Professional Documents

Culture Documents

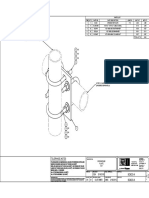

Material Part List: PT Waru Teknikatama

Material Part List: PT Waru Teknikatama

Uploaded by

hudiono cahyonoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Part List: PT Waru Teknikatama

Material Part List: PT Waru Teknikatama

Uploaded by

hudiono cahyonoCopyright:

Available Formats

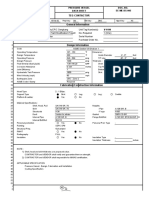

JOB NO.

: 06-WTO-012

PT WARU TEKNIKATAMA ITEM NO.

DOC. NO.

:

:

ALL

06-WTO-012-MPL REV. 0

DOC. TITLE : DATE : 1-Dec-06

QUATITY : TOTAL OF 2 UNIT(S)

CLIENT : PROFAB/EXPRO

MATERIAL PART LIST Page : 1 of 1

PREP'D : KUS CHK'D: SUH Date Printed: 12/1/2006

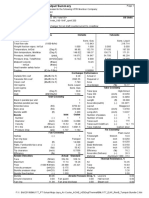

QTY FOR TOTAL

NO. ITEM NO. DESCRIPTION MATERIAL SIZE REMARK

2 UNITS

1 10.01-10.0Seamless Tube SA 179 O.D. 19.05 x 2.11 Min W/T ( 14 BWG) x length (See table attach 152 Note 1 Note 3 Note 5

2 01.01-01.0Spacer SA 179 O.D. 19.05 x 2.11 Min W/T ( 14 BWG) x 5500 16 Note 1 Note 3 Note 5

2 02.01 Tube Sheet SA 105N OD 597x 40 thk FMS(See skecth) 2 Note 1 Note 3

3 30.05 Pipe for shell SA 106 Gr. B pipe 16" NPS x Sch. STD x 5600 Lg 2 Note 1 Note 3

4 30.06 Pipe for channel shell SA 106 Gr. B Pipe 16" NPS xSch. STD x 400 Lg 2 Note 1 Note 3

5 30.01 Head SA 516-70 387 I.D x 9.525 Nom thk,6 Min. Thk. A.F w/ 38 SF (see sketch) 4 Note 1 Note 3

6 31.05 Girth flange for Shell & Channel SA 105N ASME B16.5 Flg 16" NPS x1 50# WNRF Sch. STD neck 4 Note 1 Note 3

7 40.00 Stud bolt c/w 2nuts for girth flange SA 193-B7/A 194-2H1" UNC-180 LG Stud bolt c/w 2 Nuts 38 Note 1 Note 3 Note 4 (included 6 for spares)

8 05.01 BAFFLES SA36 382 OD x 6 PL ( SEE SKETCH) 24 Note 2

9 08.01 Tie Rods SA36 12.7 OD x 5000 lg 4 Note 2

10 08.02 Tie Rods SA36 12.7 OD x 5500 lg 12 Note 2

11 12.01 Pulling Eyes SA325 3/4" UNC (see sketch) 4 Note 1 Note 3

12 12.02 Pulling Plug SA105N 3/4" UNC x 30 lg 4 Note 1 Note 3

13 12.03 Dowel pin SA36 12 DIA x 46 Lg 2 Note 2

14 30.69 Impigement Plate SA36 162 OD x 6 PL 2 Note 2

15 32.01 Nozzle Flanges T1,T2,S1,S2 SA105N ASME B16.5 Flg 6" NPS x1 50# WNRF Sch. 80 neck 8 Note 1 Note 3

16 33.01 Nozzle Neck T1,T2,S1,S2 SA106 Gr. B pipe 6" NPS x Sch. 80 x 138 Lg 8 Note 1 Note 3

17 34.01 Reinforcement Pad T1,T2,S1,S2 SA 516-70 270 OD x 9.525 PL 8 Note 1 Note 3

18 32.02 Nozzle Flange V SA105N ASME B16.5 Flg 2" NPS x1 50# WNRF Sch. 80 neck 2 Note 1 Note 3

19 33.02 Nozzle Neck V SA106 Gr. B pipe 2" NPS x Sch. 160 x 118 Lg 2 Note 1 Note 3

20 32.03 Blind Flange V SA105N ASME B16.5 Blind Flg 2" NPS x1 50# RF Blind 2 Note 1 Note 3

21 40.04 Gasket V SWSSNAF to suit to ASME B16.5 2" NPS x1 50# 2 Note 1

22 40.03 Stud bolt c/w 2nuts for nozzle V SA 193-B7/A 194-2H1" UNC-180 LG Stud bolt c/w 2 Nuts 10 Note 1 Note 3 Note 4 (included 2 for spares)

23 14.55 Partition plate SA 516-70 665 Lg x 383 w x 12.7 PL 2 Note 1 Note 3

24 30.65 Reinforcement Pad of lug SA 516-70 665 Lg x 383 w x 9.53 PL 4 Note 1 Note 3

25 30.66 Base plate SA 516-70 178 Lg x 170 w x 9.53 PL 4 Note 1 Note 3

26 30.67 Top plate SA 516-70 170 Lg x 68 w x 9.53 PL 4 Note 1 Note 3

27 30.68 Lug Rib SA 516-70 200 Lg x 50 w x 9.53 PL 8 Note 1 Note 3

28 30.71 Name plate Rib SA 516-70 160 Lg x 160 w x 6.35 PL 2 Note 1 Note 3

29 30.70 Name plate Bracket SA 36 200 Lg x 170 w x 6 PL 2 Note 2

30 40.01 Nuts on Tie Rods SA194-2H 1/2" UNC HEX NUT 32 Note 2

MATERIAL NOTE :

NOTE 1 MATERIAL TEST CERTIFICATES ARE IN ACCORDANCE WITH EN-10204 TYPE 3.2

NOTE 2 MATERIAL TEST CERTIFICATES ARE IN ACCORDANCE WITH EN-10204 TYPE 2.2

NOTE 3 CARBON CONTENT SHALL BE 0.22% MAX. AND CARBON EQUVALENT 0.45%MAX

CARBON EQUVALENT VALUE IS CALCULATED BY FOLLOWING FORMULAs :

Ceq (a) = C + Mn/6 + 0.04 <= 0.45 and

Ceq (b) = C + Mn/6 + (Cr+Mo+V)/5 + (Cu+Ni)/15 <= 0.45

NOTE 4 MATERIAL SHALL HAVE HAVE COMPOSITION : (% Cr + % Mo + % Ni ) = 0.5 AND SUPPLIED IN THE QUENCHED AND TEMPERED CONDITION

NOTE 5 SPARES ARE NOT INCLUDED

You might also like

- Valves Barendsen PDFDocument63 pagesValves Barendsen PDFidontlikeebooksNo ratings yet

- Exact Solutions Navier Stokes WangDocument19 pagesExact Solutions Navier Stokes WangToddharrisNo ratings yet

- CFDDocument7 pagesCFDwahtoiNo ratings yet

- Air Release Valve Selection & SizingDocument1 pageAir Release Valve Selection & SizingMahmoud Eldusoky100% (1)

- Precision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetDocument1 pagePrecision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetAnonymous AyDvqgNo ratings yet

- Format No.:DEPL/ENGG/F-07: Rev No/Date: 00 / 18-Aug-2021Document3 pagesFormat No.:DEPL/ENGG/F-07: Rev No/Date: 00 / 18-Aug-2021Dinesh MNo ratings yet

- WWM03 (Assembly)Document1 pageWWM03 (Assembly)Evgeni GenkovNo ratings yet

- WWM02 (Assembly)Document1 pageWWM02 (Assembly)Debabrata SahaNo ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeDocument2 pagesPrecision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeAnonymous AyDvqgNo ratings yet

- WWM02 (Assembly)Document1 pageWWM02 (Assembly)Evgeni GenkovNo ratings yet

- 7.5 Kva BomDocument2 pages7.5 Kva BomDinesh MNo ratings yet

- Screenshot 2022-10-13 at 13.50.16Document14 pagesScreenshot 2022-10-13 at 13.50.16medio saputraNo ratings yet

- Engineering Bill of Material: Pt. Duta Hita JayaDocument1 pageEngineering Bill of Material: Pt. Duta Hita Jayaper nandoNo ratings yet

- Engineering Bill of Material: Pt. Duta Hita JayaDocument1 pageEngineering Bill of Material: Pt. Duta Hita Jayaper nandoNo ratings yet

- Jce 67 2015 8 4 1361 enDocument1 pageJce 67 2015 8 4 1361 enSilviuSNo ratings yet

- 22-256-23-065-FORG-6228-Am-1 RevisedDocument16 pages22-256-23-065-FORG-6228-Am-1 RevisedAgni DuttaNo ratings yet

- Oo-06 Arr't of Anchor HandlingDocument8 pagesOo-06 Arr't of Anchor HandlingCelal BozdoganNo ratings yet

- ROKA-GENFGENA000-MEC-DAS-PHR-2001-00 - Vent Stack Size A Rantau Bais Kulin SihangatDocument1 pageROKA-GENFGENA000-MEC-DAS-PHR-2001-00 - Vent Stack Size A Rantau Bais Kulin SihangatBudi KamilNo ratings yet

- Surge Tank - DrawingDocument5 pagesSurge Tank - Drawingabdulazeez88No ratings yet

- Pt. Duta Hita Jaya: Engineering Bill of MaterialDocument1 pagePt. Duta Hita Jaya: Engineering Bill of Materialper nandoNo ratings yet

- How To Win Lane and FarmDocument4 pagesHow To Win Lane and FarmtrivediarjunNo ratings yet

- ED1801 Ventilation Fan WOKDocument46 pagesED1801 Ventilation Fan WOKJOHAN VILCHEZNo ratings yet

- Cementing ProgrammeDocument11 pagesCementing ProgrammeAutumn Assirem TrefoilNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- WMA312 (Assembly)Document1 pageWMA312 (Assembly)GopiNo ratings yet

- Plate - ADocument1 pagePlate - ASumit SinghNo ratings yet

- 6CHMT (Assembly)Document1 page6CHMT (Assembly)Debabrata SahaNo ratings yet

- BHA #1 ProposalDocument1 pageBHA #1 ProposalJose PalumboNo ratings yet

- Spares List - CriticalDocument1 pageSpares List - Criticalalonsito6031No ratings yet

- Ilovepdf MergedDocument9 pagesIlovepdf MergedRajashree PawarNo ratings yet

- 4 (Nse"r.: MaterialDocument78 pages4 (Nse"r.: MaterialAvishek GuptaNo ratings yet

- Samif1 MS 769 DW 0006Document1 pageSamif1 MS 769 DW 0006ahmed saadNo ratings yet

- Piping Specification: Piping Class: A2ADocument30 pagesPiping Specification: Piping Class: A2AAbhijeet WayaseNo ratings yet

- 2 X 300 Rev GTV CW-12MW - 170207Document1 page2 X 300 Rev GTV CW-12MW - 170207Debasis Pattnaik DebaNo ratings yet

- WWM01 (Assembly)Document1 pageWWM01 (Assembly)Evgeni GenkovNo ratings yet

- Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityDocument5 pagesKu-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityAbdur RehmanNo ratings yet

- Boiler AccesoriesDocument127 pagesBoiler Accesoriesramnath008100% (1)

- UntitledDocument5 pagesUntitledNithin GNo ratings yet

- Gigabyte 8simlh - Rev 3.02Document32 pagesGigabyte 8simlh - Rev 3.02Denis MartinsNo ratings yet

- Daily Welding Record LPDocument27 pagesDaily Welding Record LProbby moneNo ratings yet

- Gigabyte 8simlh - Rev 3.02Document32 pagesGigabyte 8simlh - Rev 3.02Denis MartinsNo ratings yet

- 62D pai markingDocument1 page62D pai markingnestor.bonaventeNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- TS-WX206A Pioneer ServiceDocument8 pagesTS-WX206A Pioneer ServiceinformagicNo ratings yet

- Material Forms-List of ConstruCertDocument4 pagesMaterial Forms-List of ConstruCertHanuman RaoNo ratings yet

- WCL8 (Assembly)Document1 pageWCL8 (Assembly)Md.Bellal HossainNo ratings yet

- ST3634 1829BW FX-S Din-X SD 011009 - BridgestoneDocument3 pagesST3634 1829BW FX-S Din-X SD 011009 - BridgestoneA̶l̶x̶a̶n̶d̶e̶r̶ PaniNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- 1 - KNOCK OUT DRUM I.D. 1808.8mm-Mariout Materials List Rev.0 PDFDocument2 pages1 - KNOCK OUT DRUM I.D. 1808.8mm-Mariout Materials List Rev.0 PDFHisham ElsayedNo ratings yet

- Packing StandardDocument1 pagePacking Standardavi.singh849291No ratings yet

- Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Document2 pagesPt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Solikhul HarisNo ratings yet

- Model: Zrd075Ac Capacity: 750 CFM Sl. No. Item Name Description of Material Quantity UnitDocument3 pagesModel: Zrd075Ac Capacity: 750 CFM Sl. No. Item Name Description of Material Quantity UnitSudipta DeyNo ratings yet

- Pulley Bracket-ModelDocument1 pagePulley Bracket-ModelSumon DuttaNo ratings yet

- Material Take-Off List: Sub-Floor Mounted IndoorDocument2 pagesMaterial Take-Off List: Sub-Floor Mounted IndoorAsif SajwaniNo ratings yet

- Strainer PDFDocument7 pagesStrainer PDFvinoj chandranNo ratings yet

- Pl Tower Aa2+12 (11 Set)Document7 pagesPl Tower Aa2+12 (11 Set)Fachrul RasyidNo ratings yet

- 81745H Basic - Swivel, CS4 7 (963 1338)Document2 pages81745H Basic - Swivel, CS4 7 (963 1338)rwinmillNo ratings yet

- ALL Specification Sheet ExcelDocument20 pagesALL Specification Sheet Exceladitya.ablazeexportNo ratings yet

- WPS PQR CompressedDocument5 pagesWPS PQR CompressedBalaje MantravadiNo ratings yet

- Drum Data Sheet: Ctci CorporationDocument4 pagesDrum Data Sheet: Ctci Corporationjdaig17No ratings yet

- Ed1801 - Inst & MFG - DWG - of - Sea - Chest - Cover - (Er & Aux - R)Document11 pagesEd1801 - Inst & MFG - DWG - of - Sea - Chest - Cover - (Er & Aux - R)luisNo ratings yet

- PTP1 20191127Document73 pagesPTP1 20191127Thaung Myint OoNo ratings yet

- Samif1-Ms-769-Dw - Revc-0003Document1 pageSamif1-Ms-769-Dw - Revc-0003ahmed saadNo ratings yet

- 23BMJ-048-MTO-Rev - 0 Special ToolsDocument1 page23BMJ-048-MTO-Rev - 0 Special Toolshudiono cahyonoNo ratings yet

- Shaft Run-Out Tolerance Record 12-H-1114 12-H-1115 12-H-1119Document4 pagesShaft Run-Out Tolerance Record 12-H-1114 12-H-1115 12-H-1119hudiono cahyonoNo ratings yet

- Mom Kom E-016Document2 pagesMom Kom E-016hudiono cahyonoNo ratings yet

- Shaft Run-Out Tolerance Record 14-H-1110Document2 pagesShaft Run-Out Tolerance Record 14-H-1110hudiono cahyonoNo ratings yet

- Report Hydrostatic Test Pipeline 6 InchDocument4 pagesReport Hydrostatic Test Pipeline 6 Inchhudiono cahyonoNo ratings yet

- TH Bun3 01 Gen BTC Mec Ga 0016 01 - Rev. 01 General Arrangement Drawing ...Document4 pagesTH Bun3 01 Gen BTC Mec Ga 0016 01 - Rev. 01 General Arrangement Drawing ...hudiono cahyonoNo ratings yet

- Ejw BDocument1 pageEjw Bhudiono cahyonoNo ratings yet

- Ejw ADocument1 pageEjw Ahudiono cahyonoNo ratings yet

- 26071-V74A-E-315-01-00002-00C - General Arrangement For Fuel Oil Heater E-315-01 PDFDocument3 pages26071-V74A-E-315-01-00002-00C - General Arrangement For Fuel Oil Heater E-315-01 PDFhudiono cahyonoNo ratings yet

- Boq Sipil Line Conveyor VendorDocument5 pagesBoq Sipil Line Conveyor Vendorhudiono cahyonoNo ratings yet

- Belt Conveyor BC 02A, BW 1200 A Conveyor UnitDocument3 pagesBelt Conveyor BC 02A, BW 1200 A Conveyor Unithudiono cahyonoNo ratings yet

- Tugas Hydrostatic - (Hudiono 05.2018.1.90369) 1Document2 pagesTugas Hydrostatic - (Hudiono 05.2018.1.90369) 1hudiono cahyonoNo ratings yet

- Img 20171117 0001Document1 pageImg 20171117 0001hudiono cahyonoNo ratings yet

- 2K Method PDFDocument5 pages2K Method PDFMiguel Antonio Francisco ReyesNo ratings yet

- Section5 2Document35 pagesSection5 2adil_farooq_6No ratings yet

- ServDocument74 pagesServDANIEL VARGAS RODRIGUEZ100% (6)

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Chapter 5 SolutionDocument7 pagesChapter 5 SolutionAli M AntthoNo ratings yet

- Sh3 Potential FlowDocument1 pageSh3 Potential FlowS.A. BeskalesNo ratings yet

- Manual Mod l30 Gas Hydraulic Tanks Hand Pump Replacement Shafer en 84896Document4 pagesManual Mod l30 Gas Hydraulic Tanks Hand Pump Replacement Shafer en 84896Abdeldjalil AchourNo ratings yet

- 3 - Fluid - Energy Equation and Applications of The Bernoulli's Equation - 2020 - 22Document20 pages3 - Fluid - Energy Equation and Applications of The Bernoulli's Equation - 2020 - 22Dennis AduNo ratings yet

- cfd1 IntroDocument6 pagescfd1 IntrowhateverNo ratings yet

- Moody DiagramDocument1 pageMoody DiagramASQNo ratings yet

- FMM Question Set 1Document16 pagesFMM Question Set 1Abhijit KuchbhilikhtaNo ratings yet

- Lattice-Boltzmann Analysis of Three-Dimensional Ice Shapes Naca 23012 2015Document12 pagesLattice-Boltzmann Analysis of Three-Dimensional Ice Shapes Naca 23012 2015Miliani AhmedNo ratings yet

- Resources Links: Online Resources To Learn CFDDocument1 pageResources Links: Online Resources To Learn CFDomi flashNo ratings yet

- Hydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCDocument1 pageHydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCJeff L DjambakNo ratings yet

- RMG 832 - 2000 - 09 - GB - BildschirmDocument8 pagesRMG 832 - 2000 - 09 - GB - BildschirmclauNo ratings yet

- The Soot-Blower Control Valve Solution Herbert L. Miller Curtis G. SterudDocument5 pagesThe Soot-Blower Control Valve Solution Herbert L. Miller Curtis G. Sterudadkon mksNo ratings yet

- Dust Collector Outage Inspection & Service FormDocument1 pageDust Collector Outage Inspection & Service FormErmiyas Mistre100% (1)

- Tyco Dry Pipe Valve DPV-1Document20 pagesTyco Dry Pipe Valve DPV-1Joshua SnyderNo ratings yet

- Fluid Friction Noncircular Ducts: E. Walker, A. Whan, R. R. RothfusDocument6 pagesFluid Friction Noncircular Ducts: E. Walker, A. Whan, R. R. RothfusRajeev PandeyNo ratings yet

- 2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisDocument23 pages2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisSachin ShindeNo ratings yet

- Valves and ActuationDocument180 pagesValves and ActuationKarthikaNo ratings yet

- Q & A - Jacketed SystemDocument2 pagesQ & A - Jacketed SystemArindomNo ratings yet

- High Efficiency Double Suction Centrifugal PumpDocument49 pagesHigh Efficiency Double Suction Centrifugal PumpKristomiDerMarine-IngenieurNo ratings yet

- ThaerRoomi WindTunnel PDFDocument15 pagesThaerRoomi WindTunnel PDFRajNo ratings yet

- Saso Iso 5167 5 2020 eDocument20 pagesSaso Iso 5167 5 2020 eJoalbert PalaciosNo ratings yet