Professional Documents

Culture Documents

Marine Operation and Maintenance Manual

Marine Operation and Maintenance Manual

Uploaded by

Moch ImronCopyright:

Available Formats

You might also like

- K19 Industrial and Marine Operation and Maintenance Manual - Maintenance Schedule FullDocument13 pagesK19 Industrial and Marine Operation and Maintenance Manual - Maintenance Schedule FullLeandro Mauricio100% (3)

- QSK78 Owners Manual PDFDocument17 pagesQSK78 Owners Manual PDFjengandxb100% (2)

- Cummins K-Series Engine Schedule MaintenanceDocument31 pagesCummins K-Series Engine Schedule Maintenancenagari Power100% (5)

- CAT G3500 Gas Engine Maintenance ScheduleDocument3 pagesCAT G3500 Gas Engine Maintenance ScheduleQaiser Iqbal67% (6)

- Escorts Construction Equipment: Hydra-14 - HDDocument265 pagesEscorts Construction Equipment: Hydra-14 - HDMM Spares67% (3)

- SUZUKI DF200 225 250 Service Man 2Document49 pagesSUZUKI DF200 225 250 Service Man 2Candido IsazaNo ratings yet

- Diesel Engine Maintenance ChecklistDocument6 pagesDiesel Engine Maintenance Checklistjohnnybe5180% (5)

- D6RDocument8 pagesD6RHelar W. Cutipa MachacaNo ratings yet

- LandRover Discovery Service SheetDocument2 pagesLandRover Discovery Service Sheetmichkapp50% (2)

- KTA 50 Maintenance ScheduleDocument32 pagesKTA 50 Maintenance ScheduleIsmail AlsaadNo ratings yet

- Maintenance Schedule 20 Juil 09Document15 pagesMaintenance Schedule 20 Juil 09MussardNo ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument4 pagesMaintenance Interval Schedule: Operation and Maintenance ManualKJDNKJZEFNo ratings yet

- d11t Manual de MantenimientoDocument4 pagesd11t Manual de MantenimientoAnonymous SpT4OHYMyNo ratings yet

- Recommended Maintenance ScheduleDocument50 pagesRecommended Maintenance ScheduleSpectrumRaijinNo ratings yet

- Pms ReportDocument327 pagesPms ReportalsitorNo ratings yet

- Preventeve Maintenance ProgramDocument4 pagesPreventeve Maintenance ProgramAHMADNo ratings yet

- Maintenance Intervals (16-2523C)Document4 pagesMaintenance Intervals (16-2523C)HassanSadiq100% (1)

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFDocument4 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFSaid FahmiNo ratings yet

- Cummins K19 Maintainence ScheduleDocument13 pagesCummins K19 Maintainence Schedulesxturbo100% (1)

- C32 Service InformationDocument11 pagesC32 Service InformationErissonNo ratings yet

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDocument11 pagesDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshNo ratings yet

- Interval Service CB24Document4 pagesInterval Service CB24Alvaro Jose Peñata GiraldoNo ratings yet

- Marine and Industrial qsk60Document10 pagesMarine and Industrial qsk60Muhammad IshfaqNo ratings yet

- Power Unit MaintenanceDocument11 pagesPower Unit MaintenanceAzlan RafiqueNo ratings yet

- Gas Genset Maintenance ScheduleDocument3 pagesGas Genset Maintenance ScheduleMutahirrasoolNo ratings yet

- Maintenace Intervale Schedule 980HDocument5 pagesMaintenace Intervale Schedule 980HAlberto BastidasNo ratings yet

- Type Iii Test: Description of The Ageing Test For Verifying The Durability of Anti Pollution Devices From 2/3 WheelersDocument10 pagesType Iii Test: Description of The Ageing Test For Verifying The Durability of Anti Pollution Devices From 2/3 WheelersBikash Kumar MallickNo ratings yet

- QSK23 Maintenance Schedule 102-002Document7 pagesQSK23 Maintenance Schedule 102-002Marino MatevskiNo ratings yet

- Maintenance Intervals: When RequiredDocument3 pagesMaintenance Intervals: When RequiredSain MezaNo ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument3 pagesMaintenance Interval Schedule: Operation and Maintenance ManualsxturboNo ratings yet

- 160M Maintenance IntervalDocument3 pages160M Maintenance IntervalJoko WahonoNo ratings yet

- Maintenance Interval Schedule: SMCS Code: 7000Document4 pagesMaintenance Interval Schedule: SMCS Code: 7000wilbert tapia maqueraNo ratings yet

- PM 250 3306BDocument3 pagesPM 250 3306BGregk DirgantaraNo ratings yet

- Compresor Tuflo 550Document6 pagesCompresor Tuflo 550Ramón José Aponte FrancoNo ratings yet

- General Information: Industrial EnginesDocument17 pagesGeneral Information: Industrial EnginesjengandxbNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- Maintenance Interval Schedule D9Document3 pagesMaintenance Interval Schedule D9oki brownnesNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument3 pagesMaintenance Interval Schedule: When Requiredsxturbo100% (1)

- 2009-07-25 203857 3408 Marine OverhaulDocument5 pages2009-07-25 203857 3408 Marine OverhaulRuth RuizNo ratings yet

- 0 Calendrier D'entretienDocument4 pages0 Calendrier D'entretienkebbabi abdelhamidNo ratings yet

- Experiment 1Document10 pagesExperiment 1Shweta YadavNo ratings yet

- Experiment 2Document21 pagesExperiment 2Shweta YadavNo ratings yet

- 3512B SD Engines Maintenance IntervalsDocument4 pages3512B SD Engines Maintenance Intervalsharikrishnanpd3327No ratings yet

- Service Programme Backhoe Loaders: Construction EquipmentDocument5 pagesService Programme Backhoe Loaders: Construction EquipmentMACHINERY101GEARNo ratings yet

- Lubrication and MaintenanceDocument18 pagesLubrication and MaintenanceRamon AcostaNo ratings yet

- Service Bulletin: TitleDocument13 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Maintenance ScheduleDocument8 pagesMaintenance ScheduleWaleed OmdaNo ratings yet

- Scheduling A Top End OverhaulDocument3 pagesScheduling A Top End OverhaulVictor NunezNo ratings yet

- OMM-Maintenance Interval Schedule - Prime (SEBU9019-22)Document4 pagesOMM-Maintenance Interval Schedule - Prime (SEBU9019-22)AnggoroNo ratings yet

- Cummins Om ManualDocument2 pagesCummins Om ManualVellai Pandi PNo ratings yet

- D6R Maintenance Interval ScheduleDocument12 pagesD6R Maintenance Interval Schedulepedro sanchezNo ratings yet

- Intervalos de Matenimiento Cat 320dDocument5 pagesIntervalos de Matenimiento Cat 320dMaurizio Rodriguez PeñaNo ratings yet

- Piper Aircraft Corporation: Haven, Pennsylvania, U.S.ADocument2 pagesPiper Aircraft Corporation: Haven, Pennsylvania, U.S.AmaximeNo ratings yet

- Maintenance Interval ScheduleDocument4 pagesMaintenance Interval ScheduleYUSRO BAHRUL HADI KUSUMANo ratings yet

- Ufgs 33 08 55Document46 pagesUfgs 33 08 55Yagmur SimsekNo ratings yet

- MMS8T Crane ManualDocument19 pagesMMS8T Crane Manualkatepol8264No ratings yet

- General Information: 102-002 Maintenance ScheduleDocument10 pagesGeneral Information: 102-002 Maintenance ScheduleLaiqNo ratings yet

- C12 2KS 保养周期Document3 pagesC12 2KS 保养周期linkangjun0621No ratings yet

- Mantenimiento Lek 3500Document4 pagesMantenimiento Lek 3500Ana María AcostaNo ratings yet

- Section 5 - Maintenance Schedule and Service ProceduresDocument42 pagesSection 5 - Maintenance Schedule and Service ProceduresHipolito Caraballo100% (1)

- Technical Note: I - I - Subject: Abnormal Consumption of Engine OilDocument4 pagesTechnical Note: I - I - Subject: Abnormal Consumption of Engine Oilmebarki aberraoufNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Bosch Router 1617 EVS - Owner's ManualDocument72 pagesBosch Router 1617 EVS - Owner's ManualJennifer WatsonNo ratings yet

- Control Panel: A World of Energy SolutionsDocument11 pagesControl Panel: A World of Energy SolutionsFabian SolanoNo ratings yet

- GV 250 SM 5Document22 pagesGV 250 SM 5Fabrizio FloresNo ratings yet

- Instruction Manual - Diswasher Bosch SKS62E32EUDocument56 pagesInstruction Manual - Diswasher Bosch SKS62E32EUAudrey HernandezNo ratings yet

- Wireless Control Module (WCM) : Group 42CDocument102 pagesWireless Control Module (WCM) : Group 42CToponari MedveNo ratings yet

- Logik15: Logika Control S.R.LDocument17 pagesLogik15: Logika Control S.R.LsebastianNo ratings yet

- Faltblatt Janus-Zylinder 09-19 ENGDocument8 pagesFaltblatt Janus-Zylinder 09-19 ENGJelena GraovčevićNo ratings yet

- Photometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15Document1 pagePhotometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15emreNo ratings yet

- VLSI GTU Question Bank 2014Document4 pagesVLSI GTU Question Bank 2014Amish TankariyaNo ratings yet

- CASE 580 Super M+Document6 pagesCASE 580 Super M+Dian SikumbangNo ratings yet

- BajajDocument15 pagesBajajArief FirmantoNo ratings yet

- Decanter Centrifuge: Alfa Laval Alfa LavalDocument30 pagesDecanter Centrifuge: Alfa Laval Alfa LavalYousef AlipourNo ratings yet

- Detailed Lesson Plan in Automotive Technology - 11Document7 pagesDetailed Lesson Plan in Automotive Technology - 11Rio BesañesNo ratings yet

- C&P PTFE Slide BearingsDocument1 pageC&P PTFE Slide BearingsAchraf BoudayaNo ratings yet

- 57tw 66tw Set Instructions 0230-0369rb 1Document4 pages57tw 66tw Set Instructions 0230-0369rb 1maximo alejandro RauschenbachNo ratings yet

- Lambda Sensor LSU 4.9 Datasheet 51 en 2779147659Document4 pagesLambda Sensor LSU 4.9 Datasheet 51 en 2779147659Germán Gómez BeltránNo ratings yet

- Twido - Programmable Controller - TWDLCAE40DRFDocument3 pagesTwido - Programmable Controller - TWDLCAE40DRFLem Otarola OsorioNo ratings yet

- Thermostatic Expansion Valves Type T2 / TE2: Data SheetDocument16 pagesThermostatic Expansion Valves Type T2 / TE2: Data SheetHuynh Nhat VuNo ratings yet

- Toyota Voxy Equipment SheetDocument3 pagesToyota Voxy Equipment SheetIrsanNo ratings yet

- SIM908 Reference Design Guide Application Note V1.00Document17 pagesSIM908 Reference Design Guide Application Note V1.00jonydanceNo ratings yet

- Powerscreen Conveyor BrochureDocument5 pagesPowerscreen Conveyor BrochureDaniel BianchiniNo ratings yet

- AKG enDocument10 pagesAKG encarlosNo ratings yet

- Factors On Which Self Inductance of CoilDocument19 pagesFactors On Which Self Inductance of CoilRaj Parida80% (5)

- DC MotorsDocument2 pagesDC MotorsMeggy VillanuevaNo ratings yet

- Automatic Folding Door - GILGEN FFMDocument2 pagesAutomatic Folding Door - GILGEN FFMBochra Hkilani ZoghlamiNo ratings yet

- ANT AQU4518R4 1355 DatasheetDocument2 pagesANT AQU4518R4 1355 DatasheetJawad83% (6)

- Aft-Catalog s3 SecDocument10 pagesAft-Catalog s3 SecwemersonsrNo ratings yet

- Danfoss - B25GL - R134a - 220 - 50Document4 pagesDanfoss - B25GL - R134a - 220 - 50JahazielNo ratings yet

Marine Operation and Maintenance Manual

Marine Operation and Maintenance Manual

Uploaded by

Moch ImronOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Operation and Maintenance Manual

Marine Operation and Maintenance Manual

Uploaded by

Moch ImronCopyright:

Available Formats

(/qs3/pubsys2/xml/en/manual/4021330/4021330-titlepage.

html)

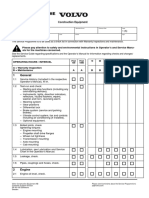

General Information

Industrial Applications

For your convenience, listed below are the section numbers that contain specific instructions

for performing the maintenance

checks listed in the maintenance schedule.

Perform maintenance at whichever interval occurs first. At each scheduled maintenance

interval, perform all previous checks

that are due for scheduled maintenance.

Maintenance Procedures at Daily Interval4 (Section 3)

Crankcase Breather Tube - Check

Fuel-Water Separator - Drain

Lubricating Oil Level - Check

Fan, Cooling - Check

Coolant Level - Check

Air Intake Piping - Check4

Air Tanks and Reservoirs - Drain4

Drive Belts - Check

Maintenance Procedures at 250 Hours, or 3 Months1, 2, 4 (Section 5)

Fuel Filter (Spin-On Type) - Change

Lubricating Oil and Filters - Change1

Charge-Air Cooler - Check4

Charge-Air Piping - Check4

Air Cleaner Restriction - Check4

Air Compressor - Check4

Radiator Pressure Cap - Check

Maintenance Procedures at 500 Hours, or 6 Months2, 3, 4 (Section 7)

Coolant Filter, if equipped - Change

Supplemental Coolant Additive (SCA) and Antifreeze Concentration - Check2, 3

Air Compressor Discharge Lines - Check4

Maintenance Procedures at 1000 Hours, or 1 Year4 (Section 9)

Overhead Set - Adjust

Cooling Fan Belt Tensioner - Check

Air Cleaner Assembly (Engine-Mounted) - Change4

2 3 4 5

Maintenance Procedures at 2000 Hours, or 2 Years2, 3, 4, 5 (Section 10)

Vibration Damper, Rubber - Inspect for Reuse

Vibration Damper, Viscous - Inspect for Reuse

Cooling System - Flush2, 3, 5

Air Compressor Discharge Lines - Check4

1. The lubricating oil and lubricating oil filter interval can be adjusted based on fuel

consumption, gross vehicle weight, and

idle time. Refer to Oil Drain Intervals in this

section.

2. Test the SCA concentration level every 6 months unless concentration is over three units;

then check at every oil drain interval

until concentration is below three units.

3. Antifreeze check interval is every oil change or 500 hours or 6 months, whichever occurs

first. The operator must use a heavy-duty year-round antifreeze that meets the chemical

composition of ASTM D6210. The antifreeze change interval

is 2 years. Antifreeze is

essential for freeze, overheat, and corrosion protection.

4. Follow the manufacturer's recommended maintenance procedures for the starter,

alternator, generator, batteries, electrical

components, engine brakes, exhaust brake,

charge-air cooler, air compressor, refrigerant compressor, and fan clutch.

5. This cooling system requirement to Flush at this scheduled maintenance includes Drain,

Flush, and Fill.

Marine Applications

Maintenance Procedures at Daily Interval1 (Section 3)

Fuel-Water Separator - Drain

Lubricating Oil Level - Check

Coolant Level - Check

Sea Water Strainer - Clean

Marine Gear - Check1

Drive Belts - Check

Maintenance Procedures at 75 Hours or 3 Months3 (Section 4)

Zinc Anode - Check3

Cooling System Hoses - Check

Sea Water Hoses - Check

Air Cleaner Restriction - Check

Batteries - Check

Battery Cables and Connections - Check

Component Connector and Pin Inspection - Check

Maintenance Procedures at 300 Hours or 1 Year1, 2 (Section 6)

Fuel Filter (Spin-On Type) - Change

Fuel-Water Separator Element - Replace

Lubricating Oil and Filters - Change2

Coolant Filter, if equipped - Change

Engine Coolant Heater - Check

Marine Gear Oil Cooler - Flush1

Supplemental Coolant Additive (SCA) and Antifreeze Concentration - Check2

Heat Exchanger - Flush

Sea Water Pump - Replace

Aftercooler Assembly (Sea Water) - Flush

Air Cleaner Assembly (Engine-Mounted) - Check

Air Intake Piping - Check

Marine Gear Oil - Check1

Radiator Pressure Cap - Check

Engine Wiring Harness - Check

Maintenance Procedures at 600 Hours or 2 Years (Section 8)

Vibration Damper, Rubber - Inspect for Reuse

Vibration Damper, Viscous - Inspect for Reuse

Overhead Set - Adjust

Cooling System - Flush4

Cooling Fan Belt Tensioner- Check

1. Consult the marine gear manufacturer operator's manual for specifications and

recommendations.

2. Refer to Refer to Procedure 018-024 in Section V.

(/qs3/pubsys2/xml/en/procedures/41/41-018-024.html)

3. Depending upon the quality of electrical bonding and water conditions, increased

maintenance is sometimes necessary.

4. This cooling system requirement to Flush at this scheduled maintenance includes Drain,

Flush, and Fill.

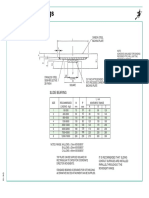

Oil Drain Intervals

Refer to the following flowchart to determine the maximum recommended oil change and

filter change intervals in kilometers,

miles, hours, or months, whichever comes first.

Is the vehicle one of those listed below?

Truck crane/yard spotter

Paver/crane/backhoe

Dozer/scrape/skipper

If Yes -

Select the correct oil drain interval from Table 1.

If No -

Is the vehicle one of those listed below?

Tractor/combine/irrigation equipment

Generator set/air compressor/fire equipment

If Yes -

Select the correct oil drain interval from Table 2.

If No -

Select the correct oil drain interval from Table 3.

Table 1, Oil Drain Intervals*

Vehicle/Equipm

Kilometers Miles Hours Months

ent

Truck

crane/yard 10,000 6,000 250 3

spotter

Paver/crane/ba

N/A N/A 250 3

ckhoe

Dozer/scraper/

N/A N/A 250 3

skidder

Table 2, Oil Drain Intervals*

Vehicle/Equipm

Kilometers Miles Hours Months

ent

Tractor/combin

e/irrigation N/A N/A 250 3

equipment

Generator

set/air

N/A N/A 250 3

compressor/fir

e pump

Table 3, Oil Drain Intervals*

Vehicle/Equipm

Kilometers Miles Hours Months

ent

All others 10,000 6,000 250 3

*Units equipped with a 26.5 liter [28 qt] high capacity oil pan can extend intervals to 500

hours.

Last Modified: 29-Jul-2015

You might also like

- K19 Industrial and Marine Operation and Maintenance Manual - Maintenance Schedule FullDocument13 pagesK19 Industrial and Marine Operation and Maintenance Manual - Maintenance Schedule FullLeandro Mauricio100% (3)

- QSK78 Owners Manual PDFDocument17 pagesQSK78 Owners Manual PDFjengandxb100% (2)

- Cummins K-Series Engine Schedule MaintenanceDocument31 pagesCummins K-Series Engine Schedule Maintenancenagari Power100% (5)

- CAT G3500 Gas Engine Maintenance ScheduleDocument3 pagesCAT G3500 Gas Engine Maintenance ScheduleQaiser Iqbal67% (6)

- Escorts Construction Equipment: Hydra-14 - HDDocument265 pagesEscorts Construction Equipment: Hydra-14 - HDMM Spares67% (3)

- SUZUKI DF200 225 250 Service Man 2Document49 pagesSUZUKI DF200 225 250 Service Man 2Candido IsazaNo ratings yet

- Diesel Engine Maintenance ChecklistDocument6 pagesDiesel Engine Maintenance Checklistjohnnybe5180% (5)

- D6RDocument8 pagesD6RHelar W. Cutipa MachacaNo ratings yet

- LandRover Discovery Service SheetDocument2 pagesLandRover Discovery Service Sheetmichkapp50% (2)

- KTA 50 Maintenance ScheduleDocument32 pagesKTA 50 Maintenance ScheduleIsmail AlsaadNo ratings yet

- Maintenance Schedule 20 Juil 09Document15 pagesMaintenance Schedule 20 Juil 09MussardNo ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument4 pagesMaintenance Interval Schedule: Operation and Maintenance ManualKJDNKJZEFNo ratings yet

- d11t Manual de MantenimientoDocument4 pagesd11t Manual de MantenimientoAnonymous SpT4OHYMyNo ratings yet

- Recommended Maintenance ScheduleDocument50 pagesRecommended Maintenance ScheduleSpectrumRaijinNo ratings yet

- Pms ReportDocument327 pagesPms ReportalsitorNo ratings yet

- Preventeve Maintenance ProgramDocument4 pagesPreventeve Maintenance ProgramAHMADNo ratings yet

- Maintenance Intervals (16-2523C)Document4 pagesMaintenance Intervals (16-2523C)HassanSadiq100% (1)

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFDocument4 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFSaid FahmiNo ratings yet

- Cummins K19 Maintainence ScheduleDocument13 pagesCummins K19 Maintainence Schedulesxturbo100% (1)

- C32 Service InformationDocument11 pagesC32 Service InformationErissonNo ratings yet

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDocument11 pagesDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshNo ratings yet

- Interval Service CB24Document4 pagesInterval Service CB24Alvaro Jose Peñata GiraldoNo ratings yet

- Marine and Industrial qsk60Document10 pagesMarine and Industrial qsk60Muhammad IshfaqNo ratings yet

- Power Unit MaintenanceDocument11 pagesPower Unit MaintenanceAzlan RafiqueNo ratings yet

- Gas Genset Maintenance ScheduleDocument3 pagesGas Genset Maintenance ScheduleMutahirrasoolNo ratings yet

- Maintenace Intervale Schedule 980HDocument5 pagesMaintenace Intervale Schedule 980HAlberto BastidasNo ratings yet

- Type Iii Test: Description of The Ageing Test For Verifying The Durability of Anti Pollution Devices From 2/3 WheelersDocument10 pagesType Iii Test: Description of The Ageing Test For Verifying The Durability of Anti Pollution Devices From 2/3 WheelersBikash Kumar MallickNo ratings yet

- QSK23 Maintenance Schedule 102-002Document7 pagesQSK23 Maintenance Schedule 102-002Marino MatevskiNo ratings yet

- Maintenance Intervals: When RequiredDocument3 pagesMaintenance Intervals: When RequiredSain MezaNo ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument3 pagesMaintenance Interval Schedule: Operation and Maintenance ManualsxturboNo ratings yet

- 160M Maintenance IntervalDocument3 pages160M Maintenance IntervalJoko WahonoNo ratings yet

- Maintenance Interval Schedule: SMCS Code: 7000Document4 pagesMaintenance Interval Schedule: SMCS Code: 7000wilbert tapia maqueraNo ratings yet

- PM 250 3306BDocument3 pagesPM 250 3306BGregk DirgantaraNo ratings yet

- Compresor Tuflo 550Document6 pagesCompresor Tuflo 550Ramón José Aponte FrancoNo ratings yet

- General Information: Industrial EnginesDocument17 pagesGeneral Information: Industrial EnginesjengandxbNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- Maintenance Interval Schedule D9Document3 pagesMaintenance Interval Schedule D9oki brownnesNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument3 pagesMaintenance Interval Schedule: When Requiredsxturbo100% (1)

- 2009-07-25 203857 3408 Marine OverhaulDocument5 pages2009-07-25 203857 3408 Marine OverhaulRuth RuizNo ratings yet

- 0 Calendrier D'entretienDocument4 pages0 Calendrier D'entretienkebbabi abdelhamidNo ratings yet

- Experiment 1Document10 pagesExperiment 1Shweta YadavNo ratings yet

- Experiment 2Document21 pagesExperiment 2Shweta YadavNo ratings yet

- 3512B SD Engines Maintenance IntervalsDocument4 pages3512B SD Engines Maintenance Intervalsharikrishnanpd3327No ratings yet

- Service Programme Backhoe Loaders: Construction EquipmentDocument5 pagesService Programme Backhoe Loaders: Construction EquipmentMACHINERY101GEARNo ratings yet

- Lubrication and MaintenanceDocument18 pagesLubrication and MaintenanceRamon AcostaNo ratings yet

- Service Bulletin: TitleDocument13 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Maintenance ScheduleDocument8 pagesMaintenance ScheduleWaleed OmdaNo ratings yet

- Scheduling A Top End OverhaulDocument3 pagesScheduling A Top End OverhaulVictor NunezNo ratings yet

- OMM-Maintenance Interval Schedule - Prime (SEBU9019-22)Document4 pagesOMM-Maintenance Interval Schedule - Prime (SEBU9019-22)AnggoroNo ratings yet

- Cummins Om ManualDocument2 pagesCummins Om ManualVellai Pandi PNo ratings yet

- D6R Maintenance Interval ScheduleDocument12 pagesD6R Maintenance Interval Schedulepedro sanchezNo ratings yet

- Intervalos de Matenimiento Cat 320dDocument5 pagesIntervalos de Matenimiento Cat 320dMaurizio Rodriguez PeñaNo ratings yet

- Piper Aircraft Corporation: Haven, Pennsylvania, U.S.ADocument2 pagesPiper Aircraft Corporation: Haven, Pennsylvania, U.S.AmaximeNo ratings yet

- Maintenance Interval ScheduleDocument4 pagesMaintenance Interval ScheduleYUSRO BAHRUL HADI KUSUMANo ratings yet

- Ufgs 33 08 55Document46 pagesUfgs 33 08 55Yagmur SimsekNo ratings yet

- MMS8T Crane ManualDocument19 pagesMMS8T Crane Manualkatepol8264No ratings yet

- General Information: 102-002 Maintenance ScheduleDocument10 pagesGeneral Information: 102-002 Maintenance ScheduleLaiqNo ratings yet

- C12 2KS 保养周期Document3 pagesC12 2KS 保养周期linkangjun0621No ratings yet

- Mantenimiento Lek 3500Document4 pagesMantenimiento Lek 3500Ana María AcostaNo ratings yet

- Section 5 - Maintenance Schedule and Service ProceduresDocument42 pagesSection 5 - Maintenance Schedule and Service ProceduresHipolito Caraballo100% (1)

- Technical Note: I - I - Subject: Abnormal Consumption of Engine OilDocument4 pagesTechnical Note: I - I - Subject: Abnormal Consumption of Engine Oilmebarki aberraoufNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Bosch Router 1617 EVS - Owner's ManualDocument72 pagesBosch Router 1617 EVS - Owner's ManualJennifer WatsonNo ratings yet

- Control Panel: A World of Energy SolutionsDocument11 pagesControl Panel: A World of Energy SolutionsFabian SolanoNo ratings yet

- GV 250 SM 5Document22 pagesGV 250 SM 5Fabrizio FloresNo ratings yet

- Instruction Manual - Diswasher Bosch SKS62E32EUDocument56 pagesInstruction Manual - Diswasher Bosch SKS62E32EUAudrey HernandezNo ratings yet

- Wireless Control Module (WCM) : Group 42CDocument102 pagesWireless Control Module (WCM) : Group 42CToponari MedveNo ratings yet

- Logik15: Logika Control S.R.LDocument17 pagesLogik15: Logika Control S.R.LsebastianNo ratings yet

- Faltblatt Janus-Zylinder 09-19 ENGDocument8 pagesFaltblatt Janus-Zylinder 09-19 ENGJelena GraovčevićNo ratings yet

- Photometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15Document1 pagePhotometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15emreNo ratings yet

- VLSI GTU Question Bank 2014Document4 pagesVLSI GTU Question Bank 2014Amish TankariyaNo ratings yet

- CASE 580 Super M+Document6 pagesCASE 580 Super M+Dian SikumbangNo ratings yet

- BajajDocument15 pagesBajajArief FirmantoNo ratings yet

- Decanter Centrifuge: Alfa Laval Alfa LavalDocument30 pagesDecanter Centrifuge: Alfa Laval Alfa LavalYousef AlipourNo ratings yet

- Detailed Lesson Plan in Automotive Technology - 11Document7 pagesDetailed Lesson Plan in Automotive Technology - 11Rio BesañesNo ratings yet

- C&P PTFE Slide BearingsDocument1 pageC&P PTFE Slide BearingsAchraf BoudayaNo ratings yet

- 57tw 66tw Set Instructions 0230-0369rb 1Document4 pages57tw 66tw Set Instructions 0230-0369rb 1maximo alejandro RauschenbachNo ratings yet

- Lambda Sensor LSU 4.9 Datasheet 51 en 2779147659Document4 pagesLambda Sensor LSU 4.9 Datasheet 51 en 2779147659Germán Gómez BeltránNo ratings yet

- Twido - Programmable Controller - TWDLCAE40DRFDocument3 pagesTwido - Programmable Controller - TWDLCAE40DRFLem Otarola OsorioNo ratings yet

- Thermostatic Expansion Valves Type T2 / TE2: Data SheetDocument16 pagesThermostatic Expansion Valves Type T2 / TE2: Data SheetHuynh Nhat VuNo ratings yet

- Toyota Voxy Equipment SheetDocument3 pagesToyota Voxy Equipment SheetIrsanNo ratings yet

- SIM908 Reference Design Guide Application Note V1.00Document17 pagesSIM908 Reference Design Guide Application Note V1.00jonydanceNo ratings yet

- Powerscreen Conveyor BrochureDocument5 pagesPowerscreen Conveyor BrochureDaniel BianchiniNo ratings yet

- AKG enDocument10 pagesAKG encarlosNo ratings yet

- Factors On Which Self Inductance of CoilDocument19 pagesFactors On Which Self Inductance of CoilRaj Parida80% (5)

- DC MotorsDocument2 pagesDC MotorsMeggy VillanuevaNo ratings yet

- Automatic Folding Door - GILGEN FFMDocument2 pagesAutomatic Folding Door - GILGEN FFMBochra Hkilani ZoghlamiNo ratings yet

- ANT AQU4518R4 1355 DatasheetDocument2 pagesANT AQU4518R4 1355 DatasheetJawad83% (6)

- Aft-Catalog s3 SecDocument10 pagesAft-Catalog s3 SecwemersonsrNo ratings yet

- Danfoss - B25GL - R134a - 220 - 50Document4 pagesDanfoss - B25GL - R134a - 220 - 50JahazielNo ratings yet