Professional Documents

Culture Documents

Poster Jornada 2019

Poster Jornada 2019

Uploaded by

OSCAR BENJAMIN JORDAN SUAREZCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poster Jornada 2019

Poster Jornada 2019

Uploaded by

OSCAR BENJAMIN JORDAN SUAREZCopyright:

Available Formats

MICROSTRUCTURE OF ENCAPSULATED SOURSOP (Annona muricata L.

)

LEAVES EXTRACT BY SPRAY DRYING

Oscar B. Jordán1; Patricia, Glorio2; Leslie V. Vidal3

1Cordon Bleu University, Lima, Peru; 2National Agrarian University La Molina, Lima, Peru; 3University of Concepcion, Concepcion, Chile.

INTRODUCTION

The current technologies of delivering bioactive compounds for the

food industry do not properly ensure their availability and functionality.

In the last years, the consumption of Annona muricata leaves has

been extended due to its anticancer properties attributed to

phytochemicals like acetogenins, alkaloids and phenolic compounds.

One of the most promising technologies that can solve the above-

mentioned difficulties is microencapsulation, which implies the

trapping and controlled releasing of bioactive compounds usually

sensitive to environmental factors. Among the available

microencapsulation techniques there is spray drying, during this

process small drops of a liquid containing the interest compounds are

turned into dry particles as the solvent is evaporated, but this process

can induce microstructural changes that causes a further degradation

of the encapsulated compound. This work aimed to investigate the

microstructure of encapsulated soursop (Annona muricata L.) leaves

Figure 1. Soursop (Annona muricata L.) leaves conditioning.

extract by spray drying in relation to type and concentration of the

encapsulant.

MATERIALS AND METHODS

When using GA, a higher quantity of rough particles is observed (Fig. 4), due to the

rapid shrinkage occurring in the early stages of drying as solvent diffuses through the

Extraction

wall (Rosenberg et al., 1985; Walton, 2000). Tolun et al. (2016) indicate that particles

Extraction was performed using grinded dry leaves (Fig. 1) macerated at 70 °C for with rough surfaces are more sensitive to oxidation reactions compared to those with

30 min with a hydroalcoholic solution (20 % Ethanol) in a relation of 1 to 36 (w/v). a smooth surface because of their greater surface areas.

The extract (EXT) was further centrifuged at 2500 rpm for 30 min.

Microencapsulation A B

The supernatant was mixed with gum arabic (GA) and maltodextrin (MD) at 5 and

10 % and then the mixtures were homogenized (Ultra Turrax®) for 5 min at 10000

and 15000 rpm (22±2°C). Subsequently the solvent was evaporated using a spray

dryer (Büchi B-290) with a feed nozzle diameter of 1 mm at 140 °C with a feeding

rate of 10 mL/min. A general illustration of the resulting powder is showed in Fig. 2.

E

Morphological characterization and

particle size

Structural characteristics of the powders

were observed using a SEM Microscope

C D

(JEOL JSM-6380 LV), with an increasing

magnification ranging from 1200 to 20000x.

Particle size was defined by measuring the

diameter of more than 650 particles from

SEM photographs.

Figure 2. Appareance of the

microencapsulated extract

RESULTS AND DISCUSSIONS

Figure 3 shows the original morphological characteristics of the admixtures (the sole

extract, and the encapsulants), each component has a unique morphology related to

Figure 4. Soursop leaves extract microcapsules using gum arabic (A and B) and

its chemical nature and to the process involved during its fabrication. It is useful to maltodextrin (C and D) at 5 and 10%, respectively.

employ well characterized encapsulants in terms of microstructural properties for a

better understanding of transformation of liquids into fluidized dried solids. Using both encapsulants (GA and MD) fragmented particles were obtained (Fig. 4e);

however, the incidence of fragmentation decreased as concentration increased.

Likewise, it is probable that the active principles had been incorporated into the wall;

A B C consequently, there is a central void which is characteristic of a multiple core structure

(Akhavan Mahdavi et al., 2016). It should be noted that a low ratio of fragmented

particles is a good indicator of the encapsulation process, this condition ensures a

higher protection of the inner compounds.

CONCLUSIONS

Spray drying technology enabled to obtain microcapsules from soursop leaves extract

employing gum arabic and maltodextrin as encapsulants; from morphological analysis, it

was found that the most suitable encapsulant was maltodextrin at 10%, since the

sphericity index was higher as the encapsulant concentration increased, whereas

fragmentation decreased.

ACKNOWLEDGEMENT

Figure 3. Microphotographs of spray dried soursop leaves extract (A), gum

arabic (B), and maltodextrin (C). This research is a partial result of an internship financed by Alianza del Pacífico.

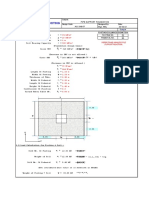

Table 1. Ranges of particle sizes for REFERENCES

each treatment

Microparticles exhibited spherical shape and ▪ Akhavan Mahdavi, S.; Mahdi Jafari, S.; Assadpoor, E.; Dehnad, D. 2016. Microencapsulation

heterogeneous size ranging from 0,28 to optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. International Journal

Diámetro of Biological Macromolecules 85: 379–385.

13,43 µm (Table 1). Spherical morphology is Sample

(µm) ▪ Corrigan, O.I. 1995. Thermal analysis of spray dried products. Thermochimica Acta 248: 245-258.

characteristic of the spray drying process ▪ Rosenberg, M.; Kopelman, I.J.; Talmon, Y. 1985. A scanning electron microscopy study of

(Tonon et al., 2009); although, is dependant EXT GA 5% 0.28 - 13.87 microencapsulation. J. Food Sci. 50: 139-144.

of the encapsulant type (Corrigan, 1995). ▪ Tonon, R.; Brabet, C.; Hubinger, M. 2009. Influence of drying air temperature and carrier agent

EXT GA 10% 0.25 - 11.21 concentration on the physicochemical properties of açai juice powder. Ciência e Tecnologia de

EXT MD 5% Alimentos 29(2): 444-450.

0.29 - 12.86 ▪ Walton, D.E. 2000. The morphology of spray-dried particles: A qualitative view. Drying Technology

EXT MD 10% 0.30 - 13.43 18(9):1943-1986.

You might also like

- Phase Change Lab ReportDocument1 pagePhase Change Lab ReportSean Munroe100% (5)

- External Load On PipelineDocument21 pagesExternal Load On PipelineindeskeyNo ratings yet

- 004-PA-16 Technosheet ICP2 LRDocument2 pages004-PA-16 Technosheet ICP2 LRHossam Mostafa100% (1)

- Biofoam Dari Serat PisangDocument9 pagesBiofoam Dari Serat PisangziziNo ratings yet

- 10 Ijsrm - CopieDocument4 pages10 Ijsrm - CopieEL Hassania EL HERRADINo ratings yet

- Phytochemical Mahkota DewaDocument18 pagesPhytochemical Mahkota DewaZaky KunNo ratings yet

- JYoungPharm 10 2 s79Document5 pagesJYoungPharm 10 2 s79IlkurgumNo ratings yet

- Mikroenkapsulasi Minyak Sawit Mentah Dengan Penyalut Maltodekstrin Dan Isolat Protein KedelaiDocument10 pagesMikroenkapsulasi Minyak Sawit Mentah Dengan Penyalut Maltodekstrin Dan Isolat Protein KedelaiAmalia Noviyanti AmelNo ratings yet

- Composites Part B: M. Mures An-Pop, L.B. Chiriac, F. Martin, S. SimonDocument7 pagesComposites Part B: M. Mures An-Pop, L.B. Chiriac, F. Martin, S. SimonMayangNo ratings yet

- Synthesis and Characterization of Banana Peel Derived Biopolymer HydroxyapatiteDocument3 pagesSynthesis and Characterization of Banana Peel Derived Biopolymer HydroxyapatiteSilver ShadesNo ratings yet

- Accepted Manuscript: 10.1016/j.ijbiomac.2018.08.065Document20 pagesAccepted Manuscript: 10.1016/j.ijbiomac.2018.08.065Hoang-Minh NguyenNo ratings yet

- Phaleria Macrocarpa: Nur ShafiqahDocument17 pagesPhaleria Macrocarpa: Nur ShafiqahZaky KunNo ratings yet

- MICROENCAPSULATION of PROPOLIS With Gum Arabic and MaltodextrinDocument17 pagesMICROENCAPSULATION of PROPOLIS With Gum Arabic and MaltodextrinDiah Kartika PratamiNo ratings yet

- Nanoencapsulating of Kaffir Lime Oil With Coacervation Method Using Arabic Gum and Maltodextrin As EncapsulantDocument6 pagesNanoencapsulating of Kaffir Lime Oil With Coacervation Method Using Arabic Gum and Maltodextrin As EncapsulantPremier PublishersNo ratings yet

- 4.1 2 PDFDocument6 pages4.1 2 PDFNela SharonNo ratings yet

- A New Alternative Adsorbent For The Removal of Cationic Dyes From Aqueous SolutionDocument9 pagesA New Alternative Adsorbent For The Removal of Cationic Dyes From Aqueous Solutionmona aminNo ratings yet

- Structural Characterization of Cellulose ObtainedDocument5 pagesStructural Characterization of Cellulose ObtainedRezza MarcellaNo ratings yet

- Solid State PharmaceuticsDocument6 pagesSolid State PharmaceuticsPrajyot SononeNo ratings yet

- HOAINAMDocument7 pagesHOAINAMShiny SunnyNo ratings yet

- Lubis 2018 IOP Conf. Ser. Mater. Sci. Eng. 309 012100Document10 pagesLubis 2018 IOP Conf. Ser. Mater. Sci. Eng. 309 012100vatimoteoNo ratings yet

- Salah 2017Document6 pagesSalah 2017Kanesti KamajayaNo ratings yet

- Asian Journal of ChemistryDocument5 pagesAsian Journal of ChemistryDr. Yedhu Krishnan RNo ratings yet

- Treatment of Uf Membranes With Simple and Formulated Cleaning AgentsDocument11 pagesTreatment of Uf Membranes With Simple and Formulated Cleaning Agentsquangvlog017No ratings yet

- Tổng Hợp Nano Chitosan-hóa Học NgaDocument8 pagesTổng Hợp Nano Chitosan-hóa Học NgaTrang ThùyNo ratings yet

- Self-Healing Ability and Adhesion Strength of Capsule Embedded Coatings-Micro and Nano Sized Capsules Containing Linseed OilDocument9 pagesSelf-Healing Ability and Adhesion Strength of Capsule Embedded Coatings-Micro and Nano Sized Capsules Containing Linseed OilMia karolinaNo ratings yet

- IFRJ-2011-106 RajeevDocument6 pagesIFRJ-2011-106 RajeevAdauto AlvesNo ratings yet

- Antimicrobial Properties and Phytochemical Constituents of An Antidiabetic PlantDocument36 pagesAntimicrobial Properties and Phytochemical Constituents of An Antidiabetic PlantRomy WacasNo ratings yet

- Synthesis and Characterization of Polyacrylonitrile Based Precursor Beads For The Removal of The Dye Malachite Green From Its Aqueous SolutionsDocument11 pagesSynthesis and Characterization of Polyacrylonitrile Based Precursor Beads For The Removal of The Dye Malachite Green From Its Aqueous SolutionsSantoshi MohantaNo ratings yet

- Formulation and Evaluation of Microemulsion Based Topical Hydrogel Containing LornoxicamDocument8 pagesFormulation and Evaluation of Microemulsion Based Topical Hydrogel Containing LornoxicamsafrinpujiNo ratings yet

- MST543 Lab Report (Exp 2)Document8 pagesMST543 Lab Report (Exp 2)Ain Syafeeqa Kamarul AzemiNo ratings yet

- Ecotoxicology and Environmental Safety: Munagapati Venkata Subbaiah, Dong-Su KimDocument9 pagesEcotoxicology and Environmental Safety: Munagapati Venkata Subbaiah, Dong-Su KimSoussou PerlaNo ratings yet

- Zhang 2021Document10 pagesZhang 2021Val Andrea TuazonNo ratings yet

- Pua 2013Document6 pagesPua 2013Sergio mauricio sergioNo ratings yet

- Saudi Pharm JournalDocument9 pagesSaudi Pharm Journaldini hanifaNo ratings yet

- 2008 Article 41018Document9 pages2008 Article 41018sarvesh patilNo ratings yet

- Extraction 11 1-S2.0-S1878535214000793-MainDocument8 pagesExtraction 11 1-S2.0-S1878535214000793-MainZineb fella MahiNo ratings yet

- InTech-Enhancing Biogas Production and Uasb Start Up by Chitosan AdditionDocument18 pagesInTech-Enhancing Biogas Production and Uasb Start Up by Chitosan AdditionZhaira MhaeNo ratings yet

- 1 s2.0 S2238785419306635 MainDocument9 pages1 s2.0 S2238785419306635 Maindhy182No ratings yet

- Antioxidant Properties of Garcinia Mangostana L (Mangosteen) RindDocument6 pagesAntioxidant Properties of Garcinia Mangostana L (Mangosteen) RindCristover FernandoNo ratings yet

- Ijcpa 2013002Document3 pagesIjcpa 2013002AHMED MOHAMMED MAHMOUD MUSTAFANo ratings yet

- Ecotoxicology and Environmental Safety: R. Vinoth Kumar, Aloke Kumar Ghoshal, G. PugazhenthiDocument7 pagesEcotoxicology and Environmental Safety: R. Vinoth Kumar, Aloke Kumar Ghoshal, G. PugazhenthiVinoth KumarNo ratings yet

- Journal Modeling and Optimization of the Parameters Affecting the in-situ Microencapsulation Process for Producing Epoxy-based Self-healing Anti-corrosion CoatingsDocument11 pagesJournal Modeling and Optimization of the Parameters Affecting the in-situ Microencapsulation Process for Producing Epoxy-based Self-healing Anti-corrosion Coatingsmuhddanishikmal14No ratings yet

- Journal Modeling and Optimization of the Parameters Affecting the in-situ Microencapsulation Process for Producing Epoxy-based Self-healing Anti-corrosion CoatingsDocument11 pagesJournal Modeling and Optimization of the Parameters Affecting the in-situ Microencapsulation Process for Producing Epoxy-based Self-healing Anti-corrosion Coatingsmuhddanishikmal14No ratings yet

- 4736 17213 1 PBDocument10 pages4736 17213 1 PBHanifah AyuNo ratings yet

- 2018 Kunusa, FTIR, XRD and SEM Analysis of Microcrystalline Cellulose (MCC) Fibers From Corncorbs in Alkaline TreatmentDocument9 pages2018 Kunusa, FTIR, XRD and SEM Analysis of Microcrystalline Cellulose (MCC) Fibers From Corncorbs in Alkaline TreatmentirNo ratings yet

- International Journal of Biological MacromoleculesDocument10 pagesInternational Journal of Biological MacromoleculesNathan NogueraNo ratings yet

- Application of Gum Arabic and Maltodextrin For Encapsulation ofDocument10 pagesApplication of Gum Arabic and Maltodextrin For Encapsulation ofNicolas AvendañoNo ratings yet

- Encapsulation of Temulawak ExtractDocument6 pagesEncapsulation of Temulawak ExtractJulian Sukrisna SusiloNo ratings yet

- Polymer Self HealingDocument14 pagesPolymer Self HealingVinícius H. SouzaNo ratings yet

- Kamarudin 2016Document8 pagesKamarudin 2016Jose perezNo ratings yet

- Revestimento Comestivel Cera de CarnaubaDocument12 pagesRevestimento Comestivel Cera de CarnaubaRaquel FernandesNo ratings yet

- IC3PE2018 Kuntari FebiDocument10 pagesIC3PE2018 Kuntari FebiAulia Rizki ramadhantiNo ratings yet

- Adi 2007Document5 pagesAdi 2007RolandoIgorLeivaNo ratings yet

- Tong 2020 Estradiol RemovalDocument8 pagesTong 2020 Estradiol RemovalIssaoui MansourNo ratings yet

- Adsorption of Methylene Blue in Aqueous Phase by Fly Ash, Clay and Walnut Shell As AdsorbentsDocument6 pagesAdsorption of Methylene Blue in Aqueous Phase by Fly Ash, Clay and Walnut Shell As AdsorbentsEL Hassania EL HERRADINo ratings yet

- Hollow Microspheres of Diclofenac Sodium - A Gastroretentive Controlled Delivery SystemDocument5 pagesHollow Microspheres of Diclofenac Sodium - A Gastroretentive Controlled Delivery Systemapi-19973331No ratings yet

- Environmental PollutionDocument10 pagesEnvironmental Pollutionpratikxeo3No ratings yet

- Recovery of Protein & Microbial Cells Using Adsorptive Bubble Separation TechniqueDocument9 pagesRecovery of Protein & Microbial Cells Using Adsorptive Bubble Separation Techniqueromita duttaNo ratings yet

- Ketoprofen-Carboxymethyl Chitosan Microparticles Prepared by Spray Drying: Optimization and EvaluationDocument3 pagesKetoprofen-Carboxymethyl Chitosan Microparticles Prepared by Spray Drying: Optimization and EvaluationAgusNo ratings yet

- Chitosan-Carboxymethylcellulose BasedDocument7 pagesChitosan-Carboxymethylcellulose BasedRaghav MehraNo ratings yet

- Mazza Et Al. (2023) - Microencapsulation of Marjoram Essential OilDocument11 pagesMazza Et Al. (2023) - Microencapsulation of Marjoram Essential OilTainara SerpaNo ratings yet

- DRRRNewpapernew 2015Document10 pagesDRRRNewpapernew 2015Syed babar ali shahNo ratings yet

- Spray Drying Techniques for Food Ingredient EncapsulationFrom EverandSpray Drying Techniques for Food Ingredient EncapsulationNo ratings yet

- Chem Project HiteshDocument16 pagesChem Project HiteshSahil Sharma64% (14)

- Total Area 272 Sq. Meters: Waste DisposalDocument1 pageTotal Area 272 Sq. Meters: Waste DisposalMANPOWER ORMOCNo ratings yet

- Ashby 2003Document11 pagesAshby 2003Gajaraj GajapathiNo ratings yet

- BS4449/1997 & BS 4449/2005/ASTM A 615/A 615/M: Reinforcement Steel SpecificationsDocument1 pageBS4449/1997 & BS 4449/2005/ASTM A 615/A 615/M: Reinforcement Steel Specificationsgreat_triskelionNo ratings yet

- Atom ScienceDocument26 pagesAtom ScienceSanjay PandeyNo ratings yet

- Kalmetall W Kalpraxis GBDocument12 pagesKalmetall W Kalpraxis GBkaniappan sakthivelNo ratings yet

- Supercapacitors: Supercapacitor ConstructionDocument6 pagesSupercapacitors: Supercapacitor ConstructionAnonymous fwI1UcnNo ratings yet

- Selective Laser SinteringDocument24 pagesSelective Laser SinteringRahul GandhiNo ratings yet

- Introduction To Industrial Minerals-Springer Netherlands (1995)Document287 pagesIntroduction To Industrial Minerals-Springer Netherlands (1995)Kathleen SuanzoNo ratings yet

- How To Turn Plastic Waste Into Diesel Fuel CheaplyDocument25 pagesHow To Turn Plastic Waste Into Diesel Fuel CheaplyJeno Zsolt DudasNo ratings yet

- How Long Does Composting TakeDocument5 pagesHow Long Does Composting TakeLadylyn NuñezNo ratings yet

- Fatigue and Fracture Book 2011Document5 pagesFatigue and Fracture Book 2011JackobNo ratings yet

- Pipe Manufacturer's Data Sheet 1Document231 pagesPipe Manufacturer's Data Sheet 1Mumtaz Ahmed Ghumman100% (1)

- HBI TestingDocument15 pagesHBI Testingreva cmNo ratings yet

- Safecon Builders and Trading: Warehouse Detailed Cost EstimateDocument21 pagesSafecon Builders and Trading: Warehouse Detailed Cost EstimateJessybel Acosta MendozaNo ratings yet

- PC1220R Infino LotteDocument1 pagePC1220R Infino LotteSCAR GONZALEzNo ratings yet

- Flexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete Beams Reinforced With GFRP and Steel RebarsDocument17 pagesFlexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete Beams Reinforced With GFRP and Steel Rebarsmohamed ellithyNo ratings yet

- Lec 2 MECHANICAL PROPERTIESDocument61 pagesLec 2 MECHANICAL PROPERTIESAsfand YarNo ratings yet

- Aluminum Glass and Windows For QuotationDocument2 pagesAluminum Glass and Windows For Quotationjarellano08No ratings yet

- Plastolith 122 He Data SheetDocument2 pagesPlastolith 122 He Data SheetRaj BalasubramaniamNo ratings yet

- FEED WATER TREATMENT FROM AVT (R) TO AVT (O) LDocument14 pagesFEED WATER TREATMENT FROM AVT (R) TO AVT (O) Lprakash100% (2)

- Study and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelDocument6 pagesStudy and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelIJARTESNo ratings yet

- BQ-04-Taman OUG N Taman Yarl Rev Budget RevDocument16 pagesBQ-04-Taman OUG N Taman Yarl Rev Budget RevMuhammad LuqmanNo ratings yet

- Design FootingsDocument9 pagesDesign FootingsRupesh KhandekarNo ratings yet

- Lec 3Document14 pagesLec 3anuda09No ratings yet

- All-Temperature Zinc Batteries With High-Entropy Aqueous ElectrolyteDocument11 pagesAll-Temperature Zinc Batteries With High-Entropy Aqueous Electrolytepeizx123No ratings yet

- The Influence of Grain Size On The Tensile and Fatigue Behavior of 7075 t6 Aluminum SheetDocument8 pagesThe Influence of Grain Size On The Tensile and Fatigue Behavior of 7075 t6 Aluminum SheetHoai Anh VuNo ratings yet