Professional Documents

Culture Documents

Sampling Systems

Sampling Systems

Uploaded by

Widodo PutraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sampling Systems

Sampling Systems

Uploaded by

Widodo PutraCopyright:

Available Formats

DRY SAMPLING SYSTEMS

DRY SAMPLING SYSTEMS

DRY SAMPLING SYSTEMS

The key to any quality or process control program is correct sampling. McLanahan Corporation offers a wide range of sampling equipment to

provide the correct solution to your sampling problem. For more than 50 years, McLanahan Corporation has provided accurate and reliable

sampling solutions to clients across a broad range of industries handling an extensive variety of bulk materials. McLanahan Sampling Systems

are designed to provide a solution to each client’s unique sampling situation while complying with relevant sampling standards, respecting

sampling theory and following industry best practices.

Sampling is the process of selecting a relatively small amount of a material that will correctly represent a larger amount of that same material.

As both producers and consumers of products work to maintain strict quality and process standards, the focus on collecting samples for

analysis that accurately and precisely represent the larger lot of material becomes increasingly important.

CROSS BELT SAMPLERS

Cross Belt Samplers are an easily implemented, cost-effective means of collecting

representative samples and improving the safety of quality and process control

personnel. McLanahan Cross Belt Samplers can be installed on existing conveyor

frames without interfering with the conveyor belt. Top-notch design and expertise at

McLanahan provide a properly engineered and applied solution that will provide the

basis for successful quality and process control programs.

How It Works

A McLanahan Cross Belt Sampler automatically removes a portion of material from

a moving conveyor belt. This is accomplished using a rotating counter-weighted

sample cutter assembly that travels through one 360-degree rotation per activation.

The cutter assembly quickly accelerates from a parked position over the sampler

discharge area and, after a brief period of steady-state motion, passes through the

moving material flow before rapidly stopping in its original parked position above

the sample discharge – ejecting collected sample material into the discharge. Any

fine material that may be present on the surface of the conveyor belt is removed

by a wiper attached to the lower rear surface of the sample cutter. When properly

adjusted, the result is a clean and accurate swipe across the conveyor belt. Cross Belt Sampler

The McLanahan CutZone System

Properly contouring and supporting the conveyor belt is crucial to consistently

collecting complete sample increments with a Cross Belt Sampler, especially

when fine particle sized material is involved. To address this critical requirement,

McLanahan offers the CutZone belt contouring and support system to closely

match the profile of the conveyor belt to the radius of the sample cutter assembly

rotation. The CutZone system consists of two multi-segment idlers that support the

conveyor belt on either side of the sampler and a radiused impact deck that holds

the conveyor belt at the correct profile and prevents deflection of the conveyor belt

while a sample increment is collected. McLanahan CutZone System

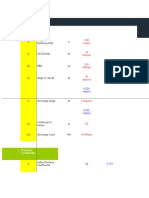

Cross Belt Sampler Specifications

Conveyor Belt Width 12”-96” [300mm-2400mm]

Conveyor Belt Speed Up to 1,500ft/min [7.6m/s]

Feed Rate Up to 10,000stph [9000mtph]

Material Size 12” [300mm]

Installed Power Up to 150hp [112kW]

*Standard models. Other options are available depending on application details.

2 | Dry Sampling Systems

DRY SAMPLING SYSTEMS

CROSS BELT SAMPLER-BASED SYSTEMS

Cross Belt Sampler-based multi-stage sampling systems are available in a variety of arrangements and configurations based upon the client’s

sampling application and facility layout requirements. Systems can be provided as an addition to existing infrastructure, as semi-portable skid-

mounted units or in a modular building.

Semi-Portable Skid-Mounted Arrangement Module Building-Based Two Stage Sampling System

Mirrored Module Building-Based Two Stage Sampling Systems Two Stage Sampling System in Existing Structure

Module Building Cutaway

Sample Crusher

Module Top Access Platform

Ventilation Fan

Electrical Room HVAC

Sample Collection Containers

Electrical Room Divider

Bi-Directional Secondary Sample Conveyor

Cross Belt Sampler

Dry Sampling Systems | 3

DRY SAMPLING SYSTEMS

FALLING STREAM SAMPLERS

Falling Stream Samplers are a common type of sampler that are used to collect

sample material from a main process flow that is either in a free-falling condition

or traveling through some trajectory, such as at the discharge of a conveyor.

A Simple Design for Easy Maintenance

Falling Stream Samplers tend to be simpler in design and function and usually

offer highly reliable operation with relatively low maintenance requirements.

This style of sampling is well suited to high flow rate applications where minimal

downtime is a requirement, such as loadout systems. Falling Stream Samplers

come in all manner of shapes, sizes, and configurations, but regardless of the

machine in question, the basic function of this type of machine is essentially the

same. A sample cutter is parked on one side of a moving material flow. When a

sample increment is to be collected, the cutter drive assembly (which varies by

machine type) will move the cutter through the material flow at a constant speed,

collecting a sample increment.

Drive Units

Falling Stream Sampler drive units vary by machine type but are usually one of

three types of drives: gear-reducer driven rack and pinion, gear-reducer driven

chain and sprocket, and hydraulic cylinder.

Bottom Dump Style Sample Cutter

Falling Stream Sampler Specifications

Conveyor Belt Width 12”-96” [300mm-2400mm]

Conveyor Belt Speed Up to 1,500ft/min [7.6m/s]

Feed Rate Up to 20,000stph [18000mtph]

Material Size 12” [300mm]

Installed Power Up to 40hp [30kW]

*Standard models. Other options are available depending on application details.

Falling Stream Style Secondary Sampler Drive Base Assembly for a Standard Duty Overhead Carriage Style

Falling Stream Sampler

4 | Dry Sampling Systems

DRY SAMPLING SYSTEMS

FALLING STREAM SAMPLER-BASED SYSTEMS

Falling Stream Sampling Systems are typically installed in a transfer tower where a conveyor discharges into another portion of a process or

where material is free falling in transfer chutework.

The goal of a sampling program is to accurately represent a relatively large amount of material with a relatively small amount of sample. A

greater amount of sample collection and processing completed within a mechanical sampling system, in an automatic fashion, will result in a

more correct, efficient and cost-effective sampling program.

A complete mechanical sampling system will incorporate as many types of sampling equipment as necessary to meet the needs of the

application and satisfy layout requirements while minimizing the total number of pieces of equipment. More handling and transferring of

samples introduces more potential sources of error into the sample collection and handling process.

Falling Stream Sampler-Based Two Stage Sampling System Falling Stream-Based Loadout Sampling System

Overhead Carriage Style Falling Stream Sampler Two Stage Falling Stream-Based Sampling System

Dry Sampling Systems | 5

DRY SAMPLING SYSTEMS

SAMPLE CRUSHING

Dependable, heavy-duty crushing options for low feed rates is a market niche covered by the McLanahan line of sample crushing products.

From Jaw Crushers, to Hammermills, to Double Roll Crushers, an option likely exists within the McLanahan product offering that will meet your

low tonnage, high dependability requirements.

The McLanahan Sample Hammermill Crushers (MiniMacs) Rockertooth Crushers feature a high crushing ratio and a unique

are typically used in applications processing moderately hard, “rocking” style of impact hammer. They can process mildly abrasive,

friable materials with low abrasiveness. Similar to other types of moderately hard, friable feed material that contains larger lumps

Hammermills, these machines are capable of a high reduction ratio of material or small amounts of harder inclusions. These machines

and can generate a relatively high amount of fines in the crushed can also be fitted with fixed hammers to produce relatively coarse

product. crushed output gradations or for lump breaking applications.

Sample Double Roll Crushers and Mini-Sizers are simply smaller Sample Jaw Crushers are smaller scale versions of the popular

scale versions of the Double Roll Crusher and Direct Drive Crusher overhead eccentric design. Sample Jaw Crushers feature the same

(DDC) product groups for which McLanahan has become well- operating principles and robust design associated with larger jaw

known. These machines tend to produce a more cubical product with crusher offerings in a more compact, lower feed rate configuration.

minimal fines generation.

6 | Dry Sampling Systems

DRY SAMPLING SYSTEMS

AUGER SAMPLERS

In an ideal situation, bulk materials are mechanically sampled from a moving material flow. Examples of ideal sampling locations include on

a moving belt conveyor, free-falling in a vertical chute or as material is discharged from a conveyor at a transfer point. In actuality, this is not

always possible, and other means of sample collection must be used. The most common example of this situation is where material to be

sampled is confined in some type of container for transportation purposes.

Bulk materials are frequently transported via truck, rail, or other container, and often there is no other option for sampling other than to collect

samples from the transport container, particularly in as-shipped and as-received situations. These are the types of applications in which Auger

Sampling Systems are well suited.

Once primary sample increments are collected by the primary Auger Sampler, processing those increments is the same as in any number of

other multi-stage sampling systems for which McLanahan has become well-known.

12” Diameter Sample Auger 20” Diameter Sample Auger

Single Stage Truck Auger System Two Stage Truck Auger System with Sample Building

Dry Sampling Systems | 7

DRY SAMPLING SYSTEMS

OTHER SAMPLING EQUIPMENT

A complete mechanical sampling system can consist of a number of different types of equipment that may not be specifically limited to

sample collection equipment. Other types of equipment can include crushers (Hammermills, Jaw Crushers and Roll Crushers), conveyors,

mixers, dividers and multi-station collectors, to name a few common machines.

Automatic Diverter Gate for Crusher Bypass 2 Station Linear Sample Collector 8 Station Rotary Sample Collector

Vezin Sampler Traveling Hopper Secondary Sampler Motor Control Center

Heavy Duty Sample Conveyor

More Information :

Product Sales : Widodo Putra | 0823 1370 0163 | widodo.putra@beltcare.com

PT. Suprabakti Mandiri

Jl. Danau Sunter Utara Blok A No. 9 Sunter, Jakarta Utara - 14350.

Phone : 021-658 33666 | Fax : 021-658 33666 | e-mail: info@beltcare.com

You might also like

- CPL Flight Planning ManualDocument94 pagesCPL Flight Planning ManualChina LalaukhadkaNo ratings yet

- Swax 7000 Primary Sweep Sampler PDFDocument4 pagesSwax 7000 Primary Sweep Sampler PDFgicnt100% (1)

- OTE Slurry Sampling Eng WebDocument8 pagesOTE Slurry Sampling Eng Webjazz_2012No ratings yet

- Francis Pitard Report 2007Document22 pagesFrancis Pitard Report 2007Roberto Garcias MoraNo ratings yet

- Servopac Gyratory CompactorDocument8 pagesServopac Gyratory CompactorLeandro GomesNo ratings yet

- Supply and Installation of Analyzer and Sampling SystemDocument17 pagesSupply and Installation of Analyzer and Sampling SystemErnesto R. Castillo100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Evidence Part IDocument10 pagesEvidence Part IVitz IgotNo ratings yet

- Cortador de Muestras RamseyDocument4 pagesCortador de Muestras RamseyalexNo ratings yet

- Sampling Solutions LRDocument8 pagesSampling Solutions LRmanoj983@gmail.comNo ratings yet

- Cross Belt Sampling SystemsDocument17 pagesCross Belt Sampling Systemsmahesa34No ratings yet

- Automatic Samplers: Proven & DependableDocument6 pagesAutomatic Samplers: Proven & DependableHarish KumarNo ratings yet

- Powerscreen Crushing Range USE FOR ALL MODELSDocument25 pagesPowerscreen Crushing Range USE FOR ALL MODELSFreddy AlgabaNo ratings yet

- Posiciones de DragalinaDocument7 pagesPosiciones de DragalinaarturoNo ratings yet

- Data Ambr Crossflow spc2084 e PDF DataDocument6 pagesData Ambr Crossflow spc2084 e PDF DatalabstemcellNo ratings yet

- Vezin SamplerDocument2 pagesVezin Samplerjaime zavalaNo ratings yet

- Production Services Tractor System: A Versatile Approach To Horizontal ConveyanceDocument8 pagesProduction Services Tractor System: A Versatile Approach To Horizontal Conveyanceariosabz100% (1)

- QCX AutoSampling - ENDocument9 pagesQCX AutoSampling - ENtonyNo ratings yet

- Chain For Wet Scrapper ConveyorDocument18 pagesChain For Wet Scrapper ConveyorHarish AG workNo ratings yet

- ScenchDocument4 pagesScenchKoteswara RaoNo ratings yet

- Central Pollution Control Board: Cems - The Ultimate Tool For Emission RegulationDocument46 pagesCentral Pollution Control Board: Cems - The Ultimate Tool For Emission RegulationRaden MasNo ratings yet

- Rieter Servotrail Brochure 93062 enDocument8 pagesRieter Servotrail Brochure 93062 enVignesh WaranNo ratings yet

- 1000SR Brochure 2017 EN PDFDocument1 page1000SR Brochure 2017 EN PDFmarceloaav1100% (1)

- 1000SR Brochure 2017 EN PDFDocument1 page1000SR Brochure 2017 EN PDFmarceloaav1No ratings yet

- MetecDocument2 pagesMetecmanuelfpmgaNo ratings yet

- Powerscreen India Crushing Screening Conveyor Brochure 2023 (WEB)Document36 pagesPowerscreen India Crushing Screening Conveyor Brochure 2023 (WEB)Sabitavo MandalNo ratings yet

- Fatigue Testing Machine JNT2000 Series: ConfigurationDocument2 pagesFatigue Testing Machine JNT2000 Series: ConfigurationRajaSekarsajjaNo ratings yet

- Installation and Operation of Densitometers 2205Document4 pagesInstallation and Operation of Densitometers 2205CRT ServicesNo ratings yet

- WM - Jiskoot Sampling OverviewDocument4 pagesWM - Jiskoot Sampling OverviewSaravanakumar RajagopalNo ratings yet

- Samstat 30 D10668Document4 pagesSamstat 30 D10668Yonh Yunior Ticona CallaNo ratings yet

- 1.1 - Sampling HandbookDocument28 pages1.1 - Sampling HandbookAndrés Castillo NavarroNo ratings yet

- Dry Cross-Cut Sampling Solutions: Your Specialist in Process EquipmentDocument6 pagesDry Cross-Cut Sampling Solutions: Your Specialist in Process EquipmenttounsiNo ratings yet

- Powerscreen Metrotrak Brochure EN 2018Document1 pagePowerscreen Metrotrak Brochure EN 2018Nelson Andrade VelasquezNo ratings yet

- Powerscreen 1000 Maxtrak: Cone CrusherDocument13 pagesPowerscreen 1000 Maxtrak: Cone CrusherVanderley Alves100% (1)

- Hapman ConveyorDocument11 pagesHapman ConveyorMuhammed Reevky Avicenna Al-Asqalani100% (1)

- Cilas Ecosizer 2006Document2 pagesCilas Ecosizer 2006Pedro SanchezNo ratings yet

- Analyzer Sample Cond Basic MT I atDocument3 pagesAnalyzer Sample Cond Basic MT I atAnonymous dPUUgoNo ratings yet

- H CAM Carbon in Ash Monitor.Document4 pagesH CAM Carbon in Ash Monitor.Hammad AshrafNo ratings yet

- 4 Slice Refurbished CT Scan MachineDocument26 pages4 Slice Refurbished CT Scan MachineOnirisNo ratings yet

- MAEFH Multi Axial Testing Machines MICROTESTDocument6 pagesMAEFH Multi Axial Testing Machines MICROTESTMIGUEL LOPEZNo ratings yet

- Module 3 - Simulation of Crushing and ScreeningDocument6 pagesModule 3 - Simulation of Crushing and ScreeningJesus SanchezNo ratings yet

- AnalyzerDocument86 pagesAnalyzersarmistha patnaiKNo ratings yet

- Construction Equipment: 1. Allround Bridging SystemDocument4 pagesConstruction Equipment: 1. Allround Bridging SystemDhruvilJakasaniyaNo ratings yet

- TSS PDFDocument4 pagesTSS PDFJohn GiannakopoulosNo ratings yet

- Mechatronics: Dongwoo Kang, Kihyun Kim, Dongmin Kim, Jongyoup Shim, Dae-Gab Gweon, Jaehwa JeongDocument9 pagesMechatronics: Dongwoo Kang, Kihyun Kim, Dongmin Kim, Jongyoup Shim, Dae-Gab Gweon, Jaehwa JeongMAHESH VNo ratings yet

- Catalog - Conveyor Systems OverviewDocument16 pagesCatalog - Conveyor Systems Overviewleomariano21No ratings yet

- Flexco Conveyor ProductsDocument32 pagesFlexco Conveyor ProductsDaniel KrismantoroNo ratings yet

- Conveyor DCI 0311Document2 pagesConveyor DCI 0311Kelvin Kindice MapurisaNo ratings yet

- Articulos de Tranportadores de SolidosDocument18 pagesArticulos de Tranportadores de SolidosKYRA NAZARETH MOREIRA BERGESNo ratings yet

- Tacmina Motor SXDA1Document12 pagesTacmina Motor SXDA1arisqi wahyuNo ratings yet

- UCC Wet-To-Dry Brochure PDFDocument12 pagesUCC Wet-To-Dry Brochure PDFNadia Hana SorayaNo ratings yet

- Wireline Coring Benefits Duplex UsaDocument2 pagesWireline Coring Benefits Duplex UsaMark GarrettNo ratings yet

- Steelex International - Two Wheel Pipe Blasting Machine 2W - 48 PIPEDocument1 pageSteelex International - Two Wheel Pipe Blasting Machine 2W - 48 PIPEchrisperryuaeNo ratings yet

- Presentación de Actividades Realizadas Durante Prácticas Pre ProfesionalesDocument28 pagesPresentación de Actividades Realizadas Durante Prácticas Pre ProfesionalesCésar EstrellaNo ratings yet

- Screening OKDocument30 pagesScreening OKMGB EMBEDDED CAPASNo ratings yet

- Weigh Feeder 14 4381 TF 90 125 Spec ADocument4 pagesWeigh Feeder 14 4381 TF 90 125 Spec ARaj K SharmaNo ratings yet

- Crisplant LS 4000flexbeltDocument4 pagesCrisplant LS 4000flexbeltqi_1986No ratings yet

- SamplingDocument8 pagesSamplingSreedhar BellaryNo ratings yet

- New Sensors and Processing ChainFrom EverandNew Sensors and Processing ChainJean-Hugh ThomasNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Crusher GuideDocument19 pagesCrusher GuideWidodo PutraNo ratings yet

- Indramas - Brochure - Gse BentolinerDocument5 pagesIndramas - Brochure - Gse BentolinerWidodo PutraNo ratings yet

- Alfi Cahya Jeconiah Wibisono Widodo Putra Falconika Mega S Moh Rayan DarmawanDocument12 pagesAlfi Cahya Jeconiah Wibisono Widodo Putra Falconika Mega S Moh Rayan DarmawanWidodo PutraNo ratings yet

- Alfi Cahya Jeconiah Wibisono Widodo Putra Falconika Mega S Moh Rayan DarmawanDocument12 pagesAlfi Cahya Jeconiah Wibisono Widodo Putra Falconika Mega S Moh Rayan DarmawanWidodo PutraNo ratings yet

- Newmaninan Concept of A GentlemanDocument4 pagesNewmaninan Concept of A GentlemanSakib Abrar TasnimNo ratings yet

- Nano + ArchitectureDocument7 pagesNano + ArchitectureBoneyPhilipNo ratings yet

- Exercise 6 Make An Incident Report and Conduct An InvestigationDocument5 pagesExercise 6 Make An Incident Report and Conduct An InvestigationRoxana BaltatescuNo ratings yet

- Baessler (1903) - Ancient Peruvian Art. Contributions To The Archaeology of The Empire of The Incas From His CollectionsDocument99 pagesBaessler (1903) - Ancient Peruvian Art. Contributions To The Archaeology of The Empire of The Incas From His Collectionsabrah-cadabrahNo ratings yet

- Assessing Speaking SkillsDocument2 pagesAssessing Speaking SkillsDaniel MyoNo ratings yet

- Banking Assessment 10Document10 pagesBanking Assessment 10AMARJEET SINGHNo ratings yet

- A Z of Simple Living BookDocument68 pagesA Z of Simple Living Bookdrsubramanian100% (4)

- '21 Kona Bicycles Owner's Manual PDFDocument46 pages'21 Kona Bicycles Owner's Manual PDFInsight PeruNo ratings yet

- Welc OME..Document26 pagesWelc OME..Priya RamNo ratings yet

- 11 - Trigonometric IdentitiesDocument6 pages11 - Trigonometric IdentitiesQwert RNo ratings yet

- Tepid-Sponge-Bath PRSDocument4 pagesTepid-Sponge-Bath PRSmaryNo ratings yet

- A+ Blog-Class-8-Chemistry-Samagra-Chapter-7-Question Pool (Em)Document9 pagesA+ Blog-Class-8-Chemistry-Samagra-Chapter-7-Question Pool (Em)Riya Maria SijuNo ratings yet

- Nippon SteelDocument7 pagesNippon SteelAnonymous 9PIxHy13No ratings yet

- SH Catalogue - Neuro & SpinalDocument17 pagesSH Catalogue - Neuro & SpinalSaqibullah ShahzadNo ratings yet

- Advatage and DisadadvatagesDocument5 pagesAdvatage and DisadadvatagesPawan PathakNo ratings yet

- WGST 3809A - Feminist ThoughtDocument12 pagesWGST 3809A - Feminist ThoughtIonaNo ratings yet

- I) Height of Retaining Wall H: Preliminary DataDocument10 pagesI) Height of Retaining Wall H: Preliminary DataOmPrakashNo ratings yet

- Charles Spurgeon Scriptural IndexDocument59 pagesCharles Spurgeon Scriptural IndexjohndagheNo ratings yet

- Michael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)Document23 pagesMichael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)JustinWagnerNo ratings yet

- Zeus - AntipasDocument2 pagesZeus - AntipasPaw LabadiaNo ratings yet

- Worksheet 2A-QP MS (Dynamics)Document6 pagesWorksheet 2A-QP MS (Dynamics)kolNo ratings yet

- Introduction Main PDFDocument3 pagesIntroduction Main PDFshubhu11No ratings yet

- 102 192 1 SMDocument8 pages102 192 1 SMLinaNo ratings yet

- Overflow Traffic Overflow Traffic in A Loss SystemDocument17 pagesOverflow Traffic Overflow Traffic in A Loss SystemChuong DangNo ratings yet

- 07. ĐỀ THI VÀO LỚP 10-CẦN THƠ (2020-2021)Document8 pages07. ĐỀ THI VÀO LỚP 10-CẦN THƠ (2020-2021)Vương ThànhNo ratings yet

- Research Paper JDocument19 pagesResearch Paper JBlankxxe meloNo ratings yet

- For School PaperDocument7 pagesFor School PaperHanzelkris CubianNo ratings yet

- BUET Prospectus CIVILDocument111 pagesBUET Prospectus CIVILMashrur AbidNo ratings yet