Professional Documents

Culture Documents

Raw Material Selection Guide Copper

Raw Material Selection Guide Copper

Uploaded by

Santosh KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raw Material Selection Guide Copper

Raw Material Selection Guide Copper

Uploaded by

Santosh KumarCopyright:

Available Formats

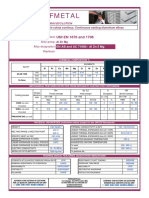

Stamping Material Selection Guide

Bend Rating Key:

Green Yellow Orange Red

ESI’s Bend Rating scale measures the formability of a Easy formability Moderate formability; Limited formability; Difficult formability;

material based on its ability to bend or form without possible strain chance of tearing likelihood of tearing

tearing or breaking. “Green” designates easier formability

all the way through “red” as most difficult.

Radii for various thicknesses, whereas “t”=times thickness. 0t to 3t 3t to 6t 6t to 9t 9t +

Copper

Yield Strength Density

Tensile Strength Elongation Minimum

Recommended Conditions Bend Hardness (lb/cu in) Corrosion

Summary Applications Magnetic? Minimum (KSI) Minimum (0.2% offset) Cost?

Finishes? Available Rating (Min-Max) Resistance

(% 2" Gauge) (lb/in³) (g/cm³)

KSI MPa KSI MPa

110 Copper

No 26 179 45% 10 69 15T 47-57 0.322 8.913 $$$$

Annealed

Rockwell

C110 1/4 Hard No 36 248 25% 28 193 0.322 8.913 $$$$

B 25 Min

C110 is comprised of 99.9% pure

Bus Bars, welding

copper. It is extremely ductile Rockwell

Tin, Nickel, fixtures, anodes, C110 1/2 Hard No 40 276 22% 34 234 0.322 8.913 $$$$

with high electrical conductivity, B 40 Min

110 outstanding thermal conductiv-

Electroless ground straps, plumb-

Rockwell

Nickel, Sliver ing fitting, electrical C110 Hard No 48 331 12% 43 296 0.322 8.913 $$$$

ity, and high resistance to soil B 50 Min

components

corrosion.

C110 Extra Rockwell

No 53 365 6% 48 331 0.322 8.913 $$$$

Hard B 60 Min

Rockwell

C110 Spring No 55 379 4% 51 352 0.322 8.913 $$$$

B 62 Min

C194 Rockwell

No 40 276 26% 36 248 0.322 8.913 $$$$

Annealed B 40 Min

C194 is a first generation high

Rockwell

performance alloy used around C194 1/4 Hard No 45 310 23% 21 145 0.322 8.913 $$$$

B 48 Min

the world. It combines excellent

electrical conductivity with high Connectors, semi- Rockwell

Tin, Nickel, C194 1/2 Hard No 53 365 17% 43 296 0.322 8.913 $$$$

tensile strength, good soldera- conductor pins and B 52 Min

194 bility, and plateability. It appears

Electroless

leadframes, sockets, Rockwell

Nickel, Sliver C194 Hard No 60 414 7% 58 400 0.322 8.913 $$$$

in applications such as semi- mass terminations B 61 Min

conductor pins and leadframes,

C194 Extra Rockwell

connectors, sockets, and mass No 67 462 3% 65 448 0.322 8.913 $$$$

Hard B 67 Min

terminations.

Rockwell

C194 Spring No 70 483 2% 68 469 0.322 8.913 $$$$

B 68 Min

C195 Rockwell

No 50-60 345-414 26% 28 193 0.322 8.913 $$$$

Annealed B 50 Min

Alloy C195 is a high strength, Rockwell

C195 1/4 Hard No 60-72 414-496 14% 57 393 0.322 8.913 $$$$

high electrical conductivity B 61 Min

copper alloy. With a balanced

Rockwell

combination of strength and Tin, Nickel, Electrical hardware, C195 1/2 Hard No 68-78 469-538 6% 71 490 0.322 8.913 $$$$

B 69 Min

195 conductibity, this alloy is used in Electroless spring terminal appli-

Rockwell

an array of applications, includ- Nickel, Sliver cations C195 3/4 Hard No 75-85 517-586 3% 77 531 0.322 8.913 $$$$

B 72 Min

ing electrical hardware. It allows

parts to be reduced in size with- Rockwell

C195 Hard No 82-90 565-621 2% 83 572 0.322 8.913 $$$$

out forgoing performance. B 73 Min

Rockwell

C195 Spring No 88-97 607-669 2% 88 607 0.322 8.913 $$$$

B 74 Min

About Us

Engineering Specialties Inc. (ESI) delivers custom manufacturing solutions, specializing in production metal stamping,

CNC machining and advanced assembly capabilities. For more information about ESI, visit www.esict.com.

Contact Us Today View our Resource Library

452 Twin Lakes Rd • North Branford, CT 06471

www.esict.com • Email: info@esict.com • Phone: 800-486-5546 • Fax: 800-486-2825 pg 1 of 1

You might also like

- Minimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Document10 pagesMinimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Hadi VeyseNo ratings yet

- EASA Part-66 Module 17 QBDocument53 pagesEASA Part-66 Module 17 QBFaisal Ahmed Newon80% (5)

- D6R Series III Track Type Tractor Power Train SystemDocument2 pagesD6R Series III Track Type Tractor Power Train SystemIH Medrano78% (9)

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- Raw Material Selection Guide BrassDocument1 pageRaw Material Selection Guide BrassSantosh KumarNo ratings yet

- Raw Material Selection Guide Beryllium CopperDocument1 pageRaw Material Selection Guide Beryllium CopperSantosh KumarNo ratings yet

- Chemical Composition: Copper Alloy DataDocument11 pagesChemical Composition: Copper Alloy DataLin DouaiNo ratings yet

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelNo ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- En 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table8Document1 pageEn 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table8yw_oulalaNo ratings yet

- 2.KR-3000 (B)Document2 pages2.KR-3000 (B)Sun SunNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- Kme STOL76 C19010 enDocument1 pageKme STOL76 C19010 enMattia Terri TerrandoNo ratings yet

- VCTF10KDocument2 pagesVCTF10KgeekcourseonlineNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Lec 10Document57 pagesLec 10Pejman HNo ratings yet

- PNA 400_Cu-OF_C10200-E.NDocument2 pagesPNA 400_Cu-OF_C10200-E.Ntatto198No ratings yet

- Cu ZN 10Document1 pageCu ZN 10Sara RiddleNo ratings yet

- Cusn10-Pna 292 enDocument2 pagesCusn10-Pna 292 enRissi CHNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENYulwido AdiNo ratings yet

- Palluna 468: Palladium-Nickel ElectrolyteDocument2 pagesPalluna 468: Palladium-Nickel ElectrolyteWaskito BudiawanNo ratings yet

- Composition % Combination of Properties: The Benefits of Cal Wrought CNCDocument6 pagesComposition % Combination of Properties: The Benefits of Cal Wrought CNCAshesh MokidiNo ratings yet

- 1 4509Document2 pages1 4509Umesh KotadiaNo ratings yet

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267No ratings yet

- High Alumina Wear Resistance Liners (Cumituff) : S.No Attributes Unit ValueDocument1 pageHigh Alumina Wear Resistance Liners (Cumituff) : S.No Attributes Unit ValueRivky Haris RizaldyNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENjurreijndersNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- EN71000 From ReinferdenDocument2 pagesEN71000 From ReinferdenJason WuNo ratings yet

- Thin Film DepositionDocument13 pagesThin Film DepositionMustakim MdNo ratings yet

- Welding Process, DefectsDocument44 pagesWelding Process, DefectskundanNo ratings yet

- Hascelik-Acsr 490-65Document1 pageHascelik-Acsr 490-65Maxence MenandezNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- A21 Ex Rect eDocument1 pageA21 Ex Rect ededosimoesNo ratings yet

- CT Burden Calculation ReportDocument6 pagesCT Burden Calculation ReportMd Mahbubur RahmanNo ratings yet

- Properties of Copper and Copper AlloysDocument1 pageProperties of Copper and Copper Alloysankesh_ghoghariNo ratings yet

- Spur Gear Spec Some Manufactures Dimension PDFDocument52 pagesSpur Gear Spec Some Manufactures Dimension PDFagus wahyudiNo ratings yet

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62No ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- Tech - Spec.ACSR 95.15Document1 pageTech - Spec.ACSR 95.15Ilir DalipiNo ratings yet

- 3 KH-500W (PW)Document2 pages3 KH-500W (PW)Sun SunNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Dws Info Gd50 Slicklines For High Temperature and High Pressure WellsDocument1 pageDws Info Gd50 Slicklines For High Temperature and High Pressure WellsAyesha AleemNo ratings yet

- CuZn39Pb2Document3 pagesCuZn39Pb2samucasNo ratings yet

- Ampco 22: Technical Data SheetDocument1 pageAmpco 22: Technical Data SheetdedosimoesNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Yellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloyDocument3 pagesYellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloySohail ShaikhNo ratings yet

- Matweb:, The Online Materials Database Aluminum 6201-T6Document2 pagesMatweb:, The Online Materials Database Aluminum 6201-T6Raj PrasanthNo ratings yet

- Bour S A0011536976 1Document4 pagesBour S A0011536976 1Alex Prim NavajasNo ratings yet

- Minimum Bending Radii For Cables: Solid Conductor Solid ConductorDocument1 pageMinimum Bending Radii For Cables: Solid Conductor Solid ConductorRinodhNo ratings yet

- En 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table10Document1 pageEn 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table10yw_oulalaNo ratings yet

- Stainless Steel Stick Electrodes (Smaw)Document1 pageStainless Steel Stick Electrodes (Smaw)Rana AsifNo ratings yet

- Avx FilmDocument20 pagesAvx FilmVilnis PetersonsNo ratings yet

- ASTM C91000 - CuSn15 - Tin Bronze AlloysDocument1 pageASTM C91000 - CuSn15 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- Adhesive and Sealant 11Document3 pagesAdhesive and Sealant 11AsrinNo ratings yet

- Copper Alloy C95200Document11 pagesCopper Alloy C95200Lin DouaiNo ratings yet

- Cuzn37-Pna 243 enDocument2 pagesCuzn37-Pna 243 enAbrahan Tinco PariNo ratings yet

- Rocker Switch PDFDocument2 pagesRocker Switch PDFJoshua ForbesNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document1 pageRaffmetal: UNI EN 1676 and 1706swaroop NalamNo ratings yet

- Ampco 45: Technical Data SheetDocument2 pagesAmpco 45: Technical Data SheetcristianoluzNo ratings yet

- Copper Alloy C83600Document12 pagesCopper Alloy C83600guardmob-1No ratings yet

- Homemade Hydraulic Ram Pump For Livestock WaterDocument19 pagesHomemade Hydraulic Ram Pump For Livestock WaterHartoyo Gondomulia100% (1)

- Psychometric Properties and ProcessesDocument40 pagesPsychometric Properties and ProcessesUser140035No ratings yet

- Kyrgyz State Technical University Named After I.razzakovDocument17 pagesKyrgyz State Technical University Named After I.razzakovSaleem IqbalNo ratings yet

- Solenoid Actuator KitDocument2 pagesSolenoid Actuator KitJM CENo ratings yet

- Steel Base Plate DesignDocument3 pagesSteel Base Plate DesignJohn Aries SarzaNo ratings yet

- Thermodynamics SK MondalDocument265 pagesThermodynamics SK MondalSãröj ShâhNo ratings yet

- ME2258 Manufacturing Technology Lab IIDocument14 pagesME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்No ratings yet

- Guyson Ultrasonic Spare Parts ListDocument1 pageGuyson Ultrasonic Spare Parts ListYoutube For EducationNo ratings yet

- Study of Influence of Notch Root RadiusDocument12 pagesStudy of Influence of Notch Root RadiusLuan CaetanoNo ratings yet

- Template Pipe PlateDocument1 pageTemplate Pipe PlateFarhan AmzarNo ratings yet

- 317 Training Manual 0704Document219 pages317 Training Manual 0704mliugong100% (4)

- HAZOP ExampleDocument3 pagesHAZOP Exampleshaggy hopkinsNo ratings yet

- Beating Weathercock PDFDocument3 pagesBeating Weathercock PDFMarco PalloneNo ratings yet

- Bff3242 Heat Transfer 21516Document9 pagesBff3242 Heat Transfer 21516nadiyaxx0% (1)

- Bomba Modelo 630 Metálica SandpiperDocument20 pagesBomba Modelo 630 Metálica SandpiperGiussep RicardoNo ratings yet

- Pipe Size Rules of ThumbDocument6 pagesPipe Size Rules of ThumbIndunil Warnasooriya100% (1)

- Procedure To Complete Iavl When Idle Speed Needs To Be ReducedDocument5 pagesProcedure To Complete Iavl When Idle Speed Needs To Be ReducedZNN9002No ratings yet

- 330 CaterpillarDocument6 pages330 CaterpillarpopNo ratings yet

- Pump Vacuum Suck Dust CycloneDocument5 pagesPump Vacuum Suck Dust CycloneDeo Anugrah UtomoNo ratings yet

- Chap 41 PDFDocument22 pagesChap 41 PDFnelson escuderoNo ratings yet

- G1119 UsDocument212 pagesG1119 UspcrateroNo ratings yet

- Tribology of Polymers Adhesion, Friction, Wear, and Mass-TransferDocument12 pagesTribology of Polymers Adhesion, Friction, Wear, and Mass-TransferDersein SaraozNo ratings yet

- Bolt Group Coefficient For Eccentric LoadsDocument5 pagesBolt Group Coefficient For Eccentric LoadsAnonymous 1rLNlqUNo ratings yet

- Lesson Plan DMEDocument6 pagesLesson Plan DMEmaruthupandian gNo ratings yet

- Secure and Reliable, Even Where Lubrication Is Poor: MR-D Double Seal With Diamondface in Bioculture ProductionDocument2 pagesSecure and Reliable, Even Where Lubrication Is Poor: MR-D Double Seal With Diamondface in Bioculture ProductionmunhNo ratings yet

- My Design of Steel Structures Book Details 1692069768Document26 pagesMy Design of Steel Structures Book Details 1692069768Satyam Kumar MishraNo ratings yet

- Metal Mart - PurlinDocument3 pagesMetal Mart - PurlinChris VenganoNo ratings yet