Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsPP 63 kVA GTP UHBVN

PP 63 kVA GTP UHBVN

Uploaded by

gauravgarg1123Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Circular Vendor MGT PortalDocument2 pagesCircular Vendor MGT Portalgauravgarg1123No ratings yet

- Load Losses and Short-Circuit Resistances of DistrDocument16 pagesLoad Losses and Short-Circuit Resistances of Distrgauravgarg1123No ratings yet

- List Manufacturers Empanelled VendorsDocument14 pagesList Manufacturers Empanelled Vendorsgauravgarg1123No ratings yet

- Intent For ProcurementDocument11 pagesIntent For Procurementgauravgarg1123No ratings yet

- Similarities of Trf.Document1 pageSimilarities of Trf.gauravgarg1123No ratings yet

- Pre-Bid Queries Replies Compressed Compressed CompressedDocument12 pagesPre-Bid Queries Replies Compressed Compressed Compressedgauravgarg1123No ratings yet

- BEE Star Label ExtentionDocument1 pageBEE Star Label Extentiongauravgarg1123No ratings yet

- 02 HaryanaDocument11 pages02 Haryanagauravgarg1123No ratings yet

- Tendernotice 1 2Document23 pagesTendernotice 1 2gauravgarg1123No ratings yet

- Tender No Lot 3Document2 pagesTender No Lot 3gauravgarg1123No ratings yet

- FAQ RDS Scheme 2Document15 pagesFAQ RDS Scheme 2gauravgarg1123No ratings yet

- Finance 1256112Document1 pageFinance 1256112gauravgarg1123No ratings yet

- LOA GGN-I 11KV Supply TED-296Document6 pagesLOA GGN-I 11KV Supply TED-296gauravgarg1123No ratings yet

- 400 630 & 990 KVA DTsDocument3 pages400 630 & 990 KVA DTsgauravgarg1123No ratings yet

- Techsummary 299004Document1 pageTechsummary 299004gauravgarg1123No ratings yet

- Tendernotice 3 2Document1 pageTendernotice 3 2gauravgarg1123No ratings yet

- 200 Kva DTFDocument4 pages200 Kva DTFgauravgarg1123No ratings yet

- Action Plan StructureDocument12 pagesAction Plan Structuregauravgarg1123No ratings yet

- 01 RDSS OverviewDocument7 pages01 RDSS Overviewgauravgarg1123No ratings yet

- Tendernotice 1 38Document2 pagesTendernotice 1 38gauravgarg1123No ratings yet

- Notice Inviting Tender RDSS LR Part B FS Phase IDocument1 pageNotice Inviting Tender RDSS LR Part B FS Phase Igauravgarg1123No ratings yet

- Tendernotice 1 49Document810 pagesTendernotice 1 49gauravgarg1123No ratings yet

- Head Office List 10Document3 pagesHead Office List 10gauravgarg1123No ratings yet

- Tendernotice 1 28Document2 pagesTendernotice 1 28gauravgarg1123No ratings yet

- Tendernotice 1 30Document1 pageTendernotice 1 30gauravgarg1123No ratings yet

- Tendernotice 1 29Document3 pagesTendernotice 1 29gauravgarg1123No ratings yet

- Tendernotice 1 31Document5 pagesTendernotice 1 31gauravgarg1123No ratings yet

- Tendernotice 2 4Document1 pageTendernotice 2 4gauravgarg1123No ratings yet

- Tendernotice 1 39Document2 pagesTendernotice 1 39gauravgarg1123No ratings yet

- Thyssenkrupp Electrical Steel Product RangeDocument32 pagesThyssenkrupp Electrical Steel Product Rangegauravgarg1123No ratings yet

PP 63 kVA GTP UHBVN

PP 63 kVA GTP UHBVN

Uploaded by

gauravgarg11230 ratings0% found this document useful (0 votes)

4 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

4 views10 pagesPP 63 kVA GTP UHBVN

PP 63 kVA GTP UHBVN

Uploaded by

gauravgarg1123Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 10

GUARANTEED & OTHER PARTICULARS FOR DISTRIBUTION TRANSFORMERS

~ OSC

[Guaranteed Particular of 63 KVA OTe

[Reply ofthe firm

[Make & Manufacturer

[pF NOUSTRIES PVT.LTD.

[A-16, NEW FOCAL POINT, DABWAL|

l2 era |ROAD, BATHINDA

5 [ota mint row 220 VOUS

fe —— rag ev sana

ae JANORFHOUS CORE “GRADE AV}

[Trans faves

> [over aig want eouaton Gare be ished by hearse n wpe othe da [1.125%

¢__—[Msram onpraTeo oT

[Winds reine mood %

[5 ory Tremanet sre

[7 ——[Wagnen o a) Cuenta

fs ]Wort votone fm

[Estima vata om

[keane

[sma vatage ow

is [warn Votan 120)

[5 ]restacs of ang aT aC Tah ERT

Jv inang ms) iar Ome

[ov nrg os. 67 Oks

0 [rl on ones va] 7E 09, soo

[Foal ones 00% ad 8 don sow

iz Foal Losses odo 7 ae 6 ow

[sore dest vedo

svg aan

[pein La AMAT

fz [earns

b_—loaeatv am

boven om

[eT Peo Ps ion

[Jer redatn corse DE an hon igs

econ Ss Ona 7 Nan Bang 3

Je [Ary pont ot wining tank esta ad

is [enya Toa 6

jp Juni

[four aur ae

feb var ora

Fon sid sas arse

Bross —_!

fs os sso ne

Sao putea

15 |Reguaienal

funy Tai

plese aay Be

7 enon a 75009C 0 OH aan pa

ia [Fash Tet

inv ab SOTTO Tp a

3 RAO Hz Thins Nee

3 lover geet Tet Dole Voge & pao7TOOTE

20 Jobe requestor int E

[ings am

fr ——| Wott oar

js fears annaten oS) Ta

[Iie 20

[.__[tancarungs (ces of ae wale 8k oophatom pn DT) is FT TRS Se Wt

foi

le Joray any ora a Les Fata)

fra si EK

bs for baa

PP tadustries Pvt. Led.

wv. 034

[ay for frst fing (rnp

rao ies

[Grade of oi uses

[As per 1S: $36 with latest amendements

3 iakars name [Sava Apar coulomb JOS

A [SOV atthe ime offing JAs per IS: 935 with latest amendements

pa [Transformer

i [Over ingth X breadth X haghE [950 600 x 205) mim

2 Frank tent X breadth X eight [208 300 2585) mm

5 ickness of pate fo

a Sige plate (min) 3.15 me

b op & Bottom plate (rin) 5.00 mam

25 [Radiation

h Heat cissipaton by tank walle exclusive batom plate [5503 wat

2 Heat dissipation by cooing tube. 7 wats

A Dia & thickness of cooling tube is Swe

ther eaiulation sheet for selecing Gosling eee to ensure that he Wanstormes capable

ls living continuous rates output wihout oxcooding temperature ree is enclosed. =

be Inter layer insulation provided in design for

i FTop & botiom ayer kraft paper

a [in between al ayer [Epoxy Dotted Krai paper

B [Dota of end insulation Press Board & Empire Sleaves

a Whether wedges are provide at 60 tins of the HV cal [Not Required

27 Insulation materials provided

a For Conductors (1) HV (2) LV, Hv-Super Enamel as H,LVBPO

b [For Cove [as per

25 |Material and Sin ofthe wire used ~

a lev. [Aion

a [swarm 11.40 me

b bia [40 mm (1.596 me)

2 lv. Tarn

a Sup sie [710x335 mm

ib No.of Conductors i parallel 5

lc ota area of cross section (sg. mm) [sara me

23 Is the name plate gives al particulars as requred n Tendor ves.

Weer BEE siar 2 Label Plate & Mancatory BIS corfeaton Ta. harkng as pases |,

130_|1s:11a0 Par12014 with energy efficiency level-3 ls pasted on each tansformer

Bo ariculrs of Bushings HV LV

i [Maker's name [any reputed make

i [Type 15-3347/5_ 1160 [as por iSS'3967 a 155: 2000

We Rating as per. z [As per 185:3847 & 18S: 2009

o [Dry power requency votage wiisiand test [As per 15:3547 & ISS: 2099

Wet power frequency votage withstand test

[As per 15:3547 & SS: 2009

Sy

el i

Gl 3(s0 ‘eo

PP Industries Pvt. Ltd.

Managihg Director

". 0

ADDITIONAL DETAILS 20KVA FORMAT-II

NIT NO. 11/UHIMMW/XENIP.1VGH-/2563 dated: 21.02.2022

S.no. [Description unit Remarks

AMORPHOUS CORE GRADE]

a eccee Grade _[antt0-2555-84 OR BETTER

2 [Core Diameter mm 170.2 mm x 84.80 mm

3_[Gross core area fem? 144.33,

4_|Net core area com? 129.00

5 [Flux Density Tesla 7-40 (Max)

6 _|Wt of core kg. 159.0

7__ |Loss per kg. of core at the specified fx density watts 0.20

6 _ [Core window height mm) 287

'9_[Center to center distance of the core mm) 230

40_|No, of Lv Tums per phase nos 62

71_|No. of HV tums per phase nos 2728

12 _|Size of LV conductor bare/eovered mm 710% 5.35/7 30x3.55

13 _|Size of HV conductors bare/covered mm) 4.40/1.45

14 |No. of parallels(LV) nos 3

45 |Current density of HV winding ‘Almin® 7.50 Max

46 |Current density of LV winding ‘Almm? 7.50 Max

17_|We of the LV winding for Transformer kg. 21.500

18 _|We of the HV winding for transformer kg. 30.500

19 _|No.of LV coils/phase nos 1

20 _[No. of HV coils/phase os 1

21 [Height of LV windings rom) 245 with end packing

22 [Height of HV windings rom) 245 with end packing

23 _[ID/OD of LV windings mm) 178 x 92 /230 x 138

24 [ID/Od of HV windings: mm) 250 x 158 / 315 x 220

25 _|Size of the duct in LV winding mom) NA

26 _|Size of the duct in HV winging mm) NA

27 [Size of the duct between HV & LV mm mm + 1mm PB cylinder

28 [HV winding to LV winding clearance mm) 40 mm with insulation

29 [HV winding to tank clearance(minimum) mm [Bushing Side 40 mm andl

INon Bushing side 30 mm

30_|Calculated impedance % 4.50

31_|HV to earth creepage distance mm) 25mmiKV.

32_[LVto earth creepage distance 25mmiKV.

Date: 07.03.2022

Place : Bathinda

d Es .

c: ,

aA 3

PP Indo:

“ve

For P.P. industries Pvt. Ltd.

DISTRIBUTION TRANSFORMER

P.P. INDUSTRIES PVT LIMITED

‘A-16, NEW FOCAL POINT, BATHINDA (PUNJAB)

<¢-mall: info@ppindustries.com, Phone: 0164-2284995,

[LPH 151 warkea Dist Transformer

[ENERGY EFFICIENCY LEVEL

2 (NEW)

|STANDARD- 1S 1180 (Part-3) : 2021

MAX. TOTAL LOSSES AT 50%

kVA

63

LOAD AT 75°C

300 W

VOLTS AT { HV

INO LOAD Ww.

11000

MAX. TOTAL LOSSES AT

433

{100% LOAD AT 75°C

1050 W

| ((™

wy

75/28 KV

[TYPE OF COOLING Kg

ONAN

-/3KV

oO °c

HV

wv

331

fewe.rse {

wos

35

40

84.00

MASS OF OIL. (KG)

100

FREQUENCY HZ

50.

[TOTAL MASS: (KG)

500

[VECTOR GROUP

Dyn 11

[Vou. OF on. (UR)

120

IMPEDANCE VOLTS %

4.50)

MONTH & YEAR OF MFG.

‘2022

[GUARANTEE PERIOD

72 months|

[SERIAL NO.

[CUSTOMER

UHBVN, PANCHKULA,

NIT NO.

1S/UHIMMIXEN/P-IVQH-1/2565 Dt 03.03.2022

P.0.NO.

DATE OF INSPECTION

iii

2n2u dv aw

Pate Size: 175mm 105s

MADE IN INDIA

materia

iw

Alumina

P,P. INDUSTRIES PRIVATE LIMITED - BATHINDA

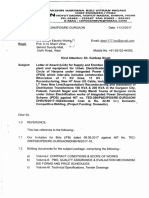

[Tae JRATING & TERMINAL MARKING PLATE,

RATING [63 KWA, 1170.433 KV, 3-PHASE, LEVEL-2{NEW) ALUMINIUM

WOUND AMORPHOUS CORE DISTRIBUTION TRANSFORMER

[DRAWING NO. [HR63/EEL2(N)/NP/22-003

PPIPL, BATHINDA,

9%

oe

63 KVA/AMORPHOUS

,

PP Industri

<

Managi

Pvt. Lid.

g Director

415

3

ul

gis

NuMfaeR OF PSR FINS = 12 NOS. overall lnensions _

ae Noe] Svea ERECT ary

feted eet soon ‘B05 15_|SILIGAGEL DEHYDRATING BREATHER 7

fk OF sR FINS = 225 nm So ef puseunoniev en Pocus on ;

2 fot boon waren 17 nV STA =|

Set waron | caso evar | 12 ftrorane urmtes 3

Sat CLEARANCES" A (ove) | 1i_prsusep STEEL PLATE RASITORS 3

Ahk: SIDE WALL = 315 MM S_INAIR (mm) | 11 jerasoeb STE PLATERAS a

SHEET: SIDE WALL = 5.00 MM PHASE TO PHASE | 255 75 |? |EARTHING TERMINALS. 2

[PHASE TO EARTH 140 ‘40 ‘8 | TRANSFORMER PULLING LUGS 4

fnew CHART “Firms Gna rou sibs 4

: : fen WEIGHT —| + [any atau ooo FCAT ;

m AAAA COREA WINING |—KG" "|" pas| ¢ [ev ourooon eustaNES Lar=<08 7

FA ~ [TANK & FITTING KG 155 | 4 [GL LEVEL GAUGE WITH MARKING 1

MASS OF oI | Ke —|400| 3 lec conserwaron wir ona PLUG ;

Le | ouome or ow | Urn —|—490| 3 [eon.onon verre ;

VStar wetcnr—|—Ke—| soo + fetencunomme wir car ;

a

GENERAL OUTLINE DRAWING OF 63 KVA, 11/0.433 KV, SPHASE, EE LEVEL-2 (NEW), ALM.

WOUND, AMORPHOUS CORE NON SEALED TYPE DISTRIBUTION TRANSFORMER

[ORDER NO.

[CUSTOMER [UHBYN, PANCHKULA Drawn By: Er. Sardooi Singh

TS. NO. [37 UFUMIN/XENTP GHT2565 —Joatea: ‘08.03.2022

ING NO ——[HR6a/EEL 2N/AMT/GAl22-001 INOTE: ALL DIMENSIONS ARE IN MM

PP. INDUSTRIES PVT.LTD, A-16, NEWFOCAL POINT - BATHINDA

oa

=

f

iL

F

c SIDE VIEW Eye

pas a

A ‘NO. OF COIL LEG 1 7

| = GY INSULATION OF CONDUCTOR] Dc ENC

A oe a

Z TPE OF ORE AMORPHOUS

: : = Bee ae

J J WINDOW HEIGHT (WH) 257

L| D onmpuer TORE LENGTH (CL) 230 ean

Z Lee L ‘SNo_| DESCRIPTION ary

ae 1 eeermeensmere ta

DRAWN BY Pp P.P.INDUSTRIES PVT.LTD.

wre CHECKED BY- THTLE: RATING: 140.433KV, 63 KVA, PHASE, DATE ‘sonte NTS

Attonensbwanc es . ‘cone & con. aL 2 NEw, aLuwintum wouno, |=} | __o70:2002

G) ORES LSVCUDECOMITEDFRON TER VIEWS APPROVED BY | ASSEMBLY NON SEALED TYPE, AMORPHOUS "ALL DIMENSIONS ARE INN

7 2 3 a 5 6 1 7 3

FLUX

CORE STEP WIDTH

DENSITY CALCULATIONS

= 170.2 mm

CORE STEP THICKNESS = 84.80 mm.

GROSS AREA OF CORE = 170.2 mm x 84.80 mm

= 14433 mm?

NO. OF LT TURNS = 62 nos,

LV RATED VOLTAGE — = 250 Volts.

= 4.44 xfxBmxAxNXxSFx10 ©

FLUX DENSITY (Bm) =

250x 10°

4.44 x 50 x 14433 x 62 x 0.90

= 1.40 Tesla

2

P.P.INDUSTRIES PVT.LTD.

A-16 NEW FOCAL POINT BATHINDA (Pb)

FLUX DENSITY

CALCULATIONS

DATE

SCALE: NTS

arma isms Kies eos

2-PHASE, EEL-aqeim, Luu WOUND, |P@ [07052002

Tce ERE

AMORPHOUS CORE DISTRIBUTION

HR63/AMDT/FLUXI22-004

‘TRANSFORMER lORAWING No.

360 >

HT BUSHING ASSEMBLY

a aT se eee

BRE RTE ORY POLE WORD za (rs)

HE UNITE WET PANOCAGE WISN aw)

12780 RD SEE MPULSE VOLTA WET | 5.

+ | meuuee 7 2a [PORES ena SLE

5 Seana WishEn FoR GENER PURPOEE | 01 [come

LT BUSHING ASSEMBLY

FATED RATING Ta 7250

“ONE MINUTE. ORY PFVOLTAGE WiTSTAND [KY (RUS)

‘ORE MINUTE WET P>FVOLTAGE WITHSTAND [KY (RUS)

CCREEPAGE OTANCE uae

a

a 7 DESCRIPTION aR a.

(01 RSULATOR UPPER PROCELAN Ol

02] NSULATOR LOWER PROCELAN o

os|srew wiz BRASS ol

[04 TOP ENO WASHER ass oF

5 [STEM WASHER Ss oo

06 |SeaLne WAShER (Grea) | SrRTHRTIS RUBBER OT

07 [sean wasnt CYPE-W) | NORE of

(98 /SEALNO WASHER (PEN) [NORE ot

09 |SEALNG CASKET NORE o

TO|SEAING GASKET NORE oo

TOC NOT wi aRaSs os

P.P.INDUSTRIES PVT.LTD.

PP Industries Pvt, Ltd. Ac16 NEW FOCAL POINT BATHINDA (Pb)

‘TLE: Se lo SALE: NTS

LT& HT BUSHING ANO BRASS

STEM FITTING ASSEMBLY

Manas ctor

P-P, INDUSTRIES PVT LIMITED ” OSE

NITNO. 121UHNAMxXENP-WaHZS6s — COOLING CALCULATIONS.

TANK DIMENSIONS Kvaz 63

LENGTH 805 mm

WIDTH 390 mm

HEIGHT (Avg) 535 mm

ITOTAL LOSSES AT 100 % LOAD AT 75°C 1050 w

|TOTAL LOSSES TO BE DISSIPATED 1050 w

IN AREA OF TANK SIDES 1.279 m

B TOTAL EFFECTIVE PLAIN AREA 1.279 m

ic LENGTH OF FINS (225 mm WIDTH) 12 x 300 mm

TOTAL TUBE SURFACE AREA = 1.620 m

LOSSES DISSIPATION :

1. PLAIN SURFACE 500 wim? 1.279 X 500 = 639 w

2. RADIATORS 352 wim? 1.620 X 352 = 867 w

‘3. TOTAL LOSS DISSIPATED = 1206.3 w

Hence — Top Oil Temp. Rise = 35 x (1050/1206.3) = 30.46 °c

Winding Temp. Rise = 31.45 +6 = 36.46 *c

Which is within the permissible limits

[CALCULATION FOR HOT SPOT TEMPERATURE

PARTICULARS DESCRIPTION

Maximum top oil temp. rise over 40 “c ambient temp. 35°C

[Average oil temperature (35x08) 2 °C

Maximum winding temp. rise 40 °C

[Average gradient between winding and oll (40 - 28) 120 °C

Maximum gradient between winding and oil (12x44) 132 °C

Maximum hot spot temp. over 40 °c ambient (13.2+35+40) 882 °C

|Which is less than max. allowable limit of 9 °C

PPIPL, BATHINDA, 63 KVA/AMORPHOUS

P-P. INDUSTRIES PVT LIMITED

NIT NO. 13/UHMMKENIP-WVOH.U2665 KVA= 68

CALCULATION OF NO LOAD LOSSES & CURRENT AT RATED VOLTAGE

CORE MATERIAL & GRADE: AMORPHOUS CORE GRADE AM10-25S5-84 OR BETTER

AT FLUX DENSITY 1.40 T, CORE LOSS: wks. 0.20 w

TOTAL CORE WEIGHT Kos, 159.0 ke

CALCULATED LOSS 02 X 159 318 w

CORE HANDLING FACTOR (Approx.) 45%

TOTAL CALCULATED NO .LOAD LOSS. 46.1 Ww

GUARANTEED NO LOAD LOSSES 60.0 w

CALCULATION OF NO LOAD CURRENT AT RATED VOLTAGE:

AT FLUX DENSITY 1.407, VA/KG: 0.80

TOTAL CORE WEIGHT 159.0 KG

REACTIVE COMPONENT OF CURRENT = 0.170 4

(VAIKG.* CORE WT.) * V ph

ASSUMING HANDLING FACTOR = 100

‘TOTAL REACTIVE CURRENT 2 x 047 0.339 A

CALCULATED NO LOAD LOSSES AT RATED VOLTAGE = 4611 w

ACTIVE COMPONENTS OF CURRENT 46.11 (3250) 0.081 A

TOTAL NO LOAD CURRENT = SQRT( 0.3392 )*+ _0.061_y'2)

= [0.345 Ja

NO LOAD CURRENT IS MUCH LESS THAN THE GUARANTEED FIGURES e 3 % of RATED CURRENT

ICALCULATION FOR NO LOAD CURRENT AT 12.5% OVER VOLTAGE

FLUX DENSITY AT 112.5% OVER VOLTAGE 1.875 1

VAIKG = 375 va

WATT/ KG 0.35 w

PHASE VOLTAGE 281.3 v

NO LOAD LOSS AT 1.575 TESLA 035 x 189 x 1.45 80.7 w

(including 45% handling factor)

REACTIVE COMPONENT OF NO LOAD CURRENT

375 X 159 13*281) 0.707 a

AFTER INCLUDING HANDLING FACTOR OF 100% 1413 A

ACTIVE COMPONENT OF NO LOAD CURRENT AT 1.575T 860.693 1(3K281) 0.096 A

TOTAL NO LOAD CURRENT AT 1.575 TESLA = SQRT(( 1.413 )*2-_0.096_y*2)

=Lrat7 Ja

NO LOAD CURRENT IS MUCH LESS THAN THE GUARANTEED FIGURES i 6 % of RATED CURRENT

PPIPL, BATHINDA

es Pt. Lad.

4

ing Director

63 KVA/AMORPHOUS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Circular Vendor MGT PortalDocument2 pagesCircular Vendor MGT Portalgauravgarg1123No ratings yet

- Load Losses and Short-Circuit Resistances of DistrDocument16 pagesLoad Losses and Short-Circuit Resistances of Distrgauravgarg1123No ratings yet

- List Manufacturers Empanelled VendorsDocument14 pagesList Manufacturers Empanelled Vendorsgauravgarg1123No ratings yet

- Intent For ProcurementDocument11 pagesIntent For Procurementgauravgarg1123No ratings yet

- Similarities of Trf.Document1 pageSimilarities of Trf.gauravgarg1123No ratings yet

- Pre-Bid Queries Replies Compressed Compressed CompressedDocument12 pagesPre-Bid Queries Replies Compressed Compressed Compressedgauravgarg1123No ratings yet

- BEE Star Label ExtentionDocument1 pageBEE Star Label Extentiongauravgarg1123No ratings yet

- 02 HaryanaDocument11 pages02 Haryanagauravgarg1123No ratings yet

- Tendernotice 1 2Document23 pagesTendernotice 1 2gauravgarg1123No ratings yet

- Tender No Lot 3Document2 pagesTender No Lot 3gauravgarg1123No ratings yet

- FAQ RDS Scheme 2Document15 pagesFAQ RDS Scheme 2gauravgarg1123No ratings yet

- Finance 1256112Document1 pageFinance 1256112gauravgarg1123No ratings yet

- LOA GGN-I 11KV Supply TED-296Document6 pagesLOA GGN-I 11KV Supply TED-296gauravgarg1123No ratings yet

- 400 630 & 990 KVA DTsDocument3 pages400 630 & 990 KVA DTsgauravgarg1123No ratings yet

- Techsummary 299004Document1 pageTechsummary 299004gauravgarg1123No ratings yet

- Tendernotice 3 2Document1 pageTendernotice 3 2gauravgarg1123No ratings yet

- 200 Kva DTFDocument4 pages200 Kva DTFgauravgarg1123No ratings yet

- Action Plan StructureDocument12 pagesAction Plan Structuregauravgarg1123No ratings yet

- 01 RDSS OverviewDocument7 pages01 RDSS Overviewgauravgarg1123No ratings yet

- Tendernotice 1 38Document2 pagesTendernotice 1 38gauravgarg1123No ratings yet

- Notice Inviting Tender RDSS LR Part B FS Phase IDocument1 pageNotice Inviting Tender RDSS LR Part B FS Phase Igauravgarg1123No ratings yet

- Tendernotice 1 49Document810 pagesTendernotice 1 49gauravgarg1123No ratings yet

- Head Office List 10Document3 pagesHead Office List 10gauravgarg1123No ratings yet

- Tendernotice 1 28Document2 pagesTendernotice 1 28gauravgarg1123No ratings yet

- Tendernotice 1 30Document1 pageTendernotice 1 30gauravgarg1123No ratings yet

- Tendernotice 1 29Document3 pagesTendernotice 1 29gauravgarg1123No ratings yet

- Tendernotice 1 31Document5 pagesTendernotice 1 31gauravgarg1123No ratings yet

- Tendernotice 2 4Document1 pageTendernotice 2 4gauravgarg1123No ratings yet

- Tendernotice 1 39Document2 pagesTendernotice 1 39gauravgarg1123No ratings yet

- Thyssenkrupp Electrical Steel Product RangeDocument32 pagesThyssenkrupp Electrical Steel Product Rangegauravgarg1123No ratings yet