Professional Documents

Culture Documents

U.S. Air Filtration, Inc.: Air To Media Guide

U.S. Air Filtration, Inc.: Air To Media Guide

Uploaded by

Akbar Khan 7118016Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U.S. Air Filtration, Inc.: Air To Media Guide

U.S. Air Filtration, Inc.: Air To Media Guide

Uploaded by

Akbar Khan 7118016Copyright:

Available Formats

U.S.

Air Filtration, Inc.

AIR TO MEDIA GUIDE

d en

t tio d en

t tio

ive v e lle onm Ra ive v e lle onm Ra

s i o / C s i o / C

Dust Type plo ras ontrnvir eA te Dust Type plo ras ontrnvir eA te

Ex Ab C E Fir Ra Ex Ab C E Fir Ra

Abrasive Blasting Detergents 2.2

• Black Beauty 1.4 Diatomaceous earth 2.5

• All others 1.8 Dyes 1.3

Activated carbon 2.5

Alfalfa 3.0 Fertilizer 2.2*

Alumina 2.5 Fiberboard 3.0

Ambient air filtration 3.5 Fiberglass 3.5

Arc washing (Gouging) * Flour 2.0

Asbestos 3.3 Fly ash 1.8

Baking powder 2.5 Frit 1.8

Barley (see Grain) Furnaces *

Bauxite 2.0

Beet pulp – Grain

Bentonite 2.0 • Corn 3.5

Beryllium 2.0 • Rice 3.5

Boric acid 1.8 Granite 2.0

Bran 3.5 Graphite 2.0

Brazing 2.2 Grinding

Buffing & polishing 3.5* • Aluminum 2.0

• Bake shoe 3.5

Calcium carbonate 1.8 • Cast iron 1.8

Carbon black • Composites 3.5

• Fused 1.1 • Rubber 3.8

• Sintered 1.9 • Steel 2.0

Cardboard 3.5 • Titanium 1.0

Cement 1.8 Gypsum 2.5

Ceramic 1.8

Chaff, grain 3.5 Iron oxide (Rust) 1.8

Chromium 1.5

Clay (& Brick & Marble) 1.8 Kaolin 1.5

Coal 1.8

Cocoa 1.8 Lead oxide 1.1

Coffee 1.8 Lead powder 1.5

Coke 1.7 Leather 3.5

Composites 3.5 Lime 2.5

Corn meal 3.0 Lime, hydrated 1.8

Corn starch 2.5 Limestone 2.5

Corn sugar 2.0 Lignite 2.0

Cutting

• Laser Malt 3.0

Metal 1.1 Meal 3.0

Non-metal 1.1 Metal, powdered 2.5

• Oxyacetylene 1.4-1.7 Metallizing

• Plasma 1.1 •Electric arc spray .04

• Plasma arc spray 1.2

• Powder flame spray 1.2

• Wire flame spray 1.2

* Check with Facility

Air to Media Guide Cont’d

nt tio nt tio

e e ed nme Ra e e ed nme Ra

siv i v l

o ol / C siv i v l

o ol / C

Dust Type plo ras ontrnvir eA te Dust Type plo ras ontrnvir eA te

Ex Ab C E Fir Ra Ex Ab C E Fir Ra

Metallic fume 1.1 Soldering (Welding) 1.8

Mica (Rock) 2.0 Soybean (Grain) 3.0

Milk solids (Powders) 3.0 Soybean meal 3.0

Starch 2.4

Oyster shell 1.8 Surgical starch 1.0

Paint pigments 2.0 Sugar (Glazed bags) 2.0

Paper 3.5

Pharmaceuticals Talc 2.0

• Dry powder 2.0 Talcum powder 2.0

• Coating 2.0 Titanium (see application) 1.8

Plaster 2.5 Titanium dioxide 2.2

Powder coating Tobacco 3.0

• Black 1.0 Toner 1.2

• White & colors 2.5

• Teflon 1.8 Weld fume

• Source capture 1.8

Quartz 3.0 Laser welding 1.7

Plasma arc welding 1.7

Rice 2.0 All others 2.2

Rock, mineral 3.0 • Ambient 3.5

Rubber 1.8 Laser welding 2.1

Rye (Grain) 3.5 Plasma arc welding 2.1

All others 2.8

Salicylic acid 1.8 Weld fume, soldering 2.2

Salt (Mineral) 3.5 Wheat (Grain) 3.0

Sand (Non foundry) 2.2 Woodworking

Sand (Foundry) 2.0 • Sanding 4.0

Selenium 1.8 • High speed cutting 4.0

Shale (Rock) 2.0 • Low speed cutting & –

Silica 2.5 planing

Silica, fumed 0.8

Silicates 2.2

Slate (Rock) 2.0

Soapstone 2.2

Soda ash 2.0

Controlled Environment = 70˚F (21˚C). 40% RH * Check with Facility

Explosive = Vents Required

Abrasive = AR Inlets Required

Fire = Sprinkler Header / Fire Media

You might also like

- BOM SampleDocument7 pagesBOM SampleRobles HenryNo ratings yet

- Allowable Velocity and Maximum Shear Stress Streambank and Shoreland Protection Code 580Document2 pagesAllowable Velocity and Maximum Shear Stress Streambank and Shoreland Protection Code 580toantutoantuNo ratings yet

- Specific Gravity of Common Materials1 PDFDocument1 pageSpecific Gravity of Common Materials1 PDFDrew B MrtnzNo ratings yet

- Specific Gravity - Density of Metals, Minerals, & Ceramics From READEDocument10 pagesSpecific Gravity - Density of Metals, Minerals, & Ceramics From READEisra alkhatibNo ratings yet

- Kandhal Lecture 1 On Bitumen: Refining, Types and Conventional Properties (Handouts)Document8 pagesKandhal Lecture 1 On Bitumen: Refining, Types and Conventional Properties (Handouts)Prof. Prithvi Singh Kandhal100% (4)

- Class Note 2Document20 pagesClass Note 2nitin chaudharyNo ratings yet

- Date: Note No. By: Sheet No.: AlignmentDocument7 pagesDate: Note No. By: Sheet No.: AlignmentStructural SpreadsheetsNo ratings yet

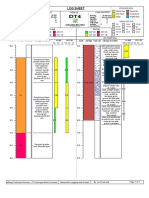

- SamplesoilreportDocument1 pageSamplesoilreportmanishdgNo ratings yet

- Log Sheet: Hole IdDocument1 pageLog Sheet: Hole IdJoinNo ratings yet

- Specific Gravity Table Metals Minerals Ceramics SubstanceDocument7 pagesSpecific Gravity Table Metals Minerals Ceramics SubstanceDadang YuliNo ratings yet

- Process Flow PDFDocument4 pagesProcess Flow PDFPyarilal SNo ratings yet

- SI3241NZ5Document61 pagesSI3241NZ5limariolimario27No ratings yet

- Densit@) I de Materiale (KG/DM) : Denumirea) I Marca Valoarea Denumirea) I Marca ValoareaDocument4 pagesDensit@) I de Materiale (KG/DM) : Denumirea) I Marca Valoarea Denumirea) I Marca Valoareajo_rz_57No ratings yet

- Cement PropertiesDocument1 pageCement Propertieskranthi kumarNo ratings yet

- Process Flow Contd.: 19 March 2019 Ref. Page No. 163 of TPM Activity ReportDocument1 pageProcess Flow Contd.: 19 March 2019 Ref. Page No. 163 of TPM Activity ReportPyarilal SNo ratings yet

- Annexure - IDocument11 pagesAnnexure - Imurthy kotiNo ratings yet

- WS ON ATMOSPHERE ErgergergDocument3 pagesWS ON ATMOSPHERE ErgergergPehel BirawatNo ratings yet

- 123cost EstimDocument116 pages123cost EstimCharles AjayiNo ratings yet

- Foundry Sand Additives and Additive TheoriesDocument3 pagesFoundry Sand Additives and Additive Theoriesk zNo ratings yet

- Supplemental Specifications Hl775-9S Bucket Selection Chart: With Tier 3 Engine InstalledDocument6 pagesSupplemental Specifications Hl775-9S Bucket Selection Chart: With Tier 3 Engine Installedyasinyou143No ratings yet

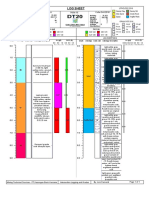

- DT20Document1 pageDT20JoinNo ratings yet

- Supplemental Specifications Hl775-9S Bucket Selection Chart: With Tier 3 Engine InstalledDocument6 pagesSupplemental Specifications Hl775-9S Bucket Selection Chart: With Tier 3 Engine InstalledRando PerezNo ratings yet

- Dasar - Dasar BanDocument29 pagesDasar - Dasar BanAhmad RaniNo ratings yet

- Mini Canal 2022.ex: HeatingDocument20 pagesMini Canal 2022.ex: HeatingAdnan HalilovicNo ratings yet

- HL775-9S Jul2017Document6 pagesHL775-9S Jul2017Hermogenes Jesus Nestares CastañedaNo ratings yet

- New Agenda PDFDocument1 pageNew Agenda PDFPyarilal SNo ratings yet

- Process Flow Pellet Plant - 01: Dry GrindingDocument1 pageProcess Flow Pellet Plant - 01: Dry GrindingPyarilal SNo ratings yet

- 1.homogeneous Hold Loading ConditionsDocument6 pages1.homogeneous Hold Loading ConditionsABHIROOP KNo ratings yet

- Labor Production EstimateDocument42 pagesLabor Production EstimateKaJong JaclaNo ratings yet

- 2.0 Composition of Water Based Drilling Muds (WBM) and Drill Cuttings 2.1 Drilling Muds Used Offshore in The U.S. and AbroadDocument9 pages2.0 Composition of Water Based Drilling Muds (WBM) and Drill Cuttings 2.1 Drilling Muds Used Offshore in The U.S. and AbroadIvan JorgeNo ratings yet

- Screw Conveyor Power Input and CapacityDocument3 pagesScrew Conveyor Power Input and CapacityDavid StichNo ratings yet

- Bulking Shrinkage and Bulk Density Information Rev 2022 GM WfgdcpvtihamDocument5 pagesBulking Shrinkage and Bulk Density Information Rev 2022 GM WfgdcpvtihamEr Amit ChhonkerNo ratings yet

- Treatmentsch I&IIDocument13 pagesTreatmentsch I&IIPc typeNo ratings yet

- Milestone PPT 14012023Document10 pagesMilestone PPT 14012023sabir aliNo ratings yet

- 2016-17b FCE345 Highway MaterialsDocument90 pages2016-17b FCE345 Highway MaterialsLukasi DeoneNo ratings yet

- Coal Production 2013: (In Millions of Tons)Document1 pageCoal Production 2013: (In Millions of Tons)bjtelmoNo ratings yet

- Bentonite Analysis Minerals 2022-2Document1 pageBentonite Analysis Minerals 2022-2Krdnz KrdnzNo ratings yet

- Densities of Various Materials As Per ASCE-10Document8 pagesDensities of Various Materials As Per ASCE-10irfanquadriNo ratings yet

- Tablas CM y CV - Asce 7-10Document9 pagesTablas CM y CV - Asce 7-10Josep R HerreraNo ratings yet

- Trial Mix EstimatesDocument4 pagesTrial Mix Estimateshenjie mirasolNo ratings yet

- Process Flow NewDocument1 pageProcess Flow NewPyarilal SNo ratings yet

- New Process New NewDocument1 pageNew Process New NewPyarilal SNo ratings yet

- (R Value Is 'Thermal Resistance Per M ) R RequiredDocument2 pages(R Value Is 'Thermal Resistance Per M ) R RequiredBob BingoNo ratings yet

- 000007638Document29 pages000007638Vipin PatniNo ratings yet

- Cost - Breakdown ArekaDocument251 pagesCost - Breakdown ArekaMohammed GagiNo ratings yet

- Cost Breakdown TerchaDocument251 pagesCost Breakdown TerchaMohammed GagiNo ratings yet

- Work Shop Layout by MeDocument1 pageWork Shop Layout by Mejanrel sedorifaNo ratings yet

- Form Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11Document117 pagesForm Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11halieyNo ratings yet

- Block 1 Types & Uses of AC-NTDocument6 pagesBlock 1 Types & Uses of AC-NTmehdiNo ratings yet

- Density Computations For Ceramics: N V A A NDocument10 pagesDensity Computations For Ceramics: N V A A NAaila AkhterNo ratings yet

- Elemental Solid Sulfur: Number: A-102 Issue Date: 03/10/98 Replaces: 12/18/95 Page 1 of 2Document2 pagesElemental Solid Sulfur: Number: A-102 Issue Date: 03/10/98 Replaces: 12/18/95 Page 1 of 2Abdul BasithNo ratings yet

- Butyl & Natural Reclaim RubberDocument3 pagesButyl & Natural Reclaim Rubbervinod kumarNo ratings yet

- 13 - Crossplot MethodsDocument29 pages13 - Crossplot MethodsDwisthi SatitiNo ratings yet

- MoistTech CCS3000Document4 pagesMoistTech CCS3000Box IdeaNo ratings yet

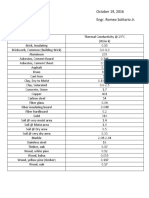

- Aljhon E. Dela Cruz October 19, 2016 Bsme - 4 Engr. Romeo Solitario JRDocument3 pagesAljhon E. Dela Cruz October 19, 2016 Bsme - 4 Engr. Romeo Solitario JRaljhonNo ratings yet

- Revised Local Material Cost From Towns ModifiedDocument14 pagesRevised Local Material Cost From Towns ModifiedMohammed GagiNo ratings yet

- Royalty-Rates 678Document3 pagesRoyalty-Rates 678Jaydeep BhawalNo ratings yet

- 2018 - 12 - 13 - Dutco - Program of WorkDocument1 page2018 - 12 - 13 - Dutco - Program of WorkAburvarajNo ratings yet

- ENG202 ACE - 02 Cement Chemistry Rev0808Document20 pagesENG202 ACE - 02 Cement Chemistry Rev0808Marlon Nieves LeónNo ratings yet

- Designofa 12 KwaircooledwaterchillerwithdrawingsDocument136 pagesDesignofa 12 KwaircooledwaterchillerwithdrawingsAkbar Khan 7118016No ratings yet

- Brand New Mcquay Smart Tools (V2.0) Officially Launching: Marketing BulletinDocument5 pagesBrand New Mcquay Smart Tools (V2.0) Officially Launching: Marketing BulletinAkbar Khan 7118016No ratings yet

- Ahu Selection SoftwareDocument2 pagesAhu Selection SoftwareAkbar Khan 7118016No ratings yet

- Single Skin AHU Will Update To FUW-F Series: Marketing BulletinDocument4 pagesSingle Skin AHU Will Update To FUW-F Series: Marketing BulletinAkbar Khan 7118016No ratings yet

- Planning Information Manual - ENDocument16 pagesPlanning Information Manual - ENAkbar Khan 7118016No ratings yet

- GRC BO Access ControlDocument6 pagesGRC BO Access ControlJohn SpartonNo ratings yet

- Alya Fauziyyah - Thesis - 1610117320004Document31 pagesAlya Fauziyyah - Thesis - 1610117320004Muhammad FahrurajiNo ratings yet

- Daifuku MIT BrochureDocument5 pagesDaifuku MIT BrochureZiqi LinNo ratings yet

- Safety RelayDocument28 pagesSafety Relayeric_sauvageau1804No ratings yet

- Demag ZKKE ManualDocument5 pagesDemag ZKKE ManualAlan MaciasNo ratings yet

- Confident Engineering Company ProfileDocument2 pagesConfident Engineering Company ProfileRATHNA KUMARNo ratings yet

- Nyquist Stability CriterionDocument4 pagesNyquist Stability CriterionRajeev KumarNo ratings yet

- Point 21 Sales Catalogue (Eichholtz)Document31 pagesPoint 21 Sales Catalogue (Eichholtz)Point 21No ratings yet

- Condensation Risk Assessment 2007 10Document15 pagesCondensation Risk Assessment 2007 10Clef GonadanNo ratings yet

- B05 - Environmental AccountingDocument10 pagesB05 - Environmental AccountingAcca BooksNo ratings yet

- Adult Education 2Document7 pagesAdult Education 2Azubuike ChidiNo ratings yet

- Engineering Fundamentals An Introduction To Engineering Chapter 01Document31 pagesEngineering Fundamentals An Introduction To Engineering Chapter 01Ana ChavezNo ratings yet

- Fosroc - Nitocote PE 135Document8 pagesFosroc - Nitocote PE 135guru sathya bharathyNo ratings yet

- Al 9351 Tractor and Farm EquipmentsDocument2 pagesAl 9351 Tractor and Farm EquipmentsDhivya PNo ratings yet

- FilterDocument2 pagesFilterNguyen PhatNo ratings yet

- Day 1 - ListeningDocument19 pagesDay 1 - ListeningVanessa AmandaNo ratings yet

- Burnette, Pollack, ForsythDocument12 pagesBurnette, Pollack, ForsythAmadeus ChinNo ratings yet

- Stepan Formulation 1110Document2 pagesStepan Formulation 1110Jan Velasco100% (1)

- Ccna Report On Project WanDocument60 pagesCcna Report On Project Wanmanoum2No ratings yet

- ĐỀ 1Document13 pagesĐỀ 1Thu Hà Huỳnh ThịNo ratings yet

- Article IDocument8 pagesArticle IMuhammad Nuril Wahid FauziNo ratings yet

- Eee-III-Analog Electronic Circuits (15ee34) - Question PaperDocument4 pagesEee-III-Analog Electronic Circuits (15ee34) - Question PaperchaitanyaNo ratings yet

- Approximations and Round-Off ErrorsDocument10 pagesApproximations and Round-Off ErrorsbadarNo ratings yet

- Introduction To Humanities: Taleb - Eli@skylineuniversity - Ac .AeDocument8 pagesIntroduction To Humanities: Taleb - Eli@skylineuniversity - Ac .AeAmjad khanNo ratings yet

- A Report On Self Defence Workshop For Women and GirlsDocument7 pagesA Report On Self Defence Workshop For Women and GirlsANJALI GHANSHANINo ratings yet

- The English Paragraph: What Is A Paragraph?Document6 pagesThe English Paragraph: What Is A Paragraph?Khin Maung HtweNo ratings yet

- 13 Jan - 2019Document51 pages13 Jan - 2019Xen Operation DPHNo ratings yet

- Problem Statement: Fluid CepDocument6 pagesProblem Statement: Fluid CepMuneer AhmedNo ratings yet

- Vertical Bearings Type WV: Diameter Range 125... 710 MMDocument12 pagesVertical Bearings Type WV: Diameter Range 125... 710 MMLuis CeronNo ratings yet

- October 24 - Gestalt PsychologyDocument23 pagesOctober 24 - Gestalt PsychologyEdgar Miralles Inales ManriquezNo ratings yet