Professional Documents

Culture Documents

PD 0158 SM 01

PD 0158 SM 01

Uploaded by

FAIZAN AHMEDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PD 0158 SM 01

PD 0158 SM 01

Uploaded by

FAIZAN AHMEDCopyright:

Available Formats

GENERAL NOTES

min.75mm

1. GENERAL 4. CONCRETE CONSTRUCTION

a. a. All structural surfaces in contact with earth (other than tanks and pool) shall be coated with two coats of hot

b. Read all drawings in conjunction with architectural, geotechnical bitumen of 10/20 grade at the rate of 1.0kg / sq. m / coat.

plumbing, mechanical, electrical & any other relevant trade drawings. b. Before casting of any structural member the contractor shall ensure that all embeded items for electrical,

c. Notes given in this drawing are applicable to all drawings unless mentioned otherwise, notes mechnical, HVAC, plumbing , structural steel and other works are properly located and firmly secured in

written on a drawing shall be applicable to that particular drawing only. unless otherwise cross-refered. place and proper spacing (min. one pipe diameter, clear) between pipe is achived.

d. All materials and workmanship shall conform to the specifications of the contract documents. c. Electro-mechanical vibrator must be used for compaction of fresh concrete.

In absnce of any specifications. All materials & workmanship shall conform to relevant. American/British

5. SHORING AND BRACING (STIRRUPS & TIE REINF.)

Codes and standards (as listed in PD-00158-SM-01A) and shall be subject to approval of the Engineer.

e. The contactor shall be responsible for the safety of the structures during construction. He shall also verify a. Shore and brace all parts of the structure during construction. To the extent necessary to ensure complete

all dimensions and levels before execution of work. Any discrepancy, error or omission, if found shall be safety, strength & serviceability of all structural elements under all conditions of load which may occure

brought to the notice of the engineer for correction and approval. during construction. Such shoring & bracing is the contactor's sole responsibility and is not shown on

f. The contactor shall co-ordinate with various services drawings for sizes & location of all structural structural drawings or specified in the project.

members, openings, floor finishes, pipes etc. b. The contactor shall be responsible for the safety and stability of the slopes and shall provide shoring &

g. The contactor shall be responsible for the excution of the dewatering system where so required during bracing during excavation & construction. Wherever and whenever required.

construction. 6. ELECTRICAL CONDUITS min.60mm

h. All dimensions are in millimetres (mm) & levels in metres . a. Conduits for electrical works shall be placed within the reinforced concrete. They shall be placed within the

i. Do not scale the drawings, dimensions given on the drawing, shall govern. middle third of the sections in beams and within the middle half of the thickness in slabs. Spacing between (PRIMARY REINF.)

j. All fabrication, painting, erection and quailty control is to be done in accordance with latest applicable parallel conduits shall not be less than 150mm.

ACI/British specifications.

k. Backfilling around foundations & walls shall be well compacted layers not exceeding 150 mm in 7. STRUCTURAL STEEL

thickness.Backfill material shall consist of 25mm or 20mm minus (i.e.,less than 5% passing #200 a. All structural steel shall conform to ASTM A 36.

seive),clean,well graded,angular,crushed gravel or rock, compacted to 98%. b. All connections bolts shall conform to ASTM A 325.

2. REINFORCEMENT CONCRETE 8. LEGEND

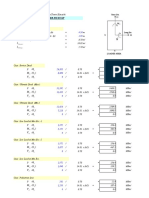

splice length

a. Structural design is based on the building codes requrements for reinforced concrete of American MS Mild steel

Concrete Institute (ACI 318-99) Polyvinyle chloride BEAM SPLICE (TYP) (STIRRUPS & TIE REINF.) (PRIMARY REINF.)

PVC

b. All structural concrete shall conform to American Concrete Institute (ACI) requirements.

splice length

CI Cast Iron

c. The minimum compressive cylinder strength of lean/blinding concrete shall be (7MPa) at 28 days. 1.5 x larger bar diameter or 40mm minimum

d. The minimum compressive cylinder strength of structural concrete shall be (28MPa) at 28 days. DI Ductile Iron

e. Every step of construction has to be inspected by the Engineer and no concreting shall be carried out SQ Square 8

layers use 25mm bar

7

C.J Construction joint

spacing between

untill written permission is given. VERTICAL BAR SPACING IN A COLUMN 6

f. For water retaining structure proper waterproofing admixtures to be used in concrete. T&B Top & Bottom 5

4

3. REINFORCEMENT STEEL EF Each Face 3

spacing between bars in a layer 2

a. All reinforcing Steel shall be hot rolled deformed bars conforming to ASTM A 615 grade60 or BS 4449, having BF Both Faces 1

shall be larger bar diameter 0 ISSUED FOR CONSTRUCTION 16-12-19

minimum yield strength of (414 MPa) NF Near Face No. Description:

or 25mm whichever is greater

FF Far Face Revisions

ID Inner Diameter Project:

b. Clear cover to reinforcement shall be: Diameter of bar (mm) COLUMN SPLICE (TYP) BAR SPACING IN A BEAM ASHAR FOUNTAIN

Structural Elements Clear Cover (mm) 9. WATER PROOFING

a.Foundations 75 a. Entire interior and exterior surfaces of tanks & pool shall be coated with water proofing material as shown in

b.Beams & Columns 40 architectural drawings.

c.Roof Slabs 25 b. Integral waterproofing admixture Betocrete-C16 by AQUAFIN SCHOMBURG or approved equivalent for

d.Tanks & Pool all around 50 tanks and pool concrete shall be used.

NOTE:The other waterproofing components shall be compatible with integral waterproofing admixture being used.

c. Minimum Overlaps (Splice lengths) of Bars/plate shall be

Typical Top Bars

780mm ALL PIPE SLEEVES SHALL BE CAST IN CONCRETE

975mm WITH PUDDLE FLANGE AND SWELL BARS.

1250mm CORE CUTTING IS NOT ALLOWED.

1500mm

( e) PVC Water stop = 300 mm

d. All reinforcing steel should be accurately located in the forms and held firmly in place before & during the

placement of concrete. By means of wire and supports adequate to prevent displacement during the course of Bahria Town Pvt.Ltd

SuperHighway Karachi

construction.Reinforcement to be inspected by the Engineer prior to casting of concrete.

Drawing Title:

GENERAL NOTES

Scale= @ A0 Date: 16-12-2019

DRAWN BY. STR.ENGINEER Revised.

A.U.H ANAS

Approved By:

GM.STRUCTURE

Dwg. No. Rev. No.

PD-0158-SM-01 00

You might also like

- Bailey Bridge Design Dwgs 39m Supstr+SubstrDocument16 pagesBailey Bridge Design Dwgs 39m Supstr+SubstrPrakash Singh RawalNo ratings yet

- Structural Design of Transformer PadDocument17 pagesStructural Design of Transformer PadArchilles P. AdverderadaNo ratings yet

- Metal ReinforcementDocument43 pagesMetal ReinforcementRonnel Jan BalsamoNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Barrier Design by Yield Line Aashto LRFDDocument2 pagesBarrier Design by Yield Line Aashto LRFDFAIZAN AHMEDNo ratings yet

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- Culvert Drawing BinderDocument5 pagesCulvert Drawing BinderAhmed Nader KhurshidNo ratings yet

- Structural AnalysisnewDocument6 pagesStructural AnalysisnewJunith Jay CalinawanNo ratings yet

- Notes For Structural DrawingsDocument3 pagesNotes For Structural DrawingsQaiser KhanNo ratings yet

- Division 3: Concrete SpecificationsDocument12 pagesDivision 3: Concrete SpecificationsKae MoNo ratings yet

- 09 28 13 Cement Board CeilingsDocument6 pages09 28 13 Cement Board CeilingsWagih NabihNo ratings yet

- Proposed Boarding House (Specifications)Document7 pagesProposed Boarding House (Specifications)Marc Kenneth ConchaNo ratings yet

- Sankhuwa Supstr+Substr-Design DwgsDocument12 pagesSankhuwa Supstr+Substr-Design DwgsPrakash Singh RawalNo ratings yet

- SECTION 03 41 00 Structural Precast Concrete Part 1 - GeneralDocument16 pagesSECTION 03 41 00 Structural Precast Concrete Part 1 - Generalraja qammarNo ratings yet

- General NotesDocument4 pagesGeneral NotesRinaldi DwiyantoNo ratings yet

- Cast in Place ConcreteDocument16 pagesCast in Place ConcreteabdouNo ratings yet

- SECTION 06 16 63 Cementitious SheathingDocument4 pagesSECTION 06 16 63 Cementitious SheathingJuanPaoloYbañezNo ratings yet

- ConstructionDocument8 pagesConstructionGaspar Lig-ang TolomiaNo ratings yet

- General specifications-GILODocument7 pagesGeneral specifications-GILOHannah Cesaree Mae TadeoNo ratings yet

- General Construction Note: F E D C B A L K J I H GDocument1 pageGeneral Construction Note: F E D C B A L K J I H Gengsamim.walizadaNo ratings yet

- Project: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle OrinaDocument7 pagesProject: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle Orinatyn de guzmanNo ratings yet

- SECTION 04 20 00 Unit MasonryDocument37 pagesSECTION 04 20 00 Unit MasonryJuanPaoloYbañezNo ratings yet

- SECTION 03 30 53 (Short-Form) Cast-In-Place ConcreteDocument13 pagesSECTION 03 30 53 (Short-Form) Cast-In-Place ConcreteJuanPaoloYbañezNo ratings yet

- Technical Specifications:: Construction of Concrete Pavement For Parking AreaDocument2 pagesTechnical Specifications:: Construction of Concrete Pavement For Parking AreaAnton_Young_1962No ratings yet

- Quality Procedure For ConcreteDocument12 pagesQuality Procedure For ConcreteEdrian DiazNo ratings yet

- Criterios de Diseño EstructuralDocument16 pagesCriterios de Diseño Estructuralangelus95No ratings yet

- Section 042000 - Unit MasonryDocument18 pagesSection 042000 - Unit Masonrysmaliyakkal786No ratings yet

- Section 03410-Precast Structural ConcreteDocument5 pagesSection 03410-Precast Structural ConcreteMØhãmmed ØwięsNo ratings yet

- Tensile Membrane Structures: Name of Project Page - of - July 9, 2013Document18 pagesTensile Membrane Structures: Name of Project Page - of - July 9, 2013jackNo ratings yet

- Dr. Chen's NotesDocument2 pagesDr. Chen's NoteskesharinareshNo ratings yet

- General Specifications MoryDocument7 pagesGeneral Specifications MoryHannah Cesaree Mae TadeoNo ratings yet

- Prestressing For Concrete StructuresDocument18 pagesPrestressing For Concrete StructuresIm ChinithNo ratings yet

- Keystone Compac PDocument8 pagesKeystone Compac PcinevaundevaNo ratings yet

- PVC SpecificationDocument17 pagesPVC SpecificationDavid Ruelas50% (2)

- PFEIFER Structures Section 133100 PVC SpecificationDocument17 pagesPFEIFER Structures Section 133100 PVC Specificationtidipa8386No ratings yet

- Electrical BOQ Plot C LPSDocument5 pagesElectrical BOQ Plot C LPSAgrawal PrajaktaNo ratings yet

- SECTION 03 41 13 Precast Concrete Hollow Core Planks Spec Writer NoteDocument4 pagesSECTION 03 41 13 Precast Concrete Hollow Core Planks Spec Writer NoteJuanPaoloYbañezNo ratings yet

- Plot A 007: Curtain Wall and Glazed AssembliesDocument6 pagesPlot A 007: Curtain Wall and Glazed AssembliesRACHED ABBOUDNo ratings yet

- Specifications PDFDocument30 pagesSpecifications PDFRivaiNo ratings yet

- Diaphragm/slurry Wall SpecificationDocument27 pagesDiaphragm/slurry Wall SpecificationRoy PersonalNo ratings yet

- Mozaik Climbing Wall Performance SpecDocument5 pagesMozaik Climbing Wall Performance SpecHarryDammanickNo ratings yet

- SECTION 07620 Sheet Metal Flashing and Trim Part 1 - General 1.1 General RequirmentsDocument5 pagesSECTION 07620 Sheet Metal Flashing and Trim Part 1 - General 1.1 General RequirmentsIm ChinithNo ratings yet

- Punta Fuego SpecsDocument5 pagesPunta Fuego SpecsMark Gregory RimandoNo ratings yet

- Expansion JointDocument7 pagesExpansion JointAbbas FarisNo ratings yet

- Specifications (San Carlos Heights)Document10 pagesSpecifications (San Carlos Heights)Bryan Soriano PascualNo ratings yet

- Section 09250Document9 pagesSection 09250Im ChinithNo ratings yet

- Pump HouseDocument6 pagesPump HouseHitesh GajeraNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-68Document7 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-68030093No ratings yet

- 3C. Switchgear IsolatorDocument17 pages3C. Switchgear Isolatoraviral mishraNo ratings yet

- Mw07620-Sheet Metal Flashing and TrimDocument8 pagesMw07620-Sheet Metal Flashing and TrimBanner BruceNo ratings yet

- Acousti-Seal 933E TDS PDFDocument20 pagesAcousti-Seal 933E TDS PDFsheenaho88No ratings yet

- Specifications Segment Inserts & GasketsDocument6 pagesSpecifications Segment Inserts & Gasketssatan007No ratings yet

- UG-IV-1-Concrete WorkDocument8 pagesUG-IV-1-Concrete WorkshreejeshNo ratings yet

- SECTION 14 31 00 Escalators: Contract SpecificationsDocument33 pagesSECTION 14 31 00 Escalators: Contract SpecificationsfalulhoodNo ratings yet

- Building SpecsDocument3 pagesBuilding SpecsAllen Robert WaganNo ratings yet

- Sequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualDocument31 pagesSequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualNirmal KishorNo ratings yet

- Technical Specs of PoleDocument22 pagesTechnical Specs of Poleanon_237992751No ratings yet

- Construction Notes: Hurricane Ties Connection DetailDocument8 pagesConstruction Notes: Hurricane Ties Connection DetailCristina Dangla CruzNo ratings yet

- Schedule D From Section 7Document53 pagesSchedule D From Section 7gowtham reddyNo ratings yet

- Construction SpecificationDocument9 pagesConstruction SpecificationAbdullah MangatongNo ratings yet

- Structural Notes Question AnswerDocument3 pagesStructural Notes Question AnswerIrahmae IranNo ratings yet

- Tech-Specs MonticelloDocument3 pagesTech-Specs MonticelloProvido, Ronald Frederick PNo ratings yet

- Composite Panel SpecificationDocument6 pagesComposite Panel SpecificationracvilleNo ratings yet

- Camber by Coefficients of Pci-Bridge Design ManualDocument4 pagesCamber by Coefficients of Pci-Bridge Design ManualFAIZAN AHMED100% (1)

- PD 0158 SM 03Document1 pagePD 0158 SM 03FAIZAN AHMEDNo ratings yet

- PD 0158 SM 06Document1 pagePD 0158 SM 06FAIZAN AHMEDNo ratings yet

- Slab by CoefficientsDocument7 pagesSlab by CoefficientsFAIZAN AHMEDNo ratings yet

- Seismic Forces CalculationDocument112 pagesSeismic Forces CalculationFAIZAN AHMEDNo ratings yet

- Design Loads On Pilecap (Circular Shaft)Document2 pagesDesign Loads On Pilecap (Circular Shaft)FAIZAN AHMEDNo ratings yet

- IET Member Transfer FormDocument4 pagesIET Member Transfer FormFAIZAN AHMEDNo ratings yet

- Diaphragms For Gravity Loads (AASHTO)Document14 pagesDiaphragms For Gravity Loads (AASHTO)FAIZAN AHMEDNo ratings yet

- Design Loads On Pier-Pilecap (Rectangular)Document2 pagesDesign Loads On Pier-Pilecap (Rectangular)FAIZAN AHMEDNo ratings yet

- Dramix 3D 4535BL-4535BLDocument1 pageDramix 3D 4535BL-4535BLricpieralisiNo ratings yet

- PROKON General ColumnDocument4 pagesPROKON General Columnsusan87No ratings yet

- Site Cast ConcreteDocument26 pagesSite Cast ConcretexaekneNo ratings yet

- Single Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIDocument12 pagesSingle Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIasad_naqvi100% (2)

- Cyclic Load Tests On Prestressed and Partially Prestressed Beam-Column Joints PARK & THOMPSONDocument27 pagesCyclic Load Tests On Prestressed and Partially Prestressed Beam-Column Joints PARK & THOMPSONprakashsomuNo ratings yet

- Component Response To Flexural, Axial and Shearing ForcesDocument31 pagesComponent Response To Flexural, Axial and Shearing ForcesEkky CecilNo ratings yet

- Effect of External Post-Tensioning in Retrofitting of RC BeamsDocument8 pagesEffect of External Post-Tensioning in Retrofitting of RC BeamsŽarko LazićNo ratings yet

- Steel To Concrete Simple Connection Example 1Document12 pagesSteel To Concrete Simple Connection Example 1CSEC Uganda Ltd.No ratings yet

- Sample Internship Report On Building Structures by Birhan SeteDocument46 pagesSample Internship Report On Building Structures by Birhan SeteBirhan SeteNo ratings yet

- BOQ Ato Abdulkader MuzemilDocument5 pagesBOQ Ato Abdulkader Muzemildawitggg100% (1)

- For Construction: Abbreviations Reference Drawings List (Standard Drawings) Legend Abbreviations Legend Legend 0Document1 pageFor Construction: Abbreviations Reference Drawings List (Standard Drawings) Legend Abbreviations Legend Legend 0rajendraNo ratings yet

- 08 c1152 - Apdu42 - Afc - Calcs (FKTP) - FinalDocument999 pages08 c1152 - Apdu42 - Afc - Calcs (FKTP) - FinalGeeNo ratings yet

- 248 1 CTRDocument111 pages248 1 CTRmohammed_fathelbabNo ratings yet

- BQ C6 PermataDocument42 pagesBQ C6 PermataGnabBangNo ratings yet

- R.V.CONSTRUCTIONS, SY NOS 631&644, BIT Nos.1,2,3 (Part)Document7 pagesR.V.CONSTRUCTIONS, SY NOS 631&644, BIT Nos.1,2,3 (Part)Ali HassenNo ratings yet

- T040032 00Document17 pagesT040032 00Doanh HoangNo ratings yet

- Structural ResidenceDocument4 pagesStructural Residence2226558No ratings yet

- Shiela S. Portillo Ang Specification 09112021Document9 pagesShiela S. Portillo Ang Specification 09112021JR De LeonNo ratings yet

- BEC 6 - Module 1.1 Introduction To Reinforced ConcreteDocument17 pagesBEC 6 - Module 1.1 Introduction To Reinforced Concretejohnpaul mosuelaNo ratings yet

- Amendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument3 pagesAmendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - Specificationraviteja036No ratings yet

- Bolted Bamboo Joints Reinforced With Fibers: SciencedirectDocument7 pagesBolted Bamboo Joints Reinforced With Fibers: SciencedirectVale RieNo ratings yet

- Improvement of The Dhaka (Katchpur) - Sylhet National Highway (N2) Into A 4-Lane Highway With Service Lane On Both SidesDocument20 pagesImprovement of The Dhaka (Katchpur) - Sylhet National Highway (N2) Into A 4-Lane Highway With Service Lane On Both SidesAdvut TonmoyNo ratings yet

- Full Download PDF of (Original PDF) Reinforced Concrete Design (9th Edition) All ChapterDocument43 pagesFull Download PDF of (Original PDF) Reinforced Concrete Design (9th Edition) All Chaptertiecoabuso100% (6)

- Final Internship ReportDocument49 pagesFinal Internship ReportUzair AhmadNo ratings yet

- Job Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006Document11 pagesJob Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006mahesh naikNo ratings yet

- Analysis and Design of Multi - Storey Building Under Load CombinationDocument8 pagesAnalysis and Design of Multi - Storey Building Under Load CombinationDebendra Dev KhanalNo ratings yet

- Steel Reinforcement For Concrete - BS 8666:2005: Shape Code Shape CodeDocument6 pagesSteel Reinforcement For Concrete - BS 8666:2005: Shape Code Shape CodeРумен ДрагановNo ratings yet

- LECTURE EstimateDocument47 pagesLECTURE EstimatePocholo BustosNo ratings yet