Professional Documents

Culture Documents

Checking The Engine Coolant Level

Checking The Engine Coolant Level

Uploaded by

Phạm Hoài MinhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checking The Engine Coolant Level

Checking The Engine Coolant Level

Uploaded by

Phạm Hoài MinhCopyright:

Available Formats

106931678_002

Engine coolant (Checking the level)

NOTICE: The engine coolant level should be checked every 10 hours of operation or each day, whichever occurs

first. For engine coolant specifications, see Capacities .

NOTE: Handle and dispose of the waste in accordance with environmental regulations, laws and government codes.

Checking the engine coolant level

To check the engine coolant level, proceed as follows:

1. Keep all unauthorized personnel clear of the area.

2. Park the machine on a flat, level, firm surface, away

from any obstacles.

3. Position the arm, boom and bucket or implement as

shown.

4. Set the park brake.

5. Place the safety lever in the function lockout posi-

tion.

6. Place the ignition key in the "OFF" position to shut

down the engine.

NHC0257 1

7. Remove the ignition key.

8. Put the safety lever in the locked position.

9. Wait for the engine to cool.

10. Open the engine hood to access the components

of the cooling system.

11. Use the rod (1) located to the side of the expansion

tank (2) to lock the hood correctly.

12. Check the coolant level via the display (3) located

on the side of the expansion tank, as shown in the

figure.

13. The fluid level should be visible in the sight glass.

14. If the level is low, remove the filler cap (4) from the

expansion tank. Top up the level until the fluid is

visible in the sight glass.

NOTE: Do not open the radiator cap. COIL16CEX0005AA 2

15. Install the expansion tank filler cap. Make sure that

the cap is latched properly.

NOTICE: When you top up the system, maintain the same

percentage of water and antifreeze currently used in the

system. Use clean water that is free of chlorinated com-

pounds whenever possible. See Engine coolant (Chang-

ing) for more information.

NOTE: The cooling system is pressurized. Only check the

level of coolant in the tank when the fluid is cold and the en-

gine is shut down. Coolant can blow out and cause burns.

1 13 June 2022 ZC883 EN

106931860_010

Consumables

International

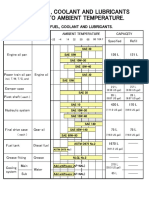

Type / Application Recommended oil Capacity

Specification

Engine oil (Tropical region) No.1 Engine Oil™ Super

SAE 15W-40; API CI-4 16.5 L ( 4.4 US gal )

(With remote oil filter) SAE 15W-40

Engine oil (Cold region) SAE 10W-30 CI-4 Engine

SAE 10W-30; API CI-4 16.5 L ( 4.4 US gal )

(With remote oil filter) Oil

System capacity - 410.0

Fuel tank Light oil (Diesel) (-)

L ( 108.3 US gal )

Extended Life OAT

Cooling system OAT EG2, 50-50 Premix 25.0 L ( 6.6 US gal )

Coolant/Antifreeze

Premium Hydraulic Oil Multigrade ISO VG 46,

Total system capacity -

Hydraulic oil HV46 Multi-Grade An- DIN 51524-3 HVLP 46, An-

295.0 L ( 77.9 US gal )

ti-Wear ti-Wear (AW)

Premium Hydraulic Oil Multigrade ISO VG 46,

Total system capacity -

Hydraulic sump tank HV46 Multi-Grade An- DIN 51524-3 HVLP 46, An-

162.0 L ( 42.8 US gal )

ti-Wear ti-Wear (AW)

Hypoid Gear Oil EP SAE SAE 85W-140, API GL 5,

Swing drive case 6.0 L ( 1.6 US gal )

85W-140 Extreme Pressure (EP)

Hypoid Gear Oil EP SAE SAE 85W-140, API GL 5,

Final drive case (per side) 5.0 L ( 1.3 US gal )

85W-140 Extreme Pressure (EP)

Adhesive Loctite® 262™ Loctite® 262™ As required

Windshield washer Water Water 1.5 L ( 0.4 US gal )

Grease fittings

International Specifica-

Application Recommended Capacity

tion

Attachment pins 4.8 kg

NLGI 2, lithium soap

Tensioner wheel cylinder Multi-Purpose Moly grease, 3% molybdenum 0.46 kg

Idler Grease EP / AW / NLGI 2 disulfide, Extreme Pres- 3.5 kg

sure (EP), Anti-Wear

Slew ring 14.0 kg

Gear oil

Recommend- International

Application Per roller capacity Capacity

ed Specification

3.78 L (Standard carriage)

Lower track rollers 270 mL

4.32 L (Long carriage)

Shell HELIX

SAE-40

Upper track rollers HX3 SAE 40 120 mL 0.48 L

Take up roller 265 mL 0.53 L

Air Con

International Specifica-

Type Recommended Capacity

tion

Synthetic polyolester

(POE) lubricant for HFC

Compressor specifications (-) 250 mL

R134A of required viscosi-

ty ISO VG 68

1 13 June 2022 ZC883 EN

106931860_010

International Specifica-

Type Recommended Capacity

tion

Environmentally-friendly

Air conditioning gas speci- 0.950 - 1.050 kg ( 2.094

R134a hydro fluoro carbon gas

fications - 2.315 lb )

HFC R134A

2 13 June 2022 ZC883 EN

106931810_003

Engine coolant (Changing)

CAUTION

Burn hazard!

Hot coolant can spray out if you remove the filler cap while the system is hot. After the system has

cooled, turn the filler cap to the first notch and wait for all pressure to release before proceeding.

Failure to comply could result in minor or moderate injury.

C0043A

NOTICE: The engine coolant must be drained and changed. The cooling system must be cleaned every 2000 hours

of operation or every year, whichever comes first, or more frequently (shorter periods) when you operate the machine

in extreme conditions. For engine coolant specifications, see Capacities .

NOTE: A mixture of 50 % anti-freeze and 50 % water must be used in this machine. This mixture is recommended

for use in locations where minimum ambient temperatures are above –37 °C ( –34 °F ) . If the ambient temperature

is lower, adjust the composition of the mixture to 60 % anti-freeze and 40 % water. You should use anti-freeze

and water in your machine all year.

Draining and cleaning the system and changing the engine coolant

To drain, clean the system, and replace the engine

coolant, proceed as follows:

1. Keep all unauthorized personnel clear of the area.

2. Park the machine on a flat, level, firm surface, away

from any obstacles.

3. Turn the upper structure 90 ° to achieve easy ac-

cess to the drain register.

4. Position the arm, boom and bucket or implement as

shown.

5. Set the park brake.

6. Turn the manual throttle fully counter-clockwise.

NHC0259 1

7. Place the safety lever in the function lockout posi-

tion.

8. Place the ignition key in the "OFF" position to shut

down the engine.

9. Remove the ignition key.

10. Put the safety lever in the locked position.

11. Wait for the engine to cool.

1 13 June 2022 ZC883 EN

106931810_003

Drainage of the engine coolant system

1. Open the engine hood. Use the retaining rod (1)

located adjacent to the expansion tank (2) to lock

the hood in the open position.

2. Slightly loosen the radiator cap (3) to relieve

the pressure inside the cooling system complete-

ly. Then loosen the cap and completely remove the

cap.

3. Remove the cap (4) under the radiator from under-

neath the upper structure.

4. Place a container of suitable capacity under the

drain valve (5) .

5. Open the drain valve. Let the coolant drain into the

container. COIL16CEX0005AA 2

6. After the coolant has completely drained, close the

drain valve.

7. Carefully inspect the hose clamps. Make sure that

the clamps are free from damage.

NOTE: Replace the clamps if necessary.

8. Tighten the clamps if they are loose.

9. Check that there are no leaks in the radiator or in

the hoses. Also check that there is no damage or

accumulation of dirt.

NHC0353 3

NHC0285A 4

2 13 June 2022 ZC883 EN

106931810_003

Flushing and filling the cooling system

To flush and fill the engine cooling system, proceed as

follows:

1. Fill the system with clean water and a cleaning

agent through the filler neck of the expansion tank

until the tank is completely full.

2. Install and tighten the cap (3) of the expansion tank

(2) . Place the ignition key in the “START” position

to start the engine.

3. Start the engine. Let the engine run at a speed

slightly over idle, until the coolant temperature

reaches 80 °C ( 176 °F ) . .Then, let the engine

run for about 10 minutes.

4. Place the ignition key in the “OFF” position to shut COIL16CEX0005AA 5

down the engine again.

5. Drain the water with the cleaning agent. Follow the

procedure described above.

6. Then refill the cooling system with clean water only

and flush the system again.

7. Repeat this operation until the water drained comes

out clean.

8. Make sure that the drain valve (5) is fully closed.

Use the recommended coolant to fill the system

through the filler neck of the expansion tank. Fill un-

til it is completed full. See Capacities for coolant

specifications.

NHC0285A 6

9. Install the expansion tank cap (3) .

10. Start the engine again. Let the engine run for a few

minutes to allow the full deaeration of the system.

11. Stop the engine. Let the engine cool off. Check the

coolant level through the expansion tank level sight

glass (6) .

12. The coolant level should be between visible in the

sight glass.

13. If the coolant level is low, top up as necessary

through the cap (3) of the expansion tank.

14. Close the radiator compartment access door and

the engine hood.

COIL16CEX0009AA 7

NOTE: Do not open the radiator cap (7) . The cooling system is pressurized. Only check the level of coolant in the

tank when the fluid is cold and the engine is shut down. Coolant can blow out and cause burns.

3 13 June 2022 ZC883 EN

You might also like

- Cycle SyncingDocument43 pagesCycle SyncingHeShot MeDown100% (2)

- Manual Motor WC30D Tier-3 SM PDFDocument105 pagesManual Motor WC30D Tier-3 SM PDFAndres Abril100% (1)

- Lube Oil SystemDocument3 pagesLube Oil SystemCharan Kumar100% (1)

- Engine Oil (Checking The Level) : WarningDocument4 pagesEngine Oil (Checking The Level) : WarningPhạm Hoài MinhNo ratings yet

- 保养Document48 pages保养jackNo ratings yet

- O&M FD40-7T KomatsuDocument35 pagesO&M FD40-7T Komatsujheison valencia100% (2)

- معلومات الزيوت للمعداتDocument6 pagesمعلومات الزيوت للمعداتApo ghasan Al shargapiNo ratings yet

- 2010 Toyota Land Cruiser 81Document25 pages2010 Toyota Land Cruiser 81abdualkareemabudoniaNo ratings yet

- CX17BDocument2 pagesCX17BpitbullNo ratings yet

- FD35 Lubricant ListDocument2 pagesFD35 Lubricant ListErsa RahmandaNo ratings yet

- 1 Standard Parts, ServiceDocument128 pages1 Standard Parts, ServiceJulio Gaston Castellanos DuranNo ratings yet

- SRT95 OffHighway Truck Maintenance OverviewDocument11 pagesSRT95 OffHighway Truck Maintenance OverviewoktopusNo ratings yet

- 2019cuv82servicetraining PDFDocument35 pages2019cuv82servicetraining PDFvictor alfonsoNo ratings yet

- drawworks Lubrication ScheduleDocument1 pagedrawworks Lubrication SchedulelearningzabatNo ratings yet

- معلومات الزيوت للرفاعاتDocument9 pagesمعلومات الزيوت للرفاعاتApo ghasan Al shargapiNo ratings yet

- Genera 1Document14 pagesGenera 1Denis RoscaNo ratings yet

- Lubrication Specifications ChartDocument1 pageLubrication Specifications Chartמסגרת רוצחNo ratings yet

- 0.5% O Rating: G3304 Gas Petroleum EngineDocument8 pages0.5% O Rating: G3304 Gas Petroleum EngineJeff LNo ratings yet

- Lo 5 2350 262 12Document29 pagesLo 5 2350 262 12SteveNo ratings yet

- Lo 5 2350 262 12Document29 pagesLo 5 2350 262 12SteveNo ratings yet

- Section 3 Section 3: Routine MaintenanceDocument2 pagesSection 3 Section 3: Routine MaintenanceСергій БоженкоNo ratings yet

- ConsumablesDocument1 pageConsumablesMarcelo CamargoNo ratings yet

- 2008 Toyota FJ Cruiser Fluid CapacitiesDocument2 pages2008 Toyota FJ Cruiser Fluid CapacitiesRuben100% (1)

- NH L218 - Fluids & LubricantsDocument4 pagesNH L218 - Fluids & LubricantsKristomiDerMarine-Ingenieur100% (1)

- P01use of Fuel & OilDocument1 pageP01use of Fuel & OilAgus DaniNo ratings yet

- Maintenance Quick Guide - SB4312E07Document98 pagesMaintenance Quick Guide - SB4312E07joe100% (2)

- Farana F-15 Daily and Weekly ChecksDocument7 pagesFarana F-15 Daily and Weekly Checksshakti123456789No ratings yet

- 1d. MANUAL BOOK For LubricantsDocument8 pages1d. MANUAL BOOK For LubricantsFerinoviardiNo ratings yet

- Komatsu Gd611 661Document6 pagesKomatsu Gd611 661sofiane aliNo ratings yet

- Cummins C45-C100 SpecsDocument5 pagesCummins C45-C100 SpecsKayra Roussell JenningsNo ratings yet

- Subject: Recommended Oils List: Lift Truck Series All Trucks - See Chart April 1, 2006 CODE 7500Document6 pagesSubject: Recommended Oils List: Lift Truck Series All Trucks - See Chart April 1, 2006 CODE 7500murshed audatallaNo ratings yet

- P01use of Fuel & OilDocument1 pageP01use of Fuel & OilAgus DaniNo ratings yet

- PREDATOR 212 346 and 420 CC Horizontal Engines User ManualDocument32 pagesPREDATOR 212 346 and 420 CC Horizontal Engines User ManualVictor FederNo ratings yet

- Service - Service Manual Code 950 - 994 - 653Document30 pagesService - Service Manual Code 950 - 994 - 653Victor UribeNo ratings yet

- 1-Lubricating Systems For B&C p24Document24 pages1-Lubricating Systems For B&C p24Jonathan RiveraNo ratings yet

- HD CANe 8Document7 pagesHD CANe 8Abdullah ElnagishNo ratings yet

- Filters and CapacitiesDocument3 pagesFilters and CapacitiesbrunofernandesdacostNo ratings yet

- O OW WN NE ER R''S S M MA AN NU UA AL L: Operation Maintenance SpecificationsDocument4 pagesO OW WN NE ER R''S S M MA AN NU UA AL L: Operation Maintenance SpecificationsСергій БоженкоNo ratings yet

- Tata Hybrid Electric BusDocument11 pagesTata Hybrid Electric BusYashswini KabraNo ratings yet

- Mantenimiento 2001Document32 pagesMantenimiento 2001guata1013No ratings yet

- EPC Plant Lubricating Oil AVAILABLE QUANTITYDocument6 pagesEPC Plant Lubricating Oil AVAILABLE QUANTITYSiraj AhmedNo ratings yet

- Lubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingDocument159 pagesLubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingpoiufdsapuroiqNo ratings yet

- Maintenance Data (Fuel, Oil Level, Etc.) : Dimensions and WeightsDocument25 pagesMaintenance Data (Fuel, Oil Level, Etc.) : Dimensions and WeightsTemitayo Elizabeth OgunbiyiNo ratings yet

- This Replaces All Previously Published Fuel and Lubricant SpecificationsDocument1 pageThis Replaces All Previously Published Fuel and Lubricant SpecificationsMartinez AndryjNo ratings yet

- 3 JAC006-2 MaintenanceDocument12 pages3 JAC006-2 MaintenancejuanNo ratings yet

- Electro-Static Discharge (ESD) in Turbine Oils: © 2015 Exxon Mobil Corporation. All Rights ReserveDocument14 pagesElectro-Static Discharge (ESD) in Turbine Oils: © 2015 Exxon Mobil Corporation. All Rights Reserve'Izzad AfifNo ratings yet

- Branson 00 Series Engine Service Manual PDFDocument77 pagesBranson 00 Series Engine Service Manual PDFLu AlexandruNo ratings yet

- Section 3 Section 3: Routine MaintenanceDocument1 pageSection 3 Section 3: Routine MaintenanceNikNo ratings yet

- Recommended Operating Conditions - Presentation (Final)Document50 pagesRecommended Operating Conditions - Presentation (Final)Abdul WasiqNo ratings yet

- Epiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Document12 pagesEpiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Bontor TuaNo ratings yet

- FSD Oil Reservoir TanksDocument3 pagesFSD Oil Reservoir TanksRushabh MeherNo ratings yet

- 19 July 1984: Total Man-Hours Total Man-Hours Interval Man-Hours Interval Man-HoursDocument6 pages19 July 1984: Total Man-Hours Total Man-Hours Interval Man-Hours Interval Man-HoursХелфор УкраинаNo ratings yet

- Machine Profiles: D10R Track-Type TractorsDocument5 pagesMachine Profiles: D10R Track-Type TractorsJavier Pagan TorresNo ratings yet

- TATA Nano Owners Manual-10Document9 pagesTATA Nano Owners Manual-10NikhitaNo ratings yet

- Rotoflo Bomba AguaDocument22 pagesRotoflo Bomba AguaAlexis CentuNo ratings yet

- 0.5% O Rating CAT Engine Specifications: G3306 Gas Petroleum EngineDocument8 pages0.5% O Rating CAT Engine Specifications: G3306 Gas Petroleum EngineJeff LNo ratings yet

- Cir145 2023Document13 pagesCir145 2023D. Nanda KishoreNo ratings yet

- Research Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisDocument17 pagesResearch Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisjinxiaohuibabaNo ratings yet

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- The Harrod-Domar Growth ModelDocument6 pagesThe Harrod-Domar Growth ModelSimeonNo ratings yet

- Bronchial Hygiene or Airway Clearance TechniquesDocument139 pagesBronchial Hygiene or Airway Clearance TechniquesPiyush Salgaonkar100% (1)

- Technical Specification: 1) Filter Feed Pump With Motor 1 NosDocument4 pagesTechnical Specification: 1) Filter Feed Pump With Motor 1 NosKamatchi NathanNo ratings yet

- Gennady Nesis, Leonid Shulman, Malcolm Gesthuysen - Tactics in The King's IndianDocument130 pagesGennady Nesis, Leonid Shulman, Malcolm Gesthuysen - Tactics in The King's Indiancodonauta100% (1)

- DC Jow Ga Beginner CurriculumDocument2 pagesDC Jow Ga Beginner CurriculumKevinNo ratings yet

- Veins and Hydrothermal DepositsDocument2 pagesVeins and Hydrothermal Depositsalimurtadha100% (1)

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- WiringDocument147 pagesWiringYovani Cortes50% (2)

- Scavenger Hunt 2019Document2 pagesScavenger Hunt 2019Rahul AdhikariNo ratings yet

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- Unit-6 Patterns of Industrialisation PDFDocument12 pagesUnit-6 Patterns of Industrialisation PDFNavdeep SinghNo ratings yet

- Case Study of WapdaDocument34 pagesCase Study of WapdaImran Chaudhry100% (1)

- Directory of SMEs in India-2012 EditionDocument7,115 pagesDirectory of SMEs in India-2012 EditionNilesh RanaNo ratings yet

- Hilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementDocument11 pagesHilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementyosepjoltNo ratings yet

- UntitledDocument4 pagesUntitleddwky KrnwnNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- LAB 2 - Running Speed (Method 2) OEL 1Document3 pagesLAB 2 - Running Speed (Method 2) OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- Louis I KahnDocument27 pagesLouis I KahnKiran BasuNo ratings yet

- Dhauliganga ProjectDocument2 pagesDhauliganga ProjectAntra Chowdhury100% (1)

- LECLANCHE Cell Datasheet GL60 GNMC 60ahDocument2 pagesLECLANCHE Cell Datasheet GL60 GNMC 60ahChaitanyaNo ratings yet

- TPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™Document57 pagesTPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™sbrhomeNo ratings yet

- (2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Document367 pages(2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Erol BicerNo ratings yet

- Hybrid Vehicle A Study On Technology IJERTV3IS120917 PDFDocument8 pagesHybrid Vehicle A Study On Technology IJERTV3IS120917 PDFAshish MathurNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet