Professional Documents

Culture Documents

Electrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)

Electrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)

Uploaded by

ken azura0 ratings0% found this document useful (0 votes)

14 views1 pageThree electrocution cases are described that occurred when workers or equipment came too close to overhead power lines. In Case 1, a scaffold erected near a 33kV line caused a flashover, seriously injuring a worker. Case 2 involved a lorry contacting an 11kV line, electrocuting the driver. Case 3 resulted in three deaths when workers erected a steel pole too close to an 11kV line. Safety recommendations include complying with clearance regulations, notifying utilities before working near lines, implementing safety measures, training workers, and following safe work procedures to prevent such electrocutions.

Original Description:

Original Title

Safety Article 2-2009 - Working Near Overhead Power Lines

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThree electrocution cases are described that occurred when workers or equipment came too close to overhead power lines. In Case 1, a scaffold erected near a 33kV line caused a flashover, seriously injuring a worker. Case 2 involved a lorry contacting an 11kV line, electrocuting the driver. Case 3 resulted in three deaths when workers erected a steel pole too close to an 11kV line. Safety recommendations include complying with clearance regulations, notifying utilities before working near lines, implementing safety measures, training workers, and following safe work procedures to prevent such electrocutions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views1 pageElectrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)

Electrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)

Uploaded by

ken azuraThree electrocution cases are described that occurred when workers or equipment came too close to overhead power lines. In Case 1, a scaffold erected near a 33kV line caused a flashover, seriously injuring a worker. Case 2 involved a lorry contacting an 11kV line, electrocuting the driver. Case 3 resulted in three deaths when workers erected a steel pole too close to an 11kV line. Safety recommendations include complying with clearance regulations, notifying utilities before working near lines, implementing safety measures, training workers, and following safe work procedures to prevent such electrocutions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

SAFETY ARTICLE

Electrocution Risks When Working Near Overhead Power Lines

Workers who are erecting, moving or working from metal or conductive scaffoldings or boomed vehicles or handling high objects close to overhead power lines and also handling equipment or materials near power lines

are at risk of being electrocuted if no proper precautions are taken. Electrocution can happen even without getting into contact especially for the high voltage overhead lines through electrical flashovers. The following are

some of the examples of accidents that happened in the past that we can learn from:

Case No. 1 (One Person Serious Injured)

On 18 January 2008, a team of workers who were repairing a warehouse erected a mobile metal frame scaffolding (approximately 42 feet high) to facilitate the works. On oversight, the workers were moving the scaffolds

too close to the LIVE 33 kV (33,000 volts) overhead power lines (refer picture 1a & 1b) that caused an electrical flashover thereby providing a path to the ground for t he electric current.

One of the workers who was grasping the metal scaffolding sustained serious injuries (refer picture 1c & 1d). The accident caused power supply interruption that affected many customers.

Picture 1a Picture 1b Picture 1c Picture 1d

Case No. 2 (One Fatality)

On 5 August 2008, a driver of a lorry-trailer was uploading a mobile piling rig onto the trailer. In the process the mobile piling rig moved too close and eventually came into contact with the LIVE 11 kV (11,000 volts)

overhead power lines (refer picture 2a and 2b). This contact energized (charged) the lorry at 11 kV. The electric charge was insulated from the ground by the lorry’s tyres and dry tarmac road surface. However when the

driver tried to open the door of the vehicle, he became a path to the ground for the electric current. The driver was electrocuted and died on the spot (refer Picture 2c).

Picture 2a Picture 2b Picture 2c

Case No. 3 (Three Fatalities)

On 4 September 2008, a team of workers for a telecommunication company were removing an existing wood pole and wanted to replace it with a steel pole to support telecommunication cables. The steel pole was about

24.4 feet in height whilst the nearby 11 kV overhead power lines was at 22 feet above ground level (which is well above the statutory requirement under The Electricity Rules 1999 (refer picture 3a and sketch 3b)). When

the workers were erecting the steel pole, they moved it too close to t he LIVE 11 kV overhead power lines. The resulting electrical flashover through the air provided a path to the ground for the electric current.

The three workers holding the steel pole stood no chance and were electrocuted (refer picture 3c). The fourth worker was escaped but sustained electrical burns on his right foot.

Picture 3a Sketch 3b Picture 3c

SAFETY MEASURE RECOMMENDATIONS:

From the above accounts of the risk of hazards posed by the overhead power lines and metal or conductive scaffoldings or boomed vehicles or equipments near to it, the following precautions are to be observed to

prevent electrocution resulting in injuries or fatalities:

Employers, contractors and workers should comply with The Electricity Rules, 1999 particularly:

Rules 42 (d) which states “no person shall, without the lawful authority of the owner, management or licensee of the installation, as the case may be, undertake any work or engage in any activity

within 2134 millimetres (7 feet) horizontally or 2743 millimetres (9 feet) vertically of any aerial conductor operating at low voltage.

Rules 43 (j) which states “no person shall, without the lawful authority of the owner, management, or licensee of the installation, as the case may be, undertake any work or engage in any activity

within 4.57 metres (15 feet) of an aerial conductor operating at high or extra high voltage”.

Employers should notify in writing to the nearest SESCO Office when scaffoldings or vehicles or equipments or other materials or high objects are to be erected or moved in areas with overhead power lines

where the required clearances cannot be maintained. This is necessary to enable SESCO to assess the situation for appropriate safety measures to be implemented. The safety measures before any work is

initiated may include de-energizing the power lines or covering them with insulating hoses or blankets or demarcate the area for safe working clearances or where works are to be carried out where prolong

shutdown is not possible thus requiring complete re- siting of the overhead lines. The costs for implementing the safety measures shall be borne by the contractor.

Employers must ensure and verify with SESCO that the recommended safety measures have been implemented and to observe all other safety precautions prior to carrying out any work near the overhead

lines. Employers should inform their workers about the hazards of erecting, moving, or working from scaf foldings or vehicles or equipments or other materials or high objects near overhead power lines or

other energized circuits. These instructions should emphasize that most overhead high-voltage power lines are not insulated and that if in doubt, the workers should assume that such lines are not insulated.

Managers and work supervisors should conduct initial and daily surveys at the worksite before initiating any job to ensure compliances with the safety measures. Employers should also ensure the workers

are adequately trained to enable them to work near overhead power lines according to an established safe working procedure which should include handling of emergencies, ability to perform

cardiopulmonary resuscitation (CPR) and other types of training deemed necessary.

CONCLUSION

Many employers, contractors, supervisors and workers may be unaware of the risk of hazards of working near overhead power lines. If the above control measures are adhered to , particularly with regard to safe working

clearances from the aerial conductor, incidences of electrocutions such as those manifested above could be prevented.

ELECTRICAL SAFETY AWARENESS PROGRAM

Jointly published by:

SARAWAK ENERGY BERHAD ELECTRICAL INSPECTORATE UNIT

You might also like

- MS - Installation - of - Containments - QC - REV - 2Document7 pagesMS - Installation - of - Containments - QC - REV - 2irfan vpNo ratings yet

- BS en 61557-6-2007Document16 pagesBS en 61557-6-2007FélicienNo ratings yet

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDocument21 pagesMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNo ratings yet

- PDG Shopping Cart 2002: Quick Start GuideDocument26 pagesPDG Shopping Cart 2002: Quick Start GuideArvind SinghNo ratings yet

- EPDM Geomembrane Installation Guide - 4Document15 pagesEPDM Geomembrane Installation Guide - 4Mukti AwanNo ratings yet

- Release Notes - Instrument Inspector 2 - 0 - 2 - 0Document8 pagesRelease Notes - Instrument Inspector 2 - 0 - 2 - 0Adrian ReyesNo ratings yet

- Brochure1711 PDFDocument48 pagesBrochure1711 PDFmirza tuzzamanNo ratings yet

- Geo InstallationDocument33 pagesGeo Installationmauricio PEREZNo ratings yet

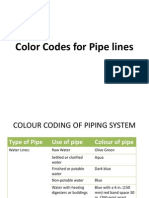

- S-3000-1360-011 - F-Specification For Identification of Piping MaterialsDocument20 pagesS-3000-1360-011 - F-Specification For Identification of Piping MaterialsMessaoud Goutas0% (1)

- EpdmDocument2 pagesEpdmhappale2002No ratings yet

- Difference-Between FRP and GRP PDFDocument3 pagesDifference-Between FRP and GRP PDFparesh_patsNo ratings yet

- Geomembrane Installation QADocument22 pagesGeomembrane Installation QAMark Kevin BechaydaNo ratings yet

- Itp FBSB Moc Fibreoptic 005 FinalDocument6 pagesItp FBSB Moc Fibreoptic 005 FinalVictor BiacoloNo ratings yet

- Desalination Plant ConstructionDocument104 pagesDesalination Plant Constructionadalcayde2514No ratings yet

- Work Procedure For Construction of CHS Electrical Building Rev. 0Document46 pagesWork Procedure For Construction of CHS Electrical Building Rev. 0ResearcherNo ratings yet

- Excavation SafetyDocument35 pagesExcavation SafetyDrew B MrtnzNo ratings yet

- 8015-0151-ENTR-41-411-EL-MS-41205 - A0 Method Statement For Cathodic Protection PDFDocument9 pages8015-0151-ENTR-41-411-EL-MS-41205 - A0 Method Statement For Cathodic Protection PDFCripoNo ratings yet

- Building InspectionsDocument2 pagesBuilding InspectionsSuresh DevarajanNo ratings yet

- Covalence S1301-M Epoxy Primer: DescriptionDocument4 pagesCovalence S1301-M Epoxy Primer: DescriptionJuan Carlos Contreras CherresNo ratings yet

- Product Sheet ASME Porocedure PDFDocument2 pagesProduct Sheet ASME Porocedure PDFHoang Diep PhanNo ratings yet

- Preview Report of A Visit To The Steel Structure WorkshopDocument2 pagesPreview Report of A Visit To The Steel Structure WorkshopMohamed BadraNo ratings yet

- Comparison: Lift N Weld Conventional Method Plain Vanilla JackingDocument1 pageComparison: Lift N Weld Conventional Method Plain Vanilla Jackingkamlesh0106100% (1)

- Method Statement Form - HDPE PN10,16 PipeDocument22 pagesMethod Statement Form - HDPE PN10,16 PipeSmith SuwanNo ratings yet

- SE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core CableDocument11 pagesSE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core Cablevishwas salunkheNo ratings yet

- L1 34258 en T Union S 2 - UV 418 TT en MDPK 5aDocument2 pagesL1 34258 en T Union S 2 - UV 418 TT en MDPK 5aKrishna VachaNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- Is 818 Code of Practice For Safety and Health For Welding and Gas CuttingDocument50 pagesIs 818 Code of Practice For Safety and Health For Welding and Gas CuttingPULSEMURALI100% (3)

- Geo InstallationDocument78 pagesGeo InstallationUdin DzonoNo ratings yet

- Tps OHLDocument88 pagesTps OHLNaseem AhmedNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- Method Statement For Dressing of Steel PoleDocument3 pagesMethod Statement For Dressing of Steel PoleMary Grace LagundinoNo ratings yet

- Work Procedure - of Plant BuildingsDocument7 pagesWork Procedure - of Plant BuildingsHiren ThakkarNo ratings yet

- 0.6 - 1 KV CV (XLPE-PVC) Rev.07Document20 pages0.6 - 1 KV CV (XLPE-PVC) Rev.07khamsone pengmanivongNo ratings yet

- Inspection Engineer - Senior Welding - Arunkumar Andavar - CVDocument7 pagesInspection Engineer - Senior Welding - Arunkumar Andavar - CVArun KumarNo ratings yet

- Camx 2015 Vaidya UabDocument11 pagesCamx 2015 Vaidya UabJuNeng NigLtdNo ratings yet

- Pressure Form Test RecordDocument1 pagePressure Form Test RecordMUHAMMAD SALIM KhanNo ratings yet

- General Works To Support Pipeline-Non Pipeline Activities-Tmg OkDocument5 pagesGeneral Works To Support Pipeline-Non Pipeline Activities-Tmg Okarif rhNo ratings yet

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormMd Shariful IslamNo ratings yet

- MC L 01A Pre Hydrotest LinewalkDocument1 pageMC L 01A Pre Hydrotest LinewalkMemyhu MahmudahNo ratings yet

- ML 07 WeldingDocument11 pagesML 07 WeldingDeepakNo ratings yet

- Method Statement For Static EquipmentDocument10 pagesMethod Statement For Static EquipmentYurizal firmansyahNo ratings yet

- SDS Electrolyte Alcad PDFDocument4 pagesSDS Electrolyte Alcad PDFkarakoukasNo ratings yet

- MC-PH01-P04-06A03-SAB-MTS-CIV-000003 Method Statement For Blinding Concr...Document16 pagesMC-PH01-P04-06A03-SAB-MTS-CIV-000003 Method Statement For Blinding Concr...ehteshamNo ratings yet

- Doha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalDocument1 pageDoha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalmeeNo ratings yet

- ISBN Guidebook Using Powered Mobile Plant Near Overhead Assets Editionn1 2018 06Document24 pagesISBN Guidebook Using Powered Mobile Plant Near Overhead Assets Editionn1 2018 06ZeljkoNo ratings yet

- Living and Working Around High Voltage Power Lines 11-07Document15 pagesLiving and Working Around High Voltage Power Lines 11-07api-49714586No ratings yet

- Specification For TransformersDocument25 pagesSpecification For Transformerswaleed.liaquat.kkNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- Polyken 2000 High TempDocument2 pagesPolyken 2000 High TempKyaw Kyaw AungNo ratings yet

- Attach-10 Work Procedure For Process Piping Prefabrication and InstallationDocument17 pagesAttach-10 Work Procedure For Process Piping Prefabrication and InstallationSukalyan BasuNo ratings yet

- S-00-1360-801 - Technical Specification For Identification On Piping MaterialsDocument12 pagesS-00-1360-801 - Technical Specification For Identification On Piping MaterialsEdison WalitNo ratings yet

- 16950s01 HV Testing ProceduresDocument1 page16950s01 HV Testing ProceduresVICTOR JOSE VILORIANo ratings yet

- ITP - Erection Instalation and Testing of Site Erected Storage TANKDocument11 pagesITP - Erection Instalation and Testing of Site Erected Storage TANKVasilica BArbarasaNo ratings yet

- Installation of Aluminium Busbar JMSDocument14 pagesInstallation of Aluminium Busbar JMSadrianNo ratings yet

- A Color Codes For Pipe Lines ANSIDocument24 pagesA Color Codes For Pipe Lines ANSIliveconnectionz282No ratings yet

- 186-19 Wpqc-W162-2''-Asme XiDocument1 page186-19 Wpqc-W162-2''-Asme Xibouchoucha jebaliNo ratings yet

- Bayblend MTR HP-1Document2 pagesBayblend MTR HP-1TECHNo ratings yet

- TG085 Placing Fiber Optic Cable Into An Underground DuctDocument11 pagesTG085 Placing Fiber Optic Cable Into An Underground DuctNaiem JalalyNo ratings yet

- MIDCO Lifting Manual SOWDocument47 pagesMIDCO Lifting Manual SOWMoetaz MohamedNo ratings yet

- UETTDRVC21A Use Climbing Techniques To Cut Vegetation Above Ground Near Live Electrical ApparatusDocument12 pagesUETTDRVC21A Use Climbing Techniques To Cut Vegetation Above Ground Near Live Electrical ApparatusTrained UpNo ratings yet

- ENOWA Safety Notice OHL Incidents 16.10.2023Document9 pagesENOWA Safety Notice OHL Incidents 16.10.2023Anas PonneathNo ratings yet

- E-Commerce (A Study of FLIPKART and AMAZON)Document43 pagesE-Commerce (A Study of FLIPKART and AMAZON)Md Imtiaz KhanNo ratings yet

- Up To 6 GHZ Low Noise Silicon Bipolar Transistor: Technical DataDocument5 pagesUp To 6 GHZ Low Noise Silicon Bipolar Transistor: Technical Datadt1301No ratings yet

- Need Help! Fanuc 11 CRT ProblemsDocument4 pagesNeed Help! Fanuc 11 CRT ProblemsindustronicaNo ratings yet

- Archive Project SummaryDocument46 pagesArchive Project SummarySantoso IbnutoroNo ratings yet

- 24000-000 RevK Automation Control Environment ACE User's ManualDocument642 pages24000-000 RevK Automation Control Environment ACE User's Manualfirstaaditya260395No ratings yet

- Preventive Maintenance Using Reliability Centred MDocument29 pagesPreventive Maintenance Using Reliability Centred MGiovanni GiudiceNo ratings yet

- CS105 SyllabusDocument2 pagesCS105 SyllabusPd BaSO4No ratings yet

- B5-1M R2004 E1985Document13 pagesB5-1M R2004 E1985JCVV1No ratings yet

- Linear Motor Technology PDFDocument73 pagesLinear Motor Technology PDFrimce77No ratings yet

- Sae As9697cDocument3 pagesSae As9697cJohn CarellaNo ratings yet

- LMI Manual Older SystemDocument101 pagesLMI Manual Older SystemStarck OliveiraNo ratings yet

- 325 525Document4 pages325 525Ela Nurlaela ElsmuslimahNo ratings yet

- LBC Put To Light Manual - Rev2Document28 pagesLBC Put To Light Manual - Rev2ANGEL JOY RABAGONo ratings yet

- X Series x13 g2 20jul09Document4 pagesX Series x13 g2 20jul09Laiq ZamanNo ratings yet

- DataSheetDocument3 pagesDataSheetWilliam VargasNo ratings yet

- Coursera 2Document1 pageCoursera 2Ranu SharmaNo ratings yet

- Navigating in The SAP System PDFDocument9 pagesNavigating in The SAP System PDFkerimNo ratings yet

- Barmex Bandas Catalogo Roulunds 416296Document154 pagesBarmex Bandas Catalogo Roulunds 416296peibolrz100% (2)

- Center of MassDocument27 pagesCenter of Massm 418No ratings yet

- 241-1592303278959-HND MSBP W4 Initiation of The Project and Project Planning Phase Part IIIDocument22 pages241-1592303278959-HND MSBP W4 Initiation of The Project and Project Planning Phase Part IIINaveenNo ratings yet

- DCI Contactless D-PAS Acquirer Host Test Plan v1.2Document88 pagesDCI Contactless D-PAS Acquirer Host Test Plan v1.2Roger CardenasNo ratings yet

- Ddco 1Document302 pagesDdco 1RISHAV SINHANo ratings yet

- Oracle Enterprise Manager Cloud Control 13c: Install Upgrade Ed2Document3 pagesOracle Enterprise Manager Cloud Control 13c: Install Upgrade Ed2Irfan AslamNo ratings yet

- Sims4CommunityLib ExceptionsDocument7 pagesSims4CommunityLib Exceptionsgwen houbenNo ratings yet

- 9866 0004 01 - Cop Rc45 and Cop Rc45 HD Sales Brochure - HighDocument4 pages9866 0004 01 - Cop Rc45 and Cop Rc45 HD Sales Brochure - HighPaula ArrascaetaNo ratings yet

- GSM Based Motor Control: A Mini Project Report OnDocument94 pagesGSM Based Motor Control: A Mini Project Report Onsra1 reddyNo ratings yet

- SG3400 3125 2500HV-20 DatasheetDocument1 pageSG3400 3125 2500HV-20 DatasheetPhani ArvapalliNo ratings yet

- Sop Mech Ms PDFDocument1 pageSop Mech Ms PDFArjit GoswamiNo ratings yet