Professional Documents

Culture Documents

Bureau Veritas - Thickness Measurements - Aceptance Criteria & Location - Offshore Loading and Offloading Buoys - Rev JMV 2002-02-27

Bureau Veritas - Thickness Measurements - Aceptance Criteria & Location - Offshore Loading and Offloading Buoys - Rev JMV 2002-02-27

Uploaded by

pelotoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bureau Veritas - Thickness Measurements - Aceptance Criteria & Location - Offshore Loading and Offloading Buoys - Rev JMV 2002-02-27

Bureau Veritas - Thickness Measurements - Aceptance Criteria & Location - Offshore Loading and Offloading Buoys - Rev JMV 2002-02-27

Uploaded by

pelotoCopyright:

Available Formats

Petroterminal de Panamá, S.A.

Dirección de Ingeniería y Mantenimiento

Gerencia de Ingeniería - Superintendencia de Inspección y Diseño

Rules for the Classification of Offshore Loading and Offloading Buoys

Thickness Measurements: Aceptance Criteria & Location

Reference: Bureau Veritas - Rule Note NR 494 DT R02 E - May 2006

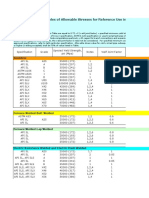

Maximum Average Pitting Depth (in) Minimum Allowable Thickness (in)

Rule Thickness or As-Built

Group of Items Description of Items Thickness (in) Pitting Intensity (%) Pitting Intensity Digrams (from 1% to 50% Intenity)

(%) Pit (in) Remanent (in) Isolated Area Item Group Zone

DECK ZONE 0.2500 1 35.0% 0.0875 0.1625 - - - 0.225

1 Deck plating 0.2500 10 32.0% 0.0800 0.1700 0.1875 0.2000 0.2250 -

Deck stiffener 0.2500 15 30.5% 0.0763 0.1738 - - 0.2250 -

2 Web 0.2500 15 30.5% 0.0763 0.1738 0.1875 0.2000 -

flange 0.2500 20 29.0% 0.0725 0.1775 0.2000 0.2125 - -

BOTTOM ZONE 0.2500 25 27.5% 0.0688 0.1813 - - - 0.225

3 Bottom plating 0.2500 30 26.0% 0.0650 0.1850 0.1875 0.2000 0.2250 -

Bottom stiffener 0.2500 40 23.0% 0.0575 0.1925 - - 0.2250 -

4 Web 0.2500 40 23.0% 0.0575 0.1925 0.1875 0.2000 - -

flange 0.2500 50 20.0% 0.0500 0.2000 0.2000 0.2125 - -

RADIAL BULKHEAD 0.2500 5 33.5% 0.0838 0.1663 - - - 0.225

5 Radial bulkhead plating 0.2500 10 32.0% 0.0800 0.1700 0.1875 0.2000 0.2250 -

Radial bulkhead stiffener 0.2500 3 35.0% 0.0875 0.1625 - - 0.2250 -

6 Web 0.2500 3 35.0% 0.0875 0.1625 0.1875 0.2000 - -

flange 0.2500 3 35.0% 0.0875 0.1625 0.2000 0.2125 - -

SIDE SHELL 0.2500 5 33.5% 0.0838 0.1663 - - - 0.225

7 Side shell plating 0.2500 5 33.5% 0.0838 0.1663 0.1875 0.2000 0.2250 -

Side shell stiffener 0.2500 10 32.0% 0.0800 0.1700 - - 0.2250 -

8 Web 0.2500 15 30.5% 0.0763 0.1738 0.1875 0.2000 - -

flange 0.2500 15 30.5% 0.0763 0.1738 0.2000 0.2125 - -

CENTRE WELL 0.2500 3 35.0% 0.0875 0.1625 - - - 0.225

9 Centre well plating 0.2500 3 35.0% 0.0875 0.1625 0.1875 0.2000 0.2250 -

Centre well stiffener (if applicable) 0.2500 3 35.0% 0.0875 0.1625 - - 0.2250 -

10 Web 0.2500 3 35.0% 0.0875 0.1625 0.1875 0.2000 - -

flange 0.2500 3 35.0% 0.0875 0.1625 0.2000 0.2125 - -

Rules for the Classification of Offshore Loading and Offloading Buoys

Thickness Measurements: Aceptance Criteria & Location

Reference: Bureau Veritas - Rule Note NR 494 DT R02 E - May 2006

Table 2 : Pitting Intensity and Corresponding

Table 1 : Local Acceptance Criteria for Buoys (Given in % of Wastage, W)

Maximum Average Depth of Pitting

1 2 3 4 Maximum average pitting depth (%

Group of items Description of items Pitting Intensity (%)

of the as built thickness)

Isolated area Item Group Zone

DECK ZONE (1) - - - 10 Isolated 35.00

1 Deck plating 25 20 10 - 5 33.50

Deck stiffener - - 10 - 10 32.00

2 Web 25 20

flange 20 15 - - 15 30.50

BOTTOM ZONE (1) - - - 10 20 29.00

3 Bottom plating 25 20 10 - 25 27.50

Bottom stiffener - - 10 - 30 26.00

4 Web 25 20

flange 20 15 - - 40 23.00

RADIAL BULKHEAD (1) - - - 10 50 20.00

5 Radial bulkhead plating 25 20 10 -

Radial bulkhead stiffener - - 10 -

6 Web 25 20

flange 20 15 - -

SIDE SHELL (1) - - - 10

7 Side shell plating 25 20 10 -

Side shell stiffener - - 10 -

8 Web 25 20

flange 20 15 - -

CENTRE WELL (1) - - - 10

9 Centre well plating 25 20 10 -

Centre well stiffener (if applicable) web - - 10 -

10 Web 25 20

flange 20 15 - -

(1) Each zone is to be evaluated separately

Note 1:Example:

The deck zone consists of two groups of items:

• deck plating, which has an average wastage of 12% (criterion 10%)

• deck stiffeners, which has an average wastage of 4% (criterion 10%)

Even though the deck plating group exceeds its acceptance criterion, the average wastage of the zone, which can be very roughly estimated at 8%, is

acceptable and thus the deck plating group can be accepted as it is.

1. Acceptance criteria for thickness measurements

1.1.1 Acceptance criteria stipulate limits of wastage which are to be taken into account for reinforcements, repairs or renewals of steel structure. These

limits are generally expressed for each structural item as a maximum percent- age of acceptable wastage (W). When the maximum per- centage of wastage

is indicated, the minimum acceptable thickness (t min) is that resulting from applying this percent- age to the rule thickness (t rule), according to the following

formula:

However, when the rule thickness is not available, the as-built thickness can be used.

Only for criteria related to in item (see [1.3.4] b), the Soci- ety may establish a list of renewal thicknesses tailored to the different structural items. In such a case

these thicknesses are used in lieu of the minimum thicknesses calculated from the percentage of wastage. Figure 1 : Location of bottom and deck measurements

Note 1: In any case, at the request of the Owner, the Society may perform a direct calculation based on the current measurements in order to permit

adjustments of the criteria.

1.1.2 In cases where the buoy has some structural elements with reduced wear margins (e.g. due to buoy refurbishment, increase of draught), the minimum

acceptable thickness for these elements is to be calculated with reference to the rule scantlings without taking account of any reduction originally agreed.

1.1.3 Decisions on steel renewals are taken by the attend- ing Surveyor applying the criteria given in the present Appendix and based on his judgement and the

actual con- dition of the buoy. Should advice be needed to support his decision, the Surveyor may refer to the relevant technical office of the Society.

1.2 Criteria

1.2.1 The acceptance criteria for the minimum thicknesses are divided into:

• criteria on local strength, given in [1.3]

• criteria on buckling strength, given in [1.4]

• criteria on pitting, given in [1.5].

1.2.2 Each measured item is to be checked against these three criteria, as far as applicable. When the criteria are not met, repairs and renewals are to be

carried out as appropriate.

1.3 Local strength criteria Figure 2 : Location of side shell measurements

1.3.1 Local strength criteria are given for each structural parts of the buoy.

1.3.2 For the evaluation of the buoy strength, it is a prereq- uisite that fillet welding between bottom, deck, side shell, radial bulkheads and centre well is

maintained effective as to keep continuity of buoy structure.

The same applies to the buoy particular structural areas (such as main bearing structure, mooring line support struc- ture… as detailed in Sec 4).

1.3.3 These structural items are also listed in Tab 1, grouped according to their position and contribution to the local strength of the buoy (see also Sec 4, Fig 1.

1.3.4 Each structural item is to be assessed according to four different criteria which vary with regard to the domain

under which it is considered, namely:

a) An isolated area, which is meant as a part of a single structural item. This criterion takes into consideration very local aspects such as grooving of a

plate or stiffener, or local severe corrosion; however, it is not to be used for pitting for which separate criteria are considered (see [1.5]). Figure 3 : Location of radial bulkhead measurements

b) An item, which is meant as an individual element such as a plate, a stiffener, etc. This criterion takes into consideration the average condition of the

item, which is assessed by determining its average thickness using the various measurements taken on the same item.

c) A group of items, which is meant as a set of elements of the same nature (plates, stiffeners…) belonging to the same zone (such as deck, one

radial bulkhead…).

d) A zone, which is meant as a set of elements of the same structural element (deck, one radial bulkhead, side shell…), contributing to the integrity and

strength of the buoy. This criterion takes into consideration the average condition of all groups of items belonging to the same zone.

1.3.5 The assessment of the thickness measurements is to be performed using the values given in Tab 1 for each struc- tural element with regard to the four

criteria defined above, in the following order:

a) Isolated areas (column 1 of Tab 1). Figure 4 : Location of stiffener measurements

If the criterion is not met, the wasted part of the item is to be dealt with as necessary.

b) Items (column 2 of Tab 1).

If the criterion is not met, the item is to be dealt with as necessary in the measured areas as far as the average condition of the item concerned is satisfactory.

In cases where some items are renewed, the average thicknesses of these items to be considered in the next step are the new thicknesses.

c) Groups of items (column 3 of Tab 1).

If the criterion is not met, a sufficient number of ele- ments are to be renewed in order to obtain an increased average thickness satisfying the considered

criterion of the group (generally the elements to be renewed are those most wasted). As an example, for the assessment of the group “deck plates” all deck

plates are measured and an average thickness of each of them is estimated. Then the average of all these values is to satisfy the crite- ria given for this group.

a) Zones (column 4 of Tab 1).

In principle, the criterion of the zone is met when all groups of items belonging to the zone meet their own criteria (see c) above). However, a greater wastage

than those given in column 3 may be accepted for one group of items if, considering the other groups of items belong- ing to the same zone, the overall

wastage of the zone does not exceed the criterion given for it in column 4.

1.4 Buckling strength criterion

1.4.1 In case buckling is observed during survey, special consideration will be given by the Society.

1.5 Pitting

1.5.1 The maximum acceptable depth for isolated pits is 35% of the as-built thickness.

1.5.2 For areas with different pitting intensity, the intensity diagrams shown in Fig 5 (at the end of the present appendix) are to be used to identify the

percentage of affected areas.

For areas having a pitting intensity of 50% or more, the maximum average depth of pits is 20% of the as-built thickness. For intermediate values

between isolated pits and 50% of affected area, the interpolation between 35% and 20% is made according to Tab 2.

1.5.3 In addition, the thickness outside the pits in the area considered is to be assessed according to [1.3] and [1.4].

Note 1: Application of filler material (plastic or epoxy compounds) is recommended as a means to stop or reduce the corrosion pro- cess, but it is not

considered an acceptable repair for pitting exceeding the maximum allowable wastage limits. Welding repairs may be accepted when performed in accordance

with procedures agreed with the Society.

2 Location of measurements

2.1.1 The locations of the measurements are identified:

• in [2.2] for the bottom and the deck

• in [2.3] for the side shell

• in [2.4] for the radial bulkheads

• in [2.5] for the stiffeners

2.1.1 The “x” on the figures indicates the location where the measurements are to be done.

2.2 Bottom and deck

2.1.1 The measurements on the bottom and the deck are to be performed as indicated in Fig 1.

2.3 Side shell

2.3.1 The measurements on the side shell are to be per- formed as indicated in Fig 2.

2.4 Radial bulkhead

2.4.1 The measurements on the radial bulkheads are to be performed as indicated in Fig 3.

2.5 Stiffener

2.5.1 The measurements on the stiffeners are to be per- formed as indicated in Fig 4.

You might also like

- Group Work - Case ChemxDocument11 pagesGroup Work - Case Chemxwerya aghamiriNo ratings yet

- Eric Evans Domain Driven Design PDFDocument2 pagesEric Evans Domain Driven Design PDFMayra10% (10)

- Geography - Study Guide - ANSWERS - Garret Nagle and Briony Cooke - Second Edition - Oxford 2017Document44 pagesGeography - Study Guide - ANSWERS - Garret Nagle and Briony Cooke - Second Edition - Oxford 2017Felix ShaoNo ratings yet

- Concrete Damaged Plasticity ModelDocument11 pagesConcrete Damaged Plasticity ModelStructural Spreadsheets100% (1)

- Neuman Interschalt PDFDocument51 pagesNeuman Interschalt PDFCostelNo ratings yet

- Preliminary DesignDocument3 pagesPreliminary DesignElmer HabloNo ratings yet

- GstarCAD 2017 USER GUIDE ภาษาไทยDocument269 pagesGstarCAD 2017 USER GUIDE ภาษาไทยPhannachet RungsrikeawNo ratings yet

- STIX Formula R4Document3 pagesSTIX Formula R4lavrikNo ratings yet

- SuccessFactors Employee Central Practice QuestionsDocument11 pagesSuccessFactors Employee Central Practice Questionsrekha89757% (7)

- E90 Nav Bus To Pro RetrofitDocument15 pagesE90 Nav Bus To Pro RetrofitSadam RexhepiNo ratings yet

- 141 Jazz Guitar LicksDocument114 pages141 Jazz Guitar LicksINTJason100% (5)

- THC ShellKit CASULADocument1 pageTHC ShellKit CASULAAdolf John Montero EceNo ratings yet

- Reed's Vol 05 Ship Construction For Marine StudentsDocument96 pagesReed's Vol 05 Ship Construction For Marine StudentsAhmed SalemNo ratings yet

- Ampair 100 FlyerDocument5 pagesAmpair 100 FlyerAbubakkar SiddiqNo ratings yet

- Duisburg Test Case: Post-Panamax Container Ship For BenchmarkingDocument15 pagesDuisburg Test Case: Post-Panamax Container Ship For BenchmarkingChahbi RamziNo ratings yet

- NR467 B1 2018-07 PDFDocument528 pagesNR467 B1 2018-07 PDFFlorencia CurettiNo ratings yet

- 3rd Paper Shallow Water Effect On Turning Motion of A Pusher Barge System Aphydro 2008Document8 pages3rd Paper Shallow Water Effect On Turning Motion of A Pusher Barge System Aphydro 2008kostas.michaNo ratings yet

- NUMECA CorporateDocument19 pagesNUMECA CorporateAji PurwantoNo ratings yet

- MARS2000 Memo CSR-H AssessmentDocument19 pagesMARS2000 Memo CSR-H Assessmentsipasit1518No ratings yet

- Tugas 2 Tebal Plat (BKI 2006)Document43 pagesTugas 2 Tebal Plat (BKI 2006)HikmahsusetyoNo ratings yet

- Fiberseal Felts and Blankets - HIGH-TEMPERATURE INSULATING MATERIALSDocument2 pagesFiberseal Felts and Blankets - HIGH-TEMPERATURE INSULATING MATERIALSEzequiel BonaniNo ratings yet

- Angle Steeldata PDFDocument2 pagesAngle Steeldata PDFRaj P. AbhaleNo ratings yet

- 5.1 Group - T Scantling Calculation Through Iso 2001Document173 pages5.1 Group - T Scantling Calculation Through Iso 2001Abdul KaderNo ratings yet

- SkyCiv Structural 3D ReportDocument15 pagesSkyCiv Structural 3D ReportAlexandreNo ratings yet

- Final Design Ship Dimensions - GilFillan - 1Document9 pagesFinal Design Ship Dimensions - GilFillan - 1Vivek SambangiNo ratings yet

- Experimental Setup: Moses: 1 Step by Step InstallationDocument9 pagesExperimental Setup: Moses: 1 Step by Step InstallationsrNo ratings yet

- Ship Design From SeriesDocument2 pagesShip Design From SeriesChitraSKNo ratings yet

- Fifty Years of The Gawn-Burrill Kca Propeller SeriesDocument11 pagesFifty Years of The Gawn-Burrill Kca Propeller Seriesoceanmaster66No ratings yet

- Iso 12217-1 Calculation Worksheet No. 9 SummaryDocument2 pagesIso 12217-1 Calculation Worksheet No. 9 Summaryyunus ahmet ilhanNo ratings yet

- Anchor Chain Locker Volume CalculationDocument1 pageAnchor Chain Locker Volume Calculationbasant_konatNo ratings yet

- 7f154160665ca8f29db6fb0a592a4b11Document114 pages7f154160665ca8f29db6fb0a592a4b11Mohammed JassimNo ratings yet

- Engine Girder CalculationsDocument1 pageEngine Girder CalculationsEko PrasetiyoNo ratings yet

- 678 TF Combo Bag E4Document2 pages678 TF Combo Bag E4MeteusNo ratings yet

- STAAD - Bending Moment in Plate Elements - Structural Analysis and Design - Forum - Structural Analysis and Design - Bentley CommunitiesDocument9 pagesSTAAD - Bending Moment in Plate Elements - Structural Analysis and Design - Forum - Structural Analysis and Design - Bentley Communitiessom_bs79No ratings yet

- 02 Chopped Strand Mat Emc300Document2 pages02 Chopped Strand Mat Emc300Carlos AlvaNo ratings yet

- Wrinkling of Sandwich PanelsDocument34 pagesWrinkling of Sandwich PanelsAnonymous hprsT3WlPNo ratings yet

- TND CalculationsDocument245 pagesTND Calculations謝明成No ratings yet

- Full Length Research Article: ISSN: 2230-9926Document9 pagesFull Length Research Article: ISSN: 2230-9926Somayeh Zaminpira100% (1)

- Blog Mechguru Com Machine Design Example of Concrete Anchor Bolt Design Calculation Part 6 Determining Concrete Breakout Strength of Anchor in ShearDocument7 pagesBlog Mechguru Com Machine Design Example of Concrete Anchor Bolt Design Calculation Part 6 Determining Concrete Breakout Strength of Anchor in ShearJoel TanNo ratings yet

- Section Modulus 012004Document2 pagesSection Modulus 012004Adarsh D. KarkiNo ratings yet

- Hull Structural Design Ships PDFDocument109 pagesHull Structural Design Ships PDFJosua MartinezNo ratings yet

- Section Modulus DrawingDocument6 pagesSection Modulus DrawingDominic VillamanteNo ratings yet

- 12 Men GRP BoatDocument4 pages12 Men GRP BoatM. R. Shahnawaz KhanNo ratings yet

- Nav Cad 2007 Demo GuideDocument21 pagesNav Cad 2007 Demo GuideMohd NyxamNo ratings yet

- HydromaxManual 1Document200 pagesHydromaxManual 1Aldy sabat TindaonNo ratings yet

- Ship StructureDocument9 pagesShip StructureMuhammad OsvaldoNo ratings yet

- Angle of Deck Edge ImmersionDocument1 pageAngle of Deck Edge ImmersionyuniardimzNo ratings yet

- Scantling Hull Girder StrengthDocument57 pagesScantling Hull Girder Strengthgelo_17No ratings yet

- Test Ii: WPA Volume Mid Area LWLDocument9 pagesTest Ii: WPA Volume Mid Area LWLMark Lester AndayaNo ratings yet

- Inflatable SailboatDocument9 pagesInflatable SailboatSorin DirjanNo ratings yet

- Volcanic Alliance Bro 200311 PDFDocument4 pagesVolcanic Alliance Bro 200311 PDFRexx MexxNo ratings yet

- Numeca Russia User Meeting 2011Document31 pagesNumeca Russia User Meeting 2011PirouzNo ratings yet

- GasAlertMicroClip User ManualDocument68 pagesGasAlertMicroClip User ManualJay Van BuurninkNo ratings yet

- 12217-1 Worksheet 1-2-3-4-5Document7 pages12217-1 Worksheet 1-2-3-4-5yunus ahmet ilhanNo ratings yet

- NAME 238 Ships Hyrostatic and StabilityDocument25 pagesNAME 238 Ships Hyrostatic and StabilityAshifur RahamanNo ratings yet

- Vibradamp DC30 122IPMDocument3 pagesVibradamp DC30 122IPMtrublu260112No ratings yet

- MV AzzirDocument106 pagesMV AzzirDominic VillamanteNo ratings yet

- 17512065laporan Analisis Perhitungan OttvDocument21 pages17512065laporan Analisis Perhitungan OttvQaedi ZihniNo ratings yet

- Trubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListDocument2 pagesTrubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListVratislav Němec ml.No ratings yet

- NortelDocument3 pagesNortelMarkNo ratings yet

- MatekDocument4 pagesMatekSigit Ayyu's PrabowoNo ratings yet

- Designed Date Details Checked Title DocnoDocument4 pagesDesigned Date Details Checked Title DocnovivekNo ratings yet

- To FrameDocument5 pagesTo FrameMuhaimin RohizanNo ratings yet

- Thick Film Chip Resistors: FeatureDocument3 pagesThick Film Chip Resistors: Featurecodap90056No ratings yet

- Formosa MS: Z110 Thru Z330Document2 pagesFormosa MS: Z110 Thru Z330Angga JuliantaraNo ratings yet

- Piles, To Batter or Not To BatterDocument5 pagesPiles, To Batter or Not To BatterpelotoNo ratings yet

- Pipe Flow Friction Factor CalculationsDocument13 pagesPipe Flow Friction Factor CalculationspelotoNo ratings yet

- Circ Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationDocument10 pagesCirc Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationpelotoNo ratings yet

- Inclined Piles - Advantages and Drawbacks of Its Use in Seismically Active RegionsDocument14 pagesInclined Piles - Advantages and Drawbacks of Its Use in Seismically Active RegionspelotoNo ratings yet

- H2S - Radio de Exposicion - Rev JMV - 25-05-2012Document10 pagesH2S - Radio de Exposicion - Rev JMV - 25-05-2012pelotoNo ratings yet

- Pipe Distributor Sizing Calculations - 07-08-2013Document26 pagesPipe Distributor Sizing Calculations - 07-08-2013pelotoNo ratings yet

- HYDRANT System Demand: Full Unit: Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemDocument4 pagesHYDRANT System Demand: Full Unit: Fire Water Demand Calculation For SUG Facilities Fire Fighting SystempelotoNo ratings yet

- ANSI Standard Pipe Data Chart - Rev 01 JMV - 03-08-18Document6 pagesANSI Standard Pipe Data Chart - Rev 01 JMV - 03-08-18pelotoNo ratings yet

- ASME B31G-1991 Corrosion Analysis: InformationDocument1 pageASME B31G-1991 Corrosion Analysis: InformationpelotoNo ratings yet

- AISC Properties Viewer - JMVDocument3 pagesAISC Properties Viewer - JMVpelotoNo ratings yet

- Engineering Useful FormulasDocument221 pagesEngineering Useful FormulaspelotoNo ratings yet

- Steel Joists - JMVDocument5 pagesSteel Joists - JMVpelotoNo ratings yet

- Bolt Torque Calculators: Bolt Diameter (D) Thread (T.P.I.) Yield Strength (Sy) Joint Type (P) Nut Factor (K)Document4 pagesBolt Torque Calculators: Bolt Diameter (D) Thread (T.P.I.) Yield Strength (Sy) Joint Type (P) Nut Factor (K)pelotoNo ratings yet

- API 650, 5.6.4, Calculation of Shell Thickness by The 1-Foot MethodDocument13 pagesAPI 650, 5.6.4, Calculation of Shell Thickness by The 1-Foot MethodpelotoNo ratings yet

- API 579-1 - Fitness-For Service Assessment - Rev JMV 05-11-2018Document13 pagesAPI 579-1 - Fitness-For Service Assessment - Rev JMV 05-11-2018pelotoNo ratings yet

- Allowable Stress in PipingDocument6 pagesAllowable Stress in PipingpelotoNo ratings yet

- API RP 1102 - Highways AnalysisDocument62 pagesAPI RP 1102 - Highways Analysispeloto100% (1)

- API 510 - Corrosion Rate and Remaining Life Calculations - Rev JMV 05-11-2018Document4 pagesAPI 510 - Corrosion Rate and Remaining Life Calculations - Rev JMV 05-11-2018pelotoNo ratings yet

- English Gs Book July MonthDocument80 pagesEnglish Gs Book July MonthMadhab PatowaryNo ratings yet

- Physics Education Thesis TopicsDocument4 pagesPhysics Education Thesis TopicsPaperWriterServicesCanada100% (2)

- Typical Details of Switchyard RequirementDocument364 pagesTypical Details of Switchyard RequirementEspro100% (1)

- Pdms 12 HvacDocument4 pagesPdms 12 HvacsadeghmsgNo ratings yet

- Bed Ict 3rd Year Revised Note For e LearningDocument12 pagesBed Ict 3rd Year Revised Note For e Learningsanjeev_999bhan100% (1)

- Hizon, Czarina May CVDocument3 pagesHizon, Czarina May CVnotapernota101No ratings yet

- Zosi Wireless NVR & Monitor SystemDocument60 pagesZosi Wireless NVR & Monitor SystemJose RamirezNo ratings yet

- IELTS All 4 Tests at Méthode Barnes Anglais RecommanderDocument21 pagesIELTS All 4 Tests at Méthode Barnes Anglais Recommanderbarnes method books internationalNo ratings yet

- Tree MusuemDocument3 pagesTree Musuemsteve geocadinNo ratings yet

- Detect Me: DirectionDocument6 pagesDetect Me: DirectionMaymay Auau100% (2)

- Credit RatingDocument15 pagesCredit RatingManisha SinghNo ratings yet

- Week 10 12. ULO C. Substantive Test of Property Plant and EquipmentDocument15 pagesWeek 10 12. ULO C. Substantive Test of Property Plant and EquipmentkrizmyrelatadoNo ratings yet

- Pediatric Vestibular Disorders PDFDocument10 pagesPediatric Vestibular Disorders PDFNati GallardoNo ratings yet

- Diass Week 2Document6 pagesDiass Week 2Danica PaglinawanNo ratings yet

- Full Project ReportDocument46 pagesFull Project ReportRakeshNo ratings yet

- Series HDocument6 pagesSeries HAviation World100% (3)

- SPWLA Log IntegrationDocument14 pagesSPWLA Log IntegrationpahlawankemalemanNo ratings yet

- Waterstop Catalog 0411Document12 pagesWaterstop Catalog 0411hks1209No ratings yet

- Format For THC 10 10 10 10 Siomairice Sa SarapDocument24 pagesFormat For THC 10 10 10 10 Siomairice Sa SarapFrost ByteNo ratings yet

- AlansDocument14 pagesAlansAnonymous 3Y1ZnENo ratings yet

- 1672298032245-ICE CE-29 - RevisionDocument86 pages1672298032245-ICE CE-29 - RevisionSoumyaranjan NayakNo ratings yet

- Create Request For QuotationDocument18 pagesCreate Request For QuotationAdauto PolizeliNo ratings yet

- C Program To Store Records of Students in An ArrayDocument5 pagesC Program To Store Records of Students in An ArrayAsh RafNo ratings yet

- Army Aviation Digest - Jan 1982Document52 pagesArmy Aviation Digest - Jan 1982Aviation/Space History LibraryNo ratings yet

- Ixys P-Channel Power Mosfets and Applications Abdus Sattar, Kyoung-Wook Seok, Ixan0064Document14 pagesIxys P-Channel Power Mosfets and Applications Abdus Sattar, Kyoung-Wook Seok, Ixan0064Kikuvi JohnNo ratings yet