Professional Documents

Culture Documents

Torque

Torque

Uploaded by

Do Duc CanhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torque

Torque

Uploaded by

Do Duc CanhCopyright:

Available Formats

BURGESS

WELL COMPANY, INC. NSF®

724 East Highway 6

Minden, Nebraska 68959-2569 U.S.A.

Phone: (308) 832-1645 or 800-762-0331 Certified to

Fax: (308) 832-0170 or 888-241-7580

E-Mail: burgesswell@rcom-net.com

NSF/ANSI 61

Http://www.burgesswell.com

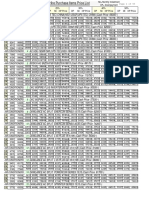

BOLT TORQUE SPECIFICATIONS: ”EON” FIBERGLASS FLANGED COLUMN PIPE

Torque Recommended

Pipe Size Increments Torque for Full

(Inches) (Ft.-Lbs.) Pressure Seal

4 5 30

6 10 40

8 10 40

10 10 45

12 10 45

BOLT TORQUE SEQUENCE: FIBERGLASS COLUMN PIPE SIZES 4” TO 12:

1 6 1 10 1

3

7 5

3 4

5 6 3 9

8 7

4

6

2 4 5 2 2 8

4” 6” & 8” 10” & 12”

FLANGE ASSEMBLY

Assemble the flanges, being joined, using a washer under both the head of the bolt and the nut. All

bolt threads must be oiled to obtain proper torque results. Finger tighten all nuts and check for proper

alignment of the flange faces. Misalignment of flange faces will cause bending stresses at the flange

and flange joint and damage may result. Correct any misalignment prior to applying torque to nuts.

APPLYING TORQUE

All nuts must be torqued in increments and sequence as shown above. Proceed through the tightening

sequence applying torque increments until the recommended torque is obtained. Recheck the torque on

each bolt in the same sequence as bolts previously tightened may have relaxed through the torque

sequence.

1/1/2008

You might also like

- Pip PNF0200 (2018)Document140 pagesPip PNF0200 (2018)Cristian Bravo100% (5)

- SKF Industrial V Belt Tension Tester PDFDocument3 pagesSKF Industrial V Belt Tension Tester PDFVeeresh nayakNo ratings yet

- Solar Centaur TroubleshootingDocument32 pagesSolar Centaur TroubleshootingFarhanNo ratings yet

- Wheel Torque SpecsDocument2 pagesWheel Torque Specseyya 007No ratings yet

- Relative Ratings of Factors Affecting The Preliminary Selection of ElectrodesDocument8 pagesRelative Ratings of Factors Affecting The Preliminary Selection of ElectrodesWilly UioNo ratings yet

- Control Charts DataDocument11 pagesControl Charts DataIGNo ratings yet

- Series Full-Port Brass Ball Valve: DescriptionDocument1 pageSeries Full-Port Brass Ball Valve: DescriptionGreg FarzettaNo ratings yet

- Formworks For SM Cauayan Phase REV2Document41 pagesFormworks For SM Cauayan Phase REV2Jan Lawrence AlbertoNo ratings yet

- Optimization of Rotary Drilling Configuration and Techniques - Mark BakerDocument57 pagesOptimization of Rotary Drilling Configuration and Techniques - Mark BakerSusy Serrano FlawersNo ratings yet

- Historical Time (Days) For Delivery Partners S.no Partner1 Partner2 Partner1 Partner2Document8 pagesHistorical Time (Days) For Delivery Partners S.no Partner1 Partner2 Partner1 Partner2suraj dhruvNo ratings yet

- Union Flexible DuctilDocument1 pageUnion Flexible DuctilAnoe NYNo ratings yet

- Pipe Span For PVC Pipe Span For CPVCDocument1 pagePipe Span For PVC Pipe Span For CPVCNag RajNo ratings yet

- Suspensions Coltrane: Masters in Mechanics: Mike Stern InterviewDocument1 pageSuspensions Coltrane: Masters in Mechanics: Mike Stern InterviewMiguel De Leon MuñizNo ratings yet

- Love Me Right 1Document3 pagesLove Me Right 1FADBASSNo ratings yet

- Penilaian Masalah Pokok PrioritasDocument3 pagesPenilaian Masalah Pokok PrioritasAa ZanyNo ratings yet

- June 2019 StatisticsDocument5 pagesJune 2019 Statisticssahra küçükeruğurluNo ratings yet

- Cheerleader Corpses: Pig DestroyerDocument3 pagesCheerleader Corpses: Pig DestroyerTauno LepistöNo ratings yet

- Resource Coordinate GraphingDocument33 pagesResource Coordinate Graphingmlamb2011No ratings yet

- Activity 8Document4 pagesActivity 8Jaysa RamosNo ratings yet

- Type ECI Stressing Anchorage: VSL Multistrand SystemsDocument1 pageType ECI Stressing Anchorage: VSL Multistrand SystemsBora CobanogluNo ratings yet

- Lampiran A PDFDocument1 pageLampiran A PDFbillyNo ratings yet

- Bill Hayton - Vietnam - Rising Dragon-Yale University Press (2010)Document273 pagesBill Hayton - Vietnam - Rising Dragon-Yale University Press (2010)Toan Tran100% (1)

- Diminished Scale Licks PDFDocument5 pagesDiminished Scale Licks PDFAgustin Valencia100% (3)

- TSB201801001Document2 pagesTSB201801001Víctor FaríasNo ratings yet

- Valvula Agulha PanamDocument16 pagesValvula Agulha PanamCarlos WotchoskiNo ratings yet

- Assembling The Crankshaft Assembling The Piston and Connect-Ing Rod AssemblyDocument1 pageAssembling The Crankshaft Assembling The Piston and Connect-Ing Rod AssemblyPHUONG NGUYENNo ratings yet

- Analysis and Design of Weld Lengths Subjected To Simultaneous Shear, Bending, Torsion and Axial LoadingDocument15 pagesAnalysis and Design of Weld Lengths Subjected To Simultaneous Shear, Bending, Torsion and Axial LoadingMing ChongNo ratings yet

- EN36492 Bolting Quick Reference GuideDocument7 pagesEN36492 Bolting Quick Reference GuidemohdfirdausNo ratings yet

- Socket Head Cap ScrewsDocument16 pagesSocket Head Cap ScrewsyauctionNo ratings yet

- Aplikasi Invest 50 l0 81 Line WawanDocument6 pagesAplikasi Invest 50 l0 81 Line WawanWawan 98No ratings yet

- Spring Return HandelDocument1 pageSpring Return Handelvaitheeswaran PNo ratings yet

- Lapres Olah Data DBP - Prasdira Ayu Maithsa Hasna - 26040121120033 - Kel1Document9 pagesLapres Olah Data DBP - Prasdira Ayu Maithsa Hasna - 26040121120033 - Kel1Yusuf RPNo ratings yet

- Filtro de Gas - MUELLERDocument2 pagesFiltro de Gas - MUELLERCarlos BaezaNo ratings yet

- SpecificationDocument2 pagesSpecificationToxic ToucanNo ratings yet

- ChainDriveVise 1-25-19 WebDocument14 pagesChainDriveVise 1-25-19 WebEliseu ChereneNo ratings yet

- 8ex10ft RCC Reamer ManualDocument14 pages8ex10ft RCC Reamer ManualIng del PeleNo ratings yet

- THOR Installation Manual - Bridge Conveyor 1925C R01 10-01-08 PDFDocument45 pagesTHOR Installation Manual - Bridge Conveyor 1925C R01 10-01-08 PDFIngeniero proyectosNo ratings yet

- Industrial V-Belt Tension Tester: General Rules of TensioningDocument3 pagesIndustrial V-Belt Tension Tester: General Rules of Tensioningdaniel castilloNo ratings yet

- Olahdata DBN Dan DBPDocument18 pagesOlahdata DBN Dan DBPYusuf RPNo ratings yet

- Deepbeam Si AashtoDocument18 pagesDeepbeam Si Aashtoahm2011No ratings yet

- Generator Diesel Engine PDFDocument5 pagesGenerator Diesel Engine PDFAlisabel Muñoz de MoralesNo ratings yet

- Fabory Fasteners Split CotterDocument7 pagesFabory Fasteners Split CotterdevendraNo ratings yet

- Teknisk-Katalog StubendsDocument1 pageTeknisk-Katalog Stubendsaceengineering08No ratings yet

- Line DefectsDocument28 pagesLine DefectsSegun TalabiNo ratings yet

- WHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualDocument9 pagesWHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualWill Freddy MartinezNo ratings yet

- Perforating Casing Collar Locator (CCL) : Titan Division - InstrumentsDocument2 pagesPerforating Casing Collar Locator (CCL) : Titan Division - InstrumentsGermanRobladilloNo ratings yet

- Kids+Apparel+Sale+v0 1Document17 pagesKids+Apparel+Sale+v0 1AbRam KNo ratings yet

- Valvula Gaveta AWWA, Mod 801 SovalDocument1 pageValvula Gaveta AWWA, Mod 801 Sovalgabriel240371No ratings yet

- CH 2 Bits 11sep2013 (A 05size) - 20130924122704.817 - XDocument12 pagesCH 2 Bits 11sep2013 (A 05size) - 20130924122704.817 - Xfatehul alamNo ratings yet

- Stock Porciones TiendasDocument3 pagesStock Porciones TiendasEdi Q. CastellanosNo ratings yet

- Data Sheet KRS-85.5: Specification Shaft SealDocument4 pagesData Sheet KRS-85.5: Specification Shaft SealTaztika Audea PutriNo ratings yet

- Axle Spare Parts - Table 2ADocument2 pagesAxle Spare Parts - Table 2Aaldino020203No ratings yet

- VLSI - CO - PO MatrixDocument103 pagesVLSI - CO - PO Matrixramesh471No ratings yet

- IPW Hot-Dip-Galvanizing Guide Rev 4 September 2019Document33 pagesIPW Hot-Dip-Galvanizing Guide Rev 4 September 2019JostNo ratings yet

- UntitledDocument2 pagesUntitled1987krishanNo ratings yet

- Bms - Arijit Singh-ModelDocument1 pageBms - Arijit Singh-ModelAabha PatelNo ratings yet

- TR Flex Fittings Sizes 4 36Document10 pagesTR Flex Fittings Sizes 4 36iytbwigxNo ratings yet

- Lecture22 dr2Document37 pagesLecture22 dr2api-3834272No ratings yet

- Coordinatometro 1 - 25000Document1 pageCoordinatometro 1 - 25000Federico CasaleNo ratings yet

- Daftar Sample Dan Diameter-1Document1 pageDaftar Sample Dan Diameter-1Intan Devi NataliasariNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Fisher Snappy Joe ESVDocument2 pagesFisher Snappy Joe ESVWynn ChoNo ratings yet

- Valve Stds AllDocument11 pagesValve Stds AllGohilakrishnan ThiagarajanNo ratings yet

- Econ Premium Fe-Test Certificate Iso 15848-1 Co1 - Co3 and Ta-Luft-RtDocument3 pagesEcon Premium Fe-Test Certificate Iso 15848-1 Co1 - Co3 and Ta-Luft-Rtemperor_vamsiNo ratings yet

- Rac 1Document3 pagesRac 1PARWAZ Technical InstituteNo ratings yet

- (IRI-07-SOP) FeedwaterSystem PDFDocument19 pages(IRI-07-SOP) FeedwaterSystem PDFvishnuNo ratings yet

- Product Information: EnglishDocument8 pagesProduct Information: EnglishAndrzej RNo ratings yet

- MSS - Valve Standards PDFDocument5 pagesMSS - Valve Standards PDFmrjn13670% (1)

- JISKOOT Hybrid Cell Sampler ManualDocument46 pagesJISKOOT Hybrid Cell Sampler ManualJuancho GuzmanNo ratings yet

- Hercules - Technical Data SheetDocument3 pagesHercules - Technical Data SheetRivelino EspinozaNo ratings yet

- Gas/Liquids Separators - Part 2: Quantifying Separation PerformanceDocument13 pagesGas/Liquids Separators - Part 2: Quantifying Separation PerformanceLizbeth Ramirez AlanyaNo ratings yet

- Deficiencies Summary: Hand Hole (N8)Document1 pageDeficiencies Summary: Hand Hole (N8)vietsdsNo ratings yet

- Kaman Catalog PDFDocument275 pagesKaman Catalog PDFmadan mohan kattaNo ratings yet

- DA (Pressurized) - Specification Data Sheet (3400)Document9 pagesDA (Pressurized) - Specification Data Sheet (3400)Manojkumar ThilagamNo ratings yet

- Development of Aero Gas Turbine Annular CombustorDocument14 pagesDevelopment of Aero Gas Turbine Annular CombustorSurya NarayananNo ratings yet

- Disscusion 4Document3 pagesDisscusion 4Mariam DalloulNo ratings yet

- Supplemental Ds 1Document2 pagesSupplemental Ds 1viksursNo ratings yet

- PriceListHirePurchase Normal 1Document55 pagesPriceListHirePurchase Normal 1Muhammad HajiNo ratings yet

- Apollo System Engineering Manual. Environmental Control SystemDocument137 pagesApollo System Engineering Manual. Environmental Control Systemjackie_fisher_email8329100% (2)

- Pekos Valves Asme Catalogue 2018Document12 pagesPekos Valves Asme Catalogue 2018Gerardo JM PalaciosNo ratings yet

- Curriculum Vitae Muni2Document3 pagesCurriculum Vitae Muni2Nurul HikmahNo ratings yet

- UNIT 2 (Steam Power Plant)Document2 pagesUNIT 2 (Steam Power Plant)mohd azeemNo ratings yet

- Data Sheets PDFDocument58 pagesData Sheets PDFRamy MahmoudNo ratings yet

- Valvula Check BykersDocument6 pagesValvula Check BykersDiego Duran100% (1)

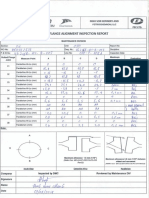

- Piping Flange Alignment Inspection Report at 070-P-103ADocument3 pagesPiping Flange Alignment Inspection Report at 070-P-103Angoctuan100% (1)

- Type 63EG-98HM Pilot-Operated Relief Valve or Backpressure RegulatorDocument8 pagesType 63EG-98HM Pilot-Operated Relief Valve or Backpressure RegulatorAlberto CastellanosNo ratings yet

- Vacuum Pupm 90612-2VB-Parts-ListDocument1 pageVacuum Pupm 90612-2VB-Parts-ListPrimero Valencia LuisNo ratings yet

- 80311-01 r3 Manual, TurbochargerDocument38 pages80311-01 r3 Manual, TurbochargerRamzi HamiciNo ratings yet

- Donaldson LPG Filter Data SheetDocument2 pagesDonaldson LPG Filter Data Sheetronald mudimuNo ratings yet