design AddedsmallOrlando Melipillan80% (5)

- New Holland W170B Tier 3 Wheel Loader Service Repair ManualDocument21 pagesNew Holland W170B Tier 3 Wheel Loader Service Repair ManualggjjjjotonesNo ratings yet

- Coaching Notes MC Design 3Document248 pagesCoaching Notes MC Design 3kristan7100% (1)

- Latest Company Profile of Jalmi ConstDocument11 pagesLatest Company Profile of Jalmi ConstArlyn OcampoNo ratings yet

- Drilling MachineDocument87 pagesDrilling MachineRamesh Panda50% (4)

- Fuel Filter 1Document2 pagesFuel Filter 1Anonymous F4tPbieYEGNo ratings yet

- Landa HS-3000 Operator ManualDocument28 pagesLanda HS-3000 Operator ManualullwnNo ratings yet

- Notes:: Supporting Beam Supported ColumnDocument2 pagesNotes:: Supporting Beam Supported Columnmassive85No ratings yet

- MOTORTECH Technical Data Sheet Ignition Coil 06.50.100 01.13.005 en 2014 11Document2 pagesMOTORTECH Technical Data Sheet Ignition Coil 06.50.100 01.13.005 en 2014 11chao wangNo ratings yet

- LEY 63 Folha de DadosDocument8 pagesLEY 63 Folha de DadoseduardoNo ratings yet

- 3 Step Stool Overview 1: Project: Drawn By: Scale (At P4) DescriptionDocument5 pages3 Step Stool Overview 1: Project: Drawn By: Scale (At P4) DescriptionMatias Rivera BelmarNo ratings yet

- Hinged Window HardwareDocument446 pagesHinged Window Hardwaredavid0775No ratings yet

- Threads - Metric ISO 724Document5 pagesThreads - Metric ISO 724sathishNo ratings yet

Deisgn of Machine Elements (MTE2202 - 2)

Deisgn of Machine Elements (MTE2202 - 2)

Uploaded by

MeghaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deisgn of Machine Elements (MTE2202 - 2)

Deisgn of Machine Elements (MTE2202 - 2)

Uploaded by

MeghaCopyright:

Available Formats

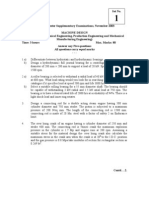

Reg. No.

IV SEMESTER B.TECH. (MECHATRONICS ENGINEERING)

END SEMESTER EXAMINATIONS, JUNE 2018

SUBJECT: DESIGN OF MACHINE LEMENTS [MTE 2202]

Time: 3 Hours MAX. MARKS: 50

Instructions to Candidates:

Answer ALL the questions.

Data not provided may be suitably assumed with justification

1A The load F on a simply supported shaft shown in Fig Q1A is 4 kN. Find the radius 05

of the fillet if the stresses at both the fillets are same. Length of the shaft between

two bearings is 1200 mm.

Fig Q1A

1B A spring-loaded safety valve for a boiler is required to blow off at a pressure of 05

1.5 N/mm2. The diameter of the valve is 60 mm. Design a suitable compression

spring for the safety valve assuming spring index to be 6 and 25mm initial

compression. The maximum lift of the valve is 15 mm. The shear stress in the

spring is to be limited to 450 MPa. Take G= 0.84X 105 MPa.

2A A pair of spur gears have 20˚ full depth involute teeth. The pinion is connected to 08

35kW motor and rotates at 1440 RPM. The speed reduction is 10:1. The number

of teeth on pinion is 24. Both pinion and gear are made of case hardened steel and

[MTE 2202] Page 1 of 3

allowable bending stress is 200 N/mm2. The modulus of elasticity is 200 X 103

N/mm2. The gears are subjected to steady loads and operate 8-10 hours per day.

Design the gears.

2B. A steel bolt of size M20 is used to connect 2 plates of each 16mm thick. A soft 2

copper gasket of 3mm thickness is used in between the plates for the joint to be

leak proof. The outside and inside diameters of the gasket are 50mm and 22mm

respectively. Take modulus of elasticity of bolt material as 200MPa and for gasket

material as 120 MPa. The bolt is subjected to an axial load of 15KN. Determine

the stress induced in the bolt.

3A A deep groove ball bearing is subjected to a radial load of 2.5 kN and an axial load 5

of 0.9 kN. The shaft runs at 3000 RPM and expected to run for 15000 hours. Take

shaft diameter as 80 mm. Select a suitable bearing.

3B Square thread of a screw jack has specifications of 80×16 and is to raise a load of 5

100KN. The mean radius of the thrust collar is 65mm. The coffecient of friction

for threads and collar are 0.1 and 0.12 respectively. Determine:

(i) Torque required to raise the load.

(ii) The overall efficiency.

(iii) Check for overhauling.

4A A section of commercial shafting 2m long between bearings carries a 1000N 8

pulley at its midpoint as shown in Fig Q4A. The pulley is keyed to the shaft and

receives 30kW at 150RPM which is transmitted to a flexible coupling just outside

the right bearing. The belt drive is horizontal and the sum of the belt tensions is

8000N. Assume Cm=Ct=1.5. Calculate the necessary shaft diameter.

Fig Q4A

4B. It is required to design a square key for fixing a gear on a shaft of 25 mm diameter. 2

15 kW of power at 720 RPM is transmitted from the shaft to the gear. Key is made

[MTE 2202] Page 2 of 3

of steel 50C4 with yield stress 460 N/mm2 anf FOS of 3. Determine the key

dimensions

5A The following figure Fig Q5A shows a flat plate under a tensile load. Using a 5

design stress of 80 MPa, determine the thickness of the plate.

Fig Q5A

5B A cantilever beam of rectangular cross section has a span of 800mm. The depth is 05

200mm. The free end of the beam is subjected to a transverse load that fluctuates

80KN upwards to 50KN downwards. It is made of steel having 𝜎𝑢 = 550 MPa and

𝜎𝑦 = 400 𝑀𝑃𝑎. Find the width of section taking factor of safety 2.5. The size and

surface factors are 0.8 and 0.85 respectively.

[MTE 2202] Page 3 of 3

You might also like

- Aprilia Scarabeo 500 20052006 EN PDFDocument138 pagesAprilia Scarabeo 500 20052006 EN PDFTomDee0% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- ME-6503 Design of Machine Elements - 16 MarksDocument12 pagesME-6503 Design of Machine Elements - 16 MarksMadhu MithaNo ratings yet

- Dme Model QuestionDocument2 pagesDme Model QuestiondharaniventhanNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- B.Tech Mechatronics DOM SupplyDocument4 pagesB.Tech Mechatronics DOM SupplyMakesh KrishnaNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Assignment No-01 MEPC-301Document6 pagesAssignment No-01 MEPC-301SANDEEP BUDANIANo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Question Bank: Module 1:design For Static StrengthDocument22 pagesQuestion Bank: Module 1:design For Static Strengthcrazy hjNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- Dme 2Document6 pagesDme 2NITHISH KUMAR M SNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Dme Model QPDocument3 pagesDme Model QPCody LeeNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- 107503MEDocument7 pages107503MEPrathamNo ratings yet

- 21 ME63 Set 1&2Document7 pages21 ME63 Set 1&2prathapkumar2403No ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- Code: 13A03505: (Mechanical Engineering)Document2 pagesCode: 13A03505: (Mechanical Engineering)MrHEMAMAHEHNo ratings yet

- DMM 1 Assignment Questions FinalDocument2 pagesDMM 1 Assignment Questions FinalSrimanthula SrikanthNo ratings yet

- Design of Machine ElementDocument11 pagesDesign of Machine ElementVenkat RajaNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- Docs MEDMMIAssignments2013 PDFDocument13 pagesDocs MEDMMIAssignments2013 PDFHafiz Mahar28No ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Design of Machine Elements Question Paper SampleDocument6 pagesDesign of Machine Elements Question Paper SampleK V SATHEESHKUMAR MECHNo ratings yet

- 9A03504 Design of Machine Elements 21Document8 pages9A03504 Design of Machine Elements 21slv_prasaadNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.lavanya babuNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- DMM-1 MID-2 Assignment QuestionsDocument3 pagesDMM-1 MID-2 Assignment Questionsuppada AnilNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- Question Paper Code:: Reg. NoDocument3 pagesQuestion Paper Code:: Reg. NoSURESH KUMAR APNo ratings yet

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 pagesB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- MD ConventionalDocument8 pagesMD ConventionalBipin KumarNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Home-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsFrom EverandHome-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Linear Control Theory (MTE 2203) RCSDocument4 pagesLinear Control Theory (MTE 2203) RCSMeghaNo ratings yet

- Linear Control Theory (MTE 2203) RCS RDocument4 pagesLinear Control Theory (MTE 2203) RCS RMeghaNo ratings yet

- Linear Control Theory (MTE - 2203 - 1)Document4 pagesLinear Control Theory (MTE - 2203 - 1)MeghaNo ratings yet

- Linear Control Theory (MTE - 2203 - 2)Document3 pagesLinear Control Theory (MTE - 2203 - 2)MeghaNo ratings yet

- Gpa en ManualDocument38 pagesGpa en ManualmecmachoNo ratings yet

- Stuff BoxDocument12 pagesStuff BoxHamed GeramiNo ratings yet

- Manual de Parte GenieDocument202 pagesManual de Parte Geniejulio cesarNo ratings yet

- Vento Engine Parts For RX8Document8 pagesVento Engine Parts For RX8Jose Roberto AstiviaNo ratings yet

- How To Disassemble & Take Apart ANY Laptop in 8 Easy StepsDocument18 pagesHow To Disassemble & Take Apart ANY Laptop in 8 Easy StepsSkyNo ratings yet

- 070-251 SM - 2007 - 01 Service Manual TDSH & GDSHDocument12 pages070-251 SM - 2007 - 01 Service Manual TDSH & GDSHAlexNo ratings yet

- ME6503-Design of Machine Elements PDFDocument15 pagesME6503-Design of Machine Elements PDFkarthikNo ratings yet

- Rock DrillDocument75 pagesRock DrillElber Luis Chavez BarriosNo ratings yet

- Padeye PATIDocument43 pagesPadeye PATIbayu_23RNo ratings yet

- Civil Work Specification Part 44Document10 pagesCivil Work Specification Part 44AM MANo ratings yet

- Tronxy X3 Assemble Guide V.03Document30 pagesTronxy X3 Assemble Guide V.03everestoNo ratings yet

- Ryobi 3200PFADocument304 pagesRyobi 3200PFAmayol55No ratings yet

- MD Class Test 1Document5 pagesMD Class Test 1Sambit Das0% (1)

- TK Trunnion Mounted Ball Valves Brochure PDFDocument32 pagesTK Trunnion Mounted Ball Valves Brochure PDFAcid HadiNo ratings yet

- 28 - HitakaDocument11 pages28 - HitakaKha PhucNo ratings yet

- Spare Part List HGX4 465-4Document6 pagesSpare Part List HGX4 465-4zied touilNo ratings yet

- Ch2100x Rev 8 Parts Manual New Side Conveyors Design AddedsmallDocument230 pagesCh2100x Rev 8 Parts Manual New Side Conveyors Design AddedsmallOrlando Melipillan80% (5)

- New Holland W170B Tier 3 Wheel Loader Service Repair ManualDocument21 pagesNew Holland W170B Tier 3 Wheel Loader Service Repair ManualggjjjjotonesNo ratings yet

- Coaching Notes MC Design 3Document248 pagesCoaching Notes MC Design 3kristan7100% (1)

- Latest Company Profile of Jalmi ConstDocument11 pagesLatest Company Profile of Jalmi ConstArlyn OcampoNo ratings yet

- Drilling MachineDocument87 pagesDrilling MachineRamesh Panda50% (4)

- Fuel Filter 1Document2 pagesFuel Filter 1Anonymous F4tPbieYEGNo ratings yet

- Landa HS-3000 Operator ManualDocument28 pagesLanda HS-3000 Operator ManualullwnNo ratings yet

- Notes:: Supporting Beam Supported ColumnDocument2 pagesNotes:: Supporting Beam Supported Columnmassive85No ratings yet

- MOTORTECH Technical Data Sheet Ignition Coil 06.50.100 01.13.005 en 2014 11Document2 pagesMOTORTECH Technical Data Sheet Ignition Coil 06.50.100 01.13.005 en 2014 11chao wangNo ratings yet

- LEY 63 Folha de DadosDocument8 pagesLEY 63 Folha de DadoseduardoNo ratings yet

- 3 Step Stool Overview 1: Project: Drawn By: Scale (At P4) DescriptionDocument5 pages3 Step Stool Overview 1: Project: Drawn By: Scale (At P4) DescriptionMatias Rivera BelmarNo ratings yet

- Hinged Window HardwareDocument446 pagesHinged Window Hardwaredavid0775No ratings yet

- Threads - Metric ISO 724Document5 pagesThreads - Metric ISO 724sathishNo ratings yet