Professional Documents

Culture Documents

Imps - Short Wall (My - Vertical) : Calculation of Steel

Imps - Short Wall (My - Vertical) : Calculation of Steel

Uploaded by

pearl kachhawahCopyright:

Available Formats

You might also like

- Introduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFDocument2 pagesIntroduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFs9n9No ratings yet

- Butterfly Valve Chamber Design - 300 - 700mm DIDocument6 pagesButterfly Valve Chamber Design - 300 - 700mm DIRamakanth Putty100% (1)

- Doubly Reinforced BeamDocument8 pagesDoubly Reinforced BeamKARTHIK SGNo ratings yet

- N2006 PidDocument8 pagesN2006 PidSarah KempNo ratings yet

- Calculation For Crack WidthDocument48 pagesCalculation For Crack Widthpearl kachhawahNo ratings yet

- Short Wall - Vertical: Plate No.-961 L/C No. - 10Document12 pagesShort Wall - Vertical: Plate No.-961 L/C No. - 10pearl kachhawahNo ratings yet

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- Crack PDFDocument22 pagesCrack PDFghansaNo ratings yet

- SLAB DESIGN-300mm THK. CENTER SLABDocument2 pagesSLAB DESIGN-300mm THK. CENTER SLABvoilNo ratings yet

- Doubly Reinforced BeamDocument3 pagesDoubly Reinforced BeamriverieNo ratings yet

- Behavior of Cantilever SlabsDocument1 pageBehavior of Cantilever Slabsatoz2033No ratings yet

- Design of Pile Cap: X Y XYDocument2 pagesDesign of Pile Cap: X Y XYvoilNo ratings yet

- Design of Valve-chamber-Vc - 08 & 12-13-04-23Document26 pagesDesign of Valve-chamber-Vc - 08 & 12-13-04-23desilcharpdmcNo ratings yet

- Isolated Footing (R or S)Document19 pagesIsolated Footing (R or S)Shaniha kkNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- Input Data: Top Slab DesignDocument7 pagesInput Data: Top Slab DesignRameez Ahmed AbbasiNo ratings yet

- Phytorid STPDocument4 pagesPhytorid STPsamirbendre1No ratings yet

- B150 - Lift Roof Slab DesignDocument2 pagesB150 - Lift Roof Slab DesignGovendan GopalakrishnanNo ratings yet

- Beam DesignDocument4 pagesBeam DesignPraYush RajbhandariNo ratings yet

- Stress Check of Box CulvertDocument2 pagesStress Check of Box CulvertBRIDGE DESIGNCELLNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Document2 pagesAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- Calculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK DataDocument3 pagesCalculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK Dataasif billalNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Singly Reinforced BeamDocument3 pagesSingly Reinforced BeamriverieNo ratings yet

- Description Formula Units Location at Base: Provide Minimum SteelDocument1 pageDescription Formula Units Location at Base: Provide Minimum Steelp_ignatiusNo ratings yet

- 4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954Document3 pages4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954saubhagya majhiNo ratings yet

- Corbel R C BracketDocument2 pagesCorbel R C BracketVijendra Singh SoniNo ratings yet

- Design Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992Document2 pagesDesign Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992OmPrakashNo ratings yet

- Annexure 2 - RCC Encasement Reinf Calculation-P1Document4 pagesAnnexure 2 - RCC Encasement Reinf Calculation-P1marameez7886No ratings yet

- Depth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationDocument2 pagesDepth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationUsama ChauguleNo ratings yet

- RCC14 Crack WidthDocument1 pageRCC14 Crack WidthKha Phuc100% (1)

- Bending Strength CheckDocument2 pagesBending Strength CheckwaquarstrNo ratings yet

- Calculo de Ancho de Grieta: Curso Patología Grid Line 1 Carvajal 13-Oct-2008 1Document1 pageCalculo de Ancho de Grieta: Curso Patología Grid Line 1 Carvajal 13-Oct-2008 1YalimarLoboCNo ratings yet

- Corner Wall Design - CulvertDocument5 pagesCorner Wall Design - CulvertSuresh MahalingamNo ratings yet

- Reinforcement Design of Base Slab (Type-1)Document1 pageReinforcement Design of Base Slab (Type-1)Akshay DuggalNo ratings yet

- 8 Check For Crack Width: B) Bottom SlabDocument2 pages8 Check For Crack Width: B) Bottom SlabAnonymous jLLjBdrNo ratings yet

- 5.7 Pile CapDocument2 pages5.7 Pile CapPhilip ChanNo ratings yet

- Continuous Inner Slab Design - Bending Moment BS 8110 Hogging Moment at Over Slab SupportDocument1 pageContinuous Inner Slab Design - Bending Moment BS 8110 Hogging Moment at Over Slab Supportklára LudínováNo ratings yet

- 7 Check For Crack Width: A) Deck SlabDocument2 pages7 Check For Crack Width: A) Deck SlabAnonymous jLLjBdrNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- RCC14 Crack Width PDFDocument1 pageRCC14 Crack Width PDFmdelacua2No ratings yet

- Page 1Document1 pagePage 1Edward Albert BañagaNo ratings yet

- Shear Wall Design (IS 13920-2016)Document8 pagesShear Wall Design (IS 13920-2016)Sahil OzaNo ratings yet

- Crack Width Calculation BS 8100 BS 8007Document1 pageCrack Width Calculation BS 8100 BS 8007asdNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Solid Slab BS 8110-838 Amarj SirDocument8 pagesSolid Slab BS 8110-838 Amarj SirAamir SuhailNo ratings yet

- End Panel S3 Development of Maa Samleswari at Sambalpur: One-WayDocument1 pageEnd Panel S3 Development of Maa Samleswari at Sambalpur: One-Wayselvakumar sNo ratings yet

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 23-Nov-2020 34 CHG R68Document1 pageSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 23-Nov-2020 34 CHG R68Aung MayNo ratings yet

- STP Rusayl Oman: Double Shell Combined Circular TankDocument1 pageSTP Rusayl Oman: Double Shell Combined Circular TankRahulNo ratings yet

- Middle Wall (All Intermediate Walls)Document3 pagesMiddle Wall (All Intermediate Walls)epe civilNo ratings yet

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110christopherNo ratings yet

- Confinement Reinforcement of Pier ShaftDocument2 pagesConfinement Reinforcement of Pier ShaftMayurSoniNo ratings yet

- Circular Section Crack Width Under Pure TensionDocument1 pageCircular Section Crack Width Under Pure TensionAbinash ModakNo ratings yet

- Maximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapDocument1 pageMaximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapsivaNo ratings yet

- Slab Design Vehicle MovementDocument21 pagesSlab Design Vehicle MovementsivaNo ratings yet

- South Mara Hydro Power Project: Kenya Tea Development Agency, KTDA Base MKN 29-Aug-2016Document1 pageSouth Mara Hydro Power Project: Kenya Tea Development Agency, KTDA Base MKN 29-Aug-2016Kagwi MauriceNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- Cone Penetration of Lubricating Grease: Standard Test Methods ForDocument14 pagesCone Penetration of Lubricating Grease: Standard Test Methods ForRodrigo Briceño IbarraNo ratings yet

- A Laboratory-Centered Approach To Introducing Engineering Students To Electric Circuit and Electric Systems ConceptsDocument6 pagesA Laboratory-Centered Approach To Introducing Engineering Students To Electric Circuit and Electric Systems ConceptsVia Marie MesaNo ratings yet

- Radio Wave Propagation An Introduction For The Non-Specialist by John A. RichardsDocument4 pagesRadio Wave Propagation An Introduction For The Non-Specialist by John A. RichardsAKHI9No ratings yet

- Paulino, Paul Tyrone R. Assignment 3Document14 pagesPaulino, Paul Tyrone R. Assignment 3Tyrone PaulinoNo ratings yet

- Acade My: Design Procedure For Channel/i - Section Purlins (!)Document7 pagesAcade My: Design Procedure For Channel/i - Section Purlins (!)18TK-5-129No ratings yet

- Unit 1 - Mechanics - Spring 2017 - 1Document32 pagesUnit 1 - Mechanics - Spring 2017 - 1Robot BotNo ratings yet

- Medicinal Chemistry - Heterocyclic CompoundsDocument37 pagesMedicinal Chemistry - Heterocyclic CompoundsnasibdinNo ratings yet

- Energy Efficiency PPT NotesDocument2 pagesEnergy Efficiency PPT Notesapi-235634024No ratings yet

- Materi Ke 6 Rule of MixtureDocument9 pagesMateri Ke 6 Rule of Mixtureashish narangNo ratings yet

- Basic Water PropertiesDocument12 pagesBasic Water PropertiesBryan GraczykNo ratings yet

- Performance Specification: Hot Side Cold SideDocument2 pagesPerformance Specification: Hot Side Cold SideStevan KrstojevicNo ratings yet

- Introduction To Composite Material Modeling With SolidWorks Simulation PremiumDocument26 pagesIntroduction To Composite Material Modeling With SolidWorks Simulation Premiumanon_282863388100% (1)

- Gambica Bs en 61439 Guide Ed2 2013Document47 pagesGambica Bs en 61439 Guide Ed2 2013Osama_Othman0150% (2)

- Chapter 1 Introduction To Communication SystemsDocument59 pagesChapter 1 Introduction To Communication Systemswleum100% (1)

- Open Quantum System Dynamics - S41534-019-0235-YDocument10 pagesOpen Quantum System Dynamics - S41534-019-0235-YKaushik NandiNo ratings yet

- First Push 2024 Grade 12 Marking Guide March 2024Document12 pagesFirst Push 2024 Grade 12 Marking Guide March 2024lemonlululu1No ratings yet

- Matlab: Sharadindu AdhikariDocument9 pagesMatlab: Sharadindu AdhikariSharadindu AdhikariNo ratings yet

- Sartorius Cata Integrated Lab Equipment S 0300 eDocument430 pagesSartorius Cata Integrated Lab Equipment S 0300 eedal_108No ratings yet

- Spectrophotometric Determination of Salicylamide and ParacetamolDocument6 pagesSpectrophotometric Determination of Salicylamide and Paracetamoliabureid7460No ratings yet

- Slope Stability Analysis Analiza Interna Input DataDocument22 pagesSlope Stability Analysis Analiza Interna Input DatananesculNo ratings yet

- Security Lock ProjectDocument13 pagesSecurity Lock Projecttaha199No ratings yet

- Lab 2Document13 pagesLab 2ahmedNo ratings yet

- Gis LecDocument6 pagesGis LecNiño Mar CenaNo ratings yet

- Tube Settling ThailandDocument110 pagesTube Settling ThailandbkkbrazilNo ratings yet

- Pressure Relief Valve ZDB Z2DBDocument8 pagesPressure Relief Valve ZDB Z2DBKikist ErsNo ratings yet

- HMT Senthil CompressDocument515 pagesHMT Senthil Compresssathiyapriyan2003No ratings yet

- 4 Building Codes ACI EC2Document6 pages4 Building Codes ACI EC2NhuVan NguyenNo ratings yet

- Resume CAE - NVH Engineer Xiao Wu 171030Document1 pageResume CAE - NVH Engineer Xiao Wu 171030XiaoWuNo ratings yet

Imps - Short Wall (My - Vertical) : Calculation of Steel

Imps - Short Wall (My - Vertical) : Calculation of Steel

Uploaded by

pearl kachhawahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Imps - Short Wall (My - Vertical) : Calculation of Steel

Imps - Short Wall (My - Vertical) : Calculation of Steel

Uploaded by

pearl kachhawahCopyright:

Available Formats

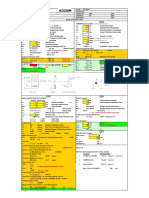

CALCULATION OF STEEL

IMPS - SHORT WALL (My - VERTICAL)

PLATE No.- 1739 L/C No.- 11

Maximum Moment (M) = 18.80 KNm

Factored Moment (Mu) = 28.20 KNm

2

Axial Stress in Plate (Tv) = 0.14 N/mm

2

Factored Axial Stress in Plate (1.5 xTv) = 0.21 N/mm

Force (p) 52.50 KN

Thickness Provided (D) = 250.00 mm

Effective Depth (d) = 194.00 mm

Clear Cover to walls = 50.00 mm

2

Grade of Steel (Fe) = 500.00 N/mm

2

Grade of Concrete (M) = 25.00 N/mm

Diameter of Steel Bars = 12.00 mm

Spacing of Steel bars provided = 150.00 mm c/c

2

Area of Steel Required for Bending (Ast.req) = 334.33 mm

2

Area of steel for axial tension = 60.3448 mm

2

Total area of steel required = 394.67 mm

Ref : cls

Distribution Steel for provided Thickness = 0.24 % 8.1.1

2

Minimum Area of Steel Required 300 mm

Hence, Area of Steel Provided is maximum of Ast. And Ast.

Min. = 394.67 mm2

2

Area of Steel Provided 753.60 mm

Ast prov > Ast Req HENCE OK

CRACK WIDTH CALCULATIONS

IMPS - SHORT WALL (My - VERTICAL)

PLATE No.- 1739 L/C No.- 11

Refer Annexure B IS 3370-2009 part 2

Fck = 25.00 N/mm2

fy = 500.00 N/mm2

Area of Reinforcement, As = 753.60 mm2

b = 1000 mm

h = 250.00 mm

d = 194.00 mm

Minimum Cover to Tension r/f = 50.00 mm

Maximum Bar Spacing = 150.00 mm c/c

Provided Bar Dia = 12.00 mm

Applied Service Moment (Ms) = 19 KNm

acr =(((S/2)^2+(CO+DIA/2)^2)^(1/2)-DIA/2) = 88 mm

CALCULATIONS

Moduli of Elasticity of Concrete (5000fck) = 25000.00 N/mm2

Ec = 25.00 KN/mm2

Moduli of Elasticity of Steel = 210000 N/mm2

Es = 210 KN/mm2

Modular Ratio a = (Es/ Ec) = 8.40

r = (As/bd) = 0.00388

Depth of Neutral Axis, "x" = 43.63 mm

x =((-a.r)+((a.r)2+2.a.r)^1/2)).d)

Z = (d -(x/3)) = 179.46

2

Reinforcement Stress (fs) [fs =Ms/ (As.Z)] = 139.01 N/mm

2

Concrete Stress (fc) [fc =(fs.As)/(0.5.b.x)] = 4.80 N/mm

Strain at Soffit of Concrete wall =

Ɛ1 = (fs/Es).((h-x)/(d-x)) Ɛ1 = 0.000909

Strain due to Stiffening Effect of Concrete Between Cracks (Ɛ2)

Ɛ2 = (b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.2 mm USED

Ɛ2 = (1.5.b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.1 mm NA

Ɛ2 = 0.00060

Average Strain for Caluculation of Crack Width "Ɛm" = 0.0003120

Calculated Crack Width "W" = 0.060086 mm

For Tension - Crack width calculation

e1 = P/(As Es) = 0.000111

Strain due to stiffening effect of concrete between cracks " e2 " = btD/EsAs as ε1<ε2, stiffening effect not

Ɛ2 = 0.001580 considered

Average strain for calculation of crack width " em " = 0.0001106 <0.8fy/Es, OK

Calculation of Crack width = 0.029061 mm

Total Crackwidth for tension +bending = 0.089146 mm

W < 0.2 mm, HENCE OK

CALCULATION OF STEEL

IMPS - SHORT WALL (Mx - HORIZONTAL)

PLATE No.- 573 L/C No.- 9

Maximum Moment (M) = 14.00 KNm

Factored Moment (Mu) = 21.00 KNm

2

Axial Stress in Plate (Tv) = 0.27 N/mm

2

Factored Axial Stress in Plate (1.5 xTv) = 0.41 N/mm

Force (p) 101.25 KN

Thickness Provided (D) = 250.00 mm

Effective Depth (d) = 195.00 mm

Clear Cover to walls = 50.00 mm

2

Grade of Steel (Fe) = 500.00 N/mm

2

Grade of Concrete (M) = 25.00 N/mm

Diameter of Steel Bars = 10.00 mm

Spacing of Steel bars provided = 150.00 mm c/c

2

Area of Steel Required for Bending (Ast.req) = 247.69 mm

2

Area of steel for axial tension = 116.3793 mm

2

Total area of steel required = 364.07 mm

Ref : cls

Distribution Steel for provided Thickness = 0.24 % 8.1.1

2

Minimum Area of Steel Required 300 mm

Hence, Area of Steel Provided is maximum of Ast. And Ast.

Min. = 364.07 mm2

2

Area of Steel Provided 523.33 mm

Ast prov > Ast Req HENCE OK

CRACK WIDTH CALCULATIONS

IMPS - SHORT WALL (Mx - HORIZONTAL)

PLATE No.- 573 L/C No.- 9

Refer Annexure B IS 3370-2009 part 2

Fck = 25.00 N/mm2

fy = 500.00 N/mm2

Area of Reinforcement, As = 523.33 mm2

b = 1000 mm

h = 250.00 mm

d = 195.00 mm

Minimum Cover to Tension r/f = 50.00 mm

Maximum Bar Spacing = 150.00 mm c/c

Provided Bar Dia = 10.00 mm

Applied Service Moment (Ms) = 14 KNm

acr =(((S/2)^2+(CO+DIA/2)^2)^(1/2)-DIA/2) = 88 mm

CALCULATIONS

Moduli of Elasticity of Concrete (5000fck) = 25000.00 N/mm2

Ec = 25.00 KN/mm2

Moduli of Elasticity of Steel = 210000 N/mm2

Es = 210 KN/mm2

Modular Ratio a = (Es/ Ec) = 8.40

r = (As/bd) = 0.00268

Depth of Neutral Axis, "x" = 37.24 mm

x =((-a.r)+((a.r)2+2.a.r)^1/2)).d)

Z = (d -(x/3)) = 182.59

2

Reinforcement Stress (fs) [fs =Ms/ (As.Z)] = 146.52 N/mm

2

Concrete Stress (fc) [fc =(fs.As)/(0.5.b.x)] = 4.12 N/mm

Strain at Soffit of Concrete wall =

Ɛ1 = (fs/Es).((h-x)/(d-x)) Ɛ1 = 0.000941

Strain due to Stiffening Effect of Concrete Between Cracks (Ɛ2)

Ɛ2 = (b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.2 mm USED

Ɛ2 = (1.5.b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.1 mm NA

Ɛ2 = 0.00087

Average Strain for Caluculation of Crack Width "Ɛm" = 0.0000706

Calculated Crack Width "W" = 0.013743 mm

For Tension - Crack width calculation

e1 = P/(As Es) = 0.000307

Strain due to stiffening effect of concrete between cracks " e2 " = btD/EsAs as ε1<ε2, stiffening effect not

Ɛ2 = 0.002275 considered

Average strain for calculation of crack width " em " = 0.0003071 <0.8fy/Es, OK

Calculation of Crack width = 0.081079 mm

Total Crackwidth for tension +bending = 0.094821 mm

W < 0.2 mm, HENCE OK

CALCULATION OF STEEL

IMPS - LONG WALL (My - VERTICAL)

PLATE No.- 745 L/C No.- 9

Maximum Moment (M) = 12.18 KNm

Factored Moment (Mu) = 18.27 KNm

2

Axial Stress in Plate (Tv) = 0.12 N/mm

2

Factored Axial Stress in Plate (1.5 xTv) = 0.18 N/mm

Force (p) 45.00 KN

Thickness Provided (D) = 250.00 mm

Effective Depth (d) = 194.00 mm

Clear Cover to walls = 50.00 mm

2

Grade of Steel (Fe) = 500.00 N/mm

2

Grade of Concrete (M) = 25.00 N/mm

Diameter of Steel Bars = 12.00 mm

Spacing of Steel bars provided = 150.00 mm c/c

2

Area of Steel Required for Bending (Ast.req) = 216.60 mm

2

Area of steel for axial tension = 51.7241 mm

2

Total area of steel required = 268.33 mm

Ref : cls

Distribution Steel for provided Thickness = 0.24 % 8.1.1

2

Minimum Area of Steel Required 300 mm

Hence, Area of Steel Provided is maximum of Ast. And Ast.

Min. = 300.00 mm2

2

Area of Steel Provided 753.60 mm

Ast prov > Ast Req HENCE OK

CRACK WIDTH CALCULATIONS

IMPS - LONG WALL (My - VERTICAL)

PLATE No.- 745 L/C No.- 9

Refer Annexure B IS 3370-2009 part 2

Fck = 25.00 N/mm2

fy = 500.00 N/mm2

Area of Reinforcement, As = 753.60 mm2

b = 1000 mm

h = 250.00 mm

d = 194.00 mm

Minimum Cover to Tension r/f = 50.00 mm

Maximum Bar Spacing = 150.00 mm c/c

Provided Bar Dia = 12.00 mm

Applied Service Moment (Ms) = 12 KNm

acr =(((S/2)^2+(CO+DIA/2)^2)^(1/2)-DIA/2) = 88 mm

CALCULATIONS

Moduli of Elasticity of Concrete (5000fck) = 25000.00 N/mm2

Ec = 25.00 KN/mm2

Moduli of Elasticity of Steel = 210000 N/mm2

Es = 210 KN/mm2

Modular Ratio a = (Es/ Ec) = 8.40

r = (As/bd) = 0.00388

Depth of Neutral Axis, "x" = 43.63 mm

x =((-a.r)+((a.r)2+2.a.r)^1/2)).d)

Z = (d -(x/3)) = 179.46

2

Reinforcement Stress (fs) [fs =Ms/ (As.Z)] = 90.06 N/mm

2

Concrete Stress (fc) [fc =(fs.As)/(0.5.b.x)] = 3.11 N/mm

Strain at Soffit of Concrete wall =

Ɛ1 = (fs/Es).((h-x)/(d-x)) Ɛ1 = 0.000589

Strain due to Stiffening Effect of Concrete Between Cracks (Ɛ2)

Ɛ2 = (b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.2 mm USED

Ɛ2 = (1.5.b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.1 mm NA

Ɛ2 = 0.00060 as ε1<ε2, stiffening effect not

Average Strain for Caluculation of Crack Width "Ɛm" = 0.0005886 considered

Calculated Crack Width "W" = 0.113371 mm

For Tension - Crack width calculation

e1 = P/(As Es) = 0.000095

Strain due to stiffening effect of concrete between cracks " e2 " = btD/EsAs as ε1<ε2, stiffening effect not

Ɛ2 = 0.001580 considered

Average strain for calculation of crack width " em " = 0.0000948 <0.8fy/Es, OK

Calculation of Crack width = 0.024909 mm

Total Crackwidth for tension +bending = 0.138280 mm

W < 0.2 mm, HENCE OK

CALCULATION OF STEEL

IMPS - LONG WALL (Mx - HORIZONTAL)

PLATE No.- 667 L/C No.- 9

Maximum Moment (M) = 16.60 KNm

Factored Moment (Mu) = 24.90 KNm

2

Axial Stress in Plate (Tv) = 0.43 N/mm

2

Factored Axial Stress in Plate (1.5 xTv) = 0.65 N/mm

Force (p) 161.25 KN

Thickness Provided (D) = 250.00 mm

Effective Depth (d) = 194.00 mm

Clear Cover to walls = 50.00 mm

2

Grade of Steel (Fe) = 500.00 N/mm

2

Grade of Concrete (M) = 25.00 N/mm

Diameter of Steel Bars = 12.00 mm

Spacing of Steel bars provided = 150.00 mm c/c

2

Area of Steel Required for Bending (Ast.req) = 295.21 mm

2

Area of steel for axial tension = 185.3448 mm

2

Total area of steel required = 480.55 mm

Ref : cls

Distribution Steel for provided Thickness = 0.24 % 8.1.1

2

Minimum Area of Steel Required 300 mm

Hence, Area of Steel Provided is maximum of Ast. And Ast.

Min. = 480.55 mm2

2

Area of Steel Provided 753.60 mm

Ast prov > Ast Req HENCE OK

CRACK WIDTH CALCULATIONS

IMPS - LONG WALL (Mx - HORIZONTAL)

PLATE No.- 667 L/C No.- 9

Refer Annexure B IS 3370-2009 part 2

Fck = 25.00 N/mm2

fy = 500.00 N/mm2

Area of Reinforcement, As = 753.60 mm2

b = 1000 mm

h = 250.00 mm

d = 194.00 mm

Minimum Cover to Tension r/f = 50.00 mm

Maximum Bar Spacing = 150.00 mm c/c

Provided Bar Dia = 12.00 mm

Applied Service Moment (Ms) = 17 KNm

acr =(((S/2)^2+(CO+DIA/2)^2)^(1/2)-DIA/2) = 88 mm

CALCULATIONS

Moduli of Elasticity of Concrete (5000fck) = 25000.00 N/mm2

Ec = 25.00 KN/mm2

Moduli of Elasticity of Steel = 210000 N/mm2

Es = 210 KN/mm2

Modular Ratio a = (Es/ Ec) = 8.40

r = (As/bd) = 0.00388

Depth of Neutral Axis, "x" = 43.63 mm

x =((-a.r)+((a.r)2+2.a.r)^1/2)).d)

Z = (d -(x/3)) = 179.46

2

Reinforcement Stress (fs) [fs =Ms/ (As.Z)] = 122.75 N/mm

2

Concrete Stress (fc) [fc =(fs.As)/(0.5.b.x)] = 4.24 N/mm

Strain at Soffit of Concrete wall =

Ɛ1 = (fs/Es).((h-x)/(d-x)) Ɛ1 = 0.000802

Strain due to Stiffening Effect of Concrete Between Cracks (Ɛ2)

Ɛ2 = (b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.2 mm USED

Ɛ2 = (1.5.b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.1 mm NA

Ɛ2 = 0.00060

Average Strain for Caluculation of Crack Width "Ɛm" = 0.0002056

Calculated Crack Width "W" = 0.039608 mm

For Tension - Crack width calculation

e1 = P/(As Es) = 0.000340

Strain due to stiffening effect of concrete between cracks " e2 " = btD/EsAs as ε1<ε2, stiffening effect not

Ɛ2 = 0.001580 considered

Average strain for calculation of crack width " em " = 0.0003396 <0.8fy/Es, OK

Calculation of Crack width = 0.089257 mm

Total Crackwidth for tension +bending = 0.128866 mm

W < 0.2 mm, HENCE OK

CALCULATION OF STEEL

IMPS RAFT (My - SHORTER SPAN)

PLATE No.- 3331 L/C No.- 10

Maximum Moment (M) = 15.27 KNm

Factored Moment (Mu) = 22.91 KNm

2

Axial Stress in Plate (Tv) = 0.04 N/mm

2

Factored Axial Stress in Plate (1.5 xTv) = 0.05 N/mm

Force (p) 15.75 KN

Thickness Provided (D) = 300.00 mm

Effective Depth (d) = 244.00 mm

Clear Cover to walls = 50.00 mm

2

Grade of Steel (Fe) = 500.00 N/mm

2

Grade of Concrete (M) = 25.00 N/mm

Diameter of Steel Bars = 12.00 mm

Spacing of Steel bars provided = 150.00 mm c/c

2

Area of Steel Required for Bending (Ast.req) = 215.91 mm

2

Area of steel for axial tension = 18.1034 mm

2

Total area of steel required = 234.01 mm

Ref : cls

Distribution Steel for provided Thickness = 0.24 % 8.1.1

2

Minimum Area of Steel Required 360 mm

Hence, Area of Steel Provided is maximum of Ast. And Ast.

Min. = 360.00 mm2

2

Area of Steel Provided 753.60 mm

Ast prov > Ast Req HENCE OK

CRACK WIDTH CALCULATIONS

IMPS RAFT (My - SHORTER SPAN)

PLATE No.- 3331 L/C No.- 10

Refer Annexure B IS 3370-2009 part 2

Fck = 25.00 N/mm2

fy = 500.00 N/mm2

Area of Reinforcement, As = 753.60 mm2

b = 1000 mm

h = 300.00 mm

d = 244.00 mm

Minimum Cover to Tension r/f = 50.00 mm

Maximum Bar Spacing = 150.00 mm c/c

Provided Bar Dia = 12.00 mm

Applied Service Moment (Ms) = 15 KNm

acr =(((S/2)^2+(CO+DIA/2)^2)^(1/2)-DIA/2) = 88 mm

CALCULATIONS

Moduli of Elasticity of Concrete (5000fck) = 25000.00 N/mm2

Ec = 25.00 KN/mm2

Moduli of Elasticity of Steel = 210000 N/mm2

Es = 210 KN/mm2

Modular Ratio a = (Es/ Ec) = 8.40

r = (As/bd) = 0.00309

Depth of Neutral Axis, "x" = 49.61 mm

x =((-a.r)+((a.r)2+2.a.r)^1/2)).d)

Z = (d -(x/3)) = 227.46

2

Reinforcement Stress (fs) [fs =Ms/ (As.Z)] = 89.08 N/mm

2

Concrete Stress (fc) [fc =(fs.As)/(0.5.b.x)] = 2.71 N/mm

Strain at Soffit of Concrete wall =

Ɛ1 = (fs/Es).((h-x)/(d-x)) Ɛ1 = 0.000546

Strain due to Stiffening Effect of Concrete Between Cracks (Ɛ2)

Ɛ2 = (b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.2 mm USED

Ɛ2 = (1.5.b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.1 mm NA

Ɛ2 = 0.00068 as ε1<ε2, stiffening effect not

Average Strain for Caluculation of Crack Width "Ɛm" = 0.0005464 considered

Calculated Crack Width "W" = 0.110429 mm

For Tension - Crack width calculation

e1 = P/(As Es) = 0.000033

Strain due to stiffening effect of concrete between cracks " e2 " = btD/EsAs as ε1<ε2, stiffening effect not

Ɛ2 = 0.001896 considered

Average strain for calculation of crack width " em " = 0.0000332 <0.8fy/Es, OK

Calculation of Crack width = 0.008718 mm

Total Crackwidth for tension +bending = 0.119147 mm

W < 0.2 mm, HENCE OK

CALCULATION OF STEEL

IMPS RAFT (Mx - LONGER SPAN)

PLATE No.- 1109 L/C No.- 9

Maximum Moment (M) = 13.60 KNm

Factored Moment (Mu) = 20.40 KNm

2

Axial Stress in Plate (Tv) = 0.15 N/mm

2

Factored Axial Stress in Plate (1.5 xTv) = 0.23 N/mm

Force (p) 68.85 KN

Thickness Provided (D) = 300.00 mm

Effective Depth (d) = 244.00 mm

Clear Cover to walls = 50.00 mm

2

Grade of Steel (Fe) = 500.00 N/mm

2

Grade of Concrete (M) = 25.00 N/mm

Diameter of Steel Bars = 12.00 mm

Spacing of Steel bars provided = 150.00 mm c/c

2

Area of Steel Required for Bending (Ast.req) = 192.30 mm

2

Area of steel for axial tension = 79.1379 mm

2

Total area of steel required = 271.43 mm

Ref : cls

Distribution Steel for provided Thickness = 0.24 % 8.1.1

2

Minimum Area of Steel Required 360 mm

Hence, Area of Steel Provided is maximum of Ast. And Ast.

Min. = 360.00 mm2

2

Area of Steel Provided 753.60 mm

Ast prov > Ast Req HENCE OK

CRACK WIDTH CALCULATIONS

IMPS RAFT (Mx - LONGER SPAN)

PLATE No.- 1109 L/C No.- 9

Refer Annexure B IS 3370-2009 part 2

Fck = 25.00 N/mm2

fy = 500.00 N/mm2

Area of Reinforcement, As = 753.60 mm2

b = 1000 mm

h = 300.00 mm

d = 244.00 mm

Minimum Cover to Tension r/f = 50.00 mm

Maximum Bar Spacing = 150.00 mm c/c

Provided Bar Dia = 12.00 mm

Applied Service Moment (Ms) = 14 KNm

acr =(((S/2)^2+(CO+DIA/2)^2)^(1/2)-DIA/2) = 88 mm

CALCULATIONS

Moduli of Elasticity of Concrete (5000fck) = 25000.00 N/mm2

Ec = 25.00 KN/mm2

Moduli of Elasticity of Steel = 210000 N/mm2

Es = 210 KN/mm2

Modular Ratio a = (Es/ Ec) = 8.40

r = (As/bd) = 0.00309

Depth of Neutral Axis, "x" = 49.61 mm

x =((-a.r)+((a.r)2+2.a.r)^1/2)).d)

Z = (d -(x/3)) = 227.46

2

Reinforcement Stress (fs) [fs =Ms/ (As.Z)] = 79.34 N/mm

2

Concrete Stress (fc) [fc =(fs.As)/(0.5.b.x)] = 2.41 N/mm

Strain at Soffit of Concrete wall =

Ɛ1 = (fs/Es).((h-x)/(d-x)) Ɛ1 = 0.000487

Strain due to Stiffening Effect of Concrete Between Cracks (Ɛ2)

Ɛ2 = (b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.2 mm USED

Ɛ2 = (1.5.b.(h-x)2)/(3.Es.As.(d-x)) For Crack Width of 0.1 mm NA

Ɛ2 = 0.00068 as ε1<ε2, stiffening effect not

Average Strain for Caluculation of Crack Width "Ɛm" = 0.0004866 considered

Calculated Crack Width "W" = 0.098352 mm

For Tension - Crack width calculation

e1 = P/(As Es) = 0.000145

Strain due to stiffening effect of concrete between cracks " e2 " = btD/EsAs as ε1<ε2, stiffening effect not

Ɛ2 = 0.001896 considered

Average strain for calculation of crack width " em " = 0.0001450 <0.8fy/Es, OK

Calculation of Crack width = 0.038111 mm

Total Crackwidth for tension +bending = 0.136463 mm

W < 0.2 mm, HENCE OK

You might also like

- Introduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFDocument2 pagesIntroduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFs9n9No ratings yet

- Butterfly Valve Chamber Design - 300 - 700mm DIDocument6 pagesButterfly Valve Chamber Design - 300 - 700mm DIRamakanth Putty100% (1)

- Doubly Reinforced BeamDocument8 pagesDoubly Reinforced BeamKARTHIK SGNo ratings yet

- N2006 PidDocument8 pagesN2006 PidSarah KempNo ratings yet

- Calculation For Crack WidthDocument48 pagesCalculation For Crack Widthpearl kachhawahNo ratings yet

- Short Wall - Vertical: Plate No.-961 L/C No. - 10Document12 pagesShort Wall - Vertical: Plate No.-961 L/C No. - 10pearl kachhawahNo ratings yet

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- Crack PDFDocument22 pagesCrack PDFghansaNo ratings yet

- SLAB DESIGN-300mm THK. CENTER SLABDocument2 pagesSLAB DESIGN-300mm THK. CENTER SLABvoilNo ratings yet

- Doubly Reinforced BeamDocument3 pagesDoubly Reinforced BeamriverieNo ratings yet

- Behavior of Cantilever SlabsDocument1 pageBehavior of Cantilever Slabsatoz2033No ratings yet

- Design of Pile Cap: X Y XYDocument2 pagesDesign of Pile Cap: X Y XYvoilNo ratings yet

- Design of Valve-chamber-Vc - 08 & 12-13-04-23Document26 pagesDesign of Valve-chamber-Vc - 08 & 12-13-04-23desilcharpdmcNo ratings yet

- Isolated Footing (R or S)Document19 pagesIsolated Footing (R or S)Shaniha kkNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- Input Data: Top Slab DesignDocument7 pagesInput Data: Top Slab DesignRameez Ahmed AbbasiNo ratings yet

- Phytorid STPDocument4 pagesPhytorid STPsamirbendre1No ratings yet

- B150 - Lift Roof Slab DesignDocument2 pagesB150 - Lift Roof Slab DesignGovendan GopalakrishnanNo ratings yet

- Beam DesignDocument4 pagesBeam DesignPraYush RajbhandariNo ratings yet

- Stress Check of Box CulvertDocument2 pagesStress Check of Box CulvertBRIDGE DESIGNCELLNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Document2 pagesAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- Calculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK DataDocument3 pagesCalculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK Dataasif billalNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Singly Reinforced BeamDocument3 pagesSingly Reinforced BeamriverieNo ratings yet

- Description Formula Units Location at Base: Provide Minimum SteelDocument1 pageDescription Formula Units Location at Base: Provide Minimum Steelp_ignatiusNo ratings yet

- 4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954Document3 pages4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954saubhagya majhiNo ratings yet

- Corbel R C BracketDocument2 pagesCorbel R C BracketVijendra Singh SoniNo ratings yet

- Design Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992Document2 pagesDesign Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992OmPrakashNo ratings yet

- Annexure 2 - RCC Encasement Reinf Calculation-P1Document4 pagesAnnexure 2 - RCC Encasement Reinf Calculation-P1marameez7886No ratings yet

- Depth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationDocument2 pagesDepth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationUsama ChauguleNo ratings yet

- RCC14 Crack WidthDocument1 pageRCC14 Crack WidthKha Phuc100% (1)

- Bending Strength CheckDocument2 pagesBending Strength CheckwaquarstrNo ratings yet

- Calculo de Ancho de Grieta: Curso Patología Grid Line 1 Carvajal 13-Oct-2008 1Document1 pageCalculo de Ancho de Grieta: Curso Patología Grid Line 1 Carvajal 13-Oct-2008 1YalimarLoboCNo ratings yet

- Corner Wall Design - CulvertDocument5 pagesCorner Wall Design - CulvertSuresh MahalingamNo ratings yet

- Reinforcement Design of Base Slab (Type-1)Document1 pageReinforcement Design of Base Slab (Type-1)Akshay DuggalNo ratings yet

- 8 Check For Crack Width: B) Bottom SlabDocument2 pages8 Check For Crack Width: B) Bottom SlabAnonymous jLLjBdrNo ratings yet

- 5.7 Pile CapDocument2 pages5.7 Pile CapPhilip ChanNo ratings yet

- Continuous Inner Slab Design - Bending Moment BS 8110 Hogging Moment at Over Slab SupportDocument1 pageContinuous Inner Slab Design - Bending Moment BS 8110 Hogging Moment at Over Slab Supportklára LudínováNo ratings yet

- 7 Check For Crack Width: A) Deck SlabDocument2 pages7 Check For Crack Width: A) Deck SlabAnonymous jLLjBdrNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- RCC14 Crack Width PDFDocument1 pageRCC14 Crack Width PDFmdelacua2No ratings yet

- Page 1Document1 pagePage 1Edward Albert BañagaNo ratings yet

- Shear Wall Design (IS 13920-2016)Document8 pagesShear Wall Design (IS 13920-2016)Sahil OzaNo ratings yet

- Crack Width Calculation BS 8100 BS 8007Document1 pageCrack Width Calculation BS 8100 BS 8007asdNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Solid Slab BS 8110-838 Amarj SirDocument8 pagesSolid Slab BS 8110-838 Amarj SirAamir SuhailNo ratings yet

- End Panel S3 Development of Maa Samleswari at Sambalpur: One-WayDocument1 pageEnd Panel S3 Development of Maa Samleswari at Sambalpur: One-Wayselvakumar sNo ratings yet

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 23-Nov-2020 34 CHG R68Document1 pageSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 23-Nov-2020 34 CHG R68Aung MayNo ratings yet

- STP Rusayl Oman: Double Shell Combined Circular TankDocument1 pageSTP Rusayl Oman: Double Shell Combined Circular TankRahulNo ratings yet

- Middle Wall (All Intermediate Walls)Document3 pagesMiddle Wall (All Intermediate Walls)epe civilNo ratings yet

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110christopherNo ratings yet

- Confinement Reinforcement of Pier ShaftDocument2 pagesConfinement Reinforcement of Pier ShaftMayurSoniNo ratings yet

- Circular Section Crack Width Under Pure TensionDocument1 pageCircular Section Crack Width Under Pure TensionAbinash ModakNo ratings yet

- Maximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapDocument1 pageMaximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapsivaNo ratings yet

- Slab Design Vehicle MovementDocument21 pagesSlab Design Vehicle MovementsivaNo ratings yet

- South Mara Hydro Power Project: Kenya Tea Development Agency, KTDA Base MKN 29-Aug-2016Document1 pageSouth Mara Hydro Power Project: Kenya Tea Development Agency, KTDA Base MKN 29-Aug-2016Kagwi MauriceNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- Cone Penetration of Lubricating Grease: Standard Test Methods ForDocument14 pagesCone Penetration of Lubricating Grease: Standard Test Methods ForRodrigo Briceño IbarraNo ratings yet

- A Laboratory-Centered Approach To Introducing Engineering Students To Electric Circuit and Electric Systems ConceptsDocument6 pagesA Laboratory-Centered Approach To Introducing Engineering Students To Electric Circuit and Electric Systems ConceptsVia Marie MesaNo ratings yet

- Radio Wave Propagation An Introduction For The Non-Specialist by John A. RichardsDocument4 pagesRadio Wave Propagation An Introduction For The Non-Specialist by John A. RichardsAKHI9No ratings yet

- Paulino, Paul Tyrone R. Assignment 3Document14 pagesPaulino, Paul Tyrone R. Assignment 3Tyrone PaulinoNo ratings yet

- Acade My: Design Procedure For Channel/i - Section Purlins (!)Document7 pagesAcade My: Design Procedure For Channel/i - Section Purlins (!)18TK-5-129No ratings yet

- Unit 1 - Mechanics - Spring 2017 - 1Document32 pagesUnit 1 - Mechanics - Spring 2017 - 1Robot BotNo ratings yet

- Medicinal Chemistry - Heterocyclic CompoundsDocument37 pagesMedicinal Chemistry - Heterocyclic CompoundsnasibdinNo ratings yet

- Energy Efficiency PPT NotesDocument2 pagesEnergy Efficiency PPT Notesapi-235634024No ratings yet

- Materi Ke 6 Rule of MixtureDocument9 pagesMateri Ke 6 Rule of Mixtureashish narangNo ratings yet

- Basic Water PropertiesDocument12 pagesBasic Water PropertiesBryan GraczykNo ratings yet

- Performance Specification: Hot Side Cold SideDocument2 pagesPerformance Specification: Hot Side Cold SideStevan KrstojevicNo ratings yet

- Introduction To Composite Material Modeling With SolidWorks Simulation PremiumDocument26 pagesIntroduction To Composite Material Modeling With SolidWorks Simulation Premiumanon_282863388100% (1)

- Gambica Bs en 61439 Guide Ed2 2013Document47 pagesGambica Bs en 61439 Guide Ed2 2013Osama_Othman0150% (2)

- Chapter 1 Introduction To Communication SystemsDocument59 pagesChapter 1 Introduction To Communication Systemswleum100% (1)

- Open Quantum System Dynamics - S41534-019-0235-YDocument10 pagesOpen Quantum System Dynamics - S41534-019-0235-YKaushik NandiNo ratings yet

- First Push 2024 Grade 12 Marking Guide March 2024Document12 pagesFirst Push 2024 Grade 12 Marking Guide March 2024lemonlululu1No ratings yet

- Matlab: Sharadindu AdhikariDocument9 pagesMatlab: Sharadindu AdhikariSharadindu AdhikariNo ratings yet

- Sartorius Cata Integrated Lab Equipment S 0300 eDocument430 pagesSartorius Cata Integrated Lab Equipment S 0300 eedal_108No ratings yet

- Spectrophotometric Determination of Salicylamide and ParacetamolDocument6 pagesSpectrophotometric Determination of Salicylamide and Paracetamoliabureid7460No ratings yet

- Slope Stability Analysis Analiza Interna Input DataDocument22 pagesSlope Stability Analysis Analiza Interna Input DatananesculNo ratings yet

- Security Lock ProjectDocument13 pagesSecurity Lock Projecttaha199No ratings yet

- Lab 2Document13 pagesLab 2ahmedNo ratings yet

- Gis LecDocument6 pagesGis LecNiño Mar CenaNo ratings yet

- Tube Settling ThailandDocument110 pagesTube Settling ThailandbkkbrazilNo ratings yet

- Pressure Relief Valve ZDB Z2DBDocument8 pagesPressure Relief Valve ZDB Z2DBKikist ErsNo ratings yet

- HMT Senthil CompressDocument515 pagesHMT Senthil Compresssathiyapriyan2003No ratings yet

- 4 Building Codes ACI EC2Document6 pages4 Building Codes ACI EC2NhuVan NguyenNo ratings yet

- Resume CAE - NVH Engineer Xiao Wu 171030Document1 pageResume CAE - NVH Engineer Xiao Wu 171030XiaoWuNo ratings yet