Professional Documents

Culture Documents

Welding Discontinuity Table

Welding Discontinuity Table

Uploaded by

kapsarcCopyright:

Available Formats

You might also like

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Method Statment For Earthing InstallationDocument8 pagesMethod Statment For Earthing InstallationJustin AlwarNo ratings yet

- Table - QW-416 Welding Variables For Welder Performance PDFDocument1 pageTable - QW-416 Welding Variables For Welder Performance PDFAnonymous VohpMtUSNNo ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Understanding Weld DiscontinuitiesDocument2 pagesUnderstanding Weld DiscontinuitiesMurad AlamNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- طرق وحسابات التأريضDocument18 pagesطرق وحسابات التأريضAbdallah Omar Al AyoubiNo ratings yet

- Welding ProcessDocument8 pagesWelding Processbarry bonzoNo ratings yet

- ESO 205 Nature and Properties of MaterialsDocument26 pagesESO 205 Nature and Properties of MaterialsAkshayVaidyaNo ratings yet

- STRL Calc For Gusset Plate Its ConnectionDocument25 pagesSTRL Calc For Gusset Plate Its ConnectionZeeZ HNo ratings yet

- RC08 Shear1Document13 pagesRC08 Shear1Ce WinNo ratings yet

- RCC Two Way Slab BS 8110Document9 pagesRCC Two Way Slab BS 8110sourabdaroch100% (1)

- Development of High Strength SteelDocument26 pagesDevelopment of High Strength Steelamit gajbhiyeNo ratings yet

- 3 KH-500W (PW)Document2 pages3 KH-500W (PW)Sun SunNo ratings yet

- WPS - Welding ProcessDocument1 pageWPS - Welding Processsidrui00No ratings yet

- United Industries, Inc.: Why Certify Hygienic Tubing To SA249/A269/A270 ?Document2 pagesUnited Industries, Inc.: Why Certify Hygienic Tubing To SA249/A269/A270 ?hgscanavinoNo ratings yet

- Elliott Wave - 2023102 - 01753Document1 pageElliott Wave - 2023102 - 01753bung3386No ratings yet

- Fracture AssesmentDocument30 pagesFracture AssesmentMohamedNo ratings yet

- Design of Timber BeamsDocument38 pagesDesign of Timber BeamsPaula HoNo ratings yet

- Matrice DeclansareDocument3 pagesMatrice DeclansarePaul GabrielNo ratings yet

- Red Tide West PDF NotesDocument1 pageRed Tide West PDF NotesNicolas JunkerNo ratings yet

- Foundation 1 Design ReportDocument9 pagesFoundation 1 Design ReportSameer KmNo ratings yet

- Module 1 Stresses - StrainDocument37 pagesModule 1 Stresses - StrainKedar PunaginNo ratings yet

- CES522 A 02 - Topic 2a - 3. ShearDocument7 pagesCES522 A 02 - Topic 2a - 3. ShearAizuddinNo ratings yet

- Lecture 7Document28 pagesLecture 720pwmct0739No ratings yet

- Codigo de Colores para Cables de Celdas de CargaDocument3 pagesCodigo de Colores para Cables de Celdas de CargaAragon Bautista100% (1)

- Anode Selection GuideDocument1 pageAnode Selection GuideShenhua Kronen SohneNo ratings yet

- Torsion Including Warping of Open SectionsDocument6 pagesTorsion Including Warping of Open SectionsahmedanyNo ratings yet

- Nsoft 51Document6 pagesNsoft 51Chetan GaonkarNo ratings yet

- Shear Connection I-SecDocument36 pagesShear Connection I-SecRaveendra Babu CherukuriNo ratings yet

- Design of Timber Beams PDFDocument38 pagesDesign of Timber Beams PDFRoiven Dela Rosa Trinidad100% (2)

- Distortion Residual Stress - Post-Weld Heat Treatment: Welding MetallurgyDocument27 pagesDistortion Residual Stress - Post-Weld Heat Treatment: Welding MetallurgyjoehodohNo ratings yet

- Gmaw and FcawDocument3 pagesGmaw and FcawMadidj_2014No ratings yet

- Define of WPS & PQRDocument16 pagesDefine of WPS & PQRThanh Hua100% (1)

- Civil Engineering Study Program (CESP) State Polytechnic of MalangDocument41 pagesCivil Engineering Study Program (CESP) State Polytechnic of MalangDita LestariNo ratings yet

- Aparatus MV Indoor Breaker BrochureDocument24 pagesAparatus MV Indoor Breaker BrochureNurul MukhlisiahNo ratings yet

- Gear Lubricants EffectDocument37 pagesGear Lubricants EffectTatumi Sobue100% (1)

- Bang Chuyen Doi Don VI Do Do CungDocument1 pageBang Chuyen Doi Don VI Do Do CungThuy DttqNo ratings yet

- Faculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityDocument52 pagesFaculty of Civil Engineering and Planning Civil Engineering Department Petra Christian Universitykenny lieNo ratings yet

- Design of Stairs 2 ACIDocument8 pagesDesign of Stairs 2 ACIKarim TammourNo ratings yet

- Earthing Kit For Cable TerminationsDocument1 pageEarthing Kit For Cable TerminationsVictor GuzmanNo ratings yet

- Junctions in Practical Devices: Oxide Insulation P - Algaas (Contacting Layer) P-Algaas (Confining Layer)Document1 pageJunctions in Practical Devices: Oxide Insulation P - Algaas (Contacting Layer) P-Algaas (Confining Layer)parambirla96No ratings yet

- Chemical Mechanical PolishingDocument38 pagesChemical Mechanical PolishingSudhanshu ShekharNo ratings yet

- Beam Report Concentrated LoadDocument8 pagesBeam Report Concentrated Loadyoshdog@gmail.comNo ratings yet

- Globe Valve: Ethyl Acetate Project 150 LbsDocument1 pageGlobe Valve: Ethyl Acetate Project 150 Lbsbiren shahNo ratings yet

- Welding For 2022 GATE ESE PSUs by S K MondalDocument84 pagesWelding For 2022 GATE ESE PSUs by S K MondalNabin MukherjeeNo ratings yet

- VersaFrame Detailed Steel Code CheckDocument3 pagesVersaFrame Detailed Steel Code CheckOsama MamdouhNo ratings yet

- cvg4145 Assignment 4 - SolutionDocument12 pagescvg4145 Assignment 4 - Solutiontajiw17001No ratings yet

- Design OF Brackets or CorbelsDocument32 pagesDesign OF Brackets or CorbelsVAIDEHI SHARMANo ratings yet

- CFSS IntroductionDocument83 pagesCFSS IntroductionSri RamNo ratings yet

- Foundation 1 Design ReportDocument18 pagesFoundation 1 Design Reportyolittle shiNo ratings yet

- ENGG 135 Design of Reinforced Concrete Structures: Shear in RC Beams Required Reading: Wight Chapter 6Document31 pagesENGG 135 Design of Reinforced Concrete Structures: Shear in RC Beams Required Reading: Wight Chapter 6Manuel MirandaNo ratings yet

- Ex2 - RestrainedBeam Lessen 2 Steel DesignDocument18 pagesEx2 - RestrainedBeam Lessen 2 Steel DesignMohammad HegazyNo ratings yet

- MJ4 2Document3 pagesMJ4 2EakJhuanNo ratings yet

- Operating Mud WindowDocument35 pagesOperating Mud WindowEmiro OspinoNo ratings yet

- Master Chart of Welding ProcessesDocument1 pageMaster Chart of Welding Processesluiz_silva1440No ratings yet

- Tabla Qw-252 - Asme IxDocument1 pageTabla Qw-252 - Asme IxAngelTinocoNo ratings yet

- MV Air Insultated Switchgear Technical Guide 1VAL1002-TG Rev A PDFDocument188 pagesMV Air Insultated Switchgear Technical Guide 1VAL1002-TG Rev A PDFRobinson GuerreroNo ratings yet

- BSEN ISO-2553 Standard Symbols For WeldingDocument16 pagesBSEN ISO-2553 Standard Symbols For Weldingاحمد عمر حديد100% (1)

- Design of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMDocument2 pagesDesign of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMGiri DharanNo ratings yet

- Lec #5 (Triaxial Compression Test)Document20 pagesLec #5 (Triaxial Compression Test)Muhammad MukhtiarNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

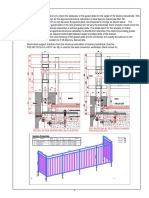

- Drum Screen - DesignDetailsDocument2 pagesDrum Screen - DesignDetailskapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

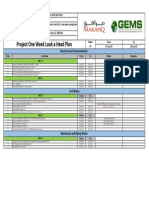

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Drum Screen Installation - GearsDocument2 pagesDrum Screen Installation - GearskapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Welding Electrode-Wire SpecificationDocument3 pagesWelding Electrode-Wire SpecificationRajan SteeveNo ratings yet

- Safety and Health RequirementsDocument979 pagesSafety and Health RequirementsafvidalNo ratings yet

- GXHQ EN CLIPS RailLok-Clip-W17 2019-02 R2.0-1Document2 pagesGXHQ EN CLIPS RailLok-Clip-W17 2019-02 R2.0-1Pedro Samuel Brito LopesNo ratings yet

- Quiz-2 Manufacturing Processes (S1-16 - ETZC235)Document6 pagesQuiz-2 Manufacturing Processes (S1-16 - ETZC235)ssanthosh073No ratings yet

- EX1800-3 TMDocument384 pagesEX1800-3 TMazry_alqadry100% (1)

- Jadual Pembahagian Masa TeoriDocument2 pagesJadual Pembahagian Masa TeoriNur ZaidanNo ratings yet

- Welding: by Msc. Ahmed Taifor AzeezDocument32 pagesWelding: by Msc. Ahmed Taifor AzeezShkar GalalyNo ratings yet

- Catalogo Normas AwsDocument52 pagesCatalogo Normas AwsJorge Enrique Montaño Marañon100% (1)

- Atlas Aluminium Datasheet 5052 Rev Oct 2013Document3 pagesAtlas Aluminium Datasheet 5052 Rev Oct 2013Jason-chungNo ratings yet

- STEEL ProblemsDocument21 pagesSTEEL ProblemsFrances Nicole QuitoNo ratings yet

- Weldindssdvg Part 2Document55 pagesWeldindssdvg Part 2sbs271187No ratings yet

- ONH AnalyzerDocument16 pagesONH AnalyzereddyewNo ratings yet

- Anvil Restoration: © Robb Gunther and Karl SchulerDocument2 pagesAnvil Restoration: © Robb Gunther and Karl SchulerKelly CooverNo ratings yet

- Iso 22991 2004 en PDFDocument11 pagesIso 22991 2004 en PDFElias JarjouraNo ratings yet

- Coletanche FinlandDocument8 pagesColetanche FinlandEvan BuntoroNo ratings yet

- TWI Ultrasonic Inspection Coursework 8Document5 pagesTWI Ultrasonic Inspection Coursework 8HassanSoboh100% (1)

- Pranay Kumar Tode Pktode@yahoo - Co.inDocument44 pagesPranay Kumar Tode Pktode@yahoo - Co.inKhabib IbragimovNo ratings yet

- Structural Tubes For Offshore Applications PDFDocument8 pagesStructural Tubes For Offshore Applications PDFFSRAEMNo ratings yet

- Characterization of Bond Line Discontinuities in A High-Mn TWIP Steel Pipe Welded by HF-ERW PDFDocument8 pagesCharacterization of Bond Line Discontinuities in A High-Mn TWIP Steel Pipe Welded by HF-ERW PDFSinan ChenNo ratings yet

- Welding Metallurgy 2Document37 pagesWelding Metallurgy 2Asad Bin Ala QatariNo ratings yet

- Set-Up Welding Equipment LO1-1.1Document7 pagesSet-Up Welding Equipment LO1-1.1Joy BuycoNo ratings yet

- Form 1 AWS D1.1Document2 pagesForm 1 AWS D1.1Bui Chi Tam100% (1)

- Metal Roof PDFDocument15 pagesMetal Roof PDFJuan TorresNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Document22 pagesBK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Panneer SelvamNo ratings yet

- Laser-Assisted Fabrication of MaterialsDocument513 pagesLaser-Assisted Fabrication of Materialssofiane haddadiNo ratings yet

- Recent Trend in Heat ExchangerDocument9 pagesRecent Trend in Heat Exchangersai100% (1)

- WPQT PHSSDocument1 pageWPQT PHSSFerdie OSNo ratings yet

- Ultrasonic TestingDocument11 pagesUltrasonic TestingapmapNo ratings yet

- Sheetmetal Technology 22Document34 pagesSheetmetal Technology 22Alfred KuwodzaNo ratings yet

Welding Discontinuity Table

Welding Discontinuity Table

Uploaded by

kapsarcOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Discontinuity Table

Welding Discontinuity Table

Uploaded by

kapsarcCopyright:

Available Formats

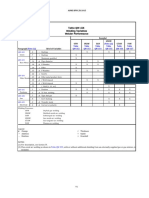

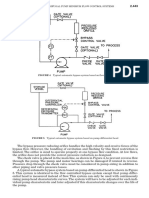

WELD QUALITY 537

Table 13.1

Discontinuities Commonly Associated with Welding Processes

Discontinuity*

Incomplete

Incomplete Joint

Welding Process Porosity Inclusions Fusion Penetration Undercut Overlap Cracks

Arc Welding Processes

Stud welding (SW) — x x — x — x

Plasma arc welding (PAW) x x x x x — x

Submerged arc welding (SAW) x x x x x x x

Gas tungsten arc welding (GTAW) x x x x x x x

Gas metal arc welding (GMAW) x x x x x x x

Flux cored arc welding (FCAW) x x x x x x x

Shielded metal arc welding (SMAW) x x x x x x x

Carbon arc welding (CAW) x x x x x x x

Resistance Welding Processes

Resistance spot welding (RSW) †x† x x x — — x

Resistance seam welding (RSEW) †x† x x x — — x

Projection welding (PW) — — x x — — x

Flash welding (FW) — — x x — — x

Upset welding (UW) — — x x — — x

Percussion welding (PEW) — — x — — — x

Oxyfuel Gas Processes

Oxyacetylene welding (OAW) x x x x x x x

Oxyhydrogen welding (OHW) x — x x — — x

Pressure gas welding (PGW) x — x — — — x

‡Solid-State Processes ‡

Cold welding (CW) — — x — — — x

Diffusion welding (DFW) — — x — — — x

Explosion welding (EXW) — — x — — — —

Forge welding (FOW) — — x — — — —

Friction welding (FW) — — x — — — —

Ultrasonic welding (UW) — — x — — — —

Other Processes

Electron beam welding (EBW) x — x x — — x

Laser beam welding (LBW) x — x x — — x

Electroslag welding (ESW) x x x x x x x

Induction welding (IW) — — x — — — x

Thermite welding (TW) x x x — — — x

* The symbol “x” indicates that the type of discontinuity may occur in welds produced by the process. The symbol “—” indicates that the occurrence of this

type of discontinuity in these welds is very rare.

† In resistance welds, “porosity”” is more properly termed “voids.”

‡ As these are not fusion processes, the appropriate term for “incomplete joining” is “incomplete welding” rather than “incomplete fusion.”

Source: Adapted from American Welding Society (AWS) Committee on Methods of Inspection, 1999, Guide for the Nondestructive Examination of Welds, ANSI/AWS B1.10:1999,

Miami: American Welding Society, Table 2.

You might also like

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Method Statment For Earthing InstallationDocument8 pagesMethod Statment For Earthing InstallationJustin AlwarNo ratings yet

- Table - QW-416 Welding Variables For Welder Performance PDFDocument1 pageTable - QW-416 Welding Variables For Welder Performance PDFAnonymous VohpMtUSNNo ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Understanding Weld DiscontinuitiesDocument2 pagesUnderstanding Weld DiscontinuitiesMurad AlamNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- طرق وحسابات التأريضDocument18 pagesطرق وحسابات التأريضAbdallah Omar Al AyoubiNo ratings yet

- Welding ProcessDocument8 pagesWelding Processbarry bonzoNo ratings yet

- ESO 205 Nature and Properties of MaterialsDocument26 pagesESO 205 Nature and Properties of MaterialsAkshayVaidyaNo ratings yet

- STRL Calc For Gusset Plate Its ConnectionDocument25 pagesSTRL Calc For Gusset Plate Its ConnectionZeeZ HNo ratings yet

- RC08 Shear1Document13 pagesRC08 Shear1Ce WinNo ratings yet

- RCC Two Way Slab BS 8110Document9 pagesRCC Two Way Slab BS 8110sourabdaroch100% (1)

- Development of High Strength SteelDocument26 pagesDevelopment of High Strength Steelamit gajbhiyeNo ratings yet

- 3 KH-500W (PW)Document2 pages3 KH-500W (PW)Sun SunNo ratings yet

- WPS - Welding ProcessDocument1 pageWPS - Welding Processsidrui00No ratings yet

- United Industries, Inc.: Why Certify Hygienic Tubing To SA249/A269/A270 ?Document2 pagesUnited Industries, Inc.: Why Certify Hygienic Tubing To SA249/A269/A270 ?hgscanavinoNo ratings yet

- Elliott Wave - 2023102 - 01753Document1 pageElliott Wave - 2023102 - 01753bung3386No ratings yet

- Fracture AssesmentDocument30 pagesFracture AssesmentMohamedNo ratings yet

- Design of Timber BeamsDocument38 pagesDesign of Timber BeamsPaula HoNo ratings yet

- Matrice DeclansareDocument3 pagesMatrice DeclansarePaul GabrielNo ratings yet

- Red Tide West PDF NotesDocument1 pageRed Tide West PDF NotesNicolas JunkerNo ratings yet

- Foundation 1 Design ReportDocument9 pagesFoundation 1 Design ReportSameer KmNo ratings yet

- Module 1 Stresses - StrainDocument37 pagesModule 1 Stresses - StrainKedar PunaginNo ratings yet

- CES522 A 02 - Topic 2a - 3. ShearDocument7 pagesCES522 A 02 - Topic 2a - 3. ShearAizuddinNo ratings yet

- Lecture 7Document28 pagesLecture 720pwmct0739No ratings yet

- Codigo de Colores para Cables de Celdas de CargaDocument3 pagesCodigo de Colores para Cables de Celdas de CargaAragon Bautista100% (1)

- Anode Selection GuideDocument1 pageAnode Selection GuideShenhua Kronen SohneNo ratings yet

- Torsion Including Warping of Open SectionsDocument6 pagesTorsion Including Warping of Open SectionsahmedanyNo ratings yet

- Nsoft 51Document6 pagesNsoft 51Chetan GaonkarNo ratings yet

- Shear Connection I-SecDocument36 pagesShear Connection I-SecRaveendra Babu CherukuriNo ratings yet

- Design of Timber Beams PDFDocument38 pagesDesign of Timber Beams PDFRoiven Dela Rosa Trinidad100% (2)

- Distortion Residual Stress - Post-Weld Heat Treatment: Welding MetallurgyDocument27 pagesDistortion Residual Stress - Post-Weld Heat Treatment: Welding MetallurgyjoehodohNo ratings yet

- Gmaw and FcawDocument3 pagesGmaw and FcawMadidj_2014No ratings yet

- Define of WPS & PQRDocument16 pagesDefine of WPS & PQRThanh Hua100% (1)

- Civil Engineering Study Program (CESP) State Polytechnic of MalangDocument41 pagesCivil Engineering Study Program (CESP) State Polytechnic of MalangDita LestariNo ratings yet

- Aparatus MV Indoor Breaker BrochureDocument24 pagesAparatus MV Indoor Breaker BrochureNurul MukhlisiahNo ratings yet

- Gear Lubricants EffectDocument37 pagesGear Lubricants EffectTatumi Sobue100% (1)

- Bang Chuyen Doi Don VI Do Do CungDocument1 pageBang Chuyen Doi Don VI Do Do CungThuy DttqNo ratings yet

- Faculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityDocument52 pagesFaculty of Civil Engineering and Planning Civil Engineering Department Petra Christian Universitykenny lieNo ratings yet

- Design of Stairs 2 ACIDocument8 pagesDesign of Stairs 2 ACIKarim TammourNo ratings yet

- Earthing Kit For Cable TerminationsDocument1 pageEarthing Kit For Cable TerminationsVictor GuzmanNo ratings yet

- Junctions in Practical Devices: Oxide Insulation P - Algaas (Contacting Layer) P-Algaas (Confining Layer)Document1 pageJunctions in Practical Devices: Oxide Insulation P - Algaas (Contacting Layer) P-Algaas (Confining Layer)parambirla96No ratings yet

- Chemical Mechanical PolishingDocument38 pagesChemical Mechanical PolishingSudhanshu ShekharNo ratings yet

- Beam Report Concentrated LoadDocument8 pagesBeam Report Concentrated Loadyoshdog@gmail.comNo ratings yet

- Globe Valve: Ethyl Acetate Project 150 LbsDocument1 pageGlobe Valve: Ethyl Acetate Project 150 Lbsbiren shahNo ratings yet

- Welding For 2022 GATE ESE PSUs by S K MondalDocument84 pagesWelding For 2022 GATE ESE PSUs by S K MondalNabin MukherjeeNo ratings yet

- VersaFrame Detailed Steel Code CheckDocument3 pagesVersaFrame Detailed Steel Code CheckOsama MamdouhNo ratings yet

- cvg4145 Assignment 4 - SolutionDocument12 pagescvg4145 Assignment 4 - Solutiontajiw17001No ratings yet

- Design OF Brackets or CorbelsDocument32 pagesDesign OF Brackets or CorbelsVAIDEHI SHARMANo ratings yet

- CFSS IntroductionDocument83 pagesCFSS IntroductionSri RamNo ratings yet

- Foundation 1 Design ReportDocument18 pagesFoundation 1 Design Reportyolittle shiNo ratings yet

- ENGG 135 Design of Reinforced Concrete Structures: Shear in RC Beams Required Reading: Wight Chapter 6Document31 pagesENGG 135 Design of Reinforced Concrete Structures: Shear in RC Beams Required Reading: Wight Chapter 6Manuel MirandaNo ratings yet

- Ex2 - RestrainedBeam Lessen 2 Steel DesignDocument18 pagesEx2 - RestrainedBeam Lessen 2 Steel DesignMohammad HegazyNo ratings yet

- MJ4 2Document3 pagesMJ4 2EakJhuanNo ratings yet

- Operating Mud WindowDocument35 pagesOperating Mud WindowEmiro OspinoNo ratings yet

- Master Chart of Welding ProcessesDocument1 pageMaster Chart of Welding Processesluiz_silva1440No ratings yet

- Tabla Qw-252 - Asme IxDocument1 pageTabla Qw-252 - Asme IxAngelTinocoNo ratings yet

- MV Air Insultated Switchgear Technical Guide 1VAL1002-TG Rev A PDFDocument188 pagesMV Air Insultated Switchgear Technical Guide 1VAL1002-TG Rev A PDFRobinson GuerreroNo ratings yet

- BSEN ISO-2553 Standard Symbols For WeldingDocument16 pagesBSEN ISO-2553 Standard Symbols For Weldingاحمد عمر حديد100% (1)

- Design of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMDocument2 pagesDesign of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMGiri DharanNo ratings yet

- Lec #5 (Triaxial Compression Test)Document20 pagesLec #5 (Triaxial Compression Test)Muhammad MukhtiarNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- Drum Screen - DesignDetailsDocument2 pagesDrum Screen - DesignDetailskapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Drum Screen Installation - GearsDocument2 pagesDrum Screen Installation - GearskapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Welding Electrode-Wire SpecificationDocument3 pagesWelding Electrode-Wire SpecificationRajan SteeveNo ratings yet

- Safety and Health RequirementsDocument979 pagesSafety and Health RequirementsafvidalNo ratings yet

- GXHQ EN CLIPS RailLok-Clip-W17 2019-02 R2.0-1Document2 pagesGXHQ EN CLIPS RailLok-Clip-W17 2019-02 R2.0-1Pedro Samuel Brito LopesNo ratings yet

- Quiz-2 Manufacturing Processes (S1-16 - ETZC235)Document6 pagesQuiz-2 Manufacturing Processes (S1-16 - ETZC235)ssanthosh073No ratings yet

- EX1800-3 TMDocument384 pagesEX1800-3 TMazry_alqadry100% (1)

- Jadual Pembahagian Masa TeoriDocument2 pagesJadual Pembahagian Masa TeoriNur ZaidanNo ratings yet

- Welding: by Msc. Ahmed Taifor AzeezDocument32 pagesWelding: by Msc. Ahmed Taifor AzeezShkar GalalyNo ratings yet

- Catalogo Normas AwsDocument52 pagesCatalogo Normas AwsJorge Enrique Montaño Marañon100% (1)

- Atlas Aluminium Datasheet 5052 Rev Oct 2013Document3 pagesAtlas Aluminium Datasheet 5052 Rev Oct 2013Jason-chungNo ratings yet

- STEEL ProblemsDocument21 pagesSTEEL ProblemsFrances Nicole QuitoNo ratings yet

- Weldindssdvg Part 2Document55 pagesWeldindssdvg Part 2sbs271187No ratings yet

- ONH AnalyzerDocument16 pagesONH AnalyzereddyewNo ratings yet

- Anvil Restoration: © Robb Gunther and Karl SchulerDocument2 pagesAnvil Restoration: © Robb Gunther and Karl SchulerKelly CooverNo ratings yet

- Iso 22991 2004 en PDFDocument11 pagesIso 22991 2004 en PDFElias JarjouraNo ratings yet

- Coletanche FinlandDocument8 pagesColetanche FinlandEvan BuntoroNo ratings yet

- TWI Ultrasonic Inspection Coursework 8Document5 pagesTWI Ultrasonic Inspection Coursework 8HassanSoboh100% (1)

- Pranay Kumar Tode Pktode@yahoo - Co.inDocument44 pagesPranay Kumar Tode Pktode@yahoo - Co.inKhabib IbragimovNo ratings yet

- Structural Tubes For Offshore Applications PDFDocument8 pagesStructural Tubes For Offshore Applications PDFFSRAEMNo ratings yet

- Characterization of Bond Line Discontinuities in A High-Mn TWIP Steel Pipe Welded by HF-ERW PDFDocument8 pagesCharacterization of Bond Line Discontinuities in A High-Mn TWIP Steel Pipe Welded by HF-ERW PDFSinan ChenNo ratings yet

- Welding Metallurgy 2Document37 pagesWelding Metallurgy 2Asad Bin Ala QatariNo ratings yet

- Set-Up Welding Equipment LO1-1.1Document7 pagesSet-Up Welding Equipment LO1-1.1Joy BuycoNo ratings yet

- Form 1 AWS D1.1Document2 pagesForm 1 AWS D1.1Bui Chi Tam100% (1)

- Metal Roof PDFDocument15 pagesMetal Roof PDFJuan TorresNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Document22 pagesBK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Panneer SelvamNo ratings yet

- Laser-Assisted Fabrication of MaterialsDocument513 pagesLaser-Assisted Fabrication of Materialssofiane haddadiNo ratings yet

- Recent Trend in Heat ExchangerDocument9 pagesRecent Trend in Heat Exchangersai100% (1)

- WPQT PHSSDocument1 pageWPQT PHSSFerdie OSNo ratings yet

- Ultrasonic TestingDocument11 pagesUltrasonic TestingapmapNo ratings yet

- Sheetmetal Technology 22Document34 pagesSheetmetal Technology 22Alfred KuwodzaNo ratings yet