Professional Documents

Culture Documents

Technical Specifications Order Key For ULDC Oil Coolers: Catalog HY10-1700/Americas

Technical Specifications Order Key For ULDC Oil Coolers: Catalog HY10-1700/Americas

Uploaded by

Alberto Solano0 ratings0% found this document useful (0 votes)

7 views1 pageThis document provides an order key and specifications for ULDC oil coolers. It explains that all positions in the order key must be filled in, and provides an example order. It then defines each position in the order key, including the cooler series, model, motor type, thermoswitch, and core bypass. The document concludes by listing material specifications, cooling capacity curves, maximum pressures and temperatures, and noting to contact Parker for advice on non-standard environments or conditions.

Original Description:

Original Title

ULDC (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an order key and specifications for ULDC oil coolers. It explains that all positions in the order key must be filled in, and provides an example order. It then defines each position in the order key, including the cooler series, model, motor type, thermoswitch, and core bypass. The document concludes by listing material specifications, cooling capacity curves, maximum pressures and temperatures, and noting to contact Parker for advice on non-standard environments or conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views1 pageTechnical Specifications Order Key For ULDC Oil Coolers: Catalog HY10-1700/Americas

Technical Specifications Order Key For ULDC Oil Coolers: Catalog HY10-1700/Americas

Uploaded by

Alberto SolanoThis document provides an order key and specifications for ULDC oil coolers. It explains that all positions in the order key must be filled in, and provides an example order. It then defines each position in the order key, including the cooler series, model, motor type, thermoswitch, and core bypass. The document concludes by listing material specifications, cooling capacity curves, maximum pressures and temperatures, and noting to contact Parker for advice on non-standard environments or conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Catalog HY10-1700/Americas ULDC

Order Key for ULDC Oil Coolers Technical Specifications

All positions must be filled in when ordering.

EXAMPLE: FLUID COMBINATIONS

ULDC - 007 -A - 000 - SA Mineral oil

Series Model Motor Type Thermoswitch Core Bypass Oil/water emulsion

Water glycol

1 2 3 4 5 Phosphate ester

1. OIL COOLER SERIES WITH DC MOTOR; ULDC MATERIAL

Cooler core Aluminum

2. COOLER SIZE/MODEL Fan blades/guard Glass fiber reinforced polypropylene

003, 004, 007, 011, 016, 020, 023, 033 Fan housing Steel

Other parts Steel

3. MOTOR vOLTAGE Surface treatment Electrostatically powder-coated

12 V =A

24 V =B COOLER CORE

Maximum static working pressure 300 psi

4. THERMOSWITCH Dynamic working pressure 200 psi*

No thermoswitch = 000 Heat transfer tolerance ±6%

100 °F = 100 Maximum oil inlet temperature 250 °F

120 °F = 120 * Tested in accordance with ISO/DIS 10771-1

140 °F = 140

160 °F = 160

175 °F = 175 COOLING CAPACITY CURvES

195 °F = 195 The cooling capacity curves in this catalogue are created using

Not listed, consult Accumulator and Cooler Division = ZZZ oil type ISO VG 46 at 250 °F.

5. CORE BYPASS* CONTACT PARKER FOR ADvICE ON

No Bypass = SW Oil temperatures > 250 °F

20 psi External Hose Bypass (standard option) = SA Oil viscosity > 100 cSt / 500 SSU

65 psi External Hose Bypass (standard option) = SB Aggressive environments

30 psi External Tube Bypass = SG Environments with heavy airborne particulates

75 psi External Tube Bypass = SH High-altitude locations

120 psi External Tube Bypass = SJ

120 °F External Thermo-Bypass = SM

140 °F External Thermo-Bypass = SN

160 °F External Thermo-Bypass = SP

195 °F External Thermo-Bypass = SQ

Full Flow External Bypass = SF

* The standard cores are single pass. Two pass cores and other options

available upon request, please consult Accumulator and Cooler Division.

The information in this brochure is subject to change without prior notice.

22

You might also like

- The Perfume Handbook PDFDocument331 pagesThe Perfume Handbook PDFNofearmak100% (8)

- R134a WC DX SCREW CHILLER USER MANUAL USER MANUAL 1 PDFDocument116 pagesR134a WC DX SCREW CHILLER USER MANUAL USER MANUAL 1 PDFSumit DasNo ratings yet

- 5 The Knee PDFDocument515 pages5 The Knee PDFjongski100% (2)

- Mvt6 and MVT 8 Version 06 OriginalDocument113 pagesMvt6 and MVT 8 Version 06 OriginalCletoCruzLNo ratings yet

- Sharp Dcinverter Ac Service ManualDocument43 pagesSharp Dcinverter Ac Service ManualAbdorrahim DahdouhNo ratings yet

- KSB - Ecoline GLF 800-2500 - 7361.14-04 PDFDocument10 pagesKSB - Ecoline GLF 800-2500 - 7361.14-04 PDFAlonso1593No ratings yet

- NL8.4MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzDocument2 pagesNL8.4MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzRabah RebouhNo ratings yet

- nl73mf 105g6772 R134a 220v 50hz 60hz 10-2019 Desd400w402Document2 pagesnl73mf 105g6772 R134a 220v 50hz 60hz 10-2019 Desd400w402tiếm nguyễnNo ratings yet

- Ecoline GTC 150-600Document12 pagesEcoline GTC 150-600Ricardo BarrosNo ratings yet

- كتالوج الشيلراتDocument54 pagesكتالوج الشيلراتFathy RakhaNo ratings yet

- KSB Valvulas de Globo GLC 300Document12 pagesKSB Valvulas de Globo GLC 300Andres Mauricio GaleanoNo ratings yet

- Danfoss TL5GDocument2 pagesDanfoss TL5GAnonymous uxZ5FYLP3jNo ratings yet

- 250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Document3 pages250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Vamshika SutarNo ratings yet

- Danfoss Secop FR7GHDocument2 pagesDanfoss Secop FR7GHwinNo ratings yet

- KW-Line Condensing Units: Product Data & SpecificationsDocument20 pagesKW-Line Condensing Units: Product Data & Specificationsdhineshbabu rNo ratings yet

- Mark Emerson 2 - 2 Series 8262 8263 General Service Solenoid Valves PG 37 40 CatalogDocument4 pagesMark Emerson 2 - 2 Series 8262 8263 General Service Solenoid Valves PG 37 40 CatalogarjunoselaoNo ratings yet

- Sc12Mlx MBP Compressor R404A/R507 208-230V 60Hz & 220-240V 50HzDocument2 pagesSc12Mlx MBP Compressor R404A/R507 208-230V 60Hz & 220-240V 50HzFRIER RefrigeraciónNo ratings yet

- Hed 4Document1 pageHed 4Arpan GajjarNo ratings yet

- ECOLINE SCF 150-600: Swing Check ValveDocument8 pagesECOLINE SCF 150-600: Swing Check ValveF Andres Serrano LunaNo ratings yet

- DAEWOO RefrigeradorDocument83 pagesDAEWOO RefrigeradorMihaela Caciumarciuc100% (2)

- Samsung RL 25 DATDocument28 pagesSamsung RL 25 DATAleksei EvchuNo ratings yet

- Water Cooled Screw Compressor ASW Series (R134a)Document45 pagesWater Cooled Screw Compressor ASW Series (R134a)AAR143No ratings yet

- Samsung Nevera Serie RB PDFDocument62 pagesSamsung Nevera Serie RB PDFAlexander NarvaezNo ratings yet

- Screw Compressor ASY (R-134) Series PDFDocument52 pagesScrew Compressor ASY (R-134) Series PDFNajam2450% (2)

- Spring Return and Double Acting Pneumatic Quarter-Turn Actuators For Output Torques To 27,624 LB - inDocument8 pagesSpring Return and Double Acting Pneumatic Quarter-Turn Actuators For Output Torques To 27,624 LB - inThanh Vuong NguyenNo ratings yet

- 300tr-Design-Water Cooled ChillerDocument2 pages300tr-Design-Water Cooled ChillerRamNo ratings yet

- ssf fsdgsr sềDocument89 pagesssf fsdgsr sềHa Bao AnhNo ratings yet

- Outdoor Cooling Units For Door or Wall Mounting: Characteristics M.U. EMO04BM1B EMO04CM1B Accessories/OptionsDocument1 pageOutdoor Cooling Units For Door or Wall Mounting: Characteristics M.U. EMO04BM1B EMO04CM1B Accessories/OptionsTomasz KownackiNo ratings yet

- Genesis Top-Mount Indoor: Hb16 Mhb11 Hb16 Mhb11Document12 pagesGenesis Top-Mount Indoor: Hb16 Mhb11 Hb16 Mhb11Hafezul RahmanNo ratings yet

- Asco Valve 8262h 8263h GP Spec r3Document4 pagesAsco Valve 8262h 8263h GP Spec r3Anonymous 6VCG1YRdNo ratings yet

- NF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: GeneralDocument2 pagesNF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: GeneralAntonio JarquiinNo ratings yet

- F 200 ABF - R449A - 50 HZDocument7 pagesF 200 ABF - R449A - 50 HZLuis TeixeiraNo ratings yet

- Free-Standing Cooler: EconomyDocument2 pagesFree-Standing Cooler: EconomyElement Back To BasicNo ratings yet

- Westinghouse R-410A Package Unit Service ManualDocument118 pagesWestinghouse R-410A Package Unit Service ManualWisam Ankah0% (1)

- Stantsia Za Zapoyavane S Poyalnik Tip Pisalka Ss 207b S Digitalen Displey 0 PDFDocument20 pagesStantsia Za Zapoyavane S Poyalnik Tip Pisalka Ss 207b S Digitalen Displey 0 PDFEmilian Angelov AngelovNo ratings yet

- Emr70hlr 513400004Document4 pagesEmr70hlr 513400004WERLAN SILVANo ratings yet

- TD 285 4PG BW Oct2015Document4 pagesTD 285 4PG BW Oct2015ingenieriavfloresNo ratings yet

- Danfos CompresorDocument2 pagesDanfos CompresorEnrique MarquezNo ratings yet

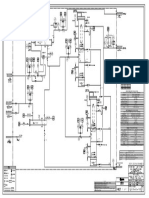

- Electric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Document1 pageElectric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Manuel SerranoNo ratings yet

- Bühler Gascooler - EGK1-2 Data Sheet PDFDocument2 pagesBühler Gascooler - EGK1-2 Data Sheet PDFvalberto75No ratings yet

- Spec 00580 PDFDocument10 pagesSpec 00580 PDFVivekNo ratings yet

- Thermostatic Mixing Valve 4Document1 pageThermostatic Mixing Valve 4member1000No ratings yet

- Tl4G Universal Compressor R134a 220-240V 50/60Hz: GeneralDocument2 pagesTl4G Universal Compressor R134a 220-240V 50/60Hz: GeneralMaria MartinNo ratings yet

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborNo ratings yet

- Spec 00580Document10 pagesSpec 00580Moises AlvarezNo ratings yet

- Taurus R Ducted Split Units: Technical Sales Guide - 60HzDocument32 pagesTaurus R Ducted Split Units: Technical Sales Guide - 60Hznizamudheen mnNo ratings yet

- Ecoline GTC 150-600Document16 pagesEcoline GTC 150-600Ruddy Fabrizio Galvez JustinianoNo ratings yet

- 30gn 19sbDocument9 pages30gn 19sbMUFERCHO30No ratings yet

- Climaguard™ Air-To-Water Indoor Heat ExchangersDocument12 pagesClimaguard™ Air-To-Water Indoor Heat ExchangersRafraf EzdineNo ratings yet

- Condensador DZ11SDocument16 pagesCondensador DZ11SIsrael ArceoNo ratings yet

- Samsung Rb215bssb Service Manual 121236Document80 pagesSamsung Rb215bssb Service Manual 121236Khandy RuthNo ratings yet

- 30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramDocument13 pages30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramBJNE01No ratings yet

- Service Manual: Wine Chiller Model NumberDocument25 pagesService Manual: Wine Chiller Model NumberHéctor AraujoNo ratings yet

- Specification Sheet Electroheat Pro 110kW 50Hz Heat Cool Dec 2021Document3 pagesSpecification Sheet Electroheat Pro 110kW 50Hz Heat Cool Dec 2021claverNo ratings yet

- CC-LOP-QRC-PLDocument16 pagesCC-LOP-QRC-PLcesardsc1No ratings yet

- AirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)Document110 pagesAirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)alexNo ratings yet

- NL11MF Standard Compressor R134a 220-240V 50Hz: GeneralDocument2 pagesNL11MF Standard Compressor R134a 220-240V 50Hz: GeneralTrkulja GoranNo ratings yet

- AUIRFR8405Document12 pagesAUIRFR8405nithinmundackal3623No ratings yet

- Hitachi ChillerDocument10 pagesHitachi ChillerMohd Khairul FahmiNo ratings yet

- Side Channel Pumps: Self-Priming, Multi-Stage TypeDocument5 pagesSide Channel Pumps: Self-Priming, Multi-Stage TypeLPG Equipment Consulting and ServicesNo ratings yet

- Fr6G Universal Compressor R134a 220-240V 50/60Hz: GeneralDocument2 pagesFr6G Universal Compressor R134a 220-240V 50/60Hz: GeneralMunir ATTARINo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Chris Haig 2010 Award Top 100 UsaDocument2 pagesChris Haig 2010 Award Top 100 Usaapi-267124068No ratings yet

- ShivSutras by H.H. Sri Sri Ravishankarji - 7 Video Sessions CoveredDocument18 pagesShivSutras by H.H. Sri Sri Ravishankarji - 7 Video Sessions Coveredorchidocean5627No ratings yet

- HNBB & Febsan Drug StudyDocument4 pagesHNBB & Febsan Drug StudyKeziah PilotosNo ratings yet

- Mobilisasi DiniDocument2 pagesMobilisasi DiniEritaNo ratings yet

- EBSCO FullText 2024 06 05 2Document10 pagesEBSCO FullText 2024 06 05 2janesuy07No ratings yet

- Mcdonald'S - Business Strategy in India: Case Study AbstractDocument5 pagesMcdonald'S - Business Strategy in India: Case Study AbstractSureshMandwaniNo ratings yet

- Simon IeltsDocument16 pagesSimon IeltsNga Hương Sô ThịNo ratings yet

- Cocktails RecipeDocument99 pagesCocktails RecipeZion Hill100% (1)

- NB, NBG, TP, TPD: Installation and Operating InstructionsDocument16 pagesNB, NBG, TP, TPD: Installation and Operating Instructionshvacr061No ratings yet

- Sampling Procedure and Tables For InspectionDocument43 pagesSampling Procedure and Tables For InspectionAnonymous AoTZuNvxNo ratings yet

- Action PlanDocument2 pagesAction PlanEduardo Lita100% (5)

- Celine at 18Document7 pagesCeline at 18Josette Mae AtanacioNo ratings yet

- BME MergedDocument1,090 pagesBME MergedYoshita MNo ratings yet

- 1C Cu Epr-Pvc 35KV@133% 2017Document2 pages1C Cu Epr-Pvc 35KV@133% 2017CarlosNo ratings yet

- Outside 2014-01Document116 pagesOutside 2014-01virgilionescuNo ratings yet

- Student Exploration: Polarity and Intermolecular ForcesDocument7 pagesStudent Exploration: Polarity and Intermolecular ForcesZhaoxiaotang EstherNo ratings yet

- Check Your Listening Comprehension - Matching SpeakersDocument50 pagesCheck Your Listening Comprehension - Matching Speakerslindazykov43719No ratings yet

- Psychological First Aid Field Operations Guide - 2nd Edition (2007)Document189 pagesPsychological First Aid Field Operations Guide - 2nd Edition (2007)api-279694446No ratings yet

- Developing and Using HR Audit ToolsDocument32 pagesDeveloping and Using HR Audit ToolsJablack Angola MugabeNo ratings yet

- NEW Chapter 4 - Product ConceptDocument21 pagesNEW Chapter 4 - Product ConceptleeminhoangrybirdNo ratings yet

- Assembly Manual For Turbine PDFDocument310 pagesAssembly Manual For Turbine PDFsamratdcpl100% (2)

- Trandafiri Ingrijire Si TaiereDocument35 pagesTrandafiri Ingrijire Si TaiereNistor MariaNo ratings yet

- Senior Manager Kim Inspired Workout PDFDocument11 pagesSenior Manager Kim Inspired Workout PDFKrrish AdhanaNo ratings yet

- Do We Know JackDocument20 pagesDo We Know JackAbdul-Ganiyu MannirNo ratings yet

- Noise HazardsDocument27 pagesNoise HazardsZainorin Ali0% (1)

- 319 6904116 Om 10 05 PDFDocument136 pages319 6904116 Om 10 05 PDFvatasaNo ratings yet

- Worksheet 25 - 26 - 3rd - MSP - EDocument8 pagesWorksheet 25 - 26 - 3rd - MSP - EMelissaNo ratings yet