Professional Documents

Culture Documents

Safety Promotion Notice: Subject: Standard Practices Recommendations For Torquing Operations

Safety Promotion Notice: Subject: Standard Practices Recommendations For Torquing Operations

Uploaded by

Ibrahim AsifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Promotion Notice: Subject: Standard Practices Recommendations For Torquing Operations

Safety Promotion Notice: Subject: Standard Practices Recommendations For Torquing Operations

Uploaded by

Ibrahim AsifCopyright:

Available Formats

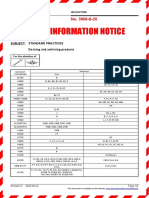

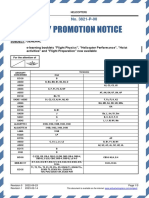

No.

3552-P-20

SAFETY PROMOTION NOTICE

SUBJECT: STANDARD PRACTICES

Recommendations for torquing operations

For the attention of

AIRCRAFT Version(s)

CONCERNED Civil Military

EC120 B

AS350 B, BA, BB, B1, B2, B3, D L1

AS550 A2, C2, C3, U2

AS355 E, F, F1, F2, N, NP

AS555 AF, AN, SN, UF, UN, AP

EC130 B4, T2

SA365 / AS365 C1, C2, C3, N, N1, N2, N3 F, Fs, Fi, K, K2

AS565 MA, MB, SA, SB, UB, MBe

SA366 GA

EC155 B, B1

SA330 J Ba, L, Jm, S1, Sm

SA341 G B, C, D, E, F, H

SA342 J L, L1, M, M1, Ma

ALOUETTE II 313B, 3130, 318B, 318C, 3180

ALOUETTE III 316B, 316C, 3160, 319B

LAMA 315B

EC225 LP

EC725 AP

AS332 C, C1, L, L1, L2 B, B1, F1, M, M1

AS532 A2, U2, AC, AL, SC, UE, UL

EC175 B

EC339 KUH/Surion

C (C23, CB, CB-4, CB-5), D (DB, DBS, DB-4, DBS-4,

BO105 CBS-5 KLH, E-4

DBS-5), S (CS, CBS, CBS-4, CBS-5), LS A-3

A-1, A-3, A-4, B-1, B-2, C-1, C-2, C-2e, D-2, D-2m, D-3,

MBB-BK117 D-2m, D-3m

D-3m

T1, T2, T2+, T3, P1, P2, P2+, P3, EC635 T1, EC635 T2+,

EC135 EC635 T3, EC635 P2+, EC635 P3,

T3H, P3H, EC635 T3H, EC635 P3H

Revision 0 2020-11-12 Page 1/5

This document is available on the internet: www.airbushelicopters.com/techpub/

No. 3552-P-20

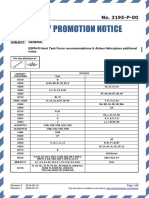

INTRODUCTION

The aim of this Safety Promotion Notice is to support the understanding of torquing practices by introducing four

explanatory videos available on the Airbus Helicopters website

(https://www.airbus.com/helicopters/safety/SafetyVideo-e-learnings.html#technicians) and on Dailymotion through

the QR codes and links given below. These videos neither intend to be exhaustive nor replace the documentation

(MTC 20-02-05-404 Assembly by screws and nuts). However, they are a complement intended to draw your

attention to the essential parts of the application, check and adjustment of a tightening torque.

The idea of introducing these information videos and this Safety Promotion Notice comes from a general

observation: numerous incidents/accidents are due to errors committed during the application of tightening torque.

Compliance with the good practices is one of the paths that enable reducing the risk and improving safety of

maintenance operators and passengers. These good practices are part of a wider approach in which, for example,

general workshop organization, time pressure or operator fatigue are factors that contribute to errors that can have

severe consequences. These other contributing factors are described, together with recommendations, in Safety

Promotion Notice No. 3399-P-20 "Visual Inspection".

Good practices common to the application, check and adjustment of a

tightening torque

https://dai.ly/k5Yl3Sf1xQRLDAw6iXr

This video shows:

• The check of the correcting factor for the procedure on an assembly with grease or

self-locking nut.

• The smooth and progressive application of the tightening torque and the position of the hands on the rotational

axis of the wrench and the grip.

Airbus Helicopters recommends the use of a digital torque

wrench to apply, check and adjust a tightening torque.

All the torque wrenches must be calibrated on a regular basis.

Preparation common to the application, check and adjustment of a tightening torque

For all the practices related to tightening torque, it is necessary to:

• Remove the seal using a plastic scraper

• Clean the zone using a cloth

• Remove the split pin or any equivalent locking component.

All these components can be dangerous in terms of FOD if they are forgotten

in the work zone. It is thus appropriate to provide all the necessary means in

terms of organization and support for the storage of all the tools and

consumables. (For example, the use of red portable bunks).

Revision 0 2020-11-12 Page 2/5

This document is available on the internet: www.airbushelicopters.com/techpub/

No. 3552-P-20

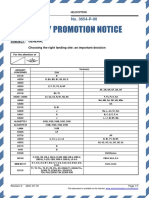

Application of tightening torque

https://dai.ly/k5qCFlVCuF9vByw6iXt

The essential steps of a torque application are as follows:

• Installation of washers, including a check of the procedure for the assembly order and

direction

• Cross-marking of the bolt end to make the installation of the split pin easier

• Installation of the nut that must make full contact

• Setting of the wrench to the minimum value defined in the procedure

• Application of the tightening torque without exceeding the maximum torque value to align the nut slot with the

split pin hole.

Check of the tightening torque

https://dai.ly/k5Y7dPxQDmsXZJw6iXo

The first essential step of the torque check is to apply a mark with a red felt pen that covers

the nut/screw assembly and the fixed support. The setting of the torque wrench to the

minimum value is also required for the preliminary steps.

Revision 0 2020-11-12 Page 3/5

This document is available on the internet: www.airbushelicopters.com/techpub/

No. 3552-P-20

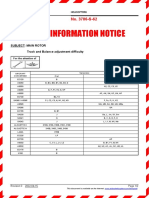

Then, the check of the tightening torque can show 3 scenarios:

• If the operator reaches the minimum torque value before alignment of the marks, torquing continues until the

marks are aligned.

• If the operator exceeds the mark before reaching the minimum torque value, but without being below 15% of

the minimum torque value, the operator applies the torque again, without exceeding the maximum torque

value.

Revision 0 2020-11-12 Page 4/5

This document is available on the internet: www.airbushelicopters.com/techpub/

No. 3552-P-20

• If the operator exceeds the mark before reaching the minimum torque value while being below 15% of the

minimum torque value, the operator removes the component for inspection.

The operator then inspects the screw/nut assembly to make sure

that it is in good condition (suspicions of fretting).

Adjustment of the tightening torque

https://dai.ly/k2hm2P8kPwQqKCw6iXn

Adjustment of the tightening torque requires:

• The application of a mark with a red felt pen that covers the nut/screw assembly and the

fixed support (see Check of the tightening torque)

• Loosening of the nut by a quarter of a turn

• Setting of the wrench to the minimum value

• Application of the tightening torque (see Application of the tightening torque).

Revision 0 2020-11-12 Page 5/5

This document is available on the internet: www.airbushelicopters.com/techpub/

You might also like

- Original PDF Essential Communication by Ronald Adler PDFDocument41 pagesOriginal PDF Essential Communication by Ronald Adler PDFmary.burklow183100% (34)

- Dell Inspiron 3493 3593 Compal FDI55 LA J081P FDI45 LA J091P 1 0Document101 pagesDell Inspiron 3493 3593 Compal FDI55 LA J081P FDI45 LA J091P 1 0Tran Minh100% (1)

- VXP System Maintenance ManualDocument105 pagesVXP System Maintenance ManualIbrahim Asif100% (1)

- Auto Pilot PDFDocument41 pagesAuto Pilot PDFharun2261No ratings yet

- SIN3868S20RN0Document2 pagesSIN3868S20RN0Maurício LopesNo ratings yet

- 3293 P 00 Rev 1 ENDocument2 pages3293 P 00 Rev 1 ENWan Nabilah Farahin WawanpinkNo ratings yet

- 3157 S 63 Rev 0 ENDocument4 pages3157 S 63 Rev 0 ENHuda LestraNo ratings yet

- Safety Information Notice - Aumento de Incidentes Por Falha Na Rotina de ManutencaoDocument3 pagesSafety Information Notice - Aumento de Incidentes Por Falha Na Rotina de Manutencaoleonardo saraivaNo ratings yet

- 3433 P 24 Rev 0 ENDocument3 pages3433 P 24 Rev 0 ENlacsmm982No ratings yet

- Safety Information Notice: Subject: Parking and Mooring Helicopter Parking For An Extended Period of Time (Work Stoppage)Document2 pagesSafety Information Notice: Subject: Parking and Mooring Helicopter Parking For An Extended Period of Time (Work Stoppage)Ibrahim AsifNo ratings yet

- IN3476 I 12 Rev1 ENDocument27 pagesIN3476 I 12 Rev1 ENGhribiNo ratings yet

- 3170 S 00 Rev 2 ENDocument11 pages3170 S 00 Rev 2 ENkrishna shahNo ratings yet

- Safety Information Notice: Subject: Equipment and Furnishings Measures To Be Taken If The Hoist Jams in OperationDocument2 pagesSafety Information Notice: Subject: Equipment and Furnishings Measures To Be Taken If The Hoist Jams in OperationIbrahim AsifNo ratings yet

- 3349 S 25 Rev 0 ENDocument3 pages3349 S 25 Rev 0 ENMário MineiroNo ratings yet

- Ata 00 - 3686-I-00 - RN02Document3 pagesAta 00 - 3686-I-00 - RN02trinidad sordoNo ratings yet

- Information Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesDocument3 pagesInformation Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesrobbertmdNo ratings yet

- SIN3463S00RN2Document3 pagesSIN3463S00RN2Maurício LopesNo ratings yet

- 3947 S 00 Rev 0 ENDocument3 pages3947 S 00 Rev 0 ENReinaldo SouzaNo ratings yet

- Airbus Winch DetailsDocument48 pagesAirbus Winch Detailszozi6030No ratings yet

- Safety Promotion Notice: Subject: Standard Practices Recommendations For Visual Inspections - Human Factor ApproachDocument12 pagesSafety Promotion Notice: Subject: Standard Practices Recommendations For Visual Inspections - Human Factor ApproachAlejandro RagoNo ratings yet

- Airbus Landing SitesDocument7 pagesAirbus Landing SitesMarcvs LewisNo ratings yet

- 3754 S 34 Rev 0 ENDocument5 pages3754 S 34 Rev 0 ENM GhNo ratings yet

- SIN3613S00RN1Document2 pagesSIN3613S00RN1Maurício LopesNo ratings yet

- Safety Information Notice: Subject: Power Plant Inspection and Maintenance of The Engine Compartment SealsDocument2 pagesSafety Information Notice: Subject: Power Plant Inspection and Maintenance of The Engine Compartment SealsIbrahim AsifNo ratings yet

- Information Notice: Subject: Fuel Fuel Quality (Was Previously Service Letter No. 1255-28-95)Document3 pagesInformation Notice: Subject: Fuel Fuel Quality (Was Previously Service Letter No. 1255-28-95)arun RajannaNo ratings yet

- Information Notice: Subject: Occurrence ReportingDocument28 pagesInformation Notice: Subject: Occurrence ReportingMário MineiroNo ratings yet

- SIN3704S25RN0Document3 pagesSIN3704S25RN0Maurício LopesNo ratings yet

- SIN3786S62RN0ERRDocument2 pagesSIN3786S62RN0ERRMaurício LopesNo ratings yet

- 3821 P 00 Rev 1 ENDocument3 pages3821 P 00 Rev 1 ENButacu LucicaNo ratings yet

- 2145 I 28 Rev 3 ENDocument4 pages2145 I 28 Rev 3 ENRaymond ZamoraNo ratings yet

- Sin TreuilDocument30 pagesSin TreuilCédric BoblinNo ratings yet

- Ata 25 - 3629-I-25 - RN00Document3 pagesAta 25 - 3629-I-25 - RN00trinidad sordoNo ratings yet

- Safety Information Notice: Subject: General Flight Safety of Helicopters - Issue of EHEST LeafletDocument21 pagesSafety Information Notice: Subject: General Flight Safety of Helicopters - Issue of EHEST LeafletFidel ArellanoNo ratings yet

- 3700 S 24 Rev 1 ENDocument6 pages3700 S 24 Rev 1 ENConstantinescu DragosNo ratings yet

- 3731 I 25 Rev 0 ENDocument1 page3731 I 25 Rev 0 ENEder Jael Edwin CaNo ratings yet

- 3700 S 24 Rev 0 ENDocument3 pages3700 S 24 Rev 0 ENJoão CorrêaNo ratings yet

- 320 Plate FailureDocument4 pages320 Plate Failuregulam husseinNo ratings yet

- Safety Information Notice: Subject: Tail Rotor Interference Between The Tail Rotor Blades and The PylonDocument2 pagesSafety Information Notice: Subject: Tail Rotor Interference Between The Tail Rotor Blades and The PylonEder Jael Edwin CaNo ratings yet

- MPC 4502 - 5502 New Fuser Detect FuseDocument4 pagesMPC 4502 - 5502 New Fuser Detect FuseMatloob Khan0% (1)

- F.a.a.-P.m.a. Model 1u128a and 1u128bDocument5 pagesF.a.a.-P.m.a. Model 1u128a and 1u128b19600702No ratings yet

- Service Manual: Conf IdentialDocument15 pagesService Manual: Conf IdentialFrank ElizaldeNo ratings yet

- TB 9 2350 369 20 1Document40 pagesTB 9 2350 369 20 1Maksym MBRNo ratings yet

- Airbus 3190Document2 pagesAirbus 3190Samir FreitasNo ratings yet

- Safety Information Notice: Subject: Tail Rotor Reminder of The Dedicated Maintenance For The Tail Rotor Trailing Edge TabDocument2 pagesSafety Information Notice: Subject: Tail Rotor Reminder of The Dedicated Maintenance For The Tail Rotor Trailing Edge TabBruno Alonso PachecoNo ratings yet

- Fuente de Laboratorio de Alta CorrienteDocument2 pagesFuente de Laboratorio de Alta CorrienteJulian Javier Canul PoolNo ratings yet

- Electrical and Instrument Taglist For Wellheads: 065514-C-FL-DG00-EL-LST-0001Document12 pagesElectrical and Instrument Taglist For Wellheads: 065514-C-FL-DG00-EL-LST-0001Jalal AlbadriNo ratings yet

- DDV Training NewDocument31 pagesDDV Training Newragdapattice100% (1)

- 3297 S 00 Rev 0 ENDocument5 pages3297 S 00 Rev 0 ENRaymond ZamoraNo ratings yet

- Fuel System Wing and Center Tank 1to 3Document19 pagesFuel System Wing and Center Tank 1to 3RAJNo ratings yet

- Dell Inspiron 3493 3593 Compal FDI55 LA-J081P FDI45 LA-J091P 1.0 PDFDocument101 pagesDell Inspiron 3493 3593 Compal FDI55 LA-J081P FDI45 LA-J091P 1.0 PDFmarco guamialamaNo ratings yet

- Tire Pressure - Function TestDocument14 pagesTire Pressure - Function TestAraNo ratings yet

- Service Manual: Conf IdentialDocument15 pagesService Manual: Conf IdentialFrank ElizaldeNo ratings yet

- 01/09/2008 20:12:06 F 0.71 C:/Users/Michel/Documents/Md - Ens/Maquettes/Tpdspic2008/Tpdspic2008-V2023-V2.Sch (SHDocument5 pages01/09/2008 20:12:06 F 0.71 C:/Users/Michel/Documents/Md - Ens/Maquettes/Tpdspic2008/Tpdspic2008-V2023-V2.Sch (SHDe Carry AymardNo ratings yet

- Alert Service Bulletin: ASB EC135-33A-023Document11 pagesAlert Service Bulletin: ASB EC135-33A-023anon_946993252No ratings yet

- Cable Gland: Type 421 FlameproofDocument2 pagesCable Gland: Type 421 FlameproofLucas ElliottNo ratings yet

- A Euas350 355 2020 TRDocument14 pagesA Euas350 355 2020 TRherbert gomesNo ratings yet

- MLG - Removal InstallationDocument14 pagesMLG - Removal InstallationKeilaeFrancisco ArceNo ratings yet

- Bill of MaterialsDocument3 pagesBill of Materialsmsc51No ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument10 pagesService Bulletin: Piper Considers Compliance MandatoryJean AbrialNo ratings yet

- Albion: Index - Alb522MbDocument18 pagesAlbion: Index - Alb522MbShauna MooreNo ratings yet

- SBAS350340028ENR0Document20 pagesSBAS350340028ENR0Ibrahim AsifNo ratings yet

- Safety Information Notice: Subject: Power Plant Inspection and Maintenance of The Engine Compartment SealsDocument2 pagesSafety Information Notice: Subject: Power Plant Inspection and Maintenance of The Engine Compartment SealsIbrahim AsifNo ratings yet

- 3504 S 63 Rev 0 ENDocument2 pages3504 S 63 Rev 0 ENIbrahim AsifNo ratings yet

- Information Notice: Subject: General Tech Data - Upcoming Revision AS350 B2/B3Document11 pagesInformation Notice: Subject: General Tech Data - Upcoming Revision AS350 B2/B3Ibrahim AsifNo ratings yet

- 350 MSM-05-B3 E MC17 A4 VOL01-1 LowDocument194 pages350 MSM-05-B3 E MC17 A4 VOL01-1 LowIbrahim AsifNo ratings yet

- Safety Information Notice: Subject: Equipment and Furnishings Measures To Be Taken If The Hoist Jams in OperationDocument2 pagesSafety Information Notice: Subject: Equipment and Furnishings Measures To Be Taken If The Hoist Jams in OperationIbrahim AsifNo ratings yet

- Safety Information Notice: Subject: Parking and Mooring Helicopter Parking For An Extended Period of Time (Work Stoppage)Document2 pagesSafety Information Notice: Subject: Parking and Mooring Helicopter Parking For An Extended Period of Time (Work Stoppage)Ibrahim AsifNo ratings yet

- Information Notice: Subject: General Tech Data: Upcoming Revision of The AS350 B2/B3 PublicationsDocument9 pagesInformation Notice: Subject: General Tech Data: Upcoming Revision of The AS350 B2/B3 PublicationsIbrahim AsifNo ratings yet

- 3532 I 67 Rev 0 ENDocument14 pages3532 I 67 Rev 0 ENIbrahim AsifNo ratings yet

- 2101 Io PlusDocument186 pages2101 Io PlusIbrahim AsifNo ratings yet

- Barfield GSTE Fuel Adaptor Cable List.101 00807Document15 pagesBarfield GSTE Fuel Adaptor Cable List.101 00807Ibrahim AsifNo ratings yet

- Iw Tec 200 01Document548 pagesIw Tec 200 01GuilhermeNo ratings yet

- Business Administration PDFDocument185 pagesBusiness Administration PDFSarah MisekNo ratings yet

- Lab Work 1Document2 pagesLab Work 1Adly HakimNo ratings yet

- Maya, Aztec, and Inca Civilizations PDFDocument116 pagesMaya, Aztec, and Inca Civilizations PDFGabriel Medina100% (2)

- Abroad Work Experience On ResumeDocument5 pagesAbroad Work Experience On Resumeafmrdrpsbbxuag100% (1)

- Adc March 2018 SolvedDocument73 pagesAdc March 2018 SolvedKish BNo ratings yet

- Thermotherapy PDFDocument51 pagesThermotherapy PDFRUdraNo ratings yet

- Scribd ResumeDocument2 pagesScribd ResumeaaronschrankNo ratings yet

- Gammagard Us PiDocument4 pagesGammagard Us Pibmartindoyle6396No ratings yet

- License Exceptions Part 740 - Page 1: 740.1 IntroductionDocument82 pagesLicense Exceptions Part 740 - Page 1: 740.1 Introductiondali layouniNo ratings yet

- Evaporation of Different Liquids PDFDocument2 pagesEvaporation of Different Liquids PDFMandyNo ratings yet

- 014 - 030 Single Reduction Worm IntroductionDocument17 pages014 - 030 Single Reduction Worm IntroductionAlejandro MartinezNo ratings yet

- Stolzle Prestige Standards BrochureDocument9 pagesStolzle Prestige Standards BrochureTomi AkingbolagunNo ratings yet

- Dsem TRM 0514 0052 1 - LRDocument68 pagesDsem TRM 0514 0052 1 - LRAbhishek JirelNo ratings yet

- Ed. William Lane, Arabic-English Lexicon - Vol.7 - 1885Document308 pagesEd. William Lane, Arabic-English Lexicon - Vol.7 - 1885Gagik DanielyanNo ratings yet

- Ross-Tech: Ross-Tech-Tip - VW/Audi Throttle Body AlignmentDocument1 pageRoss-Tech: Ross-Tech-Tip - VW/Audi Throttle Body AlignmentRubens PerazaNo ratings yet

- EU Imports of Organic Agri-Food Products: Key Developments in 2019Document17 pagesEU Imports of Organic Agri-Food Products: Key Developments in 2019Dani FrancoNo ratings yet

- FortiOS 7.0.1 CLI ReferenceDocument1,751 pagesFortiOS 7.0.1 CLI ReferenceMoacir Nunes NetoNo ratings yet

- Drivewindow BasicsDocument34 pagesDrivewindow BasicsYaa ShinNo ratings yet

- Project On Sales Promotion ParagDocument66 pagesProject On Sales Promotion ParagavnishNo ratings yet

- Unit-1 Value EngineeringDocument4 pagesUnit-1 Value Engineering2K21 B652Anand JhaNo ratings yet

- Sauer90 ServiceManual PDFDocument72 pagesSauer90 ServiceManual PDFeng13100% (7)

- Configure SPM 2012 On Windows 7 LaptopDocument7 pagesConfigure SPM 2012 On Windows 7 Laptopcgf_arNo ratings yet

- RecursionDocument9 pagesRecursionMada BaskoroNo ratings yet

- Talent AcquisitionDocument2 pagesTalent AcquisitionkiranNo ratings yet

- QuestionsDocument3 pagesQuestionsLayla RamirezNo ratings yet

- Applied Physics On Spectros PDFDocument71 pagesApplied Physics On Spectros PDFKaskus FourusNo ratings yet

- 08-01-17 EditionDocument28 pages08-01-17 EditionSan Mateo Daily JournalNo ratings yet

- Sma Negeri 1 Kotabaru: I. Answer The Following Question!Document6 pagesSma Negeri 1 Kotabaru: I. Answer The Following Question!Dian MardhikaNo ratings yet