Professional Documents

Culture Documents

Data Sheet: Applications Designation Chemical Composition

Data Sheet: Applications Designation Chemical Composition

Uploaded by

ManankOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet: Applications Designation Chemical Composition

Data Sheet: Applications Designation Chemical Composition

Uploaded by

ManankCopyright:

Available Formats

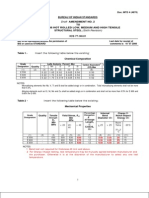

DATA SHEET 1999.03.

01

EXTRA HIGH STRENGTH STRUCTURAL PLATE

WELDOX 420 is a weldable, fine grained steel.

Applications Bridges, silos, steelwork buildings, turbines, cranes, overhead travelling cranes, dolphins, penstocks,

water towers, offshore structures, lifting tackle, etc.

Designation WELDOX 420 D with guaranteed impact toughness at 20°C.

WELDOX 420 E with guaranteed impact toughness at 50°C.

Chemical Composition C* Si* Mn* P S Nb* V* Ti* Al* Mo Ni N CEV

(ladle analysis) total

max max max max max max max max min max max max max

% % % % % % % % % % % % %

0,14 0,50 1,70 0,025 0,015 0,05 0,10 0,02 0,015 0,05 0,10 0,015 1)

1)

Plate thickness CEV

60 mm 0,39

> 60 mm 0,40

Mn Cr + Mo + V Ni + Cu

CEV = C + + + *)

Intentional alloying elements

6 5 15

Mechanical Properties Plate thickness Yield strength Tensile strength Elongation

mm ReHor Rp 0,2 min Rm A5 min

N/mm2 N/mm2 %

6 16 420 500660 19

(16)40,0 400 500660 19

(40)630 390 500660 19

(63)80,0 380 480650 19

Impact Properties Grade Test Impact energy 1) Charpy V,

temperature longitudinal specimen,

°C min., J

WELDOX 420 D 20 40

WELDOX 420 E 50 27

1)

Average of three tests.

Single value at least 70% of the specified mean value.

Testing Testing in accordance with EN 10 113-1 and EN 10 113-3.

Delivery Condition Thermomechanically rolled (M) or quenched and tempered (Q) as determined by us unless otherwise

agreed.

Delivery condition Q principally above 40 mm.

Dimensions WELDOX 420 is delivered in plate thicknesses between 6 and 80 mm. More detailed information on

dimensions is provided in our brochure E-40, General Product Information.

Certain width restrictions may apply.

Tolerances According to EN 10 029

Thickness tolerance to Class A.

Flatness tolerance to Class N (normal tolerance).

Surface finish According to EN 10 163-2

Surface requirements to Class A.

Repair conditions to Subclass 1(Repair by welding is allowed).

E-117 Sörmlandstryck Nyköping 1999

SSAB Oxelösund AB Telefon. Telefax Telex

S-613 80 Oxelösund +46 155-25 40 00 +46 155-25 40 73 50950 SSAB S www.oxelosund.ssab.se

DATA SHEET

WELDOX 420

General Technical According to our brochure E-40, General Product Information.

Delivery Requirements WELDOX 420 conforms to all technical requirements in EN 10 113-3, except as regards the delivery

condition of plate with a thickness above 40 mm.

Options 8 and 14 are applied.

Heat Treatment WELDOX 420 has obtained it's high strength by rolling at a particular temperature and by con-

and Fabrication trolled cooling. The final properties cannot be restored after the material has been heated to more

than 580°C. WELDOX 420 must therefore not be used for applications requiring fabrication at

elevated temperatures above 580°C, since the material may lose it's good properties at temperatures

above this value.

For steel in condition Q, this upper temperature limit is 600°C.

For information concerning welding and fabrication, see our brochures listed below or consult our

Technical Customer Service.

Fabrication Brochure No: Handbook No:

Machining En-10

Welding En-11 En-50

Bending

Shearing En-12

Cutting En-14

Appropriate health and saftey precautions must be taken when welding, cutting, grinding or otherwise

working on the product. Grinding, especially of primer coated plates, may produce dust with high

particle concentration. Our Technical Customer Service Department will provide further information on

request.

You might also like

- CH 17Document183 pagesCH 17Neerom Baldemoro100% (1)

- Chapter 2Document72 pagesChapter 2Shubham ChandeNo ratings yet

- Din 1630 PDFDocument3 pagesDin 1630 PDFv53100% (1)

- Ew 700Document2 pagesEw 700Stefano BarbieriNo ratings yet

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarNo ratings yet

- Hardox 500 PDFDocument2 pagesHardox 500 PDFMustafa Mahmoud ElsayedNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Hardox 450Document2 pagesHardox 450arif.haddieNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- Hardox 400 Uk PDFDocument2 pagesHardox 400 Uk PDFMario Mereni100% (1)

- C86200 Manganese BronzeDocument1 pageC86200 Manganese BronzeDeepak KumarNo ratings yet

- Acero T-1Document2 pagesAcero T-1mandrakebustosNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Project Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16Document21 pagesProject Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16kheang amgNo ratings yet

- Technical Data: 02014W104KATDocument9 pagesTechnical Data: 02014W104KATndfgdfs oishdfNo ratings yet

- Jack Portal ConnectionDocument24 pagesJack Portal ConnectionAfsal JhNo ratings yet

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesNo ratings yet

- Base Plate Box-400x8Document6 pagesBase Plate Box-400x8Amr M. AbdallahNo ratings yet

- Base Plate of Box4-400x400x8 MMDocument49 pagesBase Plate of Box4-400x400x8 MMAmr M. AbdallahNo ratings yet

- Voestalpine Heavy Plate Datasheet Durostat en 20170904Document3 pagesVoestalpine Heavy Plate Datasheet Durostat en 20170904Kristy HillNo ratings yet

- Base PlateDocument9 pagesBase PlateAmr M. AbdallahNo ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

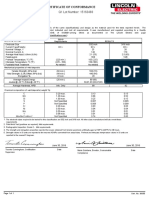

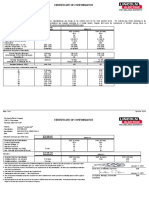

- Q1 Lot Number: 15888757: Certificate of ConformanceDocument2 pagesQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNo ratings yet

- MTD4 (4870)Document2 pagesMTD4 (4870)Muthu KumarNo ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- Din 2395-1Document4 pagesDin 2395-113393m210No ratings yet

- Classification: AWS A5.22 E310T0-1 AWS A5.22 E310T0-4: All-Weld-Metal (100%CO) 1-1. Chemical CompositionDocument2 pagesClassification: AWS A5.22 E310T0-1 AWS A5.22 E310T0-4: All-Weld-Metal (100%CO) 1-1. Chemical Compositionmohamed AdelNo ratings yet

- Ex EN 43100 AlSi10Mg (B) non-EN AB Standard AlloyDocument2 pagesEx EN 43100 AlSi10Mg (B) non-EN AB Standard Alloygtarq09No ratings yet

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- Iso 13715 PDFDocument2 pagesIso 13715 PDFnovkovic1984No ratings yet

- ML 13 FC AlSi (Cu) non-EN AB Standard AlloyDocument2 pagesML 13 FC AlSi (Cu) non-EN AB Standard Alloygtarq09No ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- Excalibur 11018M MR CertDocument2 pagesExcalibur 11018M MR CertAminNo ratings yet

- Barra Sanmac 2205Document8 pagesBarra Sanmac 2205Lei WuNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- CertMaterialTestReport E6010 Fletweld SP 1-8Document1 pageCertMaterialTestReport E6010 Fletweld SP 1-8gerosuca800No ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- Tin Bronze C90300 PDFDocument1 pageTin Bronze C90300 PDFDeepak KumarNo ratings yet

- C87600 Copper Silicon: Brass & Bronze AlloysDocument1 pageC87600 Copper Silicon: Brass & Bronze AlloysDeepak KumarNo ratings yet

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- Physical: .100" and .100" × .100" Straight, Solder Tails 929 SeriesDocument3 pagesPhysical: .100" and .100" × .100" Straight, Solder Tails 929 Seriesyamaha640No ratings yet

- EN 51500 AlMg5Si2MnDocument2 pagesEN 51500 AlMg5Si2Mngtarq09No ratings yet

- Acc Moe REPORT PDFDocument4 pagesAcc Moe REPORT PDFSabyasachi BangalNo ratings yet

- MOE Test Result of Acc ConcreteDocument4 pagesMOE Test Result of Acc ConcreteSabyasachi BangalNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- ConnectionDocument7 pagesConnectionFlavio SNo ratings yet

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Lincolnweld 888 & LA-85Document2 pagesLincolnweld 888 & LA-85Pablo PazNo ratings yet

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLNo ratings yet

- Pipeliner 7P+: Conformances Key FeaturesDocument2 pagesPipeliner 7P+: Conformances Key FeaturesAnand GNo ratings yet

- Report On Tensile Strength Tests of Reinforcing Steel BarsDocument1 pageReport On Tensile Strength Tests of Reinforcing Steel BarsarceniaNo ratings yet

- EN 47000 AlSi12 (Cu)Document2 pagesEN 47000 AlSi12 (Cu)gtarq09No ratings yet

- Project Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Document7 pagesProject Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Abdullah NajjarNo ratings yet

- Physical and Piezoelectric Properties of APC MaterialsDocument2 pagesPhysical and Piezoelectric Properties of APC MaterialsTrương Anh DuyNo ratings yet

- Ss400 Ned & Pcsir ResultsDocument1 pageSs400 Ned & Pcsir ResultsMinhas ArshadNo ratings yet

- NIC Components NMC X8S SeriesDocument2 pagesNIC Components NMC X8S SeriesNICCompNo ratings yet

- VDRSMDDocument5 pagesVDRSMDheidari.mailNo ratings yet

- Stainless Steel 1.4571Document4 pagesStainless Steel 1.4571ANKUSH PARMARNo ratings yet

- 06042016000000T_Phoenix Cel 90_ceDocument1 page06042016000000T_Phoenix Cel 90_ceJonathan Lozada CarrascoNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Fiber Laser Cutting Machine Maintenance ManualDocument5 pagesFiber Laser Cutting Machine Maintenance ManualVlatko GavrilovNo ratings yet

- Air Deflectors in Tunnel Ventilated HousesDocument5 pagesAir Deflectors in Tunnel Ventilated HousesReza Aulia PutraNo ratings yet

- Open LISEMDocument71 pagesOpen LISEMlozaNo ratings yet

- HW 4 Solution PDFDocument5 pagesHW 4 Solution PDFyesNo ratings yet

- Phase Diagram LiCl+MgCl2+KCl+H2O at 323.15K PDFDocument8 pagesPhase Diagram LiCl+MgCl2+KCl+H2O at 323.15K PDFJhos Micky Condori AndiaNo ratings yet

- Journal of Desalination and Water PurificationDocument7 pagesJournal of Desalination and Water PurificationdevyNo ratings yet

- Water-Bitumen Emulsions Based On Surfactants of Various TypesDocument8 pagesWater-Bitumen Emulsions Based On Surfactants of Various TypesAhmed TahsinNo ratings yet

- DT210 PDFDocument358 pagesDT210 PDFJohneal MatiasNo ratings yet

- SPE 96844 Light-Oil Air-Injection Performance: Sensitivity To Critical ParametersDocument11 pagesSPE 96844 Light-Oil Air-Injection Performance: Sensitivity To Critical ParametersGregorio Otero SosaNo ratings yet

- Photo ResistorsDocument20 pagesPhoto ResistorsRashmi ChaturvediNo ratings yet

- PROFILE Sameep Engineering HKPDocument85 pagesPROFILE Sameep Engineering HKPParag WadekarNo ratings yet

- Difference Between HVWS and MVWS SystemDocument1 pageDifference Between HVWS and MVWS SystemRaj Kamal100% (1)

- CE101 July 2003Document4 pagesCE101 July 2003ffgfgfgffgNo ratings yet

- Equilibria Revision Question CIE Question 1 PDFDocument16 pagesEquilibria Revision Question CIE Question 1 PDFdanielmahsa50% (2)

- Giw LCCDocument8 pagesGiw LCCCesar Leonardo Mendoza LoyolaNo ratings yet

- 2013 Vector Unit FTF Handbook PDFDocument56 pages2013 Vector Unit FTF Handbook PDFJuan Miguel Marin Quintero100% (1)

- Chem843 6Document16 pagesChem843 6soenen.bramNo ratings yet

- Unt - 0 5608 1 PDFDocument163 pagesUnt - 0 5608 1 PDFKarnalPreethNo ratings yet

- Electro ChemistryDocument7 pagesElectro ChemistryStuti KarnNo ratings yet

- Oisd-Std-141Document72 pagesOisd-Std-141Pradeep KumarNo ratings yet

- Chapter Three: Bearing Capacity of Soils (Shallow Foundations)Document15 pagesChapter Three: Bearing Capacity of Soils (Shallow Foundations)Wubetie MengistNo ratings yet

- Wedling ModelingDocument32 pagesWedling ModelingManish KumarNo ratings yet

- 238 Modeling of Gas Turbines and Steam Turbines in Combined Cycle Power Plants PDFDocument119 pages238 Modeling of Gas Turbines and Steam Turbines in Combined Cycle Power Plants PDFsenthil031277100% (2)

- Applikationsbeitrag FRECH ENDocument4 pagesApplikationsbeitrag FRECH ENDinh Thi TruongNo ratings yet

- Wave Optics PDFDocument52 pagesWave Optics PDFMD CHHIMPANo ratings yet

- English for Oil and Gas Solomchak Ozarko Moiseyenko ІDocument186 pagesEnglish for Oil and Gas Solomchak Ozarko Moiseyenko ІNeonila KryvtsunNo ratings yet

- Pro Olayanju AssDocument3 pagesPro Olayanju AssOladoyin AyodejiNo ratings yet

- 5 Sem SyllabusDocument7 pages5 Sem Syllabusadityakushwaha371No ratings yet