Professional Documents

Culture Documents

Bbe 57

Bbe 57

Uploaded by

tutucasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bbe 57

Bbe 57

Uploaded by

tutucasCopyright:

Available Formats

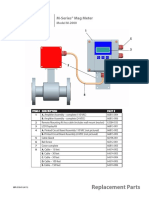

Atlas Copco Pneumatic Rock Drills

BBE 57-01

Technical specification

Top hammer rock drill for hole diameter range 64 - 115 mm

Primary advantages of a separate rotation unit

The powerful 2.7 kW piston motor combines high start-up torque and positive creep characteristics with efficient utilisation of the existing air supply. Servicing the rock drill has been kept simple and to the minimum. The entire unit can be rapidly replaced should the circumstances indicate the necessity. The reduction gear has been intentionally overdimensioned, to allow the rock drill to withstand severe stress and long-term exposure to wear with a wide margin of safety. The gear is of the permanently-lubricated type and normally does not therefore require servicing in between regular overhaul intervals. This unit also can be quickly replaced, should the need arise. The chain is a 25 mm (1) ASA 80 heavy duty, pull-tested to withstand 64.5 Nm. A specific degree of built-in elasticity evens out stress when drilling in fractured rock formations. Overpressure in the chain housing prevents dirt and water from fouling the interior.

Powerful percussion with high impact energy

The impact mechanism represents an optimal combination of large piston area, a lenghty stroke lenghth and high impact frequency; which in turn offers impressive penetration ability in all formations. Despite the rock drills high impact energy, no special maintenance is necessary. Auto-constrained rotation of the impact piston ensures that the casing surface is sufficiently lubricated during all drilling conditions. To further minimise wear, the cylinder walls are lined with hardened, wear-resistant chrome plating.

BBE 57-01

Technical Data

Rock drill

Hole diameter range Extension rod diameter Total length Total width Total height Total weight Total air consumption* excl. flushing 64 - 115 mm (2 1/2- 41/2) 38 - 45 mm (11/2 - 13/4) 900 mm (36) 350 mm (14) 440 mm (18) 170 kg 220 l/s

Rotation unit

Rating at 2400 rpm Gear ratio Rotation speed Max. torque Air consumption* Air hose diameter 2.7 kW 1:32.2 60-150 rpm 780 Nm 73 l/s 20 mm (3/4)

Flushing

Air consumption* Normal Maximum Air hose diameter 42 l/s 80 l/s 20 mm (3/4)

Impact mechanism

Cylinder bore Stroke Impact rate Air consumption* Air hose diameter 120 mm (43/4) 66 mm (25/8) 2000 blows/min 157 l/s 50 mm (2)

Part Number

Rock drill BBE 57-01 8311 0801 57

9851 1501 01b 2006-11

Copyright 2006, Atlas Copco Rock Drills AB, rebro, Sweden. Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers and drawings. llustrations and photos in this brochure may show equipment with optional extras. Specifications and equipment subjects to change without notice. Consult your Atlas Copco Customer Center for specific information.

For bench drilling, overburden drilling with ODEX and OD equipment, prospecting and water well drilling. The high torque of 780 Nm provides optimal rotation when drilling in difficult rock or when drilling deep holes. Separate, revirseble rotation unit with a powerful piston motor and overdimensioned gearing enables high drilling rates to be obtained even through overburden. Simple to service and fast component replacement.

You might also like

- Algebra For College Students 8Th Edition Blitzer Solutions Manual PDFDocument8 pagesAlgebra For College Students 8Th Edition Blitzer Solutions Manual PDFkathy.gallardo572No ratings yet

- Manual Cedarapids 4336Document36 pagesManual Cedarapids 4336Marielisa Zertuche FloresNo ratings yet

- Microsoft PowerPoint - HC160 Service Training Read-OnlyDocument21 pagesMicrosoft PowerPoint - HC160 Service Training Read-OnlyJannie van StadenNo ratings yet

- Tamrock Cha - 560Document3 pagesTamrock Cha - 560jorgemetalriffs0% (1)

- PlaintDocument3 pagesPlaintShreya Verma100% (2)

- Ficha Tecnica Alpha 30Document7 pagesFicha Tecnica Alpha 30jonathan francisco allende escobarNo ratings yet

- Roc 442PC PDFDocument4 pagesRoc 442PC PDFEVCYNo ratings yet

- Arbitration AgreementDocument3 pagesArbitration AgreementJosué Maximin ANDÉ100% (1)

- Excitation System ModelsDocument207 pagesExcitation System Modelswtorres-1100% (3)

- Robot Atlas MEYCO ME3Document8 pagesRobot Atlas MEYCO ME3Frank Prudencio ObregonNo ratings yet

- New Design DRWJ-1 (DRWJ-0.75) Underground LHD LoaDocument5 pagesNew Design DRWJ-1 (DRWJ-0.75) Underground LHD LoaHola NumerosisNo ratings yet

- BBC120 Spare PartsDocument5 pagesBBC120 Spare PartsMohan Charanchath100% (1)

- 9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855Document20 pages9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855marioxxyNo ratings yet

- Especificaciones DT820Document5 pagesEspecificaciones DT820Jorge Cid BlancoNo ratings yet

- KLR BrochureDocument23 pagesKLR BrochureblamarceloNo ratings yet

- Manual de Martillo HidraulicoDocument146 pagesManual de Martillo HidraulicoJoshua RobinsonNo ratings yet

- Roc 460PC PDFDocument4 pagesRoc 460PC PDFVictor HernanNo ratings yet

- IR LM100A Crawlair Drill PDFDocument8 pagesIR LM100A Crawlair Drill PDFAnonymous 8yIptglHhNo ratings yet

- CF75G - Oil-Injected Screw Compressor Airend: Operating RangeDocument1 pageCF75G - Oil-Injected Screw Compressor Airend: Operating Rangeahmad nh100% (1)

- Axera D06Document2 pagesAxera D06Cristián Fernando Cristóbal RoblesNo ratings yet

- Manual Del Usuario Serie TBDocument56 pagesManual Del Usuario Serie TBrogerpfr100% (1)

- Despiece Toku-Tpb90Document2 pagesDespiece Toku-Tpb90ricardoNo ratings yet

- Sandvik Du311-Tk Underground Drill: Technical SpecificationDocument4 pagesSandvik Du311-Tk Underground Drill: Technical SpecificationGabriel Ulloa100% (2)

- PL6189 R 6 RotDocument570 pagesPL6189 R 6 Rotvictor lara100% (1)

- 1100x650 Premiertrak Manual 06SP 020304Document282 pages1100x650 Premiertrak Manual 06SP 020304Borja Salanova diazNo ratings yet

- Specification of Hydraulic Crawler Drill: JD-800 JD-800E SD-1300E JD-1300E JD-1400E JD-1500E ModelDocument1 pageSpecification of Hydraulic Crawler Drill: JD-800 JD-800E SD-1300E JD-1300E JD-1400E JD-1500E ModeljayapanjaitanNo ratings yet

- Model GT205S Mobile Screening Plant Model 205S Spec Sheet: Operational ModeDocument2 pagesModel GT205S Mobile Screening Plant Model 205S Spec Sheet: Operational ModeVladimir Illich Pinzon BallenNo ratings yet

- Danfoss 520l0954Document32 pagesDanfoss 520l0954joeccorrrea100% (1)

- Mr-hl500 Data SheetDocument1 pageMr-hl500 Data SheetAlmaNo ratings yet

- 9852 1319 44 COP 44 Instructions and Part ListDocument72 pages9852 1319 44 COP 44 Instructions and Part ListCesar GutierrezNo ratings yet

- Cannon Parts ManualDocument748 pagesCannon Parts ManualjohnnyNo ratings yet

- MC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsDocument228 pagesMC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsnNo ratings yet

- Sandvik Dd311 Development Drill: Technical SpecificationDocument4 pagesSandvik Dd311 Development Drill: Technical SpecificationJuan David Rondinel BulejeNo ratings yet

- 5100045016-Basic Cradle HC160-HC170 - ADocument2 pages5100045016-Basic Cradle HC160-HC170 - ArolandNo ratings yet

- IR ECM660 III TrackdrillDocument6 pagesIR ECM660 III TrackdrillHaianh Chau100% (1)

- Raise Boring Heads: User ManualDocument40 pagesRaise Boring Heads: User ManualMaykol Ken Hasaki MaselNo ratings yet

- Boomer T1D PDFDocument4 pagesBoomer T1D PDFArturo Pedro Salgado MedinaNo ratings yet

- КПП manual - 293790 - R32366-630 - TPL-1389 - 2015-03-26Document48 pagesКПП manual - 293790 - R32366-630 - TPL-1389 - 2015-03-26Sirius PrimeNo ratings yet

- Datos Tecnicos LH202Document8 pagesDatos Tecnicos LH202Roel Aroni CuaresmaNo ratings yet

- Sandvik De130 Compact Underground and Surface Core Drill: Technical SpecificationDocument8 pagesSandvik De130 Compact Underground and Surface Core Drill: Technical SpecificationDexterNo ratings yet

- LM100Document4 pagesLM100dany riversNo ratings yet

- Specification Ranger DX800Document4 pagesSpecification Ranger DX800Nugraha SandyNo ratings yet

- Bracket Assy CP - Ph2Document3 pagesBracket Assy CP - Ph2cristian nahuelcuraNo ratings yet

- Overhaul COP 1238Document2 pagesOverhaul COP 1238gustavolimasime100% (1)

- Manuel Partes ElectricoDocument28 pagesManuel Partes ElectricoAndersonNo ratings yet

- TM 800-1200 - 2000Document126 pagesTM 800-1200 - 2000Mar SolNo ratings yet

- Catalogo Comercial Bolter 88dDocument3 pagesCatalogo Comercial Bolter 88djrgonzales240% (1)

- 286-7889 Soporte 12TNDocument8 pages286-7889 Soporte 12TNEdu Pastén MejiasNo ratings yet

- Utimec SF 350 Lube 100056983Document8 pagesUtimec SF 350 Lube 100056983RESEMIN SANo ratings yet

- Spec ST3.5 9851 2254 01 G - tcm836-1532853Document4 pagesSpec ST3.5 9851 2254 01 G - tcm836-1532853IoannisVourdounisNo ratings yet

- Sandvik Rd525 Rock Drill: Technical SpecificationDocument2 pagesSandvik Rd525 Rock Drill: Technical SpecificationWaltherEnriqueAlcocerNo ratings yet

- Lista de Partes SB 202 - NUEVOSDocument32 pagesLista de Partes SB 202 - NUEVOSFrandi Moises Asto VilaNo ratings yet

- J125-3324 Parts BookDocument184 pagesJ125-3324 Parts BookAlonsoNo ratings yet

- Catalogo DTH SandvikDocument49 pagesCatalogo DTH SandvikStevenNo ratings yet

- Atlas Copco Shank AdaptorsDocument4 pagesAtlas Copco Shank AdaptorsAntonis GogosNo ratings yet

- LIT2409 R1 PD15B Parts (05852) 9-2008Document10 pagesLIT2409 R1 PD15B Parts (05852) 9-2008Andres Florentin Pizarro LazarteNo ratings yet

- 1300 Maxtrak Crushing Brochure en 2014ddDocument1 page1300 Maxtrak Crushing Brochure en 2014ddBlake Cooley AndersonNo ratings yet

- 1000 Maxtrak Crushing Brochure en 2014 PDFDocument1 page1000 Maxtrak Crushing Brochure en 2014 PDFEndro Suhadi100% (1)

- YH-80A Parts List PDFDocument5 pagesYH-80A Parts List PDFNguyễn Quang Hưng100% (2)

- Atlas Copco Wagner Scooptram ST-2DDocument13 pagesAtlas Copco Wagner Scooptram ST-2Dait mimoune100% (1)

- Boomer104 SpecDocument4 pagesBoomer104 SpecLucho MoraNo ratings yet

- Atlas Copco: Hydraulic Rock DrillsDocument2 pagesAtlas Copco: Hydraulic Rock DrillsArturo Pedro Salgado MedinaNo ratings yet

- PerforadorasDocument2 pagesPerforadorasElias Silva100% (1)

- Perforadora COP 1638Document2 pagesPerforadora COP 1638Andy RiveraNo ratings yet

- Chapter 14 RevisedDocument18 pagesChapter 14 RevisedLim Cia ChienNo ratings yet

- TRAX CT-testing An en V01aDocument10 pagesTRAX CT-testing An en V01aJack DuffNo ratings yet

- Fine - A Major - mn0128249Document17 pagesFine - A Major - mn0128249Luca McPheeNo ratings yet

- Spidc Job Request AmendmentDocument2 pagesSpidc Job Request AmendmentBplo CaloocanNo ratings yet

- Wausau Paper Towel & Tissue v. Nittany Paper MillsDocument6 pagesWausau Paper Towel & Tissue v. Nittany Paper MillsPriorSmartNo ratings yet

- Algebra 1 End of Course WorksheetsDocument6 pagesAlgebra 1 End of Course Worksheetsf5e28dkq100% (2)

- IRP 213 01 M Series M2000 Repair PartDocument2 pagesIRP 213 01 M Series M2000 Repair PartDiana Sandra Rodriguez VillarNo ratings yet

- Superkids Grade2 Unit12 WordWorkBookPacketDocument15 pagesSuperkids Grade2 Unit12 WordWorkBookPacketАлексей ТрофимовNo ratings yet

- BS 2080Document36 pagesBS 2080Anil S Chaudhary67% (3)

- Via LA Formation FINALDocument2 pagesVia LA Formation FINALblanco.123febNo ratings yet

- CopyrightDocument3 pagesCopyrightFreda Gaile AlburoNo ratings yet

- BS en 15422 - 2008Document10 pagesBS en 15422 - 2008Ceicilia WahyuningrumNo ratings yet

- E1082 PDFDocument4 pagesE1082 PDFAntonio JNo ratings yet

- Us 95056892Document6 pagesUs 95056892ANita Zulhadj DamayantiNo ratings yet

- 04 MOA FormatDocument3 pages04 MOA FormatNicole TyNo ratings yet

- Final Draft V3 Ipr 2017ballb52Document19 pagesFinal Draft V3 Ipr 2017ballb52Atulya Singh ChauhanNo ratings yet

- Iec 60617-8 (1996)Document38 pagesIec 60617-8 (1996)martinpellsNo ratings yet

- T3905-390-02 SG-Ins Lec ENDocument264 pagesT3905-390-02 SG-Ins Lec ENNanda KumarNo ratings yet

- C8 - Marketing Reading - Chap 6 & 8Document3 pagesC8 - Marketing Reading - Chap 6 & 8Gaurav ChaudharyNo ratings yet

- Tda 7379Document7 pagesTda 7379Udi NuryadiNo ratings yet

- ThinODBC InstallationDocument8 pagesThinODBC InstallationGeorge AmousNo ratings yet

- BMI V Davis (BMI MTD)Document21 pagesBMI V Davis (BMI MTD)Christopher S. HarrisonNo ratings yet

- Arce Sons and Company Vs SelectaDocument1 pageArce Sons and Company Vs SelectaFayda CariagaNo ratings yet

- LET RatingDocument4 pagesLET Ratingjun del rosarioNo ratings yet

- In Re Owens - Pet. For Rehr'gDocument33 pagesIn Re Owens - Pet. For Rehr'gSarah BursteinNo ratings yet

- How To Handle Pleasure Resistance PDFDocument8 pagesHow To Handle Pleasure Resistance PDFValpo Valparaiso100% (1)