Professional Documents

Culture Documents

Document List-Factory Certifications, Test Reports, Licenses

Document List-Factory Certifications, Test Reports, Licenses

Uploaded by

Sudeesha Wenura Bandara0 ratings0% found this document useful (0 votes)

56 views2 pagesThis document lists various factory certifications, test reports, and licenses that are reviewed, along with notes on their availability. It covers waste and emissions testing, noise monitoring, fire safety certifications, competency certifications for various roles, boiler and lift inspections, electrical and thermographic testing, risk assessments, fire safety inspections, environmental monitoring, lighting and dust levels, workplace conditions, noise and lung function tests, and drinking water quality checks. Records of these tests and inspections are maintained.

Original Description:

Original Title

Document List-Factory certifications,Test reports,Licenses

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document lists various factory certifications, test reports, and licenses that are reviewed, along with notes on their availability. It covers waste and emissions testing, noise monitoring, fire safety certifications, competency certifications for various roles, boiler and lift inspections, electrical and thermographic testing, risk assessments, fire safety inspections, environmental monitoring, lighting and dust levels, workplace conditions, noise and lung function tests, and drinking water quality checks. Records of these tests and inspections are maintained.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

56 views2 pagesDocument List-Factory Certifications, Test Reports, Licenses

Document List-Factory Certifications, Test Reports, Licenses

Uploaded by

Sudeesha Wenura BandaraThis document lists various factory certifications, test reports, and licenses that are reviewed, along with notes on their availability. It covers waste and emissions testing, noise monitoring, fire safety certifications, competency certifications for various roles, boiler and lift inspections, electrical and thermographic testing, risk assessments, fire safety inspections, environmental monitoring, lighting and dust levels, workplace conditions, noise and lung function tests, and drinking water quality checks. Records of these tests and inspections are maintained.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

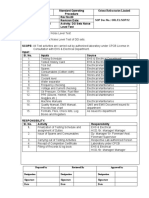

Factory certifications,Test reports,Licenses

List of Documents reviewed / Copied Y N N/A Remarks

Waste water is tested quarterly and records

2.01

available

Stack emissions is measured annually and

2.02

records available including local standards

Boundary Noise level measured annually and

2.03

records available

Annual Fire Clearance Certificate available and

2.04

in file.

Competency certifications/credentials for

2.05

Welders

Competency certifications/credentials for

2.06

Electricians

2.07 Competency certifications for Boiler Operators

Competency Certifications for Fork lift

2.08

Operators

Steam boiler certificate by the Factory

2.09

Inspecting Engineer / Chartered Engineer

Air receiver certificate by the Factory

2.10

Inspecting Engineer / Chartered Engineer

Lifts carrying goods (Hoist) are checked by the

2.11 Factory Inspecting Engineer / Chartered

Engineer

Inspection records for passenger lifts are

2.12

maintained.

2.13 Annual Electrical Safety Test conducted

2.14 Thermographic survey is conducted.

Has the factory conducted a professional

2.15 building structure safety assessment?

Assesment must be currently valid.

General Risk assessment cover all departments

and processes, is done annually either

internally or by a 3rd party specialist and

2.16

specific risk assessments are being updated

when changes to processes, equipment etc. has

been made. Records are maintained.

Does management commission fire risk

assessment by a third-party expert?Are fire

2.17

risks assessment results considered and

addressed properly?

Factory Conditions checked in every 6 months

2.18

(PHI Report)

Air quality / Ventilation reports are compliant /

2.19

recommended action taken

Lighting reports (Levels are as per ILO

2.20 requirements/ Customer standards) are

compliant / recommended action taken

Dust level reports compliant / recommended

2.21

action has been taken

Comfortable and safe working conditions are

2.22 provided within the following ambient

temperature ranges: 20°C to 28°C

Noise tests done / hazards identified &

2.23

recommended action taken

Lung functionality tests done where applicable

2.24

(High chemical expose areas).

If an employee works in an environment that is

louder than 85dB TWA, then he/she has had an

2.25

audiometric test during the first 6 months of

noise exposure and annually thereafter

Drinking water is tested once a month

2.26 (microbiological) / quarterly (chemical

analysis)

You might also like

- Buildings and Facilities Hand Over Take Over Plan TemplateDocument7 pagesBuildings and Facilities Hand Over Take Over Plan TemplateKrupa Kavach Mehta82% (11)

- 01-CTPAT Security Questionnaire PDFDocument8 pages01-CTPAT Security Questionnaire PDFSudeesha Wenura Bandara100% (1)

- Manuals Specifications Glossary November 2016Document285 pagesManuals Specifications Glossary November 2016Sunil BhoriaNo ratings yet

- Buildings and Facilities Hand Over Take Over Plan TemplateDocument7 pagesBuildings and Facilities Hand Over Take Over Plan TemplateMai Tuan Anh100% (1)

- Line Pipes Factory Acceptance Test ChecklistDocument1 pageLine Pipes Factory Acceptance Test ChecklistIdaba100% (3)

- PESTLE Analysis of NikeDocument2 pagesPESTLE Analysis of Nikevivi_15o689_1127231533% (6)

- Wandfluh Quality Assessment Report CH SEV QAR 16.0001 02 PDFDocument40 pagesWandfluh Quality Assessment Report CH SEV QAR 16.0001 02 PDFNabi HasanNo ratings yet

- Global Organic Content Standard Checklist PDFDocument4 pagesGlobal Organic Content Standard Checklist PDFSultanNo ratings yet

- Nonmetal Ducts - Guide Specification - Updated 6-2019Document17 pagesNonmetal Ducts - Guide Specification - Updated 6-2019abdullah amanullahNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- All Check List SafetyDocument5 pagesAll Check List SafetynormalNo ratings yet

- 5.16.1.c Safety Engineer Monthly Inspection ReportDocument8 pages5.16.1.c Safety Engineer Monthly Inspection ReportTayib JabbarNo ratings yet

- F 05 KDI QHSE 17a Environmental Inspection ChecklistDocument4 pagesF 05 KDI QHSE 17a Environmental Inspection ChecklistArsh AlamNo ratings yet

- 16 ZUL 9600019687 00 IZ5 PDFDocument14 pages16 ZUL 9600019687 00 IZ5 PDFLizbeth de la CruzNo ratings yet

- Open House 5Document4 pagesOpen House 5Edin ZahirovićNo ratings yet

- 23 05 19 - Meters and Gauges For Hvac SystemDocument13 pages23 05 19 - Meters and Gauges For Hvac Systemmd zubairNo ratings yet

- QAP - Gate Valve - NPCILDocument6 pagesQAP - Gate Valve - NPCILkaustavNo ratings yet

- Format PQ WHODocument6 pagesFormat PQ WHODono WayNo ratings yet

- PRES-E-04 Electrical Equipment - Oil & TransformerDocument2 pagesPRES-E-04 Electrical Equipment - Oil & TransformersalamlinNo ratings yet

- IRT Report FormatDocument7 pagesIRT Report Formatshahbaz akramNo ratings yet

- Safety and Pollution Control in Chemical Industry Course Code: 4340504Document11 pagesSafety and Pollution Control in Chemical Industry Course Code: 4340504ritikmachhi7No ratings yet

- Medb00004x5 2Document7 pagesMedb00004x5 2DriptoNo ratings yet

- Qualisteelcoat Technical Specifications Version21 31102013Document64 pagesQualisteelcoat Technical Specifications Version21 31102013Dino PedutoNo ratings yet

- Standard: FOR Commercial Interiors V2.0Document34 pagesStandard: FOR Commercial Interiors V2.0Sarthak ShuklaNo ratings yet

- BREEAM 2011 - Thermal ImagingDocument14 pagesBREEAM 2011 - Thermal ImagingnhnamNo ratings yet

- Checklist For Auditors Application2Document2 pagesChecklist For Auditors Application2JigneshBrahmbhattNo ratings yet

- AC7102 Rev K For Use On Audits On or After 15-Aug-2021Document101 pagesAC7102 Rev K For Use On Audits On or After 15-Aug-2021Agus MulyadiNo ratings yet

- Documents Checklist For Ocs & Gots 2020.01.01Document4 pagesDocuments Checklist For Ocs & Gots 2020.01.01Sultan100% (1)

- Construction SpecificationsDocument16 pagesConstruction SpecificationsTAHER AMMARNo ratings yet

- Substantial Completion ChecklistDocument2 pagesSubstantial Completion ChecklistMikeNo ratings yet

- (A) Specifications For Temperature and Humidity Chamber (Volume - 250 Liters)Document21 pages(A) Specifications For Temperature and Humidity Chamber (Volume - 250 Liters)pranavNo ratings yet

- PRES-E-01 Electrical EquipmentDocument2 pagesPRES-E-01 Electrical EquipmentsalamlinNo ratings yet

- Certificates and Test Reports DPV Pumps and Booster SystemsDocument40 pagesCertificates and Test Reports DPV Pumps and Booster SystemsAYTACNo ratings yet

- Inspection Certificates 3.1 and 2.2Document2 pagesInspection Certificates 3.1 and 2.2BE GNo ratings yet

- Supporting Guidance (WAT-SG-85) : Application of Standards To Thermal DischargesDocument10 pagesSupporting Guidance (WAT-SG-85) : Application of Standards To Thermal DischargesSyllogos KireasNo ratings yet

- Thermal Power Plant - General Technical RequirementsDocument59 pagesThermal Power Plant - General Technical RequirementsScribd_delNo ratings yet

- R08-He2se Hotel2-Keo-Spc-Su-00Document46 pagesR08-He2se Hotel2-Keo-Spc-Su-00moh amohNo ratings yet

- 10/01/2011 Project Name Testing, Adjusting, and Balancing For Hvac School Name 01 4525-1Document26 pages10/01/2011 Project Name Testing, Adjusting, and Balancing For Hvac School Name 01 4525-1Santhosh KumarNo ratings yet

- Miljöbyggnad 3.0 Nyproduktion ENDocument76 pagesMiljöbyggnad 3.0 Nyproduktion ENSabir AbdelhalimNo ratings yet

- Page 6 - Eurovent Ducted FCU - RS-6C002A-2017 v2Document1 pagePage 6 - Eurovent Ducted FCU - RS-6C002A-2017 v2SithuNo ratings yet

- Ju 001 06 Aus 0000 00 1a 0203B - 0Document57 pagesJu 001 06 Aus 0000 00 1a 0203B - 0aach17No ratings yet

- AC7102 - Rev - K - For - Use - On - Audits - On - or - After - 15-Aug-2021 (Main Induction Furnace) AUDIT SHEET 42CRMO4Document111 pagesAC7102 - Rev - K - For - Use - On - Audits - On - or - After - 15-Aug-2021 (Main Induction Furnace) AUDIT SHEET 42CRMO4amit gajbhiyeNo ratings yet

- Summary Temuan Minor Audit Resertifikasi ISO Tahun 2022 (MTC) Add EvidenceDocument13 pagesSummary Temuan Minor Audit Resertifikasi ISO Tahun 2022 (MTC) Add EvidenceReza SyailendraNo ratings yet

- Qa Templates For Electrical Construction StandardsDocument11 pagesQa Templates For Electrical Construction Standardscaleb isukuruNo ratings yet

- Indoor Air Quality Assessment - Canada PDFDocument39 pagesIndoor Air Quality Assessment - Canada PDFIbrahim SyedNo ratings yet

- Audit Checklist Blasting PaintingDocument4 pagesAudit Checklist Blasting PaintingEyoh EffiongNo ratings yet

- Guidelines For Fouling FactorsDocument8 pagesGuidelines For Fouling Factorsrajat vermaNo ratings yet

- Works Masterspec 221500Document9 pagesWorks Masterspec 221500Paolo BorlonganNo ratings yet

- ARI Guide Line 97 For Fouling Factor ApplicationsDocument8 pagesARI Guide Line 97 For Fouling Factor ApplicationsNour Saad EdweekNo ratings yet

- Inspection ProcedureDocument13 pagesInspection ProcedureSantosh Kumar100% (1)

- Works Masterspec 230594Document5 pagesWorks Masterspec 230594Joshua FernandezNo ratings yet

- Himedic Pharmaceutical (PVT) Ltd. Lahore: Qualification & ValidationDocument33 pagesHimedic Pharmaceutical (PVT) Ltd. Lahore: Qualification & Validationumair khan100% (1)

- Design Reference Guide: Existing Non-Residential BuildingDocument76 pagesDesign Reference Guide: Existing Non-Residential BuildingKoo Cheng KongNo ratings yet

- Procedure For Application of Decision RuleDocument4 pagesProcedure For Application of Decision RuleTariq AslamNo ratings yet

- SOP Noise Testing of DG SetsDocument2 pagesSOP Noise Testing of DG SetsPandu Birumakovela100% (1)

- QDRECL03003 Document and Record Storage Retention and Disposal ProcedureDocument4 pagesQDRECL03003 Document and Record Storage Retention and Disposal ProcedureAmrish KambojNo ratings yet

- Checklist For 5-Star Safety Documentation-SOADocument15 pagesChecklist For 5-Star Safety Documentation-SOAYASIRNo ratings yet

- Carbon Footprint Calculation Ed 4 ENG - v2Document13 pagesCarbon Footprint Calculation Ed 4 ENG - v2trader123No ratings yet

- 7 Mechanical Services Including Duct FixingDocument2 pages7 Mechanical Services Including Duct FixingAhmad Farhad MadaniNo ratings yet

- Design Review Checklist: Heating, Ventilating, and Air ConditioningDocument13 pagesDesign Review Checklist: Heating, Ventilating, and Air ConditioningZineddine AlicheNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Guidelines for Laboratory Design: Health, Safety, and Environmental ConsiderationsFrom EverandGuidelines for Laboratory Design: Health, Safety, and Environmental ConsiderationsNo ratings yet

- Circle With Diagonal BarDocument13 pagesCircle With Diagonal BarSudeesha Wenura BandaraNo ratings yet

- Nurse ProcessDocument7 pagesNurse ProcessSudeesha Wenura BandaraNo ratings yet

- Environment, Health and Safety Committee: MembershipDocument2 pagesEnvironment, Health and Safety Committee: MembershipSudeesha Wenura BandaraNo ratings yet

- The Employers' Federation of Ceylon: EFC@empfed - LKDocument6 pagesThe Employers' Federation of Ceylon: EFC@empfed - LKSudeesha Wenura BandaraNo ratings yet

- ZCZCZDocument1 pageZCZCZSudeesha Wenura BandaraNo ratings yet

- Developing Crisis Management Plan enDocument23 pagesDeveloping Crisis Management Plan enSudeesha Wenura BandaraNo ratings yet

- 01 - Cutting RADocument3 pages01 - Cutting RASudeesha Wenura BandaraNo ratings yet

- LifrsDocument1 pageLifrsSudeesha Wenura BandaraNo ratings yet

- I Am The Master of My ThoughtsDocument2 pagesI Am The Master of My ThoughtsSudeesha Wenura BandaraNo ratings yet

- Digital EntrepreneurshipDocument25 pagesDigital EntrepreneurshipSudeesha Wenura BandaraNo ratings yet

- Pay Advice For The Month of June 2019: Total Basic SalaryDocument1 pagePay Advice For The Month of June 2019: Total Basic SalarySudeesha Wenura BandaraNo ratings yet

- Problem Brake DownDocument9 pagesProblem Brake DownSudeesha Wenura BandaraNo ratings yet

- Avarage Smo Carder 2015Document1 pageAvarage Smo Carder 2015Sudeesha Wenura BandaraNo ratings yet

- CTPAT QuestionnaireDocument2 pagesCTPAT QuestionnaireSudeesha Wenura BandaraNo ratings yet

- CARTON LABELING REQUIREMENTS OVERVIEW (See Vendor Handbook For Specific Detail)Document1 pageCARTON LABELING REQUIREMENTS OVERVIEW (See Vendor Handbook For Specific Detail)Sudeesha Wenura BandaraNo ratings yet

- Party GMPDocument2 pagesParty GMPSudeesha Wenura BandaraNo ratings yet

- Lay Sheet: Fabric SwatchDocument1 pageLay Sheet: Fabric SwatchSudeesha Wenura BandaraNo ratings yet

- International Operational Strategy and InnovationDocument17 pagesInternational Operational Strategy and InnovationArka SamNo ratings yet

- Bus Eth 12.1Document6 pagesBus Eth 12.1Lia PalmaNo ratings yet

- Cleanroom Ensures Product Quality: Source: DIN EN ISO 14644-1:2016-06Document9 pagesCleanroom Ensures Product Quality: Source: DIN EN ISO 14644-1:2016-06Kritarth JaiswalNo ratings yet

- Towards Green Loyalty The Influences of Green PercDocument7 pagesTowards Green Loyalty The Influences of Green Percyusuf kurniawanNo ratings yet

- Com2601 PortfolioDocument15 pagesCom2601 Portfolioxoliswa mandisa dlamini100% (1)

- Q1 W3 Mod3 TheFirmItsEnvironmentDocument8 pagesQ1 W3 Mod3 TheFirmItsEnvironmentCharlene EsparciaNo ratings yet

- National Circular Economy Framework CompressedDocument59 pagesNational Circular Economy Framework Compressedsunshine7883No ratings yet

- Mgbform6 2Document3 pagesMgbform6 2Gayle BrigoleNo ratings yet

- Well CommunitiesDocument2 pagesWell CommunitiesZainab KhadimNo ratings yet

- PACTIO E Project BriefDocument5 pagesPACTIO E Project BriefVivek SivadasNo ratings yet

- ETP P&ID - Final Approved PIDsDocument16 pagesETP P&ID - Final Approved PIDsraaj bharathNo ratings yet

- Sustainability Reporting Guide 2022 - FINALDocument156 pagesSustainability Reporting Guide 2022 - FINALBW KNo ratings yet

- RT Confined Spaces StandardDocument3 pagesRT Confined Spaces StandardJohn KalvinNo ratings yet

- Rangkuman Ibm What Is CommunicationDocument5 pagesRangkuman Ibm What Is CommunicationVittorio ZuardiNo ratings yet

- Volvo L150F, L180F, L220F Recycling ManualDocument25 pagesVolvo L150F, L180F, L220F Recycling ManualJeremie NshimbiNo ratings yet

- Environmental Sustainability and Financial Performance of SmesDocument47 pagesEnvironmental Sustainability and Financial Performance of SmesMuhammadUmarNazirChishtiNo ratings yet

- Egcb TorDocument5 pagesEgcb Torrajib0403050cuetNo ratings yet

- Concept of Sustainable Development: DR Shafiq QurbanDocument49 pagesConcept of Sustainable Development: DR Shafiq QurbanJennifer ZeNo ratings yet

- Coretan Koreksi Rekap Cuti Cam - PWMDocument12 pagesCoretan Koreksi Rekap Cuti Cam - PWMdede yusufNo ratings yet

- Sustainability Approach With Digital Construction-Amy R. WidyastutiDocument28 pagesSustainability Approach With Digital Construction-Amy R. WidyastutiRevi AdikharismaNo ratings yet

- 202030060615935135021.1AnnexureA-BCMMIDPReview2020 2021FINAL20JUNE2020Document584 pages202030060615935135021.1AnnexureA-BCMMIDPReview2020 2021FINAL20JUNE2020IQaba DyosiNo ratings yet

- Tourism Impacts On Dubai - Positive & Negative - 2078 Words - Essay ExampleDocument4 pagesTourism Impacts On Dubai - Positive & Negative - 2078 Words - Essay ExampleMARSHILAKUMINNo ratings yet

- Exxonmobil Case StudyDocument10 pagesExxonmobil Case StudyMIJONo ratings yet

- Paper Mill ThesisDocument5 pagesPaper Mill Thesisafktlrreerdihj100% (2)

- Starbucks' Mission: Social Responsibility and Brand StrengthDocument3 pagesStarbucks' Mission: Social Responsibility and Brand StrengthKAYE JAVELLANA50% (2)

- University of Mauritius University of Mauritius University of Mauritius University of MauritiusDocument3 pagesUniversity of Mauritius University of Mauritius University of Mauritius University of MauritiusAtish KissoonNo ratings yet

- 3M: Innovation, Ideas, and Solution For A Modern WorldDocument2 pages3M: Innovation, Ideas, and Solution For A Modern WorldAiko GerongNo ratings yet

- Ey Esg Megatrends and Opportunities Shaping Future Report - v2Document29 pagesEy Esg Megatrends and Opportunities Shaping Future Report - v2lewi251202No ratings yet