Professional Documents

Culture Documents

Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical Properties

Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical Properties

Uploaded by

Šâįf ÄhmāđOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical Properties

Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical Properties

Uploaded by

Šâįf ÄhmāđCopyright:

Available Formats

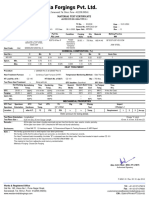

MATERIAL TEST CERTIFICATE

EN 10204 3.1

CUSTOMER NAME DATE:

ORDER NO. PROJECT:

MTC NO.

MECHANICAL TENSIONAL

PROPERTIES Y.S

DESCRIPTION OR DIMENSION ( UNIT: mm) QTY

MIN

HEAT NO. SPECS

170

17 B16.5 150LB WN RF S40 6" 50 SB05699 322.0

18 B16.5 150LB WN RF S160 6" 50

19 B16.5 600LB WN RF S80 6" 50

20 B16.5 150LB WN RF S80 6" 50

21 B16.5 900LB WN RF S80 6" 50

23 B16.5 600LB WN RF S80 6" 50

53 B16.5 150LB BL RF 6" 50

54 B16.5 600LB BL RF 6" 50

55 B16.5 900LB BL RF 6" 50

69 B16.5 150LB SO RF 6" 50

NORMALIZING 870 C 6.70hrs A.C Quenching C

HEAT TREATMENT

ARNEALING C hrs Tempering C

Chemical Composition C Si Mn P S N Cr

MAX 0.1 0.6 MAX MAX MAX MAX

Heat Specification

0.23 -0.35 -1.05 0.04 0.04 0.40 0.30

SB05699 (H) 0.19 0.28 0.84 0.014 0.006 0.05 0.07

SB05699 (P) 0.217 0.304 0.865 0.018 0.01 0.035 0.085

REMARKS: SIZE OF TEST SPECIMEN: OD12.5x50.0L

A.C: AIR COOLED

Tr: TRACE

FULLY KILLED STEEL & FINE PRACTICE GRADE

H: HEAT ANALYSIS

P: PRODUCT ANALYSIS

WE HEREBY CERTIFY THAT THE MATERIALS HEREIN HAS BEEN MADE AND TESTED IN ACCORDA

TERIAL TEST CERTIFICATE

EN 10204 3.1

TENSIONAL TEST HARDNESS CHARPY IMPACT TEST BEND TEST

T.S E.L R.A TEST TEST TEMP: DEGREE CELCIUS

UNIT: RADIUS:

MIN MIN MIN HB AVG:

MAX 187 Min:

485 22.0 30.0 ANGLE:

510.0 38.0 62 140, 138

hrs Solution C hrs

hrs Treatment

Mo Cu V CE

DIMENSIONAL INSPECTION GOOD

MAX MAX MAX MAX

0.12 0.40 0.08 0.43

ULTRASONIC EXAMINATION N/A

0.01 0.05 0.002

0.024 0.075 0.005 0.391

ND TESTED IN ACCORDANCE WITH THE AS ABOVE MATERIAL & TECHNICAL SPECIFICATION

FOR HAWK METALS

Q.C MANAGER

You might also like

- Solution Manual For Exercises: Materials Selection in Mechanical Design 5 Edition (2017)Document13 pagesSolution Manual For Exercises: Materials Selection in Mechanical Design 5 Edition (2017)Yoanela Vargas100% (1)

- SolidCAM 2016 5 Axis Basic Training Vol 1 PDFDocument33 pagesSolidCAM 2016 5 Axis Basic Training Vol 1 PDFThanh Nguyen50% (2)

- BBRF 12inch H.no. 4439Document1 pageBBRF 12inch H.no. 4439suria qaqcNo ratings yet

- 0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611Document2 pages0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611JORGE BAENANo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- Test Certificates W&HDocument1 pageTest Certificates W&HRonakNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- Sample MTC For Anchor BoltDocument1 pageSample MTC For Anchor BoltSALMAN PARVEZ ROKADIANo ratings yet

- Certificado Bothwell Ca1469Document1 pageCertificado Bothwell Ca1469erssonNo ratings yet

- Valve 2in 150 12063Document1 pageValve 2in 150 12063Mygame 1402No ratings yet

- Certif Tu inDocument18 pagesCertif Tu inSri GangaNo ratings yet

- MTC - A335 P22 Seamless PipeDocument1 pageMTC - A335 P22 Seamless PipeSri GangaNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Po31510 Fres30x24 SF48410Document1 pagePo31510 Fres30x24 SF48410Keshia Murillo PinnockNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- CAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesCAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- Atul 30,36-LoescheDocument16 pagesAtul 30,36-LoescheSales ITANo ratings yet

- Dilip Tube 20 January 2023Document1 pageDilip Tube 20 January 2023पवन द्विवेदीNo ratings yet

- Tube 20 January 2023Document1 pageTube 20 January 2023पवन द्विवेदीNo ratings yet

- H.T Strand - 3 Specification RequirementsDocument12 pagesH.T Strand - 3 Specification RequirementsKannan MurugesanNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- Test CertificateDocument2 pagesTest CertificatePRITESH100% (2)

- VTB-600-2 A105n W1834221,235,230.QR PDFDocument1 pageVTB-600-2 A105n W1834221,235,230.QR PDFJoe KylaNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- Blind Flange TCDocument1 pageBlind Flange TCDEEPAKNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- 0.75 in Hex Plug A105 3000-6000 HT Ca 1397Document2 pages0.75 in Hex Plug A105 3000-6000 HT Ca 1397JORGE BAENANo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- 1.VFB-150-2 Tr.316 90601-077 QRDocument1 page1.VFB-150-2 Tr.316 90601-077 QRSurya ManaluNo ratings yet

- Rydon Industries PVT LTD: Details of Inspection Description SpecificationDocument1 pageRydon Industries PVT LTD: Details of Inspection Description SpecificationmuthuselvanNo ratings yet

- C10-Capacity Closely Space Check-ReportDocument1 pageC10-Capacity Closely Space Check-Reportchirathip vasuvattakulNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Certificate No. 00801-16A PDFDocument1 pageCertificate No. 00801-16A PDFPaulo MoraesNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- Item - 2 - 80. SN - 3499-03-388Document1 pageItem - 2 - 80. SN - 3499-03-388Jhonatan GonzalezNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNo ratings yet

- Muc 3Document3 pagesMuc 3Phạm TiếnNo ratings yet

- Fr20-016.007-1-Bridas de 10-SlipDocument1 pageFr20-016.007-1-Bridas de 10-SlipEduardo Dudlei Jimenez CarbajalNo ratings yet

- Material 1.4057 PDFDocument3 pagesMaterial 1.4057 PDFengfaridmalkNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 316 PDFDocument1 page316 PDFViswanathan SrkNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- A105 (VF863)Document1 pageA105 (VF863)Suli HartoNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- SO18. 222369 - Sockolet3.4 - CA1293Document2 pagesSO18. 222369 - Sockolet3.4 - CA1293Jhonatan GonzalezNo ratings yet

- Perno 5.8 X 1 1.2 A307 GR-B Unc BlackDocument1 pagePerno 5.8 X 1 1.2 A307 GR-B Unc BlackMiguel dextreNo ratings yet

- Main Spindle Sleeve 28.03.2023Document1 pageMain Spindle Sleeve 28.03.2023VikrantNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan Ortega100% (1)

- Piping Class - AG70Document2 pagesPiping Class - AG70Дмитрий Рыбаков100% (1)

- Perno Hex Unc AstmDocument1 pagePerno Hex Unc AstmEsther CVNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- GEM 802 Chapter 1Document52 pagesGEM 802 Chapter 1Leah Ann ManuelNo ratings yet

- Unit One Mathematical EconomicsDocument15 pagesUnit One Mathematical EconomicsSitra AbduNo ratings yet

- Daikin VRV SelectionDocument61 pagesDaikin VRV SelectionAshok100% (1)

- Pioneers of Electronic Art (Ars Electronic A 1992)Document221 pagesPioneers of Electronic Art (Ars Electronic A 1992)Мика Шлиммер100% (7)

- 9TH - Icse - Physics - Worksheet - Upthrust in Fluids, Archimedes' Principle and Floatation 2Document7 pages9TH - Icse - Physics - Worksheet - Upthrust in Fluids, Archimedes' Principle and Floatation 2manojboaNo ratings yet

- 3 - Gear Design PDFDocument136 pages3 - Gear Design PDFRachit100% (1)

- Al Si 7 MG 03Document2 pagesAl Si 7 MG 03CSayanavaramNo ratings yet

- Supp Elements 17 For Machine DesignDocument35 pagesSupp Elements 17 For Machine DesignCyron Elden Senarillos-Talita Bangis-BodegasNo ratings yet

- Kabaasha 2018 JHE Incorporating The Modified Orifice Equation Into Pipe Network Solvers For More Realistic Leakage Modeling PDFDocument8 pagesKabaasha 2018 JHE Incorporating The Modified Orifice Equation Into Pipe Network Solvers For More Realistic Leakage Modeling PDFguhmoroNo ratings yet

- Taller 1Document1 pageTaller 1CAROLINA PINILLA ROJASNo ratings yet

- Calculation For Steel Lift Pit at Concourse LevelDocument5 pagesCalculation For Steel Lift Pit at Concourse LevelSUBIR KARMAKARNo ratings yet

- Hemp Buildings FoundationsDocument48 pagesHemp Buildings FoundationsMarekNo ratings yet

- ABB Surge Arresters - Product Overview 1HC0075750 AD enDocument16 pagesABB Surge Arresters - Product Overview 1HC0075750 AD enlagm54No ratings yet

- The Aluminum Beverage CanDocument7 pagesThe Aluminum Beverage CanDennys Quimi BorborNo ratings yet

- Zadeh and Ragazzini - An Extension of Wieners Theory of PredictionDocument11 pagesZadeh and Ragazzini - An Extension of Wieners Theory of PredictionmtichyNo ratings yet

- Hestcraft Catalog 6-22-10Document44 pagesHestcraft Catalog 6-22-10johnpotterNo ratings yet

- 1standing Waves On A StringDocument2 pages1standing Waves On A StringKateNo ratings yet

- Blast Furnace Design of The FutureDocument10 pagesBlast Furnace Design of The FutureSamanway DasNo ratings yet

- Syllabus & Schedule of IJSO Stage - I Online Test Series: S.No. Test Name & Date Physics Chemistry Mathematics BiologyDocument1 pageSyllabus & Schedule of IJSO Stage - I Online Test Series: S.No. Test Name & Date Physics Chemistry Mathematics BiologyHiten MahajanNo ratings yet

- Seminar ReportDocument43 pagesSeminar ReportRamaswamy Koodalloor Parasuraman67% (3)

- Structural Loads: V-N DiagramsDocument11 pagesStructural Loads: V-N Diagramsa320neoNo ratings yet

- 〈1229.1〉 Steam Sterilization by Direct ContactDocument3 pages〈1229.1〉 Steam Sterilization by Direct ContactAhckarawinThummaneeNo ratings yet

- Air To Air Heat Exchanger Performance: Dokuz Eylül University Graduate School of Natural and Applied SciencesDocument78 pagesAir To Air Heat Exchanger Performance: Dokuz Eylül University Graduate School of Natural and Applied SciencesNguyen Son N NguyenNo ratings yet

- Atomos, Aristotle and AlchemyDocument37 pagesAtomos, Aristotle and AlchemyAbegail GabineNo ratings yet

- SPH3U 3-2F - WORK, ENERGY POWER ASSIGNMENT UpdatedDocument18 pagesSPH3U 3-2F - WORK, ENERGY POWER ASSIGNMENT UpdatedlarrylynnmailNo ratings yet

- Solar PanelsDocument4 pagesSolar Panelsanon_610405142No ratings yet

- Analysis of Dither in PWM Control On Electro-HydraDocument7 pagesAnalysis of Dither in PWM Control On Electro-Hydraömer faruk güneyNo ratings yet

- Models - Cfd.bimetallic Strip FsiDocument18 pagesModels - Cfd.bimetallic Strip FsiHyacinthe DemisNo ratings yet