Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

30 viewsVLT® 2800 Series: The Perfect Solution For

VLT® 2800 Series: The Perfect Solution For

Uploaded by

OscarCatalogo Danfoss

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- 9098i Circuit Diagrams Overlays Issue 2Document321 pages9098i Circuit Diagrams Overlays Issue 2Robert Morris100% (1)

- 2.sumpner's Test On A Pair of Single Phase TransformersDocument5 pages2.sumpner's Test On A Pair of Single Phase Transformerschandrakanth100% (2)

- VLT® 2800 Series: The Perfect Solution ForDocument2 pagesVLT® 2800 Series: The Perfect Solution ForIván CascudoNo ratings yet

- Eaton Ats Molded Case Pa140016en en UsDocument2 pagesEaton Ats Molded Case Pa140016en en UsTodea Mihai IulianNo ratings yet

- Product Profile: Powerflex® 4M Ac DriveDocument2 pagesProduct Profile: Powerflex® 4M Ac DriveWilliam Alfonso Cañas PratoNo ratings yet

- Grundfosliterature 5270943Document2 pagesGrundfosliterature 5270943shameer_sanju1049No ratings yet

- Ultima Plus Series (1-3K-P - F - 0 - 96 - 1) LV-1901Document1 pageUltima Plus Series (1-3K-P - F - 0 - 96 - 1) LV-1901David Antonio Bonilla ChaónNo ratings yet

- FBL 2360Document14 pagesFBL 2360musarraf172No ratings yet

- Ficha Tecnica Gama Thyro IngDocument8 pagesFicha Tecnica Gama Thyro Ingjovares2099No ratings yet

- Micro Are S-DsDocument4 pagesMicro Are S-DsRichard SyNo ratings yet

- EPower 029669 5 PDFDocument14 pagesEPower 029669 5 PDFrajabharath12No ratings yet

- Liebert: S600E 20KVA (3in-3out) Eff Icient & Robust UPS For Critical ApplicationsDocument6 pagesLiebert: S600E 20KVA (3in-3out) Eff Icient & Robust UPS For Critical ApplicationsDEVI PRASAD GREENSECURENo ratings yet

- APW7142Document22 pagesAPW7142gsmaster4141No ratings yet

- AD Product Brochure-EnDocument4 pagesAD Product Brochure-EnMohamed AlkharashyNo ratings yet

- TEBECHOP DCConverter 09Document4 pagesTEBECHOP DCConverter 09kylegazeNo ratings yet

- LM5170-Q1 Multiphase Bidirectional Current Controller: 1 Features 3 DescriptionDocument71 pagesLM5170-Q1 Multiphase Bidirectional Current Controller: 1 Features 3 DescriptionBorn Lion MateNo ratings yet

- Commander C200 AC Drives: Enhance Throughput With Machine Safety, Communications, and Built-In PLCDocument2 pagesCommander C200 AC Drives: Enhance Throughput With Machine Safety, Communications, and Built-In PLCTraian SerbanNo ratings yet

- Sentinel Power: 5-6 kVA 6.5-10 kVADocument4 pagesSentinel Power: 5-6 kVA 6.5-10 kVAAhmed TitawiNo ratings yet

- TECNED Industrial Inverters UPSDocument7 pagesTECNED Industrial Inverters UPSKurt WyleNo ratings yet

- PQ1 Data SheetDocument2 pagesPQ1 Data SheetJeff KendallNo ratings yet

- Aros ST Sentry MultistandardDocument6 pagesAros ST Sentry MultistandardfedericosanchezNo ratings yet

- Datasheet Eaton 93 STS - Static Transfer SwitchDocument2 pagesDatasheet Eaton 93 STS - Static Transfer SwitchWilliam QuintelaNo ratings yet

- WRT-10D: Winding Resistance Tester With DemagnetisationDocument2 pagesWRT-10D: Winding Resistance Tester With DemagnetisationenticoNo ratings yet

- A1000 Variable Speed Drive: A Single Drive For All Your Needs With Outstanding PerformanceDocument2 pagesA1000 Variable Speed Drive: A Single Drive For All Your Needs With Outstanding PerformancesylcoNo ratings yet

- Mercury Mk3 Info SheetDocument2 pagesMercury Mk3 Info SheetJoel CostaNo ratings yet

- Siemens-Robicon-Perfect-Harmony-Air - CatalogoDocument8 pagesSiemens-Robicon-Perfect-Harmony-Air - CatalogoJuan EstradaNo ratings yet

- MODEL 1222: Electric Power Steering ControllerDocument4 pagesMODEL 1222: Electric Power Steering ControllerIker BasqueAdventureNo ratings yet

- LM 5145Document67 pagesLM 5145L IvanNo ratings yet

- 50017REVBDocument2 pages50017REVBIntercambio de ManualesNo ratings yet

- M13-ING-R6 - U-MLEsDocument6 pagesM13-ING-R6 - U-MLEsRinu RavikumarNo ratings yet

- LEVELUPS T4 ONLINE (3 - 3) - 80-400 kVADocument5 pagesLEVELUPS T4 ONLINE (3 - 3) - 80-400 kVAIvan KNo ratings yet

- Flyer A1007Document2 pagesFlyer A1007cujadiegoNo ratings yet

- D-0006-100 DB5i For ESP Applications-July2019Document2 pagesD-0006-100 DB5i For ESP Applications-July2019Jimmy F HernandezNo ratings yet

- Sentinel XR PDFDocument6 pagesSentinel XR PDFPustinjak SaharicNo ratings yet

- DLT 300 Lo SeriesDocument2 pagesDLT 300 Lo SeriesKhurram ShahzadNo ratings yet

- LEVELUPS T3 ONLINE (3 - 3) - 10-60 kVADocument4 pagesLEVELUPS T3 ONLINE (3 - 3) - 10-60 kVAIvan KNo ratings yet

- Smart SYS N1540180R48 - Datasheet - 180222Document2 pagesSmart SYS N1540180R48 - Datasheet - 180222Will F AlvesNo ratings yet

- 1U Sub RackDocument2 pages1U Sub RackPhạm NamNo ratings yet

- Wide 6 V To 75 V Input Voltage Synchronous Buck Controller: FeaturesDocument42 pagesWide 6 V To 75 V Input Voltage Synchronous Buck Controller: FeaturesDhananjayNo ratings yet

- UPS Sentry HPS Kat List en V052009Document5 pagesUPS Sentry HPS Kat List en V052009ÅsaNo ratings yet

- Gensys20core Marine Sales DocumentationDocument3 pagesGensys20core Marine Sales DocumentationDenny SetiyoNo ratings yet

- Variable Speed Benefits BROVFD-R1Document4 pagesVariable Speed Benefits BROVFD-R1momin momaniNo ratings yet

- SDH 1000-3000 PDFDocument4 pagesSDH 1000-3000 PDFPauloSempiternoNo ratings yet

- Controller Catalog 0322 Power Switching DevDocument30 pagesController Catalog 0322 Power Switching DevGarcia FranciscoNo ratings yet

- V7 Open Loop Vector Drive 1/8 - 10 HPDocument2 pagesV7 Open Loop Vector Drive 1/8 - 10 HPDavi RibeiroNo ratings yet

- sbl23xx DatasheetDocument17 pagessbl23xx DatasheetAditya JainNo ratings yet

- CTI Range Automatic Transfer SwitchDocument6 pagesCTI Range Automatic Transfer SwitchVinoth KumarNo ratings yet

- Brochure Riello Guard Tower 6-10Document4 pagesBrochure Riello Guard Tower 6-10Yerlin Larissa Barahona GarciaNo ratings yet

- Datasheet Minipack S48 WEB - SNMP Indoor CabinetDocument5 pagesDatasheet Minipack S48 WEB - SNMP Indoor Cabinetفيصل باديNo ratings yet

- FrontRear Access PDU DataSheetDocument2 pagesFrontRear Access PDU DataSheetHugo HernándezNo ratings yet

- PF7000 Brochure Drive Frame ADocument4 pagesPF7000 Brochure Drive Frame Aruben alarconNo ratings yet

- Illuminator Series E: Uninterruptible Power System Single Phase Systems 1.5kVA To 16.7kVADocument2 pagesIlluminator Series E: Uninterruptible Power System Single Phase Systems 1.5kVA To 16.7kVAdanielliram993No ratings yet

- Daker DK Plus 2000: General FeaturesDocument2 pagesDaker DK Plus 2000: General Featuresovidiu ovidiusNo ratings yet

- USDDPFP500A222 MicroDrive FS - LRDocument2 pagesUSDDPFP500A222 MicroDrive FS - LRoscar.moreno613No ratings yet

- Zener MSC 3 BrochureDocument4 pagesZener MSC 3 BrochureAswanTajuddinNo ratings yet

- D I G I T A L T H y R Istor Power Controllers (SCR)Document4 pagesD I G I T A L T H y R Istor Power Controllers (SCR)mubs73No ratings yet

- Product Bulletin: GE Consumer & IndustrialDocument8 pagesProduct Bulletin: GE Consumer & IndustrialChristian VaNo ratings yet

- FWSW-2X1 Optical Switch 2x1-FULLWELLDocument2 pagesFWSW-2X1 Optical Switch 2x1-FULLWELLionicaNo ratings yet

- VARIADOR DANFOSS Producto - 131l9905 - 20200325124055Document2 pagesVARIADOR DANFOSS Producto - 131l9905 - 20200325124055Giancarlo Reategui GuerraNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Main CatDocument33 pagesMain CatOscarNo ratings yet

- Captureds Final2Document12 pagesCaptureds Final2OscarNo ratings yet

- Torin DriveDocument1 pageTorin DriveOscarNo ratings yet

- BLT - CHOI II Brochure Ilovepdf SmallDocument18 pagesBLT - CHOI II Brochure Ilovepdf SmallOscarNo ratings yet

- Medidas de ProteccionjDocument1 pageMedidas de ProteccionjOscarNo ratings yet

- Magnet Switch MRK: Round Version With CableDocument2 pagesMagnet Switch MRK: Round Version With CableOscarNo ratings yet

- Single Bearing Block E: Accessories For Door InterlocksDocument2 pagesSingle Bearing Block E: Accessories For Door InterlocksOscarNo ratings yet

- Reversing Bearing Block U: Accessories For Door InterlocksDocument2 pagesReversing Bearing Block U: Accessories For Door InterlocksOscarNo ratings yet

- Pull Rod Deflection E - ZU: Accessories For Door InterlocksDocument2 pagesPull Rod Deflection E - ZU: Accessories For Door InterlocksOscarNo ratings yet

- Analisador de Unidade Eletrocirúrgica hf400 - eDocument23 pagesAnalisador de Unidade Eletrocirúrgica hf400 - eBruno100% (1)

- Banner SM312D Datasheet PDFDocument8 pagesBanner SM312D Datasheet PDFMarlon MorelNo ratings yet

- Fisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction ManualDocument116 pagesFisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction Manualanon_179203922No ratings yet

- Stored Energy Solutions For A Demanding World: SpecificationsDocument2 pagesStored Energy Solutions For A Demanding World: SpecificationsALEX ALEXNo ratings yet

- Telegarten Coaxial Bulk CablesDocument4 pagesTelegarten Coaxial Bulk CablesFirmansyah PanduNo ratings yet

- Users Manual 3 994639Document140 pagesUsers Manual 3 994639Parul MehtaNo ratings yet

- KTU BTech EEE 2016scheme S3S4KTUSyllabusDocument41 pagesKTU BTech EEE 2016scheme S3S4KTUSyllabusleksremeshNo ratings yet

- ASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignDocument38 pagesASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignNguyễn Hữu TàiNo ratings yet

- pm5110 DatasheetDocument9 pagespm5110 DatasheetJose Luis Lima BallesterosNo ratings yet

- Kode Eror WCPUDocument2 pagesKode Eror WCPUbagus wicaksonNo ratings yet

- System Grounding Bill Brown - Schneider Electric, Section6 - 0307, 13ppDocument13 pagesSystem Grounding Bill Brown - Schneider Electric, Section6 - 0307, 13ppmte1100% (1)

- 30 AWG Cable DATA SheetDocument2 pages30 AWG Cable DATA SheetTuýp Phờ NờNo ratings yet

- Product Specification - AirHarmony LSBA 2 3-2 4GHz Basta9 v2 (Antenna Model No - LSBA-2300-Airspan-001)Document2 pagesProduct Specification - AirHarmony LSBA 2 3-2 4GHz Basta9 v2 (Antenna Model No - LSBA-2300-Airspan-001)Ikie BarieNo ratings yet

- Thomson Consumer Integrated Circuits Ic Data Bbok 1983Document663 pagesThomson Consumer Integrated Circuits Ic Data Bbok 1983Todorosss JjNo ratings yet

- Testing and Commissioning ofDocument11 pagesTesting and Commissioning ofsushant_2525100% (1)

- Sigma SGDH 10 II Manual EN PDFDocument405 pagesSigma SGDH 10 II Manual EN PDFlauraNo ratings yet

- KIA431 SeriesDocument8 pagesKIA431 SeriesHenryAmayaLarrealNo ratings yet

- Maximum Demand: PT. Tapian NadengganDocument4 pagesMaximum Demand: PT. Tapian NadengganWallsNo ratings yet

- Engineering Manual: 38VMR072-336 Outdoor Unit For Variable Refrigerant Flow (VRF) Heat Recovery SystemDocument3 pagesEngineering Manual: 38VMR072-336 Outdoor Unit For Variable Refrigerant Flow (VRF) Heat Recovery SystemArjun MNo ratings yet

- Experiment No. 1 Introduction To MultisimDocument23 pagesExperiment No. 1 Introduction To MultisimLynndon VillamorNo ratings yet

- Mur460 4a Diodo RapidoDocument6 pagesMur460 4a Diodo RapidoJuan Carlos Callas GarayNo ratings yet

- Shojeb - Project ReportDocument11 pagesShojeb - Project ReportShojeb ShojolNo ratings yet

- Manual de Partes Motrec Tittan E-330Document58 pagesManual de Partes Motrec Tittan E-330Antonio GonzálezNo ratings yet

- Samsung HW-JM25 Manual enDocument25 pagesSamsung HW-JM25 Manual enJohn WalesNo ratings yet

- ABB Generator Protection TerminalDocument8 pagesABB Generator Protection Terminalbrock100% (1)

- Gseb Set 2 (2.1 To 4.1)Document2 pagesGseb Set 2 (2.1 To 4.1)keystonevp8No ratings yet

- Antenna EffectDocument5 pagesAntenna Effectstudius1No ratings yet

- 2010 Edition Power Cables and Wires Technical Manual PDFDocument183 pages2010 Edition Power Cables and Wires Technical Manual PDFbigbang100% (1)

VLT® 2800 Series: The Perfect Solution For

VLT® 2800 Series: The Perfect Solution For

Uploaded by

Oscar0 ratings0% found this document useful (0 votes)

30 views2 pagesCatalogo Danfoss

Original Title

Catalogo_VLT_2800

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCatalogo Danfoss

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

30 views2 pagesVLT® 2800 Series: The Perfect Solution For

VLT® 2800 Series: The Perfect Solution For

Uploaded by

OscarCatalogo Danfoss

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

VLT® 2800 Series

The VLT® 2800 series has been developed for the low power

market. The drive is extremely compact and prepared for

side-by-side mounting. The concept is modular with a power

module and a control module.

The VLT® 2800 series is designed for

stable operation in industrial environ-

ments.

The perfect solution for:

• Fans and centrifugal pumps Features Benefits

• Conveyors, centrifuges, dosing

• Ensure optimal match between drive

pumps, compressors • Automatic Motor Tuning and motor

• Special applications like cutting • Increasing performance

machines with constant speed, and • PID-controller • Optimum process control

packaging machines with a need • Interrupt start/stop • High repeatability of positional accuracy

for high precision.

• Dry run detection • No need for specific detection equipment

Power range: • Allows for control and surveillance of the

• Fieldbus communication drives from a PC or a PLC

1/3 x 200 – 240 V: 0.37 – 3.7 kW • Profibus and DeviceNet are available

3 x 380 – 480 V: 0.55 – 18.5 kW

Reliable – Maximum up-time

With 110% overload torque • Compliance with the EMC standard

• Built-in RFI filter

(normal overload) EN 55011 1A

• Excellent control for shutting down the

• Enhanced sleep mode

pump at low flow

• Max. ambient temperature 50˚ Celsius • No external cooling or

without derating oversizing necessary

– Save commissioning and

User-friendly

operating cost

• Quick Menu • Easy to use

• Pipe Fill mode • Prevents water hammering

• Allows for control and surveillance of

• Fieldbus communication the drives from a PC or a PLC

• Profibus and DeviceNet are available

PC software tools Specifications

Mains supply (L1, L2, L3)

• MCT 10

Supply voltage 200 – 240 V ±10%, 380 – 500 V ±10%

– Ideal for commissioning and

Supply frequency 50/60 Hz

servicing the drive

Displacement Power Factor (cos φ) near unity (> 0.98)

Switching on input supply L1, L2, L3 1 – 2 times/min.

• MCT 31

Output data (U, V, W)

– Harmonics calculations tool

Output voltage 0 – 100% of supply

Switching on output Unlimited

RFI filter

Ramp times 1 – 3600 sec.

The RFI filter ensures that the fre- Closed loop 0 – 132 Hz

quency converter will not disrupt

other electrical components that are Digital inputs

connected to the mains and might For start/stop, reset, thermistor, etc. 5

Logic PNP or NPN

cause operating disruption.

Voltage level 0 – 24 VDC

By fitting an RFI 1B filter module Digital outputs

between the mains supply and the No. of digital outputs 1

VLT® 2800, the solution complies with Analog inputs

the EMC norm EN 55011-1B. No. of analog inputs 2

Voltage level -10 to +10 V (scaleable)

Current level 0/4 to 20 mA (scaleable)

Pulse inputs

No. of pulse inputs 2

Voltage level 0 – 24 VDC (PNP positive logic)

Power Input current Pulse input accuracy (0.1 – 110 kHz)

PN,M

Mains Type IINV [A] IL,N [A] Analog outputs

[kW]

2803 0.37 2.2 5.9 Programmable analog outputs 1

1 x 220 – 240 V

2805 0.55 3.2 8.3 Current range at analog output 0/4 – 20 mA

2807 0.75 4.2 10.6 Relay outputs

2811 1.1 6.0 14.5 No. of relay outputs 1

2815 1.5 6.8 15.2

2822* 2.2 9.6 22.0 Fieldbus communication

2840* 3.7 16.0 31.0 RS485

2803 0.37 2.2 2.9 Ambient temperature

3 x 200 – 240 V

2805 0.55 3.2 4.0 50˚C

2807 0.75 4.2 5.1

2811 1.1 6.0 7.0

2815 1.5 6.8 7.6

2822 2.2 9.6 8.8 D

2840 3.7 16.0 14.7

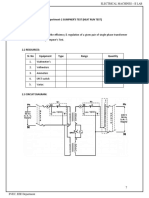

2805 0.55 1.7 1.6

2807 0.75 2.1 1.9 Cabinet sizes [mm] B C

2811 1.1 3.0 2.6

2815 1.5 3.7 3.2 Height

3 x 380 – 480 V

2822 2.2 5.2 4.7 A B C D

2830 3.0 7.0 6.1 A: 200 267.5 267.5 505

2840 4.0 9.1 8.1 a: 191 257 257 490

2855 5.5 12 10.6 Width

2875 7.5 16 14.9 B: 75 90 140 200

2880 11.0 24 24.0 b: 60 70 120 120

2881 15.0 32 32.0 Depth

2882 18.5 37.5 37.5 C: 168 168 168 244

A

* Not available with RFI filter

MP006A02 VLT® is a trademark of Danfoss A/S Produced by KKM 2007.05

You might also like

- 9098i Circuit Diagrams Overlays Issue 2Document321 pages9098i Circuit Diagrams Overlays Issue 2Robert Morris100% (1)

- 2.sumpner's Test On A Pair of Single Phase TransformersDocument5 pages2.sumpner's Test On A Pair of Single Phase Transformerschandrakanth100% (2)

- VLT® 2800 Series: The Perfect Solution ForDocument2 pagesVLT® 2800 Series: The Perfect Solution ForIván CascudoNo ratings yet

- Eaton Ats Molded Case Pa140016en en UsDocument2 pagesEaton Ats Molded Case Pa140016en en UsTodea Mihai IulianNo ratings yet

- Product Profile: Powerflex® 4M Ac DriveDocument2 pagesProduct Profile: Powerflex® 4M Ac DriveWilliam Alfonso Cañas PratoNo ratings yet

- Grundfosliterature 5270943Document2 pagesGrundfosliterature 5270943shameer_sanju1049No ratings yet

- Ultima Plus Series (1-3K-P - F - 0 - 96 - 1) LV-1901Document1 pageUltima Plus Series (1-3K-P - F - 0 - 96 - 1) LV-1901David Antonio Bonilla ChaónNo ratings yet

- FBL 2360Document14 pagesFBL 2360musarraf172No ratings yet

- Ficha Tecnica Gama Thyro IngDocument8 pagesFicha Tecnica Gama Thyro Ingjovares2099No ratings yet

- Micro Are S-DsDocument4 pagesMicro Are S-DsRichard SyNo ratings yet

- EPower 029669 5 PDFDocument14 pagesEPower 029669 5 PDFrajabharath12No ratings yet

- Liebert: S600E 20KVA (3in-3out) Eff Icient & Robust UPS For Critical ApplicationsDocument6 pagesLiebert: S600E 20KVA (3in-3out) Eff Icient & Robust UPS For Critical ApplicationsDEVI PRASAD GREENSECURENo ratings yet

- APW7142Document22 pagesAPW7142gsmaster4141No ratings yet

- AD Product Brochure-EnDocument4 pagesAD Product Brochure-EnMohamed AlkharashyNo ratings yet

- TEBECHOP DCConverter 09Document4 pagesTEBECHOP DCConverter 09kylegazeNo ratings yet

- LM5170-Q1 Multiphase Bidirectional Current Controller: 1 Features 3 DescriptionDocument71 pagesLM5170-Q1 Multiphase Bidirectional Current Controller: 1 Features 3 DescriptionBorn Lion MateNo ratings yet

- Commander C200 AC Drives: Enhance Throughput With Machine Safety, Communications, and Built-In PLCDocument2 pagesCommander C200 AC Drives: Enhance Throughput With Machine Safety, Communications, and Built-In PLCTraian SerbanNo ratings yet

- Sentinel Power: 5-6 kVA 6.5-10 kVADocument4 pagesSentinel Power: 5-6 kVA 6.5-10 kVAAhmed TitawiNo ratings yet

- TECNED Industrial Inverters UPSDocument7 pagesTECNED Industrial Inverters UPSKurt WyleNo ratings yet

- PQ1 Data SheetDocument2 pagesPQ1 Data SheetJeff KendallNo ratings yet

- Aros ST Sentry MultistandardDocument6 pagesAros ST Sentry MultistandardfedericosanchezNo ratings yet

- Datasheet Eaton 93 STS - Static Transfer SwitchDocument2 pagesDatasheet Eaton 93 STS - Static Transfer SwitchWilliam QuintelaNo ratings yet

- WRT-10D: Winding Resistance Tester With DemagnetisationDocument2 pagesWRT-10D: Winding Resistance Tester With DemagnetisationenticoNo ratings yet

- A1000 Variable Speed Drive: A Single Drive For All Your Needs With Outstanding PerformanceDocument2 pagesA1000 Variable Speed Drive: A Single Drive For All Your Needs With Outstanding PerformancesylcoNo ratings yet

- Mercury Mk3 Info SheetDocument2 pagesMercury Mk3 Info SheetJoel CostaNo ratings yet

- Siemens-Robicon-Perfect-Harmony-Air - CatalogoDocument8 pagesSiemens-Robicon-Perfect-Harmony-Air - CatalogoJuan EstradaNo ratings yet

- MODEL 1222: Electric Power Steering ControllerDocument4 pagesMODEL 1222: Electric Power Steering ControllerIker BasqueAdventureNo ratings yet

- LM 5145Document67 pagesLM 5145L IvanNo ratings yet

- 50017REVBDocument2 pages50017REVBIntercambio de ManualesNo ratings yet

- M13-ING-R6 - U-MLEsDocument6 pagesM13-ING-R6 - U-MLEsRinu RavikumarNo ratings yet

- LEVELUPS T4 ONLINE (3 - 3) - 80-400 kVADocument5 pagesLEVELUPS T4 ONLINE (3 - 3) - 80-400 kVAIvan KNo ratings yet

- Flyer A1007Document2 pagesFlyer A1007cujadiegoNo ratings yet

- D-0006-100 DB5i For ESP Applications-July2019Document2 pagesD-0006-100 DB5i For ESP Applications-July2019Jimmy F HernandezNo ratings yet

- Sentinel XR PDFDocument6 pagesSentinel XR PDFPustinjak SaharicNo ratings yet

- DLT 300 Lo SeriesDocument2 pagesDLT 300 Lo SeriesKhurram ShahzadNo ratings yet

- LEVELUPS T3 ONLINE (3 - 3) - 10-60 kVADocument4 pagesLEVELUPS T3 ONLINE (3 - 3) - 10-60 kVAIvan KNo ratings yet

- Smart SYS N1540180R48 - Datasheet - 180222Document2 pagesSmart SYS N1540180R48 - Datasheet - 180222Will F AlvesNo ratings yet

- 1U Sub RackDocument2 pages1U Sub RackPhạm NamNo ratings yet

- Wide 6 V To 75 V Input Voltage Synchronous Buck Controller: FeaturesDocument42 pagesWide 6 V To 75 V Input Voltage Synchronous Buck Controller: FeaturesDhananjayNo ratings yet

- UPS Sentry HPS Kat List en V052009Document5 pagesUPS Sentry HPS Kat List en V052009ÅsaNo ratings yet

- Gensys20core Marine Sales DocumentationDocument3 pagesGensys20core Marine Sales DocumentationDenny SetiyoNo ratings yet

- Variable Speed Benefits BROVFD-R1Document4 pagesVariable Speed Benefits BROVFD-R1momin momaniNo ratings yet

- SDH 1000-3000 PDFDocument4 pagesSDH 1000-3000 PDFPauloSempiternoNo ratings yet

- Controller Catalog 0322 Power Switching DevDocument30 pagesController Catalog 0322 Power Switching DevGarcia FranciscoNo ratings yet

- V7 Open Loop Vector Drive 1/8 - 10 HPDocument2 pagesV7 Open Loop Vector Drive 1/8 - 10 HPDavi RibeiroNo ratings yet

- sbl23xx DatasheetDocument17 pagessbl23xx DatasheetAditya JainNo ratings yet

- CTI Range Automatic Transfer SwitchDocument6 pagesCTI Range Automatic Transfer SwitchVinoth KumarNo ratings yet

- Brochure Riello Guard Tower 6-10Document4 pagesBrochure Riello Guard Tower 6-10Yerlin Larissa Barahona GarciaNo ratings yet

- Datasheet Minipack S48 WEB - SNMP Indoor CabinetDocument5 pagesDatasheet Minipack S48 WEB - SNMP Indoor Cabinetفيصل باديNo ratings yet

- FrontRear Access PDU DataSheetDocument2 pagesFrontRear Access PDU DataSheetHugo HernándezNo ratings yet

- PF7000 Brochure Drive Frame ADocument4 pagesPF7000 Brochure Drive Frame Aruben alarconNo ratings yet

- Illuminator Series E: Uninterruptible Power System Single Phase Systems 1.5kVA To 16.7kVADocument2 pagesIlluminator Series E: Uninterruptible Power System Single Phase Systems 1.5kVA To 16.7kVAdanielliram993No ratings yet

- Daker DK Plus 2000: General FeaturesDocument2 pagesDaker DK Plus 2000: General Featuresovidiu ovidiusNo ratings yet

- USDDPFP500A222 MicroDrive FS - LRDocument2 pagesUSDDPFP500A222 MicroDrive FS - LRoscar.moreno613No ratings yet

- Zener MSC 3 BrochureDocument4 pagesZener MSC 3 BrochureAswanTajuddinNo ratings yet

- D I G I T A L T H y R Istor Power Controllers (SCR)Document4 pagesD I G I T A L T H y R Istor Power Controllers (SCR)mubs73No ratings yet

- Product Bulletin: GE Consumer & IndustrialDocument8 pagesProduct Bulletin: GE Consumer & IndustrialChristian VaNo ratings yet

- FWSW-2X1 Optical Switch 2x1-FULLWELLDocument2 pagesFWSW-2X1 Optical Switch 2x1-FULLWELLionicaNo ratings yet

- VARIADOR DANFOSS Producto - 131l9905 - 20200325124055Document2 pagesVARIADOR DANFOSS Producto - 131l9905 - 20200325124055Giancarlo Reategui GuerraNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Main CatDocument33 pagesMain CatOscarNo ratings yet

- Captureds Final2Document12 pagesCaptureds Final2OscarNo ratings yet

- Torin DriveDocument1 pageTorin DriveOscarNo ratings yet

- BLT - CHOI II Brochure Ilovepdf SmallDocument18 pagesBLT - CHOI II Brochure Ilovepdf SmallOscarNo ratings yet

- Medidas de ProteccionjDocument1 pageMedidas de ProteccionjOscarNo ratings yet

- Magnet Switch MRK: Round Version With CableDocument2 pagesMagnet Switch MRK: Round Version With CableOscarNo ratings yet

- Single Bearing Block E: Accessories For Door InterlocksDocument2 pagesSingle Bearing Block E: Accessories For Door InterlocksOscarNo ratings yet

- Reversing Bearing Block U: Accessories For Door InterlocksDocument2 pagesReversing Bearing Block U: Accessories For Door InterlocksOscarNo ratings yet

- Pull Rod Deflection E - ZU: Accessories For Door InterlocksDocument2 pagesPull Rod Deflection E - ZU: Accessories For Door InterlocksOscarNo ratings yet

- Analisador de Unidade Eletrocirúrgica hf400 - eDocument23 pagesAnalisador de Unidade Eletrocirúrgica hf400 - eBruno100% (1)

- Banner SM312D Datasheet PDFDocument8 pagesBanner SM312D Datasheet PDFMarlon MorelNo ratings yet

- Fisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction ManualDocument116 pagesFisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction Manualanon_179203922No ratings yet

- Stored Energy Solutions For A Demanding World: SpecificationsDocument2 pagesStored Energy Solutions For A Demanding World: SpecificationsALEX ALEXNo ratings yet

- Telegarten Coaxial Bulk CablesDocument4 pagesTelegarten Coaxial Bulk CablesFirmansyah PanduNo ratings yet

- Users Manual 3 994639Document140 pagesUsers Manual 3 994639Parul MehtaNo ratings yet

- KTU BTech EEE 2016scheme S3S4KTUSyllabusDocument41 pagesKTU BTech EEE 2016scheme S3S4KTUSyllabusleksremeshNo ratings yet

- ASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignDocument38 pagesASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignNguyễn Hữu TàiNo ratings yet

- pm5110 DatasheetDocument9 pagespm5110 DatasheetJose Luis Lima BallesterosNo ratings yet

- Kode Eror WCPUDocument2 pagesKode Eror WCPUbagus wicaksonNo ratings yet

- System Grounding Bill Brown - Schneider Electric, Section6 - 0307, 13ppDocument13 pagesSystem Grounding Bill Brown - Schneider Electric, Section6 - 0307, 13ppmte1100% (1)

- 30 AWG Cable DATA SheetDocument2 pages30 AWG Cable DATA SheetTuýp Phờ NờNo ratings yet

- Product Specification - AirHarmony LSBA 2 3-2 4GHz Basta9 v2 (Antenna Model No - LSBA-2300-Airspan-001)Document2 pagesProduct Specification - AirHarmony LSBA 2 3-2 4GHz Basta9 v2 (Antenna Model No - LSBA-2300-Airspan-001)Ikie BarieNo ratings yet

- Thomson Consumer Integrated Circuits Ic Data Bbok 1983Document663 pagesThomson Consumer Integrated Circuits Ic Data Bbok 1983Todorosss JjNo ratings yet

- Testing and Commissioning ofDocument11 pagesTesting and Commissioning ofsushant_2525100% (1)

- Sigma SGDH 10 II Manual EN PDFDocument405 pagesSigma SGDH 10 II Manual EN PDFlauraNo ratings yet

- KIA431 SeriesDocument8 pagesKIA431 SeriesHenryAmayaLarrealNo ratings yet

- Maximum Demand: PT. Tapian NadengganDocument4 pagesMaximum Demand: PT. Tapian NadengganWallsNo ratings yet

- Engineering Manual: 38VMR072-336 Outdoor Unit For Variable Refrigerant Flow (VRF) Heat Recovery SystemDocument3 pagesEngineering Manual: 38VMR072-336 Outdoor Unit For Variable Refrigerant Flow (VRF) Heat Recovery SystemArjun MNo ratings yet

- Experiment No. 1 Introduction To MultisimDocument23 pagesExperiment No. 1 Introduction To MultisimLynndon VillamorNo ratings yet

- Mur460 4a Diodo RapidoDocument6 pagesMur460 4a Diodo RapidoJuan Carlos Callas GarayNo ratings yet

- Shojeb - Project ReportDocument11 pagesShojeb - Project ReportShojeb ShojolNo ratings yet

- Manual de Partes Motrec Tittan E-330Document58 pagesManual de Partes Motrec Tittan E-330Antonio GonzálezNo ratings yet

- Samsung HW-JM25 Manual enDocument25 pagesSamsung HW-JM25 Manual enJohn WalesNo ratings yet

- ABB Generator Protection TerminalDocument8 pagesABB Generator Protection Terminalbrock100% (1)

- Gseb Set 2 (2.1 To 4.1)Document2 pagesGseb Set 2 (2.1 To 4.1)keystonevp8No ratings yet

- Antenna EffectDocument5 pagesAntenna Effectstudius1No ratings yet

- 2010 Edition Power Cables and Wires Technical Manual PDFDocument183 pages2010 Edition Power Cables and Wires Technical Manual PDFbigbang100% (1)