Professional Documents

Culture Documents

Masterflow 622: Heavy Duty Epoxy Resin Chocking Grout

Masterflow 622: Heavy Duty Epoxy Resin Chocking Grout

Uploaded by

Andri AjaCopyright:

Available Formats

You might also like

- CE-Certification of Geosynthetics: January 2008Document21 pagesCE-Certification of Geosynthetics: January 2008Ionut FlorianNo ratings yet

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- Rosin-Rammler Paper 1980Document3 pagesRosin-Rammler Paper 1980Metalurgia En Verde100% (1)

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaNo ratings yet

- Masterflow 928T: Cementitious High Strength Non-Shrink Precision GroutDocument2 pagesMasterflow 928T: Cementitious High Strength Non-Shrink Precision GroutAnonymous XVEucVMsENo ratings yet

- Masterseal BC1822: A Non-Toxic Solvent Free High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterseal BC1822: A Non-Toxic Solvent Free High Build, Phenol Novolac Protective Epoxy Resin CoatingAlexi ALfred H. Tago100% (1)

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibNo ratings yet

- Technical Data Sheet Masterbrace 2200Document2 pagesTechnical Data Sheet Masterbrace 2200Avinash PrajapatiNo ratings yet

- Masterrheobuild 623: Retarding Superplasticising Admixture For ConcreteDocument2 pagesMasterrheobuild 623: Retarding Superplasticising Admixture For ConcreteShihab AhamedNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- Quakebond J300Sr: The Infrastructure InnovatorsDocument2 pagesQuakebond J300Sr: The Infrastructure Innovatorskhoirul ramadhanNo ratings yet

- Datasheet File Conbextra GP PremixDocument4 pagesDatasheet File Conbextra GP PremixLftea AdiNo ratings yet

- Masterbrace Adh 2200: High Strength Epoxy Bedding and Repair MortarDocument2 pagesMasterbrace Adh 2200: High Strength Epoxy Bedding and Repair MortarMadhu RaiNo ratings yet

- Megamix: Description CoverageDocument4 pagesMegamix: Description CoverageSolomon AhimbisibweNo ratings yet

- TDS MasterRheobuilld-623Document2 pagesTDS MasterRheobuilld-623Taposh PaulNo ratings yet

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124No ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- 06 KEMGROUT MC enDocument2 pages06 KEMGROUT MC enMahmoud Saeed100% (1)

- MasterRheobuild 858M TDSDocument3 pagesMasterRheobuild 858M TDSabukayes.abdinNo ratings yet

- Mastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayDocument3 pagesMastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayAbi SomutNo ratings yet

- TDS DC High Grout 210Document4 pagesTDS DC High Grout 2104919404No ratings yet

- Masterbrace Adh 2200 v4Document2 pagesMasterbrace Adh 2200 v4mahmoodawadhNo ratings yet

- BASF - MasterEmaco S5300CI - TDSDocument3 pagesBASF - MasterEmaco S5300CI - TDSKelvinNo ratings yet

- Hydroblocker Superelastic: Liquid MembraneDocument2 pagesHydroblocker Superelastic: Liquid MembraneSemir SpahicNo ratings yet

- Sikadur®-53: Product Data SheetDocument3 pagesSikadur®-53: Product Data Sheetjet toledoNo ratings yet

- Basf Masterglenium Sky 920 Tds PDFDocument4 pagesBasf Masterglenium Sky 920 Tds PDFvikasNo ratings yet

- Conbextra GP4Document4 pagesConbextra GP4Chukwuma OgbonnaNo ratings yet

- Mastertop 200 TDSDocument5 pagesMastertop 200 TDSpria prcNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewAlex Tri WijayantoNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewPeralatan Divisi3No ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 Newmanuel rgNo ratings yet

- Sikagrout®-215 (New) : Product Data SheetDocument3 pagesSikagrout®-215 (New) : Product Data SheetWahyu MahaendraNo ratings yet

- Combextra GP ExtraDocument4 pagesCombextra GP ExtrailhamNo ratings yet

- Conbextra GPXtraDocument4 pagesConbextra GPXtraJoshua EkoNo ratings yet

- Masterprotect 1825 TdsDocument3 pagesMasterprotect 1825 TdsSHAIK ASIMUDDINNo ratings yet

- MasterGlenium SKY 617 (Ingles)Document4 pagesMasterGlenium SKY 617 (Ingles)maxlehenerNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.basim.technitalNo ratings yet

- Basf Masterbrace 2200 Tds PDFDocument2 pagesBasf Masterbrace 2200 Tds PDFkrishna dhageNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamNo ratings yet

- Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentDocument3 pagesMastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentFrancois-No ratings yet

- Sikagrout - 228Document3 pagesSikagrout - 228Anonymous T7zEN6iLHNo ratings yet

- Sikatherm® Foam 45 IN: Product Data SheetDocument4 pagesSikatherm® Foam 45 IN: Product Data SheetTarun KumarNo ratings yet

- SdadsadasDocument3 pagesSdadsadasTwink Arcane 9No ratings yet

- Flo-Grout 2WWADocument2 pagesFlo-Grout 2WWAosama mohNo ratings yet

- Cempatch HM PDFDocument2 pagesCempatch HM PDFharish14586No ratings yet

- Plastiretard: Set-Retarding Admixture For ConcreteDocument3 pagesPlastiretard: Set-Retarding Admixture For ConcreteacarisimovicNo ratings yet

- Masterprotect 180 TdsDocument3 pagesMasterprotect 180 TdsShyam Prasad ThiraviamNo ratings yet

- 2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Document3 pages2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Marimuthu Vijayan100% (2)

- Conbextra Sureflow 100Document4 pagesConbextra Sureflow 100m.basim.technitalNo ratings yet

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainNo ratings yet

- Sikagrout 215 New - Pds en PDFDocument3 pagesSikagrout 215 New - Pds en PDFDeny Anarista SitorusNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- KS Product Specification 2015Document32 pagesKS Product Specification 2015Andri AjaNo ratings yet

- Easyarc 7018Document2 pagesEasyarc 7018Andri AjaNo ratings yet

- NDD010 MCS Type B Foam ChambersDocument6 pagesNDD010 MCS Type B Foam ChambersAndri AjaNo ratings yet

- DWG LMD 500Hx2000L (CL1) KT - AFY14232R0Document1 pageDWG LMD 500Hx2000L (CL1) KT - AFY14232R0Andri AjaNo ratings yet

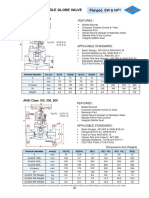

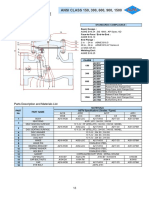

- Ansi Class 150 and 300: FL AngesDocument4 pagesAnsi Class 150 and 300: FL AngesAndri AjaNo ratings yet

- Breather Valve 2046Document3 pagesBreather Valve 2046Andri AjaNo ratings yet

- Good Year Industrial Hose Catalog 2010Document332 pagesGood Year Industrial Hose Catalog 2010Andri AjaNo ratings yet

- 01 Basic Design Structure FeaturesDocument8 pages01 Basic Design Structure FeaturesAndri AjaNo ratings yet

- Masterflow 870: Dual Shrinkage Compensated, Precision GroutDocument3 pagesMasterflow 870: Dual Shrinkage Compensated, Precision GroutAndri AjaNo ratings yet

- Masterflex 801 Asean 0509Document2 pagesMasterflex 801 Asean 0509Andri AjaNo ratings yet

- Masterflow 648CP PLUS - PDS - ASEAN - 161209Document2 pagesMasterflow 648CP PLUS - PDS - ASEAN - 161209Andri AjaNo ratings yet

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaNo ratings yet

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Document5 pagesCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNo ratings yet

- Sonolastic Ultra Asean 0509Document2 pagesSonolastic Ultra Asean 0509Andri AjaNo ratings yet

- How To Order Alfa Forged Gate, Globe, and Check ValvesDocument1 pageHow To Order Alfa Forged Gate, Globe, and Check ValvesAndri AjaNo ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- Forged Steel Needle Globe Valve: ANSI Class 800, 1500 ANSI Class 800, 1500Document1 pageForged Steel Needle Globe Valve: ANSI Class 800, 1500 ANSI Class 800, 1500Andri AjaNo ratings yet

- 00 Valve Design and ConstructionDocument3 pages00 Valve Design and ConstructionAndri AjaNo ratings yet

- Cast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Document3 pagesCast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Andri AjaNo ratings yet

- Intergard 345: Fast Drying Direct To Metal EpoxyDocument2 pagesIntergard 345: Fast Drying Direct To Metal EpoxyAndri AjaNo ratings yet

- 03b Check Valves Preesure SealDocument2 pages03b Check Valves Preesure SealAndri AjaNo ratings yet

- Interseal 670HS: Surface Tolerant EpoxyDocument2 pagesInterseal 670HS: Surface Tolerant EpoxyAndri AjaNo ratings yet

- Interprime 198Document4 pagesInterprime 198Andri AjaNo ratings yet

- Interprime 198: Product DescriptionDocument4 pagesInterprime 198: Product DescriptionAndri AjaNo ratings yet

- Interthane 990: Long Term Recoatability With AestheticsDocument2 pagesInterthane 990: Long Term Recoatability With AestheticsAndri AjaNo ratings yet

- Primocon - Anti FaulingDocument2 pagesPrimocon - Anti FaulingAndri AjaNo ratings yet

- PBH Power Line FilterDocument2 pagesPBH Power Line FilterAndri AjaNo ratings yet

- PBH Power Line FilterDocument2 pagesPBH Power Line FilterAndri AjaNo ratings yet

- Ground WireDocument3 pagesGround WireAndri AjaNo ratings yet

- Junction Boxes and Wall-Mount EnclosuresDocument1 pageJunction Boxes and Wall-Mount EnclosuresAndri AjaNo ratings yet

- DME NotesDocument133 pagesDME NotesNeeraj S GNo ratings yet

- A479A479M-15 Standard Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure VesselsDocument8 pagesA479A479M-15 Standard Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure Vesselstjt4779No ratings yet

- Assignment b3 MetfisDocument3 pagesAssignment b3 MetfisDewi Lestari Natalia MarpaungNo ratings yet

- Class 12 Final Chem ProDocument24 pagesClass 12 Final Chem Proankrs175% (4)

- Shear Strength in The New Eurocode 2. A Step ForwardDocument10 pagesShear Strength in The New Eurocode 2. A Step ForwardChineseAssassinNo ratings yet

- Design Appendix Ecs318 (Final Exam Copy)Document37 pagesDesign Appendix Ecs318 (Final Exam Copy)Muhammad Farhan Gul67% (6)

- PEF2301 - Resistência Dos Materiais e Estática Das Construções IIDocument2 pagesPEF2301 - Resistência Dos Materiais e Estática Das Construções IIrbud_dNo ratings yet

- Tabla Qw-252.1 - Asme IxDocument1 pageTabla Qw-252.1 - Asme IxAngelTinocoNo ratings yet

- Stainless SteelDocument56 pagesStainless SteelShariq KhanNo ratings yet

- 06 Linear Elasticity 03 Anisotropy PDFDocument11 pages06 Linear Elasticity 03 Anisotropy PDFebrahimpanNo ratings yet

- 1st Review 1 3Document16 pages1st Review 1 3Agent 47No ratings yet

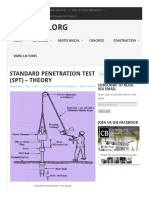

- Standard Penetration Test (SPT) - TheoryDocument5 pagesStandard Penetration Test (SPT) - Theorya769No ratings yet

- Directshear TestDocument8 pagesDirectshear TestNani TirumalasettiNo ratings yet

- FEFCO Angle of Slip 104Document4 pagesFEFCO Angle of Slip 104Ml AgarwalNo ratings yet

- Journal Pre-Proof: International Journal of PlasticityDocument78 pagesJournal Pre-Proof: International Journal of PlasticityzhuhaitingtaoNo ratings yet

- New Injection Molding Machine (SY200-I) PDFDocument5 pagesNew Injection Molding Machine (SY200-I) PDFDina FouadNo ratings yet

- 2.dislocations - 1 PDFDocument21 pages2.dislocations - 1 PDFkadambisourabhNo ratings yet

- CE2401-Design of Reinforced Concrete and Brick MasonryDocument12 pagesCE2401-Design of Reinforced Concrete and Brick MasonryJaga NathNo ratings yet

- 12 Physics Notes ch05 Magnetism and Matter PDFDocument2 pages12 Physics Notes ch05 Magnetism and Matter PDFAashna JenaNo ratings yet

- Project Report On Fiber Reinforced ConcrDocument60 pagesProject Report On Fiber Reinforced ConcrAmanuel TekalignNo ratings yet

- Gte Lab Manual PDFDocument36 pagesGte Lab Manual PDFIsrael VenkatNo ratings yet

- Two and A Half Men HouseDocument2 pagesTwo and A Half Men HousealvarolucasguillenNo ratings yet

- Soil PropertiesDocument34 pagesSoil PropertiesKaizer DAn100% (2)

- Bar ScheduleDocument9 pagesBar ScheduleDilon FernandoNo ratings yet

- Razon Tile Fix A1 Tile & Stone AdhesiveDocument3 pagesRazon Tile Fix A1 Tile & Stone Adhesiveshrikrishna rathodNo ratings yet

- Department of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurDocument6 pagesDepartment of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurNikhil MulikNo ratings yet

- Gear HoningDocument2 pagesGear HoningMargam Kiran KumarNo ratings yet

Masterflow 622: Heavy Duty Epoxy Resin Chocking Grout

Masterflow 622: Heavy Duty Epoxy Resin Chocking Grout

Uploaded by

Andri AjaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterflow 622: Heavy Duty Epoxy Resin Chocking Grout

Masterflow 622: Heavy Duty Epoxy Resin Chocking Grout

Uploaded by

Andri AjaCopyright:

Available Formats

MASTERFLOW ®622

Heavy duty epoxy resin chocking grout

DESCRIPTION Age 23oC

MASTERFLOW 622 is a rapid hardening, high strength 12 hours 80 MPa

grout, based on modified epoxy resin and is designed 24 hours 105 MPa

for use as a precision, heavy duty chocking grout for

( After 7 days cure at 23oC ± 2oC )

engineering applications. It is supplied as a solventless,

two-component system consisting of epoxy resin, Compressive Strength(ASTM D695) 120 MPa

combined with inert fillers and specially graded silica Compressive Modulus 4.0 GPa

aggregate and the hardener, to produce a high viscosity Tensile Strength(ASTM D638) 60 MPa

flowable liquid grout. Linear Shrinkage(ASTM C531-81) 0.01%

Bond Pull-out Concrete failed at 2.9 MPa

FIELDS OF APPLICATION

Setting time @ 23 oC 6 hours

• Machinery with high dynamic loads and vibration

Chemical Resistance

• Backing of steel liners of ore crushing machinery in

MASTERFLOW 622 resists most hydraulic and lubricating

mines and quarries.

oils, common organic solvents and alkalis including strong

• In corrosive environments where chemicals, oils caustic soda solutions. Chemical resistance depends on

and solvents make cementitious grouts unsuitable. the chemicals involved, their concentration, temperature

• Production line equipment that must resume and degree of exposure. Good housekeeping practices

operations with minimum downtime. such as immediate clean up of all spillage will greatly

extend the working life of the product.

• Machinery base plates, crane rails, anchor bolts

and heavy equipment where tensile strength greater SPECIFICATION

than cementitious systems can provide is required. Part A Part B Mixed Unit

MASTERFLOW 622 is not recommended when the Supply form White Dark blue Blue

temperature of the grout after mixing and placing is Viscous Heavy Liquid

unsustainable above 15oC for a period of 48 hours.

Paste Liquid

Excessive loads may induce creep. Where required

maximum thickness is greater than 50mm, additional Viscosity 30 Pa.s

aggregate may be incorporated. For achieving greater Density 1690 kg/m3

than 50 mm thickness, upper operating temperatures in

excess of 130oC and for wet substrates, please refer to APPLICATION

BASF Construction Chemicals representative.

Application Thickness

FEATURES & BENEFITS Suitable minimum and maximum thickness depend on a

number of factors including clearance, distance to be

• Resistance to vibration and impact, particularly

flowed and ambient temperature.

applicable where cycles of compression/tension

make cementitious grouts unsuitable. Due to its special engineered properties, MASTERFLOW

622 requires a “head” of grout to ensure complete filling of

• High early and ultimate strengths, minimum the space to be grouted.

production shutdown.

For grouting bedplates, a maximum of 50mm is

• Excellent chemical resistance, maximum protection recommended.

against attack from mineral acids, oils, fats, fuels, For grouting anchor bolts where flow distance is not

and strong alkali and salt solutions. critical, thinner sections (down to 3mm clearance) can be

• Excellent resistance to lubricating and hydraulic oils. placed.

• High bond strength, tenacious adhesion to prepared Surface Preparation

surfaces. To obtain maximum performance:

1. Concrete should be well cured, at least 28 days old

• Supplied in pre-measured volumes, eliminates the and have a minimum compressive strength of 25

need for complicated on-site measuring and MPa.

ensured product performance.

2. Clean surface thoroughly to remove all contaminants

TYPICAL PERFORMANCE DATA such as dirt, oil grease, wax, rust and coatings.

Compressive strength development (50mm cubes)

BASF Construction Chemicals offices in ASEAN

Singapore Malaysia Indonesia Thailand Vietnam Philippines

Tel :+65-6861-6766 Tel :+60-3-5628-3888 Tel :+62-21-526-2481 Tel :+66-2664-9222 Tel :+84-650-3743-100 Tel :+63-2-811-8000

Fax :+65-6861-3186 Fax :+60-3-5628-3776 Fax :+62-21-526-2541 Fax :+66-2664-9267 Fax :+84-650-3743-200 Fax : +63-2-838-1025

MASTERFLOW ®622

3. Remove laitance and roughen surface to ensure Pot life will vary depending on temperature and quantity

good bonding by chipping, scabbling, grit blasting mixed and placed. As a guide, the pot life of a 10 kg

or acid etching. Allow to dry thoroughly. pack mixed at 23oC, would be about 30 minutes.

Formwork ESTIMATING DATA

Must be strong and leak proof, and should be placed

within 20-25mm of base plate edge. Coat formwork with MASTERFLOW 622 is available in two component pack

debonder or cover with polythene film to allow easy of 10 kg which yields (when mixed) 5.9 litres or in bulk 5

removal of forms. kg pack yields (when mixed) 2.9 litres.

Mixing SHELF LIFE

MASTERFLOW 622 is formulated with a mix ratio of 5:1

by volume, Part A Resin to Part B hardener. Units may MASTERFLOW 622 has a shelf life of 24 months if

be split, but it is essential to maintain the correct ratio of stored unopened in original containers at moderate

Part A to Part B. The mix ratio by weight is 10:1 resin to temperatures.

hardener. Remove rim from Part B tin to ensure PACKAGING

complete removal of contents. Transfer contents of Part

B to Part A container. Mix for 3 minutes using a slow Two component system available in:

speed electric drill with a flat paddle. Avoid entrapping Packaging Part A Resin Part B Hardener

air. Use without delay.

10 kg kit 9.1 kg 0.9 kg

Placing

1. Machine Bases, Crane Rails 5 kg kit 4.55 kg 0.45 kg

Clearances must be such that grout will flow without

forming air pockets – provide ventholes. Grouting PRECAUTION

operations must be continuous with a minimum

head of 15mm. For intricate voids, gentle strapping As with all epoxy products, wear protective overalls and

may be required to assist flow. gloves – prolonged contact with skin should be avoided

as it could produce dermatitis, particularly with people

2. Anchor Bolts, Dowels, Starter Bars whose skin may be sensitive to epoxy resin system.

Holes must be completely dry. Pump or use

Ensure adequate ventilation.

tremmies for bolts in situ. For bolts placed into

preformed holes, prefill the hole with grout then Mix entire contents of each unit as supplied. Do not

slowly work the bolt into the grout. attempt to split units unless accurate measuring can be

assured.

CURING Do not use at temperatures of less than 15oC unless

No damp curing or special curing compounds are artificial means of heating can be used to assist cure.

required. Cure time will vary depending on quantity During cold weather Part A should be pre-warmed to

mixed and placed and ambient temperature. The larger between 20 and 30oC.

the volume and the higher the temperature, the shorter For detailed Health, Safety and Environmental

will be the cure time. Initial set at 23oC will be in 4 – 6 recommendations, please consult and follow all

hours. MASTERFLOW 622 will be fully cured with instructions on the product Material Safety Data Sheet.

maximum physical strength and chemical resistance at

7 days at 23oC. Do not install equipment before full

cure has been attained or creep may occur.

AN/MFlow622/v2/161209

The technical information and application advice given in this BASF Construction Chemicals publication are

STATEMENT OF based on the present state of our best scientific and practical knowledge. As the information herein is of a

general nature, no assumption can be made as to a product's suitability for a particular use or application and

RESPONSIBILITY no warranty as to its accuracy, reliability or completeness either expressed or implied is given other than

those required by law. The user is responsible for checking the suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF

NOTE Construction Chemicals either orally or in writing may be followed, modified or rejected by the owner,

engineer or contractor since they, and not BASF Construction Chemicals, are responsible for carrying out

procedures appropriate to a specific application.

You might also like

- CE-Certification of Geosynthetics: January 2008Document21 pagesCE-Certification of Geosynthetics: January 2008Ionut FlorianNo ratings yet

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- Rosin-Rammler Paper 1980Document3 pagesRosin-Rammler Paper 1980Metalurgia En Verde100% (1)

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaNo ratings yet

- Masterflow 928T: Cementitious High Strength Non-Shrink Precision GroutDocument2 pagesMasterflow 928T: Cementitious High Strength Non-Shrink Precision GroutAnonymous XVEucVMsENo ratings yet

- Masterseal BC1822: A Non-Toxic Solvent Free High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterseal BC1822: A Non-Toxic Solvent Free High Build, Phenol Novolac Protective Epoxy Resin CoatingAlexi ALfred H. Tago100% (1)

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibNo ratings yet

- Technical Data Sheet Masterbrace 2200Document2 pagesTechnical Data Sheet Masterbrace 2200Avinash PrajapatiNo ratings yet

- Masterrheobuild 623: Retarding Superplasticising Admixture For ConcreteDocument2 pagesMasterrheobuild 623: Retarding Superplasticising Admixture For ConcreteShihab AhamedNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- Quakebond J300Sr: The Infrastructure InnovatorsDocument2 pagesQuakebond J300Sr: The Infrastructure Innovatorskhoirul ramadhanNo ratings yet

- Datasheet File Conbextra GP PremixDocument4 pagesDatasheet File Conbextra GP PremixLftea AdiNo ratings yet

- Masterbrace Adh 2200: High Strength Epoxy Bedding and Repair MortarDocument2 pagesMasterbrace Adh 2200: High Strength Epoxy Bedding and Repair MortarMadhu RaiNo ratings yet

- Megamix: Description CoverageDocument4 pagesMegamix: Description CoverageSolomon AhimbisibweNo ratings yet

- TDS MasterRheobuilld-623Document2 pagesTDS MasterRheobuilld-623Taposh PaulNo ratings yet

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124No ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- 06 KEMGROUT MC enDocument2 pages06 KEMGROUT MC enMahmoud Saeed100% (1)

- MasterRheobuild 858M TDSDocument3 pagesMasterRheobuild 858M TDSabukayes.abdinNo ratings yet

- Mastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayDocument3 pagesMastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayAbi SomutNo ratings yet

- TDS DC High Grout 210Document4 pagesTDS DC High Grout 2104919404No ratings yet

- Masterbrace Adh 2200 v4Document2 pagesMasterbrace Adh 2200 v4mahmoodawadhNo ratings yet

- BASF - MasterEmaco S5300CI - TDSDocument3 pagesBASF - MasterEmaco S5300CI - TDSKelvinNo ratings yet

- Hydroblocker Superelastic: Liquid MembraneDocument2 pagesHydroblocker Superelastic: Liquid MembraneSemir SpahicNo ratings yet

- Sikadur®-53: Product Data SheetDocument3 pagesSikadur®-53: Product Data Sheetjet toledoNo ratings yet

- Basf Masterglenium Sky 920 Tds PDFDocument4 pagesBasf Masterglenium Sky 920 Tds PDFvikasNo ratings yet

- Conbextra GP4Document4 pagesConbextra GP4Chukwuma OgbonnaNo ratings yet

- Mastertop 200 TDSDocument5 pagesMastertop 200 TDSpria prcNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewAlex Tri WijayantoNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewPeralatan Divisi3No ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 Newmanuel rgNo ratings yet

- Sikagrout®-215 (New) : Product Data SheetDocument3 pagesSikagrout®-215 (New) : Product Data SheetWahyu MahaendraNo ratings yet

- Combextra GP ExtraDocument4 pagesCombextra GP ExtrailhamNo ratings yet

- Conbextra GPXtraDocument4 pagesConbextra GPXtraJoshua EkoNo ratings yet

- Masterprotect 1825 TdsDocument3 pagesMasterprotect 1825 TdsSHAIK ASIMUDDINNo ratings yet

- MasterGlenium SKY 617 (Ingles)Document4 pagesMasterGlenium SKY 617 (Ingles)maxlehenerNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.basim.technitalNo ratings yet

- Basf Masterbrace 2200 Tds PDFDocument2 pagesBasf Masterbrace 2200 Tds PDFkrishna dhageNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamNo ratings yet

- Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentDocument3 pagesMastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentFrancois-No ratings yet

- Sikagrout - 228Document3 pagesSikagrout - 228Anonymous T7zEN6iLHNo ratings yet

- Sikatherm® Foam 45 IN: Product Data SheetDocument4 pagesSikatherm® Foam 45 IN: Product Data SheetTarun KumarNo ratings yet

- SdadsadasDocument3 pagesSdadsadasTwink Arcane 9No ratings yet

- Flo-Grout 2WWADocument2 pagesFlo-Grout 2WWAosama mohNo ratings yet

- Cempatch HM PDFDocument2 pagesCempatch HM PDFharish14586No ratings yet

- Plastiretard: Set-Retarding Admixture For ConcreteDocument3 pagesPlastiretard: Set-Retarding Admixture For ConcreteacarisimovicNo ratings yet

- Masterprotect 180 TdsDocument3 pagesMasterprotect 180 TdsShyam Prasad ThiraviamNo ratings yet

- 2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Document3 pages2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Marimuthu Vijayan100% (2)

- Conbextra Sureflow 100Document4 pagesConbextra Sureflow 100m.basim.technitalNo ratings yet

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainNo ratings yet

- Sikagrout 215 New - Pds en PDFDocument3 pagesSikagrout 215 New - Pds en PDFDeny Anarista SitorusNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- KS Product Specification 2015Document32 pagesKS Product Specification 2015Andri AjaNo ratings yet

- Easyarc 7018Document2 pagesEasyarc 7018Andri AjaNo ratings yet

- NDD010 MCS Type B Foam ChambersDocument6 pagesNDD010 MCS Type B Foam ChambersAndri AjaNo ratings yet

- DWG LMD 500Hx2000L (CL1) KT - AFY14232R0Document1 pageDWG LMD 500Hx2000L (CL1) KT - AFY14232R0Andri AjaNo ratings yet

- Ansi Class 150 and 300: FL AngesDocument4 pagesAnsi Class 150 and 300: FL AngesAndri AjaNo ratings yet

- Breather Valve 2046Document3 pagesBreather Valve 2046Andri AjaNo ratings yet

- Good Year Industrial Hose Catalog 2010Document332 pagesGood Year Industrial Hose Catalog 2010Andri AjaNo ratings yet

- 01 Basic Design Structure FeaturesDocument8 pages01 Basic Design Structure FeaturesAndri AjaNo ratings yet

- Masterflow 870: Dual Shrinkage Compensated, Precision GroutDocument3 pagesMasterflow 870: Dual Shrinkage Compensated, Precision GroutAndri AjaNo ratings yet

- Masterflex 801 Asean 0509Document2 pagesMasterflex 801 Asean 0509Andri AjaNo ratings yet

- Masterflow 648CP PLUS - PDS - ASEAN - 161209Document2 pagesMasterflow 648CP PLUS - PDS - ASEAN - 161209Andri AjaNo ratings yet

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaNo ratings yet

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Document5 pagesCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNo ratings yet

- Sonolastic Ultra Asean 0509Document2 pagesSonolastic Ultra Asean 0509Andri AjaNo ratings yet

- How To Order Alfa Forged Gate, Globe, and Check ValvesDocument1 pageHow To Order Alfa Forged Gate, Globe, and Check ValvesAndri AjaNo ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- Forged Steel Needle Globe Valve: ANSI Class 800, 1500 ANSI Class 800, 1500Document1 pageForged Steel Needle Globe Valve: ANSI Class 800, 1500 ANSI Class 800, 1500Andri AjaNo ratings yet

- 00 Valve Design and ConstructionDocument3 pages00 Valve Design and ConstructionAndri AjaNo ratings yet

- Cast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Document3 pagesCast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Andri AjaNo ratings yet

- Intergard 345: Fast Drying Direct To Metal EpoxyDocument2 pagesIntergard 345: Fast Drying Direct To Metal EpoxyAndri AjaNo ratings yet

- 03b Check Valves Preesure SealDocument2 pages03b Check Valves Preesure SealAndri AjaNo ratings yet

- Interseal 670HS: Surface Tolerant EpoxyDocument2 pagesInterseal 670HS: Surface Tolerant EpoxyAndri AjaNo ratings yet

- Interprime 198Document4 pagesInterprime 198Andri AjaNo ratings yet

- Interprime 198: Product DescriptionDocument4 pagesInterprime 198: Product DescriptionAndri AjaNo ratings yet

- Interthane 990: Long Term Recoatability With AestheticsDocument2 pagesInterthane 990: Long Term Recoatability With AestheticsAndri AjaNo ratings yet

- Primocon - Anti FaulingDocument2 pagesPrimocon - Anti FaulingAndri AjaNo ratings yet

- PBH Power Line FilterDocument2 pagesPBH Power Line FilterAndri AjaNo ratings yet

- PBH Power Line FilterDocument2 pagesPBH Power Line FilterAndri AjaNo ratings yet

- Ground WireDocument3 pagesGround WireAndri AjaNo ratings yet

- Junction Boxes and Wall-Mount EnclosuresDocument1 pageJunction Boxes and Wall-Mount EnclosuresAndri AjaNo ratings yet

- DME NotesDocument133 pagesDME NotesNeeraj S GNo ratings yet

- A479A479M-15 Standard Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure VesselsDocument8 pagesA479A479M-15 Standard Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure Vesselstjt4779No ratings yet

- Assignment b3 MetfisDocument3 pagesAssignment b3 MetfisDewi Lestari Natalia MarpaungNo ratings yet

- Class 12 Final Chem ProDocument24 pagesClass 12 Final Chem Proankrs175% (4)

- Shear Strength in The New Eurocode 2. A Step ForwardDocument10 pagesShear Strength in The New Eurocode 2. A Step ForwardChineseAssassinNo ratings yet

- Design Appendix Ecs318 (Final Exam Copy)Document37 pagesDesign Appendix Ecs318 (Final Exam Copy)Muhammad Farhan Gul67% (6)

- PEF2301 - Resistência Dos Materiais e Estática Das Construções IIDocument2 pagesPEF2301 - Resistência Dos Materiais e Estática Das Construções IIrbud_dNo ratings yet

- Tabla Qw-252.1 - Asme IxDocument1 pageTabla Qw-252.1 - Asme IxAngelTinocoNo ratings yet

- Stainless SteelDocument56 pagesStainless SteelShariq KhanNo ratings yet

- 06 Linear Elasticity 03 Anisotropy PDFDocument11 pages06 Linear Elasticity 03 Anisotropy PDFebrahimpanNo ratings yet

- 1st Review 1 3Document16 pages1st Review 1 3Agent 47No ratings yet

- Standard Penetration Test (SPT) - TheoryDocument5 pagesStandard Penetration Test (SPT) - Theorya769No ratings yet

- Directshear TestDocument8 pagesDirectshear TestNani TirumalasettiNo ratings yet

- FEFCO Angle of Slip 104Document4 pagesFEFCO Angle of Slip 104Ml AgarwalNo ratings yet

- Journal Pre-Proof: International Journal of PlasticityDocument78 pagesJournal Pre-Proof: International Journal of PlasticityzhuhaitingtaoNo ratings yet

- New Injection Molding Machine (SY200-I) PDFDocument5 pagesNew Injection Molding Machine (SY200-I) PDFDina FouadNo ratings yet

- 2.dislocations - 1 PDFDocument21 pages2.dislocations - 1 PDFkadambisourabhNo ratings yet

- CE2401-Design of Reinforced Concrete and Brick MasonryDocument12 pagesCE2401-Design of Reinforced Concrete and Brick MasonryJaga NathNo ratings yet

- 12 Physics Notes ch05 Magnetism and Matter PDFDocument2 pages12 Physics Notes ch05 Magnetism and Matter PDFAashna JenaNo ratings yet

- Project Report On Fiber Reinforced ConcrDocument60 pagesProject Report On Fiber Reinforced ConcrAmanuel TekalignNo ratings yet

- Gte Lab Manual PDFDocument36 pagesGte Lab Manual PDFIsrael VenkatNo ratings yet

- Two and A Half Men HouseDocument2 pagesTwo and A Half Men HousealvarolucasguillenNo ratings yet

- Soil PropertiesDocument34 pagesSoil PropertiesKaizer DAn100% (2)

- Bar ScheduleDocument9 pagesBar ScheduleDilon FernandoNo ratings yet

- Razon Tile Fix A1 Tile & Stone AdhesiveDocument3 pagesRazon Tile Fix A1 Tile & Stone Adhesiveshrikrishna rathodNo ratings yet

- Department of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurDocument6 pagesDepartment of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurNikhil MulikNo ratings yet

- Gear HoningDocument2 pagesGear HoningMargam Kiran KumarNo ratings yet