Professional Documents

Culture Documents

BMS 06.1-Standard Operating Practices

BMS 06.1-Standard Operating Practices

Uploaded by

Tahir Iqbal. Kharpa RehanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMS 06.1-Standard Operating Practices

BMS 06.1-Standard Operating Practices

Uploaded by

Tahir Iqbal. Kharpa RehanCopyright:

Available Formats

Version 2008

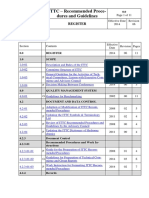

Manual 01 Manual 09

Operations Management Commercial

System

Manual 07

Manual 02 Materials

Human Resources

Manual 06.5a

Manual 02.1 Drilling Formulae

Job Description Handbook

Manual 03 Manual 06.5

Health, Safety & Well Operations

Environment Technical Handbook

Manual 03.1 Manual 06.4

Weekly HS&E Preventive

Environment Maintenance System

Manual 04 Manual 06.3

Training & Competence Task Risk Assessments

Manual 05 Manual 06 Manual 06.1 Manual 06.2

Engineering Operations And Maintenance Standard Operating Practices Well Control

ED

WEATHERFORD DRILLING INTERNATIONAL

BUSINESS MANAGEMENT SYSTEM

LL

O

MANUAL 06.1

TR

STANDARD OPERATING PRACTICES

N

O

C

N

U

Engage… Do Right… Excel

WDI BUSINESS MANAGEMENT SYSTEM Doc Ref: 06.1-00-TOC Originated by: MS

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: GS

SUBJECT: Table of Contents Revised: 31 Mar 2008 Authorised by: NE

WEATHERFORD DRILLING INTERNATIONAL

Business Management System

ED

Manual BMS 06.1 – Standard Operating Practices

LL

Table of Contents

O

TR

Section I – Introduction

BMS 06.1-10-GEN Introduction

Section II – Policy & Procedure

N

BMS 06.1-20-POL Standard Operating Practices

BMS 06.1-21-PRO Administration of Standard Operating Practices

O

Section III – Standard Operating Practices

BMS 06.1-30-STD Worksite Specific SOP Register

C

N

U

Weatherford Drilling International Page 1 of 1

WDI-BMS-06.1-00-TOC Issue 4 Rev 0

WDI BUSINESS MANAGEMENT SYSTEM Doc Ref: 06.1-10-GEN Originated by: MS

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: GS

SUBJECT: Introduction Revised: 31 Mar 2008 Authorised by: NE

INTRODUCTION

Engage… Do Right… Excel

Weatherford Drilling International (WDI) provides well construction and well maintenance

ED

services to its Customers, primarily through the safe and effective operation of its drilling rigs. In

providing service to its customers WDI aspires to excel in all aspects of its business WDI recognize

that success in service excellence requires the effective integration and involvement of its

personnel and its management system with every task it undertakes.

Engaging personnel and management systems to achieve the right outcome for every task requires

LL

leadership and management, in action. This manual forms part of the Company Operations

Management System (BMS) and the policies, procedures, standards and expectations set forth

herein are integral with the Company’s leadership and management of successful operations and

service excellence.

O

TR

STANDARD OPERATING PRACTICES

Objective

The Company believes every task can be accomplished without loss, accident or incident, and

expects every employee to engage the BMS systems and processes suitable for each task to

N

assure a successful outcome.

Each WDI worksite differs in specification, arrangement and work activity thereby demanding site

O

specific guidance for worksite personnel to be able to operate the worksite effectively. The objective

of worksite specific Standard Operating Practices is to provide each worksite with common

guidance, established for the worksite by worksite personnel, that enables consistently successful

task outcomes.

C

Standard Operating Practices Manual

N

This Manual provides employees with relevant information regarding company expectations relating

to the use of Standard Operating Practices in managing effective operations at WDI worksite.

U

This Manual also provides worksites with a means to develop, establish, maintain and control site

specific Standard Operating Practices.

Weatherford Drilling International Page 1 of 1

WDI-BMS-06.1-10-GEN Issue 4 Rev 0

WDI BUSINESS MANAGEMENT SYSTEM Doc Ref: 06.1-20-POL Originated by: MS

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: GS

SUBJECT: Standard Operating Practices Revised: 31 Mar 2008 Authorised by: NE

1.0 PURPOSE

1.1 To outline Company expectations for the use of worksite specific guidance, in the

form of Standard Operating Practices, to enable the management of effective

operations at Weatherford Drilling International (WDI) worksites.

ED

2.0 SCOPE

2.1 This manual and the requirements herein are applicable to all WDI worldwide.

LL

3.0 RESPONSIBILITIES

3.1 The worksite supervisor (Senior Toolpusher (STP) at the rig site, and Department

Head (DH) at any support base worksite), is responsible for managing the system for

the development, establishment, use and control of Standard Operating Practices

3.2

(SOP) at the worksite.

O

It is the responsibility of worksite task supervisors to identify the need for, and

TR

provide task participants with applicable SOP, and to ensure the SOP is reviewed

and modified by the task participants as may be required to suit the specific

requirements of the task on each occasion, and that the SOP and any changes are

fully understood by the task participants.

3.3 It is the responsibility of the task participants to review any applicable SOP prior to

N

the task, contribute to any required modification of the SOP to suit the task at hand,

and to understand and follow the requirements of the SOP.

3.4 It is the responsibilities of the Cost Centre Manager to monitor SOP’s at the work site

O

and recommend applicable SOP’s to be upgraded to Company wide Operating

Standards for inclusion in Manual 6.0 Operations and Maintenance, via the CDP

(refer BMS 01-24-PRO, Company Designated Person).

C

4.0 PROCEDURE

N

4.1 Each task shall be planned and suitably and sufficiently risk assessed prior to

commencement (refer BMS 03-20-POL, Risk Assessment). The risk assessment

U

shall determine the need to provide task participants with written form of step by step

instructions for tasks that consist of complex or critical sequences of steps.

4.2 The written form of instructions, part of the mitigation of risks associated with a

complex or high risk potential task, shall be developed into a Standard Operating

Practice (SOP), and incorporated into the Operations Management System (BMS)

through their inclusion in this manual. (refer BMS 06.1-21-PRO).

4.3 On every occasion a SOP is required, it shall be reviewed and modified, as required,

by the task supervisor and the task participants, to ensure the SOP adequately

addresses the specific requirements of the task at hand. Changes to the SOP to suit

Weatherford Drilling International Page 1 of 2

WDI-BMS-06.1-20-POL Issue 4 Rev 0

WDI BUSINESS MANAGEMENT SYSTEM Doc Ref: 06.1-20-POL Originated by: MS

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: GS

SUBJECT: Standard Operating Practices Revised: 31 Mar 2008 Authorised by: NE

the task at hand shall be marked on the hard copy of the SOP used at the worksite

prior to the commencement of the task. Any changes to the SOP identified by the

task supervisor or task participants during the course of the task shall be marked on

the hard copy of the SOP used at the worksite.

4.4 Where one or more SOP’s are used on tasks that cross work shifts, the SOP shall be

ED

adequately covered in shift handover communication (refer BMS 03-38-PRO) to

ensure that new shift personnel involved with any relevant task are fully informed and

aware of the requirements of any relevant SOP prior to work re-commencing.

4.5 At the end of any task covered by a SOP, the task supervisor shall return the SOP to

the worksite supervisor. All marked changes on the returned SOP shall be

considered for inclusion in future revisions of the SOP as either permanent changes

LL

or as additional guidance notes on the SOP for task participants.

5.0 REFERENCES

5.1

5.2 O

Procedure BMS 01-24-PRO Company Designated Person

Policy BMS 03-20-POL, Risk Assessment

TR

5.3 Policy BMS 03-38-PRO, Handover Procedure

5.4 Procedure BMS 06.1-21-PRO Administration of Standard Operating Procedures

N

O

C

N

U

Weatherford Drilling International Page 2 of 2

WDI-BMS-06.1-20-POL Issue 4 Rev 0

WDI BUSINESS MANAGEMENT SYSTEM SOP Ref: 06.1-21-PRO Originated by: TP

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: TP

SUBJECT: Choke Manifold Testing Revised: 31 Mar 2008 Authorised by: NE

ATTACHMENT A - EXAMPLE SOP

People

Assistant Driller

Cementer (service provider)

ED

Plant and equipment

Cement/test pump

Calibrated test chart recorder and test chart

Calibrated pressure test gauge

Surface line to choke manifold

Choke manifold

LL

Warning signs and barriers

Practice

i. AD to agree task plan with worksite supervisor, contact the Cementer.

ii. AD and Cementer to agree steps of task plan, risk assess the plan, review and modify

iii.

to work.

O

this SOP as required to suit the task plan (test program), and prepare and raise permit

AD to inform the Driller of work about to commence.

TR

iv. AD to arrange worksite announcements and barriers in place for High Pressure

Testing.

v. AD to walk plant and equipment and check integrity, including safety lines.

vi. Cementer to fill tanks with test water.

vii. AD to open all choke manifold valves and, on AD instruction, Cementer to commence

pumping at low rate to confirm line up and show of test water at end of choke manifold.

N

viii. On AD instruction, Cementer to stop pumping. (Cementer or any task observer is

authorized to stop the pumping operation at any point where there is real or perceived

concern about any aspect of the task)

O

ix. AD to close Valve #1 and, on AD instruction, Cementer to commence pumping at low

rate monitoring pump pressure.

x. Cementer raises test pressure to low pressure test point of xxpsi, stops pumping,

C

notes volume pumped and monitors pressure stabilization.

xi. Etc

xii. Etc

N

Note diagrams can be used to illustrate rig ups or layouts etc.

U

Weatherford Drilling International Page 1 of 1

WDI-BMS-06.1-21-PRO Issue 4 Rev 0

WDI BUSINESS MANAGEMENT SYSTEM Doc Ref: 06.1-21-PRO Originated by: MS

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: GS

SUBJECT: Administration of Standard Operating Practices Revised: 31 Mar 2008 Authorised by: NE

1.0 PURPOSE

1.1 To provide guidance on the administration and control of worksite specific guidance,

in the form of Standard Operating Practices (SOPs), to enable the management of

effective operations at Weatherford Drilling International (WDI) worksites.

1.2 To ensure that appropriate and current SOP’s are available to worksite personnel.

ED

2.0 SCOPE

2.1 This manual and the requirements therein are applicable to all WDI worldwide.

LL

3.0 RESPONSIBILITIES

3.1 The worksite supervisor (Senior Toolpusher (STP) at the rig site, and Department

O

Head (DH) at any support base worksite) is responsible for the system for

development, establishment, use and control of Standard Operating Practices (SOP)

at the worksite.

TR

3.2 It is the responsibility of worksite task supervisors to provide task participants with

the latest version of any applicable SOP, and to ensure the SOP is reviewed,

modified, and understood by the task participants as may be required to suit the

specific requirements of the task on each occasion.

N

3.3 It is the responsibility of the task supervisor to ensure changes to a SOP are included

as applicable in subsequent revisions of the SOP.

O

4.0 PROCEDURE

4.1 Each task shall be planned and suitably and sufficiently risk assessed prior to

commencement, refer to BMS 03-31-PRO.

C

4.2 Where a particular step or combination of steps of a task require risk mitigation in the

form of clear and specific instructions for task personnel a SOP shall be developed,

N

or, where a SOP already exists, be reviewed in consideration of the specific

circumstances of the task at hand.

U

4.3 SOP’s shall follow the format as shown in Attachment A, Example SOP attached.

SOPs shall be uniquely numbered with Rig or Cost Centre number followed by

sequential number, and with any permanent changes to an SOP recognized by a

SOP Revision.

4.4 An SOP register, refer Form BMS 06.1-30-STD-01, shall be maintained at each

worksite.

4.5 Current revisions of SOP’s shall be maintained in hard copy in this manual, and in

soft copy at a nominated worksite computer.

Weatherford Drilling International Page 1 of 2

WDI- BMS-06.1-21-PRO Issue 4 Rev 0

WDI BUSINESS MANAGEMENT SYSTEM Doc Ref: 06.1-21-PRO Originated by: MS

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: GS

SUBJECT: Administration of Standard Operating Practices Revised: 31 Mar 2008 Authorised by: NE

4.6 Each worksite shall nominate a person(s), one on site at any time, to fulfill the SOP

Administrator role. The SOP Administrator shall be responsible for maintaining

current revision SOP’s organized per this procedure. The SOP Administrator shall

not be responsible for the content of the SOP.

4.7 Where an SOP requirement is identified by risk assessment, task supervisors shall

refer to the SOP’s contained within this manual. The SOP requirement shall be

ED

fulfilled per step 4.2 of this procedure.

4.8 Management of change, refer BMS 01-25-POL requires that SOP’s be continually

reviewed against the prevailing conditions of the task at hand such that any conflict

or emerging hazard be adequately addressed prior to continuing with the work.

LL

4.9 Any changes to the SOP identified by the task supervisor or task participants prior to

or during the task shall be marked on the hard copy of the SOP used at the worksite.

Where change to an SOP is addressed during a task A Time Out For Safety (refer

BMS 03-13-POL) will be taken to ensure that task participants are fully informed and

aware of the revised requirements of the SOP prior to work re-commencing.

4.10

O

Where SOP’s are used on tasks that cross work shifts, the SOP shall be adequately

covered in shift handover communication (refer BMS 03-38-PRO) to ensure the new

TR

shift personnel involved with the task are fully informed and aware of the

requirements of the SOP prior to work re-commencing.

4.11 At the end of a task where SOP’s have been used the task supervisor shall return

the SOP to the worksite supervisor. All marked changes on the returned SOP shall

be considered for inclusion in future revisions of the SOP as either permanent

N

changes or as additional guidance notes on the SOP for task participants. The

worksite supervisor shall have the final authority of permanent change to any SOP.

O

4.12 The worksite supervisor shall advise the SOP Administrator of any required

modifications to the SOP, upon which the SOP Administrator shall incorporate the

change in a revision to the SOP.

C

5.0 REFERENCES

N

5.1 Form BMS 06.1-30-STD-01 Worksite Specific SOP Register

5.2 Attachment A, Example SOP

U

5.3 Procedure BMS 03-31-PRO Risk Assessment

5.4 Procedure BMS 03-38-PRO Handover Procedure

5.5 Policy BMS 06.1-20-POL Standard Operating Procedures.

5.6 Policy BMS 01-25-POL Management of Change

5.7 Policy BMS 03-13-POL Time Out For Safety

Weatherford Drilling International Page 2 of 2

WDI- BMS-06.1-21-PRO Issue 4 Rev 0

WDI BUSINESS MANAGEMENT SYSTEM Doc Ref: 06.1-30.STD Originated by: MS

BMS 06.1 – STANDARD OPERATING PRACTICES Originated: 31 Jul 2006 Revised by: GS

SUBJECT: Worksite Specific SOP Register Revised: 31 Mar 2008 Authorised by: NE

SOP # Rev # and Date Subject Revised Approved

By By

710-01 0 – 31 Mar 05 Choke Manifold Testing TL PC

ED

LL

O

TR

N

O

C

N

U

Weatherford Drilling International Page 1 of 1

WDI-BMS-06.1-30-STD Issue 4 Rev 0

You might also like

- Ajustes 622B PDFDocument178 pagesAjustes 622B PDFabel75% (4)

- TC-OVR-STD-PL-000500 External Coatings For Metallic PipelinesDocument65 pagesTC-OVR-STD-PL-000500 External Coatings For Metallic PipelinesRomain Perrier-CornetNo ratings yet

- NORSOK Z-008 Risk Based Maintenance & Consequence ClassificationDocument44 pagesNORSOK Z-008 Risk Based Maintenance & Consequence ClassificationWilkin Llanca Blas100% (2)

- (WHQ IMS PR009) Non Conformity Management r5 PDFDocument12 pages(WHQ IMS PR009) Non Conformity Management r5 PDFKerima MagatNo ratings yet

- Oracle Utility CCB PDFDocument4 pagesOracle Utility CCB PDFMaverick BustosNo ratings yet

- Determining Whether Gas-Leak-Detector Fluid Solutions Can Cause Stress Corrosion Cracking of Brass AlloysDocument10 pagesDetermining Whether Gas-Leak-Detector Fluid Solutions Can Cause Stress Corrosion Cracking of Brass AlloysNav TalukdarNo ratings yet

- BMS 03.1-Weekly HS&E ReportsDocument7 pagesBMS 03.1-Weekly HS&E ReportsTahir Iqbal. Kharpa Rehan100% (1)

- Manual 01 Manual 09Document1 pageManual 01 Manual 09Tahir Iqbal. Kharpa RehanNo ratings yet

- Regal E.ManualDocument24 pagesRegal E.ManualMohammed ZubairNo ratings yet

- TP-300-4 Penilaian Analisa JurangDocument3 pagesTP-300-4 Penilaian Analisa JurangNurul Huda AliNo ratings yet

- Iv Semester Diploma in Electrical Engineering Skill Based Diploma in Engineering Course ManagementDocument22 pagesIv Semester Diploma in Electrical Engineering Skill Based Diploma in Engineering Course ManagementManisha KumariNo ratings yet

- Norsok Standard Z-008: Edition 3, June 2011Document46 pagesNorsok Standard Z-008: Edition 3, June 2011Rubi HerwinNo ratings yet

- IMS Manual Iso 9000 14000 Ohsas 18000 PDFDocument10 pagesIMS Manual Iso 9000 14000 Ohsas 18000 PDF670620No ratings yet

- Aom 2019Document377 pagesAom 2019Vijay100% (2)

- Department Integrated Management System Manual: IS/ISO/9001: 2015 IS/ISO/14001: 2015Document58 pagesDepartment Integrated Management System Manual: IS/ISO/9001: 2015 IS/ISO/14001: 2015IskerNo ratings yet

- AICPA Professional Standards: Statements of Management Advisory Services As of June 1, 1980Document56 pagesAICPA Professional Standards: Statements of Management Advisory Services As of June 1, 1980Kezhael NacionNo ratings yet

- 06.SOP. Manual HandlingDocument9 pages06.SOP. Manual HandlingBhagat DeepakNo ratings yet

- 02implementing Equipment ManagementDocument11 pages02implementing Equipment ManagementCÉSAR PONCENo ratings yet

- Norsonk Risk Maintenance Z-008Document46 pagesNorsonk Risk Maintenance Z-008juan fernando bernal vasquezNo ratings yet

- CDU II Operating Manual PDFDocument562 pagesCDU II Operating Manual PDFMilind GaikwadNo ratings yet

- 1621201971019421Document3 pages1621201971019421Varun LalwaniNo ratings yet

- Iso QM Issue IV Rev 04 Dec 21Document105 pagesIso QM Issue IV Rev 04 Dec 21repair sectionNo ratings yet

- Turtle DiagramDocument22 pagesTurtle DiagramVikas0% (1)

- Siscol Ims ManualDocument131 pagesSiscol Ims ManualsamyfouadNo ratings yet

- Ims Operation Manual: Chief Operating Committee-Coc (Top Management)Document6 pagesIms Operation Manual: Chief Operating Committee-Coc (Top Management)Akd DeshmukhNo ratings yet

- KPI Metricas de Mantenimiento IndustrialDocument26 pagesKPI Metricas de Mantenimiento IndustrialFrancisco Jose TorreglosaNo ratings yet

- DFM-Kudgi BMDRMDocument20 pagesDFM-Kudgi BMDRMSathish MskNo ratings yet

- Operating and Maintenance Manuals - Solution - EdocumentsDocument3 pagesOperating and Maintenance Manuals - Solution - EdocumentsneluNo ratings yet

- Gasoline EngineDocument422 pagesGasoline EngineCARLOS BELTRÁNNo ratings yet

- Ericsson - Operational-Quality-Manual - Current 2023Document26 pagesEricsson - Operational-Quality-Manual - Current 2023jason zengNo ratings yet

- SWAS Circular R EM 004 Elements of The Management System (QEHS)Document18 pagesSWAS Circular R EM 004 Elements of The Management System (QEHS)Karina OspinaNo ratings yet

- Preparing Job Estimation and Costing: Automotive Servicing Operations ManagementDocument14 pagesPreparing Job Estimation and Costing: Automotive Servicing Operations ManagementZoscalesNo ratings yet

- ME C-15 5 and 6Document274 pagesME C-15 5 and 6nakulNo ratings yet

- POG On FEMS Project Operation Guidlines, PSK Silo - Tips - Bahagian-Perkhidmatan-Kejuruteraan-Kementerian-Kesihatan-MalaysiaDocument37 pagesPOG On FEMS Project Operation Guidlines, PSK Silo - Tips - Bahagian-Perkhidmatan-Kejuruteraan-Kementerian-Kesihatan-MalaysiaShafeek RamleeNo ratings yet

- SMK Muhammadiyah 7 Gondanglegi: Blok ADocument11 pagesSMK Muhammadiyah 7 Gondanglegi: Blok ABagus Fitri UtomoNo ratings yet

- Standards and Testing Division Quality ManualDocument28 pagesStandards and Testing Division Quality ManualAnonymous dtceNuyIFINo ratings yet

- 1b - Publicly-availablity-SMETA-Measurement-Criteria-4-Pillar-5 0 PDFDocument63 pages1b - Publicly-availablity-SMETA-Measurement-Criteria-4-Pillar-5 0 PDFLên Văn LêNo ratings yet

- Statement of Result: ITIL® QualificationDocument1 pageStatement of Result: ITIL® QualificationmantruneIINo ratings yet

- MER1MM 07V0 Planning and SchedulingDocument31 pagesMER1MM 07V0 Planning and SchedulingJaime Solano100% (1)

- Automotive Quality Management System Manual: Century Metal Recycling LimitedDocument7 pagesAutomotive Quality Management System Manual: Century Metal Recycling LimitedsunilNo ratings yet

- Report On Maintenance Programme Recommendations and DisseminationDocument13 pagesReport On Maintenance Programme Recommendations and DisseminationKunal ShahNo ratings yet

- Quality Presentation 30 Oct 17Document51 pagesQuality Presentation 30 Oct 17Syerifaizal Hj. MustaphaNo ratings yet

- Aug 2022, ARRAZI's SHEM-09 OMS-317 Management of ChangeDocument21 pagesAug 2022, ARRAZI's SHEM-09 OMS-317 Management of ChangeBilal SarhanNo ratings yet

- QACE Quality Manual Ver 6.0 Final 13oct20 As Approved by BoDDocument44 pagesQACE Quality Manual Ver 6.0 Final 13oct20 As Approved by BoDianjester15No ratings yet

- Wausau Equipment CompanyDocument4 pagesWausau Equipment CompanyNarinderNo ratings yet

- Three Wheeler's Servicing and MaintenanceDocument55 pagesThree Wheeler's Servicing and Maintenancetefera getachewNo ratings yet

- 1706229109532Document43 pages1706229109532Gonzalez GabrielNo ratings yet

- Managing Workshop/ Servicing OperationsDocument17 pagesManaging Workshop/ Servicing OperationsZoscalesNo ratings yet

- 7057.151.04 Er HS 003 WHSDocument10 pages7057.151.04 Er HS 003 WHSsandyyansikuNo ratings yet

- Liederung Des Anagementsystems: Service Manual 2009 - PreambleDocument1 pageLiederung Des Anagementsystems: Service Manual 2009 - PreamblePopa MihaiNo ratings yet

- Course Outline'15 - Operations Management - North CampusDocument4 pagesCourse Outline'15 - Operations Management - North CampusNaunit VaidNo ratings yet

- Planning and Organizing Work: Automotive Servicing Operations ManagementDocument18 pagesPlanning and Organizing Work: Automotive Servicing Operations ManagementZoscalesNo ratings yet

- RegisterDocument11 pagesRegistersyaiful.bahri13No ratings yet

- IMD Environmental MGT PlanDocument118 pagesIMD Environmental MGT PlanCarlo EstolasNo ratings yet

- SPC Work InstructionDocument8 pagesSPC Work InstructionMahendra SinghNo ratings yet

- IMS Level 1Document64 pagesIMS Level 1Vikrant Salpekar100% (1)

- ISO 22301-2019 Transition Whitepaper PDFDocument9 pagesISO 22301-2019 Transition Whitepaper PDFR H100% (1)

- ISO 9001-2008 Document Kit (Service Sector)Document8 pagesISO 9001-2008 Document Kit (Service Sector)andranormanNo ratings yet

- Training PDFDocument10 pagesTraining PDFANURAGNo ratings yet

- Be Involved: Implementing SaaS ERP Systems for SMEsFrom EverandBe Involved: Implementing SaaS ERP Systems for SMEsRating: 1.5 out of 5 stars1.5/5 (2)

- Rig Move Load Measurements: Saudi Arabian Saipem LTDDocument6 pagesRig Move Load Measurements: Saudi Arabian Saipem LTDTahir Iqbal. Kharpa RehanNo ratings yet

- BMS 03.1-Weekly HS&E ReportsDocument7 pagesBMS 03.1-Weekly HS&E ReportsTahir Iqbal. Kharpa Rehan100% (1)

- Manual 01 Manual 09Document1 pageManual 01 Manual 09Tahir Iqbal. Kharpa RehanNo ratings yet

- Interoffice Correspondence: Weatherford Drilling InternationalDocument2 pagesInteroffice Correspondence: Weatherford Drilling InternationalTahir Iqbal. Kharpa RehanNo ratings yet

- Location Acceptance HRDH 1072Document2 pagesLocation Acceptance HRDH 1072Tahir Iqbal. Kharpa RehanNo ratings yet

- Rig Move Plan May - 10Document3 pagesRig Move Plan May - 10Tahir Iqbal. Kharpa RehanNo ratings yet

- Location Acceptance HRDH 1072Document2 pagesLocation Acceptance HRDH 1072Tahir Iqbal. Kharpa RehanNo ratings yet

- Rig Move: Trip Truck No. Load DescriptionDocument7 pagesRig Move: Trip Truck No. Load DescriptionTahir Iqbal. Kharpa RehanNo ratings yet

- Rig Move Data HWYH-1013Document13 pagesRig Move Data HWYH-1013Tahir Iqbal. Kharpa RehanNo ratings yet

- Daily Mud Report No. 62: Bit Information Bit Hydraulics VOLUMES (BBL)Document5 pagesDaily Mud Report No. 62: Bit Information Bit Hydraulics VOLUMES (BBL)Tahir Iqbal. Kharpa RehanNo ratings yet

- Summit Tools Thread ConnectionlistDocument1 pageSummit Tools Thread ConnectionlistTahir Iqbal. Kharpa RehanNo ratings yet

- Coretrax, P.O Box 7639, Dammam 34325, Kingdom of Saudi Arabia Phone +966 13 833 0919Document1 pageCoretrax, P.O Box 7639, Dammam 34325, Kingdom of Saudi Arabia Phone +966 13 833 0919Tahir Iqbal. Kharpa RehanNo ratings yet

- Hole ProblemsDocument37 pagesHole ProblemsTahir Iqbal. Kharpa RehanNo ratings yet

- Khan Niazi: On Outriggers Fully Extended: 360 On Outriggers Fully Extended: Over FrontDocument1 pageKhan Niazi: On Outriggers Fully Extended: 360 On Outriggers Fully Extended: Over FrontTahir Iqbal. Kharpa RehanNo ratings yet

- Field Report T-901Document1 pageField Report T-901Tahir Iqbal. Kharpa RehanNo ratings yet

- BOP's and Well Controls Related Equipment.: Stand Pipe Manifold, Kill Manifold, Chock ManifoldDocument2 pagesBOP's and Well Controls Related Equipment.: Stand Pipe Manifold, Kill Manifold, Chock ManifoldTahir Iqbal. Kharpa RehanNo ratings yet

- Cert-Conformance For Order.Document1 pageCert-Conformance For Order.Tahir Iqbal. Kharpa RehanNo ratings yet

- Cert-Conformance For FL2Document1 pageCert-Conformance For FL2Tahir Iqbal. Kharpa RehanNo ratings yet

- Basic Lifting TechniquesDocument54 pagesBasic Lifting TechniquesTahir Iqbal. Kharpa RehanNo ratings yet

- 182-MI-S-RT-003-MUD TANK - (SGS-JUB-M-22-345-182) - MPI ReportDocument1 page182-MI-S-RT-003-MUD TANK - (SGS-JUB-M-22-345-182) - MPI ReportTahir Iqbal. Kharpa RehanNo ratings yet

- Riggers RequirementsDocument2 pagesRiggers RequirementsTahir Iqbal. Kharpa RehanNo ratings yet

- CV Gede Karya 18Document5 pagesCV Gede Karya 18Riswan PutriNo ratings yet

- GRE Vocabulary02Document20 pagesGRE Vocabulary02refdoc512No ratings yet

- Practical Research 1 Quarter 1 - Module 2: Getting The Most Out of LifeDocument15 pagesPractical Research 1 Quarter 1 - Module 2: Getting The Most Out of LifeMark Allen LabasanNo ratings yet

- Ielts Task 1Document10 pagesIelts Task 1Jana Shamseldin AbdelrahmanNo ratings yet

- Mirpur University of Science and Technology (Must), Mirpur Deparment Computer Systems Engineering (Cse)Document21 pagesMirpur University of Science and Technology (Must), Mirpur Deparment Computer Systems Engineering (Cse)Marva TouheedNo ratings yet

- Blank Risk Assessment TemplateDocument4 pagesBlank Risk Assessment TemplateMNo ratings yet

- English GrammarDocument12 pagesEnglish GrammarDhrutvan Reddy ReddiwaryNo ratings yet

- Srep 24474Document10 pagesSrep 24474RoNo ratings yet

- Chapter 16Document34 pagesChapter 16Casao JonroeNo ratings yet

- Testicular Ultrasonogram Pixel Intensity in Developing Buffalo Calves/BullsDocument7 pagesTesticular Ultrasonogram Pixel Intensity in Developing Buffalo Calves/Bullspickawwin4No ratings yet

- AI-based Chatbot For Skin Disease Prediction Using CNN and ID3 Decision TreeDocument46 pagesAI-based Chatbot For Skin Disease Prediction Using CNN and ID3 Decision TreeChumma SpamNo ratings yet

- Lesson Plan ScienceDocument6 pagesLesson Plan ScienceJuhaira DatuwataNo ratings yet

- Fda 10007Document5 pagesFda 10007Ugodilinwa Nnaemeka La SonNo ratings yet

- CLP Info SheetDocument6 pagesCLP Info SheetCarolina Mateus MoreiraNo ratings yet

- 1989 Goodman IntroductionRockMechanics 2edDocument563 pages1989 Goodman IntroductionRockMechanics 2edDiego ColaresNo ratings yet

- Ieo Sample Paper Class-12Document1 pageIeo Sample Paper Class-12cher ryNo ratings yet

- Rock Typing and Petrophysical Property EstimationDocument13 pagesRock Typing and Petrophysical Property EstimationAlyne DuarteNo ratings yet

- The Historical HebdomadDocument5 pagesThe Historical HebdomadDark JaperNo ratings yet

- Cambridge International AS & A Level: Chemistry 9701/52 March 2021Document6 pagesCambridge International AS & A Level: Chemistry 9701/52 March 2021Yue ShiNo ratings yet

- Construction Drawing PracticesDocument43 pagesConstruction Drawing PracticesT N Roland Bourge100% (1)

- Mass Transfer With Chemical Reaction in Multiphase Systems 1983 PDFDocument1,079 pagesMass Transfer With Chemical Reaction in Multiphase Systems 1983 PDFMark Herring100% (1)

- Architect: Intj-A / Intj-TDocument15 pagesArchitect: Intj-A / Intj-Tbjdevhervehroheghghbhbhotbhhortbh100% (1)

- 2020 AProductivity Assessmentof PWDEmployeesina Philippine CompanyDocument12 pages2020 AProductivity Assessmentof PWDEmployeesina Philippine CompanyRachele GreeneNo ratings yet

- GB-4540 Rev1Document42 pagesGB-4540 Rev1Алексей ХоролецNo ratings yet

- Division of Cebu Province: Lesson Exemplar TemplateDocument3 pagesDivision of Cebu Province: Lesson Exemplar TemplateBlasy Jean BaragaNo ratings yet

- Training and Certification Services in Recmin Mining SoftwareDocument3 pagesTraining and Certification Services in Recmin Mining SoftwareJoseph buluguNo ratings yet

- Fluids and Lubricants Specifications: Diesel Engine-Generator Sets With Series 2000 and 4000 MTU EnginesDocument135 pagesFluids and Lubricants Specifications: Diesel Engine-Generator Sets With Series 2000 and 4000 MTU EnginesPhat Chau ThuanNo ratings yet

- Class-6 Geography-Chapter-12-The-Planet-EarthDocument4 pagesClass-6 Geography-Chapter-12-The-Planet-Earthdpsr mathsNo ratings yet