Professional Documents

Culture Documents

U1 03 Manufacturing Cells

U1 03 Manufacturing Cells

Uploaded by

Deysi J. Barrera Mariscal0 ratings0% found this document useful (0 votes)

7 views2 pagesA manufacturing cell is a small unit consisting of one to several workstations, where each workstation contains one or more machines that perform different operations on parts being manufactured. Manufacturing cells are used for sheet metal forming and machining operations, and allow for loading/unloading materials, tool changes, part transfers between workstations, and process scheduling and control. Workload balancing is also essential, where the time of operations at each workstation is balanced to achieve constant flow and reduce lead times and in-process inventory. The article evaluates using genetic algorithms to simultaneously solve manufacturing cell formation and workload balancing problems to design optimal cellular manufacturing systems.

Original Description:

Original Title

U1 03 MANUFACTURING CELLS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA manufacturing cell is a small unit consisting of one to several workstations, where each workstation contains one or more machines that perform different operations on parts being manufactured. Manufacturing cells are used for sheet metal forming and machining operations, and allow for loading/unloading materials, tool changes, part transfers between workstations, and process scheduling and control. Workload balancing is also essential, where the time of operations at each workstation is balanced to achieve constant flow and reduce lead times and in-process inventory. The article evaluates using genetic algorithms to simultaneously solve manufacturing cell formation and workload balancing problems to design optimal cellular manufacturing systems.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views2 pagesU1 03 Manufacturing Cells

U1 03 Manufacturing Cells

Uploaded by

Deysi J. Barrera MariscalA manufacturing cell is a small unit consisting of one to several workstations, where each workstation contains one or more machines that perform different operations on parts being manufactured. Manufacturing cells are used for sheet metal forming and machining operations, and allow for loading/unloading materials, tool changes, part transfers between workstations, and process scheduling and control. Workload balancing is also essential, where the time of operations at each workstation is balanced to achieve constant flow and reduce lead times and in-process inventory. The article evaluates using genetic algorithms to simultaneously solve manufacturing cell formation and workload balancing problems to design optimal cellular manufacturing systems.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

U1 03 MANUFACTURING CELLS

What is a manufacturing cell?

It is a small unit, consisting of one to several workstations. As usual. A workstation

contains one machine (single machine cell) or multiple machines (machine group

cell), with each performing a different operation on the part.

What is his utility?

It is used primarily in sheet metal forming and machining operations. The machine

tools that are usually used in the cells are lathes, milling machines, drills, grinding

machines and electric discharge machines.

In general, cellular manufacturing capabilities include the following operations:

- Loading and unloading of raw materials and work pieces at work stations.

- Change of tools at work stations.

- Transfer of work pieces and tools between workstations.

- Scheduling and control of the total operation in the cell.

When was this article created?

2016

What else do you address after the manufacturing cell?

Workload balancing, which basically says that it is essential to consider workload

balancing to achieve a lean manufacturing system, in which cells have a constant

flow that reduces lead time and inventory in process.

Practically, workload balancing consists of balancing the total time of operations or

processes assigned to each workstation or machine in the cell.

What do they do in the article?

It is described the process developed, it begins with the introduction to the formation

of the manufacturing cells and the balancing of the workloads; then it presents the

proposed mathematical model, the structure of the genetic algorithm used with the

coding of the solutions and the implemented operators, then the methodology and

the experimental development implemented and finally, the results and conclusions

are presented.

It also covers the proposed mathematical method, the genetic algorithm,

methodology and experimental development, results and the conclusion.

What was the hypothesis?

The optimal design of cellular manufacturing systems through the simultaneous

solution of the formation of the manufacturing cells and the balancing of the

workloads using Genetic Algorithms (GA).

What is concluded from the article?

“From the values of the average percentage of deviation of the solutions with respect

to the optimum, it can be affirmed that the simultaneous solution of the formation of

the manufacturing cells and the balancing of workloads with Genetic Algorithms, is

a viable alternative that allows achieve very good solutions, with minimal deviation

from optimal values. This represents more efficient manufacturing system designs

in the industrial environment.

When considering the average time in obtaining the best solutions, a clear

advantage can be evidenced for the manufacturing system design process, since it

is possible to carry out several iterations that allow the results to be validated,

simulated or carried out a more detailed evaluation of these in a very short time.

Additionally, if changes are made to the products or processes that modify the

incidence matrix, the operating times and / or the cycle times, it is possible in a short

time to formulate new proposals to reconfigure the cells or modify the allocation of

the loads of work to achieve a better operation; this has a positive influence on

facilitating the flexibility of the system. "

You might also like

- Principles of ICD 10 Coding PDFDocument473 pagesPrinciples of ICD 10 Coding PDFSheilla Rismadwita100% (13)

- The Big Book Comes Alive (Transcribed)Document151 pagesThe Big Book Comes Alive (Transcribed)briespot100% (2)

- Process Analysis Note PDFDocument10 pagesProcess Analysis Note PDFPierrePMMartinNo ratings yet

- Hayssen Training ElectricalDocument17 pagesHayssen Training ElectricalRoberto SanchezNo ratings yet

- Jon Thompson Naked Mentalism 3Document100 pagesJon Thompson Naked Mentalism 3AlaaFathey100% (7)

- Simulation Model From Lean maNF.Document16 pagesSimulation Model From Lean maNF.Ankita BaidNo ratings yet

- Performance Analysis of A Batch Production System With Limited #ExibilityDocument10 pagesPerformance Analysis of A Batch Production System With Limited #Exibilityranjan349No ratings yet

- Best and Simple NoteDocument9 pagesBest and Simple NoteRahul DesaiNo ratings yet

- How Factory Physics Helps SimulationDocument6 pagesHow Factory Physics Helps SimulationJerome KozlowskiNo ratings yet

- Cellular Manufacturing Is A Model For WorkplaceDocument4 pagesCellular Manufacturing Is A Model For WorkplacePrashant AroraNo ratings yet

- GalactosidaseDocument2 pagesGalactosidaseThirupathi Kumara Raja SelvarajNo ratings yet

- Using SimulationDocument18 pagesUsing Simulationdr_hsn57No ratings yet

- ArenaDocument8 pagesArenaHemanthNo ratings yet

- Single Piece MovementDocument5 pagesSingle Piece MovementSaurav SinghNo ratings yet

- The Use of Simulation and Genetic Algorithm With Different Genetic Operators To Optimize Manufacturing SystemDocument12 pagesThe Use of Simulation and Genetic Algorithm With Different Genetic Operators To Optimize Manufacturing SystemSam ArNo ratings yet

- A Framework For Capacity Planning and Machine Configuration in Flexible Assembly SystemsDocument30 pagesA Framework For Capacity Planning and Machine Configuration in Flexible Assembly SystemsYan1203100% (1)

- Heijunka ReporteDocument16 pagesHeijunka Reporteastriu chiroqueNo ratings yet

- Literature Review On Cellular ManufacturingDocument8 pagesLiterature Review On Cellular Manufacturingafmzxutkxdkdam100% (1)

- Manufacturing Flow Line Systems: A Review of Models and Analytical ResultsDocument88 pagesManufacturing Flow Line Systems: A Review of Models and Analytical ResultsHairul HanizanNo ratings yet

- Balancing Mixed Ergonomics - Model Assembly Line To Reduce Work Overload in A Multi-Level Production SystemDocument9 pagesBalancing Mixed Ergonomics - Model Assembly Line To Reduce Work Overload in A Multi-Level Production SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Tact Time StudyDocument10 pagesTact Time StudyAtul SharmaNo ratings yet

- EURO Surv PDFDocument28 pagesEURO Surv PDFKailash BhosaleNo ratings yet

- Perf AutoDocument5 pagesPerf Autobrigittebardot55No ratings yet

- A Simulation Approach For Productivity Improvement of An IC FactoryDocument8 pagesA Simulation Approach For Productivity Improvement of An IC Factorycsrajmohan2924No ratings yet

- A Comparison of The Push and Pull Production SysteDocument18 pagesA Comparison of The Push and Pull Production SystePratikJagtapNo ratings yet

- Scheduling of Unrelated Parallel Manufacturing Cells With Limited Human ResourcesDocument24 pagesScheduling of Unrelated Parallel Manufacturing Cells With Limited Human ResourcesRajani JhaNo ratings yet

- Waqas GanduDocument18 pagesWaqas GanduHassaan RajpootNo ratings yet

- Cell Layout: January 2015Document5 pagesCell Layout: January 2015Khalilur Rehaman SavanurNo ratings yet

- Basics in Process Design - 2006 PDFDocument30 pagesBasics in Process Design - 2006 PDFSamuel OnyewuenyiNo ratings yet

- Disassembly Automation Automated Systems With Cognitive Abilities (Supachai Vongbunyong, Wei Hua Chen (Auth.) ) (Z-Library)Document205 pagesDisassembly Automation Automated Systems With Cognitive Abilities (Supachai Vongbunyong, Wei Hua Chen (Auth.) ) (Z-Library)372060579No ratings yet

- Overall Equipment EffectivenessDocument27 pagesOverall Equipment EffectivenessMarciano ZanottoNo ratings yet

- CellDocument1 pageCellmajitra100% (2)

- Control System Engineering - 1Document22 pagesControl System Engineering - 1Uma MageshwariNo ratings yet

- Need For Process ControlDocument4 pagesNeed For Process ControlMOHAMED MANSUR SNo ratings yet

- Cellular ManufacturingDocument12 pagesCellular ManufacturingKhushal JoshiNo ratings yet

- Ijaiem 2014 12 07 16Document6 pagesIjaiem 2014 12 07 16International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Holonic Approach For Manufacturing Execution System DesignDocument9 pagesA Holonic Approach For Manufacturing Execution System Design孫ウィーユNo ratings yet

- No Absen 5Document16 pagesNo Absen 5AliJunkoNo ratings yet

- Assignment 3 - 174660920-145 - PomDocument10 pagesAssignment 3 - 174660920-145 - PomUMAR FAROOQNo ratings yet

- 2003kuhn AutomatedFlowLine KluwerDocument27 pages2003kuhn AutomatedFlowLine KluwerAyten EliyevaNo ratings yet

- Graficos de ControlDocument7 pagesGraficos de ControlAli BadfaceNo ratings yet

- Cuatrecasas-Arbos, Fortuny-Santos, Vintro-Sanchez - 2011 - The Operations-Time Chart A Graphical Tool To Evaluate The Performance of Pro PDFDocument13 pagesCuatrecasas-Arbos, Fortuny-Santos, Vintro-Sanchez - 2011 - The Operations-Time Chart A Graphical Tool To Evaluate The Performance of Pro PDFDragan DragičevićNo ratings yet

- Simulation, Modelling FOR Manufacturing Systems: Ravinder Jhorar 2011PMM5173Document32 pagesSimulation, Modelling FOR Manufacturing Systems: Ravinder Jhorar 2011PMM5173Ravinder JhorarNo ratings yet

- Chapter OneDocument12 pagesChapter OneKelvin CeejayNo ratings yet

- Application of Queuing Theory in Quality Control of Multi-Stage Flexible Flow ShopDocument8 pagesApplication of Queuing Theory in Quality Control of Multi-Stage Flexible Flow ShopsyafiraNo ratings yet

- Control Systems Engineering: January 2010Document22 pagesControl Systems Engineering: January 2010Kanugolu Bala Ananth SaiNo ratings yet

- Multi-Objective Design of Team Oriented Assembly Systems: Joseph Bukchin, Michael MasinDocument27 pagesMulti-Objective Design of Team Oriented Assembly Systems: Joseph Bukchin, Michael MasinYu ZhangNo ratings yet

- Material Flow Control in Remanufacturing Systems WDocument26 pagesMaterial Flow Control in Remanufacturing Systems Whajahora3No ratings yet

- System Modeling and Simulation AssignmentDocument14 pagesSystem Modeling and Simulation Assignmentaws KyksNo ratings yet

- A New Method For Bottleneck DetectionDocument5 pagesA New Method For Bottleneck DetectionAmrik SinghNo ratings yet

- Research Paper On Adaptive ControlDocument4 pagesResearch Paper On Adaptive Controlvstxevplg100% (1)

- Calculating The Capacity of Chemical PlantsDocument5 pagesCalculating The Capacity of Chemical PlantsEigen GalvezNo ratings yet

- Business Process Modeling (BPM)Document4 pagesBusiness Process Modeling (BPM)Masroor Ahmed SiddiqiNo ratings yet

- A Quantitative Analysis of Cellular Manufacturing in Apparel Industry by Using SimulationDocument12 pagesA Quantitative Analysis of Cellular Manufacturing in Apparel Industry by Using SimulationSHASHANK ROHITNo ratings yet

- 5-1 Introduction:: Chapter Five Process SimulationDocument10 pages5-1 Introduction:: Chapter Five Process SimulationNoon Abdallah AbdalroufNo ratings yet

- Control Degrees of FreedomDocument11 pagesControl Degrees of FreedomAlastair WongNo ratings yet

- Control Systems Engineering: January 2010Document22 pagesControl Systems Engineering: January 2010khacsau2904No ratings yet

- Line Balancing and Optimization For Single Model Assembly Line at A Small Medium Industry (SMI)Document27 pagesLine Balancing and Optimization For Single Model Assembly Line at A Small Medium Industry (SMI)Mouad SaroutiNo ratings yet

- Markov Model For Analyzing Sensitivity To Change in Machine Repair Reliability Using Its TransitionDocument12 pagesMarkov Model For Analyzing Sensitivity To Change in Machine Repair Reliability Using Its TransitionIJRASETPublicationsNo ratings yet

- Chemical ProcessesDocument103 pagesChemical ProcessesHildemaro CarrasquelNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Critical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.From EverandCritical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.No ratings yet

- U1 01 Manufacturing SystemsDocument1 pageU1 01 Manufacturing SystemsDeysi J. Barrera MariscalNo ratings yet

- Flexible Manufacturing SystemsDocument3 pagesFlexible Manufacturing SystemsDeysi J. Barrera MariscalNo ratings yet

- U1 02 Historical Development of The ManufactureDocument2 pagesU1 02 Historical Development of The ManufactureDeysi J. Barrera MariscalNo ratings yet

- U1 05 Advanced Manufacturing MethodsDocument7 pagesU1 05 Advanced Manufacturing MethodsDeysi J. Barrera MariscalNo ratings yet

- Stamens PDFDocument10 pagesStamens PDFAmeya KannamwarNo ratings yet

- AKS32-33 TebrDocument4 pagesAKS32-33 TebrtaupiqNo ratings yet

- Statement of Principle Self-Care Including Self-Medication - The Professional Role of The PharmacistDocument5 pagesStatement of Principle Self-Care Including Self-Medication - The Professional Role of The PharmacistAprilia R. Permatasari0% (1)

- Testbank ch01Document14 pagesTestbank ch01HườngNo ratings yet

- Cases NATRES Batch1Document113 pagesCases NATRES Batch1Leo Mark LongcopNo ratings yet

- Chapter 24 Practice QuestionsDocument7 pagesChapter 24 Practice QuestionsArlene F. Montalbo100% (1)

- NIDAR, Franced Haggai G. The Brain Is The Vehicle of The MindDocument1 pageNIDAR, Franced Haggai G. The Brain Is The Vehicle of The MindHaggai NidarNo ratings yet

- Irda Jun10Document96 pagesIrda Jun10ManiNo ratings yet

- Soal BAHASA INGGRIS XIIDocument5 pagesSoal BAHASA INGGRIS XIIZiyad Frnandaa SyamsNo ratings yet

- RPS Akuntansi KeperilakuanDocument4 pagesRPS Akuntansi KeperilakuanNIWAYANRADHANo ratings yet

- Badenian Gastropods From The Collections of The Mureş County MuseumDocument26 pagesBadenian Gastropods From The Collections of The Mureş County MuseumLouisaMjjNo ratings yet

- Vitamin A & D: Chemistry, Biochemical Role, RDA & Deficiency DiseasesDocument20 pagesVitamin A & D: Chemistry, Biochemical Role, RDA & Deficiency DiseasesSELVI ANo ratings yet

- Std12 IndCulture TMDocument201 pagesStd12 IndCulture TMTholkappiyan GanesanNo ratings yet

- Skript Version30 PDFDocument90 pagesSkript Version30 PDFNguyễn TúNo ratings yet

- 1.the Perception of Local Street Food VendorsDocument28 pages1.the Perception of Local Street Food VendorsJay Vince Agpoon MendozaNo ratings yet

- Friction Worksheet: Part A Questions - Multiple ChoiceDocument2 pagesFriction Worksheet: Part A Questions - Multiple ChoiceAmos JosephatNo ratings yet

- Tone and MoodDocument8 pagesTone and MoodKristine PanalNo ratings yet

- SOAL MID TERM ENGLISH 13 Tyad 1Document6 pagesSOAL MID TERM ENGLISH 13 Tyad 1ani julitaNo ratings yet

- BenfordDocument9 pagesBenfordAlex MireniucNo ratings yet

- Asb - 212 10 140Document12 pagesAsb - 212 10 140smartasss100% (1)

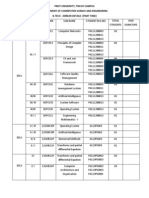

- Prist University, Trichy Campus Department of Comnputer Science and Engineering B.Tech - Arrear Details (Part Time)Document2 pagesPrist University, Trichy Campus Department of Comnputer Science and Engineering B.Tech - Arrear Details (Part Time)diltvkNo ratings yet

- Brazil Is Samba: Rhythm, Percussion, and Samba in The Formation of Brazilian National Identity (1902-1958)Document135 pagesBrazil Is Samba: Rhythm, Percussion, and Samba in The Formation of Brazilian National Identity (1902-1958)Carlos Barrientos100% (1)

- Alcohol Antiseptic 80% Topical Solution: Hand Sanitizer Non-Sterile SolutionDocument2 pagesAlcohol Antiseptic 80% Topical Solution: Hand Sanitizer Non-Sterile SolutionClarissa BagonNo ratings yet

- Economists' Corner: Weighing The Procompetitive and Anticompetitive Effects of RPM Under The Rule of ReasonDocument3 pagesEconomists' Corner: Weighing The Procompetitive and Anticompetitive Effects of RPM Under The Rule of ReasonHarsh GandhiNo ratings yet

- Foreign Body Airway ObstructionDocument16 pagesForeign Body Airway ObstructionKatNo ratings yet

- Brachy Quality GuideDocument270 pagesBrachy Quality GuideTejinder SinghNo ratings yet