Professional Documents

Culture Documents

Water Testing System

Water Testing System

Uploaded by

mnfrsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Testing System

Water Testing System

Uploaded by

mnfrsCopyright:

Available Formats

WATER SYSTEM VALIDATION

Water System Validation

Demystifying the microbiology

By Anthony Grilli SGS U.S.Testing Co.

EARLY EVERY PHARMACEUTICAL manufacturer uses water as a raw material. Whether it is an ingredient in the final product, a component used in the manufacture of the final product, or a cleaning agent used to rinse final product from the manufacturing process, water can be a vector for microbial contamination. Bacteria will proliferate in water with very little encouragement. For this reason, microbiological analysis is a very important part of the validation of any water purification system. At the same time, specific guidance on the how, what, and when of the analysis is scattered and scarce. The compendia and the regulatory guidelines offer some direction, but they dont provide all the answers. To make matters worse, the terminology often seems too flexible for a regulatory validation; this is a world of most probable numbers, colony-forming units, and indicator organisms. This article will answer some common questions that this contract microbiologist has encountered over the years.

as well. Your contact laboratory should provide you with sample containers used by its TOC analyzers autosampler. This will minimize the potential of contamination during transfer of water from container to vial. Although TOC is actually a chemical analysis, the hold time becomes important, as any microbes in the sample can fix carbon dioxide into organic carbon, thereby artificially increasing TOC over time. Ask your laboratory for data validating TOC sample hold time and methodology.

What Method Should I Run for Bioburden?

A bioburden value is the enumeration of all viable eukaryotes in the water sample. Although water can be considered a raw material, the analysis should be conducted according to USP <61> Microbial Limits. Waters low nutrient level and unique microflora are better tested with different media, temperatures and times. The media and times used should encourage fastidious gram negatives. The typical approach is to use a high nutrient medium (Plate Count Agar) and incubate it at elevated temperatures (3035C) for 48 to 72 hours. This scenario is ideal for isolating human pathogens that are accustomed to a warm, nutrient-rich environment. A different approach utilizes a low nutrient medium (R2A) and incubates at lower temperatures (2025C) for longer periods of time (5 to 7 days). This approach is better suited for waterborne organisms. A sample analyzed with the higher nutrient medium will often result in a bioburden lower than the same sample analyzed with the low nutrient medium. So why does USP <1231> Water for Pharmaceutical Purposes recommend the high nutrient scheme as generally acceptable for monitoring pharmaceutical water systems? The risk associated with the increased time needed for incubation might outweigh any benefit derived from the higher Anthony Grilli is laboratory director for SGS Life Sciences. He can reached at anthony_grilli@sgs.com.

How Should Samples Be Sent to the Lab?

Although it seems obvious, actual experience would seem to indicate otherwise: You must obtain leak-proof, sterile sampling materials. If part of your sampling includes disinfected source water, use a sample container supplemented with sodium thiosulfate to neutralize the chlorine. You must also train your staff on how to collect samples aseptically. Your contract laboratory should be able to provide sample containers and training. Collect at least 100300 mL of sample (dependent upon the number of tests to be performed). Sample volumes <100 mL are unrepresentative and therefore unacceptable.1 Document the date and time the samples are taken. Seal the samples well, and send them to the lab in a cooled insulated shipper. Your contract laboratory should conduct bacterial testing within 24 hours of sample time2, and should therefore document the time they conduct their tests. Total Organic Carbon (TOC) sampling has its considerations

110 CONTRACT PHARMA October 2004

www.contractpharma.com

WATER SYSTEM VALIDATION

plate count. If the data arent available for over a week, and the water has been long used by the time the data are available, how useful was the data? As stated by USP <1231>: The advantages of recovering injured microbes, slow growers, or fastidious bacteria should be balanced against the need to have a timely investigation and to take corrective action, as well as the ability of these microorganisms to detrimentally affect products or processes3. The more sensitive the product (parenteral, inhalant), the more sensitive the test should be.

Figure 1: P. Cepacia-related product recalls Date March 2000 August 2000 March 2004 Recall Class II recall of moisturizing lotion Class II recall of contaminated baby wipes Voluntary recall of contaminated 12-hour nasal spray Voluntary recall of sublingual CO2 sensors stored in contaminated buffered saline.

February 2004 Class II recall of aloe vera lotion sold to hospitals May 2004

What Pathogens Should I Assay For?

The USP indicates that pharmaceutical raw materials should be free from objectionable organisms. What makes an organism objectionable? Just about any organism can be objectionable under the right circumstances. The solution is to begin with the end in mind: What are you manufacturing? Who is the intended consumer? Is the product a solid oral dosage with low water activity? If so, this is a lower risk product that would not encourage microbial proliferation. Is the product a topical or ocular drug with a high water activity? Is it intended for immuno-compromised individuals? If so, the risks of infecting the consumer are higher. In this case, a screen for Pseudomonads, or gram negative non-fermenting bacteria, is recommended. Gram negative non-fermentors are ubiquitous in water, but can also be biocide-resistant, biofilm-forming, and pathogenic. One example is Burkholderia cepacia; formerly Pseudomonas cepacia, these bacteria are frequently isolated from water and have been implicated in several product recalls (see Figure 1). Gram positive organisms and fungi are rarely isolated from water. When recovered, it might indicate contamination in sampling or laboratory and subsequent retraining (although there have been reports of mold shed from gaskets in water purification systems). water was potable and that the purification system would only further clean it up. Neither assumption was true. If water is acquired from a public utility, one can ask for the testing data that shows the water is potable. However, its important to understand that a certain amount of coliforms are detected even in public drinking water. The EPA set a legal limit of no coliforms in more than 5% of samples taken in each month.5 One way of looking at this is that drinking water can contain coliforms one day a month and still comply with federal regulations. In addition, the water utility is only testing at the purification site. One cannot be sure of the integrity of the distribution between purification and use unless one tests for coliform at point of use.

How Long Should Sampling Continue?

A typical system validation might include daily monitoring for a month. But monitoring will continue after that at least once a week. A water purification system is dynamic and changing. As the seasons change, the microflora in the source water change. Witness the Cryptosporidium outbreak in Minnesota in 1993, which hospitalized 4,000 people and left 50 dead. This outbreak was seasonally influenced, occurring in the summer when water levels were low and turbidity hindered the disinfection process. Even within the plant, the purification system is changing all the time, as filters age, biofilms build, and materials corrode. Weekly monitoring allows for timely identification of alert levels, well before shutdown action levels occur. In the end, no compendium or regulatory guideline can detail an off-the-shelf microbiological validation scheme for water purification systems. There are too many different situations; the number of possible scenarios is an echo of the variety and adaptability of microbial life. Herein lies the solution: begin the validation process with the end product in mind. Focusing on the finished product discards unlikely microbial contaminants, and thereby focuses the methodology. References 1. FDA Guide to Inspections of High Purity Water Systems, 2 . Standard Methods for the Examination of Water and Wastewater, 18th Edition, American Public Health Association, Washington DC 2005 3. USP 27 <1231>Water for Pharmaceutical Purposes 4. US EPA 40CFR141.21 Total Coliform Rule 5. ibid.

Is a Coliform Test Necessary?

Water used in the manufacture of drug products must minimally be potable. The EPAs Total Coliform rule set a health goal for potable water at zero coliforms4. Coliforms are an artificial collection of bacteria devised by microbiologists and are used as an indicator of fecal contamination. They are categorized as gram negative lactose fermentors. Not all coliforms are pathogenic, but the presence of coliforms in water indicates the water is potentially unsafe. There are nonbacterial microbes of fecal origin that can make water unsafe: enteroviruses and protozoa, for example. It is not practical to screen for these organisms. Coliforms are used to indicate whether any other fecal pathogens might be present. Water collected from an onsite well must be tested for coliforms. The water is coming into the factorys purification system raw, and there is no evidence that it is coliform-free. A solid oral dosage manufacturer once found Klebsiella pneumonia in its final product and could not figure out where it was coming from. The company sampled the active, the excipients, the air and the personnel in search of the source. Eventually, the source was identified as the water used to clean the equipment. The manufacturer made the false assumption that the well

112 CONTRACT PHARMA October 2004

www.contractpharma.com

You might also like

- Chapter 7 Mosfets in Ics - Scaling, Leakage, and Other TopicsDocument43 pagesChapter 7 Mosfets in Ics - Scaling, Leakage, and Other Topicsmorcov19No ratings yet

- Doc1 ChemDocument16 pagesDoc1 ChemAishwarya Babu55% (11)

- Aquaponics Algae: How to Control, Combat and Get Rid of Algae in Aquaponics SystemFrom EverandAquaponics Algae: How to Control, Combat and Get Rid of Algae in Aquaponics SystemRating: 5 out of 5 stars5/5 (2)

- Arctander - Natural OriginDocument421 pagesArctander - Natural OriginM100% (2)

- Bacteriological Water AnalysisDocument6 pagesBacteriological Water Analysisramkrishna01No ratings yet

- Report On Microbiological Tests Carried Out For Lifesaver SystemsDocument3 pagesReport On Microbiological Tests Carried Out For Lifesaver SystemsCorporación CordesacNo ratings yet

- General Guidance For Establishing An Environmental Monitoring Program - Quality Assurance & Food SafetyDocument8 pagesGeneral Guidance For Establishing An Environmental Monitoring Program - Quality Assurance & Food SafetySQF PractitionerNo ratings yet

- Bacteriological Water AnalysisDocument8 pagesBacteriological Water AnalysisCasio Je-urNo ratings yet

- Biological Peramters of Waste WaterDocument23 pagesBiological Peramters of Waste WaterDhrijesh ChauhanNo ratings yet

- Environmental Monitoring of Manufacturing ProcessesDocument4 pagesEnvironmental Monitoring of Manufacturing ProcessesNainggolan TaruliNo ratings yet

- Literature Review On Bacteriological Analysis of Well WaterDocument9 pagesLiterature Review On Bacteriological Analysis of Well Waterbav1dik0jal3No ratings yet

- Sterility TestingDocument14 pagesSterility TestingsusubiribiNo ratings yet

- ERHDocument8 pagesERHJai MurugeshNo ratings yet

- Bacteriology of Water and Analysis: BasicsDocument37 pagesBacteriology of Water and Analysis: Basicstummalapalli venkateswara raoNo ratings yet

- Bacteriological Analysis Edited (1) صور 2Document30 pagesBacteriological Analysis Edited (1) صور 2Bourhan KassimNo ratings yet

- Bioburden USP PDFDocument4 pagesBioburden USP PDFKatyaSNNo ratings yet

- Determining Potability of WaterDocument3 pagesDetermining Potability of WaterKunal DuttaNo ratings yet

- Water QualityDocument7 pagesWater QualitydtgfNo ratings yet

- Abrera, Lucky Lynn R.-Activity5 - MicroparaDocument5 pagesAbrera, Lucky Lynn R.-Activity5 - MicroparaLucky Lynn AbreraNo ratings yet

- Microbial Indicators Jan 2013 0Document12 pagesMicrobial Indicators Jan 2013 0RAJAB TVNo ratings yet

- 5 Guide AnceDocument4 pages5 Guide AnceLeticia GallardoNo ratings yet

- Microbial Limits....Document9 pagesMicrobial Limits....Edphonce WalwaNo ratings yet

- Original Article Bacteriology Test To Detect Coliform Bacteria in Beverages Sold at University Cafeteria in MedanDocument9 pagesOriginal Article Bacteriology Test To Detect Coliform Bacteria in Beverages Sold at University Cafeteria in MedanVincentia Christinanda DonataNo ratings yet

- Water For Injection (WFI)Document10 pagesWater For Injection (WFI)Sriram Krishna100% (2)

- Environmental Sampling-A Tool To Verify The Effectiveness of Preventive Hygiene MeasuresDocument7 pagesEnvironmental Sampling-A Tool To Verify The Effectiveness of Preventive Hygiene Measuresudomsri_iNo ratings yet

- Microbiological Pharmaceutical Quality Control LabsDocument7 pagesMicrobiological Pharmaceutical Quality Control LabsDede Kizzy Black100% (1)

- Indicators of Food Microbial Quality and SafetyDocument12 pagesIndicators of Food Microbial Quality and SafetyMaryam Sar100% (1)

- Introduction To Techniques in MicrobiologyDocument4 pagesIntroduction To Techniques in MicrobiologyYusnita Damayanti100% (1)

- The Debate Coliforms, Fecal Coliforms, and Enterobacteriaceae As Indicator OrganismsDocument6 pagesThe Debate Coliforms, Fecal Coliforms, and Enterobacteriaceae As Indicator Organismspalani velanNo ratings yet

- Coliforms PDFDocument24 pagesColiforms PDFJulien Patrick CebrianNo ratings yet

- Interpreting Water Quality ResultsDocument8 pagesInterpreting Water Quality ResultsRahmat SyahrirNo ratings yet

- Week 8 Aerobic Plate CountDocument7 pagesWeek 8 Aerobic Plate CountSam 0505No ratings yet

- Bioburden ControlDocument48 pagesBioburden ControlSaint Tyagi100% (2)

- Microbiological Testing of BeveragesDocument20 pagesMicrobiological Testing of BeveragesSahil Sethi100% (1)

- DOC042.74.00438.Jun05 PDFDocument6 pagesDOC042.74.00438.Jun05 PDFvasqueznvNo ratings yet

- Water Quality and Standards PDFDocument9 pagesWater Quality and Standards PDFArly TolentinoNo ratings yet

- Tugas Pertemuan 2 Air 2020Document4 pagesTugas Pertemuan 2 Air 2020Suci DwiNo ratings yet

- Plan de Muestreo LaboDocument22 pagesPlan de Muestreo LaboValentina DiazNo ratings yet

- Usp 1112 Application of Water Activity Determination To Nonsterile Pharmaceutical ProductsDocument3 pagesUsp 1112 Application of Water Activity Determination To Nonsterile Pharmaceutical ProductsSB200 72Teo Lee ShaNo ratings yet

- Microbiological Pharmaceutical Quality Control Labs (7 - 93) - FDADocument8 pagesMicrobiological Pharmaceutical Quality Control Labs (7 - 93) - FDAArmando SaldañaNo ratings yet

- Smeets 20080415Document226 pagesSmeets 20080415PepeNo ratings yet

- Experiment 3 - Air, Water and Soil PollutionDocument9 pagesExperiment 3 - Air, Water and Soil PollutionTama KalongaNo ratings yet

- "Collection of Stool Specimen": Parasitology AssignmentDocument10 pages"Collection of Stool Specimen": Parasitology AssignmentOmar ElabdNo ratings yet

- BBL CLED Agar: ™ L007367 - Rev. 04 - May 2006Document3 pagesBBL CLED Agar: ™ L007367 - Rev. 04 - May 2006Muhammad Hadi ArwaniNo ratings yet

- BenefitsDocument4 pagesBenefitsCaroline MuthoniNo ratings yet

- 3711 MethodDocument25 pages3711 Methodkaira musahariNo ratings yet

- Ijerph 16 04463 v2Document9 pagesIjerph 16 04463 v2Trechabel OlaniganNo ratings yet

- Bacteriological Analysis of Pool WaterDocument4 pagesBacteriological Analysis of Pool WaterZenard de la CruzNo ratings yet

- FYP MSC Biotch ReportDocument66 pagesFYP MSC Biotch ReportGaurav ChauhanNo ratings yet

- ASI 10003B 7 Steps To Ensure Safe Water in HydrotherapyDocument9 pagesASI 10003B 7 Steps To Ensure Safe Water in HydrotherapyAbdullah AbdullahNo ratings yet

- Jurnal MPN PDFDocument6 pagesJurnal MPN PDFdewi novalitaNo ratings yet

- Bioburden Test, Microbiological Enumeration Test, Bacterial Endotoxins Test, Sterility Test and Microbial Testing of Water (Total Microbial Count Test and Test For Pathogen)Document56 pagesBioburden Test, Microbiological Enumeration Test, Bacterial Endotoxins Test, Sterility Test and Microbial Testing of Water (Total Microbial Count Test and Test For Pathogen)Imraan KhanNo ratings yet

- Laboratory Methods - BAM - Enumeration of - I - Escherichia Coli - I - and The Coliform BacteriaDocument15 pagesLaboratory Methods - BAM - Enumeration of - I - Escherichia Coli - I - and The Coliform BacteriaoktaNo ratings yet

- Enumeration of BacteriaDocument9 pagesEnumeration of BacteriaMAC DARREL MICHAEL MAC DARREL MICHAELNo ratings yet

- Wastewater Treatment Part 2Document7 pagesWastewater Treatment Part 2Khaled M FawzyNo ratings yet

- Hospital F W E Microbiology GuidelinesDocument24 pagesHospital F W E Microbiology GuidelinesrkssNo ratings yet

- Street FoodDocument4 pagesStreet FoodDr-Nancy ElafandyNo ratings yet

- LWR245 Biological Characteristics of WWDocument23 pagesLWR245 Biological Characteristics of WWchinyangaroseyNo ratings yet

- Molecular Microbial Diagnostic Methods: Pathways to Implementation for the Food and Water IndustriesFrom EverandMolecular Microbial Diagnostic Methods: Pathways to Implementation for the Food and Water IndustriesNo ratings yet

- Intertek Minerals Schedule of Services and Charges 2020 AUSDocument48 pagesIntertek Minerals Schedule of Services and Charges 2020 AUSVivek RanganathanNo ratings yet

- Determining The Water Holding Capacity of Microbial CelluloseDocument4 pagesDetermining The Water Holding Capacity of Microbial CellulosegoldennanukNo ratings yet

- Elems 10Document101 pagesElems 10Reynald de VeraNo ratings yet

- Indian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsDocument27 pagesIndian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsajayaghimireNo ratings yet

- Pomp EtaprimeDocument22 pagesPomp EtaprimeMarnix VanbavinckhoveNo ratings yet

- CHAPTER - BOOK - Fundición A Presión (Molde Permanente)Document10 pagesCHAPTER - BOOK - Fundición A Presión (Molde Permanente)JimyVillaNo ratings yet

- Effective Temperature ProcedureDocument4 pagesEffective Temperature ProcedurerakeshNo ratings yet

- SDB KEIM Concretal-LasurDocument8 pagesSDB KEIM Concretal-LasurgunelNo ratings yet

- Penthouse Winter 1986Document2 pagesPenthouse Winter 1986John M. CavoteNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- Min Zar TarDocument247 pagesMin Zar Tarjohndmariner123100% (13)

- GmE 202 Lecture 2 Physical Principles of Remote Sensing PDFDocument56 pagesGmE 202 Lecture 2 Physical Principles of Remote Sensing PDFJashley VillalbaNo ratings yet

- Bio Tec EcoPureBiodegradationFAQDocument6 pagesBio Tec EcoPureBiodegradationFAQH. Ali ArvasNo ratings yet

- Aits 2324 Ot I Jeea TD Paper 2 Offline SolDocument14 pagesAits 2324 Ot I Jeea TD Paper 2 Offline SolAshish SharmaNo ratings yet

- 1 s2.0 S2666790822000556 MainDocument16 pages1 s2.0 S2666790822000556 MainShrikant DeshmukhNo ratings yet

- Q1 - Module4 - G7 - 8 - BPP - Mangaldan NHSDocument11 pagesQ1 - Module4 - G7 - 8 - BPP - Mangaldan NHSElaeca AbenNo ratings yet

- Experiment 4: Gas Diffusion Coefficient: KeywordsDocument9 pagesExperiment 4: Gas Diffusion Coefficient: KeywordsMuhd Mukhrizan100% (3)

- Mastertile A 200 Msds PDFDocument11 pagesMastertile A 200 Msds PDFyaswanth reddy mummadiNo ratings yet

- COLUMN INTERNALS Part 1 - TRAYSDocument85 pagesCOLUMN INTERNALS Part 1 - TRAYSMohammadShamimNo ratings yet

- Graphical Representation of One-Dimensional, Transient Conduction in The Plane Wall, Long Cylinder, and SphereDocument5 pagesGraphical Representation of One-Dimensional, Transient Conduction in The Plane Wall, Long Cylinder, and Spherevincent02hk_57881301No ratings yet

- SAMSON 2005 Valve Sizing Sample Problems PDFDocument12 pagesSAMSON 2005 Valve Sizing Sample Problems PDFSatit hunsaNo ratings yet

- Cojinetes Lisos 4413Document56 pagesCojinetes Lisos 4413Roberto OrtegaNo ratings yet

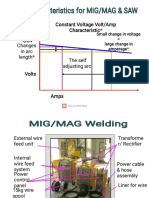

- Mig Mag Saw CswipDocument35 pagesMig Mag Saw CswipHamza DhariwalNo ratings yet

- Libro - Funcional Genomics - DNA, RNA and Protein Analysis - Springer ProtocolsDocument385 pagesLibro - Funcional Genomics - DNA, RNA and Protein Analysis - Springer ProtocolsDiana López López100% (3)

- Introduction To Optical Waveguides: Dr. Lukas ChrostowskiDocument66 pagesIntroduction To Optical Waveguides: Dr. Lukas ChrostowskiTiewsoh LikyntiNo ratings yet

- CH 1Document19 pagesCH 1abdallah elsharnobyNo ratings yet

- TIC D65 DispersantDocument4 pagesTIC D65 DispersantgeorgenzNo ratings yet

- Fusion Bonded EpoxyDocument4 pagesFusion Bonded EpoxyShakirNo ratings yet