Professional Documents

Culture Documents

Data Sheet For L.P Dosing System

Data Sheet For L.P Dosing System

Uploaded by

V U P RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet For L.P Dosing System

Data Sheet For L.P Dosing System

Uploaded by

V U P RaoCopyright:

Available Formats

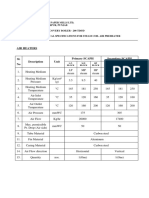

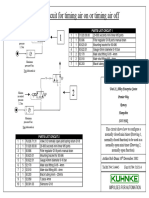

DATA SHEET FOR L.

P DOSING SYSTEM

ITEM LP DOSING SYSTEM

REF DRG. NO. VENDOR TO SPECIFY

CUSTOMER

PROJECT

COMPLETE MOUNTED METERING CUM MIXING TANK WITH ACCESSORIES, PUMPS,

SCOPE VALVES, STRAINERS, PIPING, DRIVE MOTORS, AGITATOR, PRESSURE GAUGES,

FOUNDATION BOLTS

1 MEDIUM HANDLED 0.10 % Hydrazine Solution

2 TANK CAPACITY 1no., 60Ltrs Net

3 TANK 4mm SS304

4 TANK SIZE (ID X Cylindrical Height) Dia 400mm x Ht 600mm Straight Length

5 TANK TYPE Dished Bottom & Bolted Top

6 PUMP CAPACITY 0-15LPH Adjustable @ 7Kg/sq.cm(g) Discharge Presure

7 PUMP MOC OF WETTED PARTS SS316

8 PUMP END CONNECTION Flanged

9 PUMP TYPE & MAKE Postive Displacement / Plunger , Make - VENDOR TO SPECIFY

10 PUMP MOTOR RATING VENDOR TO SPECIFY

11 NO. OF PUMPS & SYSTEM 2Nos. (1 Working + 1 Stand BY)

12 AGITATOR MOTOR RATING VENDOR TO SPECIFY

13 AGTITATOR TYPE & SPEED VENDOR TO SPECIFY

14 MOC OF AGITATOR SS304

1 No., Body - CS SS304 Wetted parts, Boroilicate Glass,Tubular with Protection rods

15 LEVEL GAUGE PER TANK

Drain 1/2" with valve, Make - VENDOR TO SPECIFY

16 D.P SWITCH 2 Nos. across the suction strainers, Make - VENDOR TO SPECIFY

17 LEVEL TRANSMITER 1 No. output : 4-20mA Make : VENDOR TO SPECIFY

18 RELIEF VALVE Spring Loaded Type, Make - VENDOR TO SPECIFY

19 SUCTION & DISCHARGE SIDE VALVES SW, Class 800, Ball valves CF8/ss304, Make - VENDOR TO SPECIFY

20 NON RETURN VALVES SW, Class 800, F304, Make - VENDOR TO SPECIFY

21 SUCTION STRAINERS Y-Type , 15NB Screwed (F) 2Nos. CF8, Make - VENDOR TO SPECIFY

22 HYDRO TEST FOR PIPING Suction 2Kg/sq.cm(g) & Discharge - 10kg/sq.cm (g)

23 INTER CONNECTION PIPING ATM 312 - TP 304 SCH 40 - ERW

24 BREATHER POT. MOC SS304

25 PRESUURE GAUGE Bourdon Type Range 0-15 Bar, 4" Dial, SS316 Wetted Parts , Make - VENDOR TO SPECIFY

26 PULSATIOM DAMPER SS304, Snubber

27 PIPE FITTINGS F304,#3000SW

28 FLANGES F304,#150/SORF for suction & discharge

29 GASKETS Non-asbestos

30 FOUNDATION BOLT & FASTENERS M.S Gr 4.6

31 BASE FRAME IS 2062

Sand blasting followed by 2 coats of RO Primer and 1 Coat Epoxy

32 PAINTING

finish paint for CS Parts

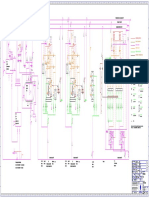

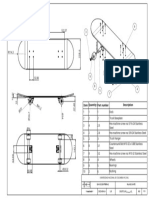

DATA SHEET FOR H.P DOSING SYSTEM

ITEM HP DOSING SYSTEM

REF DRG. NO. VENDOR TO SPECIFY

CUSTOMER

PROJECT

COMPLETE MOUNTED METERING CUM MIXING TANK WITH ACCESSORIES,

SCOPE PUMPS, VALVES, STRAINERS, PIPING, DRIVE MOTORS, AGITATOR, PRESSURE

GAUGES, FOUNDATION BOLTS

1 MEDIUM HANDLED 7.5 % Tri sodium Phosphate Solution

2 BLOW DOWN 3.0 % Continious

PREPARATION TANK METERING TANK

3 TANK CAPACITY 1 NO., 250Liters Capacity 1 NO., 130Liters Capacity

4 TANK 3mm SS304 3mm SS304

5 TANK SIZE (ID X Cylindrical Height) Dia 700mm x Ht 700mm Dia 600mm x Ht 500mm

6 TANK TYPE Dished Bottom & Bolted Top

7 PUMP CAPACITY 0 - 105 LPH Adjustable @ 90Kg/sq.cm(g) Discharge Presure

8 MPUMP MOC OF WETTED PARTS SS316

9 PUMP END CONNECTION Flanged

10 PUMP TYPE & MAKE 2.0 HP/1440 rpm/ Postive Displacement / Plunger

415V±10%,50Hz±5% , Make Swlore

3Ph, Insulation Class - F with Temp

11 PUMP MOTOR RATING rise limited to class 'B' Enclouser - TEFC, Protection - IP65, Siemens/ABB

Make

12 NO. OF PUMPS & SYSTEM 2Nos. (1 Working + 1 Stand BY)

13 AGITATOR MOTOR RATING VENDOR TO SPECIFY

14 AGTITATOR TYPE & SPEED VENDOR TO SPECIFY

15 MOC OF AGITATOR SS304

1 No., Body - CS SS304 Wetted parts, Boroilicate Glass,Tubular with

16 LEVEL GAUGE PER TANK

Protection rods Drain 1/2" with valve, Make - Pune Techtrol

17 RELIEF VALVE SS316, 1/2" NPT SET PRESSURE - 112kg/sq.cm(g) Make - Vendor to Specify

18 SUCTION SIDE VALVES SW, Class 800, Ball valves CF8/ss304 Make - Vendor to Specify

19 DISCHARGE SIDE VALVES SW, Class 800, Gate valves F304, Make - Vendor to Specify

20 NON RETURN VALVES SW, Class 800, F304, Make - Vendor to Specify

21 SUCTION STRAINERS Y-Type , 25NB Screwed (F) 2Nos. CF8 - Vendor to Specify

22 HYDRO TEST FOR PIPING Suction 2Kg/sq.cm(g) & Discharge - 135kg/sq.cm (g)

23 INTER CONNECTION PIPING ATMA 312 - TP 304 SCH 40 For Suction & SCH 80 for Discharge

Bourdon Type Range 0-200 Bar, 4" Dial, SS316 Wetted Parts ,

24 PRESUURE GAUGE

Make - VENDOR TO SPECIFY

25 PIPE FITTINGS F304,#3000SW

26 FLANGES F304,#150/SORF for suction #1500 for discharge

27 GASKETS Non-asbestos

28 FOUNDATION BOLT & FASTENERS M.S Gr 4.6

29 BASE FRAME IS 2062

Sand blasting followed by 2 coats of RO Primer and 1 Coat Epoxy

31 PAINTING

finish paint for CS Parts

You might also like

- Filter Press ManualDocument8 pagesFilter Press ManualHAYAN ENGINEERINGNo ratings yet

- 755 MASTER Packing ListDocument3 pages755 MASTER Packing Listanon_687665429No ratings yet

- Instrument Data Sheets: Revision HistoryDocument9 pagesInstrument Data Sheets: Revision Historyerik masongNo ratings yet

- Item Description Specifications Quantity I. 30 TPH Afbc SL. NODocument9 pagesItem Description Specifications Quantity I. 30 TPH Afbc SL. NOgowriNo ratings yet

- Reverse Osmosis 500 LPH 1Document7 pagesReverse Osmosis 500 LPH 1sairamwatersolutions2017No ratings yet

- HVAC BOQ Muzzafarpur 10.01.2019Document22 pagesHVAC BOQ Muzzafarpur 10.01.2019Gourav SharmaNo ratings yet

- MAB 103 - Direct Heater - LSADocument21 pagesMAB 103 - Direct Heater - LSACentrifugal SeparatorNo ratings yet

- Gate ValvesDocument13 pagesGate ValvesGhinet Teodor-ioanNo ratings yet

- ATV RUS LIM RCT 001 - MergedDocument5 pagesATV RUS LIM RCT 001 - MergedNaam Ka KyaNo ratings yet

- 4 KL Reactor Data SheetDocument4 pages4 KL Reactor Data Sheetpankil patelNo ratings yet

- De-567 Dammam Housing-6 Grounding Boq - Rev.aDocument1 pageDe-567 Dammam Housing-6 Grounding Boq - Rev.aimranNo ratings yet

- Boq AirDocument8 pagesBoq AirNeeraj AgarwalNo ratings yet

- Electrical Budget 2022 PGDocument25 pagesElectrical Budget 2022 PGarup kumar maityNo ratings yet

- 08 - FPS01 Subsea Series (Issue 4 Feb 05)Document4 pages08 - FPS01 Subsea Series (Issue 4 Feb 05)Peter RhoadsNo ratings yet

- ATFD Offer KBDocument10 pagesATFD Offer KBrajesh kothariNo ratings yet

- External Cooling Unit ACS - 1000Document133 pagesExternal Cooling Unit ACS - 1000mabdelaal2090No ratings yet

- Despiece EMVAK CAT B3cp1120-40d7-08eDocument4 pagesDespiece EMVAK CAT B3cp1120-40d7-08eRoberto BellasNo ratings yet

- Pipe Rupture ValvesDocument5 pagesPipe Rupture ValvesMS Mechanic HSM 2No ratings yet

- A700 EnglishDocument16 pagesA700 EnglishPablo MNo ratings yet

- 3/2 Direct Acting Namur Solenoid Valve: FeaturesDocument2 pages3/2 Direct Acting Namur Solenoid Valve: Featureskuru_0125No ratings yet

- Furnace, Mill Area FRL DetailsDocument12 pagesFurnace, Mill Area FRL DetailsHSM MECHNo ratings yet

- Annexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3Document3 pagesAnnexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3kallappa naikNo ratings yet

- Zupcaste Pumpe 2pfDocument13 pagesZupcaste Pumpe 2pfmilokisrNo ratings yet

- UPD-BATB-Chimney 1-BOQDocument1 pageUPD-BATB-Chimney 1-BOQAntwon CharlesNo ratings yet

- Pa Fe 117Document2 pagesPa Fe 117milton1987No ratings yet

- ENQUIRY NO.: E-Mail Dated 28.03.2019 CLIENT: M/s.M.K.Roy & Bros Projects Limited. Our Offer Ref.: LI/101/QTN/ 5237 / 3742 /2018 - 2019 Date. 28.03.2019Document3 pagesENQUIRY NO.: E-Mail Dated 28.03.2019 CLIENT: M/s.M.K.Roy & Bros Projects Limited. Our Offer Ref.: LI/101/QTN/ 5237 / 3742 /2018 - 2019 Date. 28.03.2019Vetsa VivekNo ratings yet

- Boq For Fire Fighting Work at Ro Uiic Sec-17 Chd-1Document2 pagesBoq For Fire Fighting Work at Ro Uiic Sec-17 Chd-1esdrasericconstractiondesign12No ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- ATFD PiparDocument10 pagesATFD Piparrajesh kothariNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- Water Department Standard DetDocument75 pagesWater Department Standard DetMakky MakkyNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- VAIL 10 - PP: Pressure Relief ValvesDocument2 pagesVAIL 10 - PP: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Gate-Valves Mud KingDocument13 pagesGate-Valves Mud KingWilson RiveraNo ratings yet

- Boiler Equipments SpecificationDocument3 pagesBoiler Equipments SpecificationJoydev GangulyNo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- C-J Catalog N - Cooker-CoolersDocument4 pagesC-J Catalog N - Cooker-CoolersSky SpectreNo ratings yet

- Accesorios para Control de FluidosDocument16 pagesAccesorios para Control de FluidosManuel CurayNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- O&M Manual - An Series Börger Pump - Rotex - Nord IntegralDocument266 pagesO&M Manual - An Series Börger Pump - Rotex - Nord IntegralRicardo VeraNo ratings yet

- Mcnally Sayaji Engineering LimitedDocument54 pagesMcnally Sayaji Engineering LimitedUtpalSahaNo ratings yet

- Precision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetDocument1 pagePrecision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetAnonymous AyDvqgNo ratings yet

- Self-Priming Pump T6A3 BDocument3 pagesSelf-Priming Pump T6A3 BArturoCastelloNo ratings yet

- Double SST74-SCANIA R580 (T1148AR3-1506010)Document4 pagesDouble SST74-SCANIA R580 (T1148AR3-1506010)Moh Gandhi IstowoNo ratings yet

- SBU URB PlatformDocument6 pagesSBU URB PlatformMusaab MohamedNo ratings yet

- Positive Displacement Dosing Pump: The Right Dosing ChoiceDocument12 pagesPositive Displacement Dosing Pump: The Right Dosing ChoiceTrungGVNo ratings yet

- Submersible Pump: Model S8D1 E275Document2 pagesSubmersible Pump: Model S8D1 E275frank rodriguezNo ratings yet

- Section 1720 Data - 2Document10 pagesSection 1720 Data - 2Andri AjaNo ratings yet

- Trunnion Mounted Forged Ball Valves Model FF and GG: Reduced Bore 3"-36" Full Bore 2" - 48" ASME Class 150 - 2500Document20 pagesTrunnion Mounted Forged Ball Valves Model FF and GG: Reduced Bore 3"-36" Full Bore 2" - 48" ASME Class 150 - 2500aleeimeranNo ratings yet

- Bombas de Cavidad ProgresivaDocument8 pagesBombas de Cavidad ProgresivaJohanna RojasNo ratings yet

- 26.37.40. WashingDocument12 pages26.37.40. WashingAmrit TiwariNo ratings yet

- MTOCO001008Document8 pagesMTOCO001008Mohamed Rizk100% (1)

- Project Engineering & Construction Dept: Bill of MaterialDocument2 pagesProject Engineering & Construction Dept: Bill of MaterialokagawaNo ratings yet

- 1441793840rbfatank Dada Sheet 50kl ss304Document1 page1441793840rbfatank Dada Sheet 50kl ss304Suaib VCSNo ratings yet

- Hcu/ DHT Shut Down Equipment ListDocument6 pagesHcu/ DHT Shut Down Equipment ListAdnan AkhtarNo ratings yet

- Inventory09-12-2021Document67 pagesInventory09-12-2021api-561021310No ratings yet

- 7255530-751248 Flow and Instrument Diagram, Generator Lube OilDocument2 pages7255530-751248 Flow and Instrument Diagram, Generator Lube OilMahmoud HassanNo ratings yet

- QUOTESDocument11 pagesQUOTESV U P RaoNo ratings yet

- TS Curve RPHDocument2 pagesTS Curve RPHV U P RaoNo ratings yet

- Screenshot 2023-10-08 at 9.41.21 AMDocument8 pagesScreenshot 2023-10-08 at 9.41.21 AMV U P RaoNo ratings yet

- Scaph SpecnDocument3 pagesScaph SpecnV U P RaoNo ratings yet

- 13.specification Steam and Condensate SystemDocument2 pages13.specification Steam and Condensate SystemV U P RaoNo ratings yet

- Steam Scheme 851140169-0-00Document1 pageSteam Scheme 851140169-0-00V U P RaoNo ratings yet

- Draft Award Letter - GlobalDocument2 pagesDraft Award Letter - GlobalV U P RaoNo ratings yet

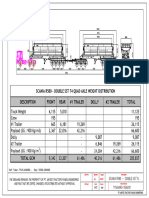

- Pzi148df01-30000 - Foundation Load DataDocument1 pagePzi148df01-30000 - Foundation Load DataV U P RaoNo ratings yet

- Steam Consumption: Example For A Single-Corrugator Work Width 2200mmDocument2 pagesSteam Consumption: Example For A Single-Corrugator Work Width 2200mmV U P RaoNo ratings yet

- Safety Data Sheet TGX-2209: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument16 pagesSafety Data Sheet TGX-2209: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingV U P RaoNo ratings yet

- Project: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedDocument2 pagesProject: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedV U P RaoNo ratings yet

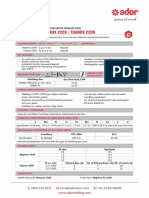

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocument1 pageMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNo ratings yet

- TG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationDocument1 pageTG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationV U P RaoNo ratings yet

- Power Plant and Calculations - Safety Valves and Its Basic ConceptsDocument4 pagesPower Plant and Calculations - Safety Valves and Its Basic ConceptsV U P RaoNo ratings yet

- BHG Actvie CahtDocument6 pagesBHG Actvie CahtV U P RaoNo ratings yet

- Stuffing Box: SR No DescriptionDocument2 pagesStuffing Box: SR No DescriptionV U P RaoNo ratings yet

- GardnerDenver-EBE99N Compressor PARTSDocument48 pagesGardnerDenver-EBE99N Compressor PARTSsmag29No ratings yet

- MillingDocument54 pagesMillingNelsan PatelNo ratings yet

- Nokia N8 Repair GuideDocument13 pagesNokia N8 Repair GuideRishabh LakhanpalNo ratings yet

- National Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsDocument27 pagesNational Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsNitin B maske100% (1)

- J910-YQ02-P0ZEN-140941 - Typical Installation Cable Raceway - Rev.2 (AWC)Document7 pagesJ910-YQ02-P0ZEN-140941 - Typical Installation Cable Raceway - Rev.2 (AWC)Devy MangimbaNo ratings yet

- EUMACH YZC CatalogueDocument2 pagesEUMACH YZC CatalogueAbhishek VelagaNo ratings yet

- Mini Timer CircuitDocument1 pageMini Timer CircuitSaeed QahremaniNo ratings yet

- Browning 1251297 CatalogDocument10 pagesBrowning 1251297 CatalogThe Maison MaidsNo ratings yet

- NullDocument4 pagesNullnateNo ratings yet

- Title: Backhoe (Boom) Model Number: B900 Serial Number: B4UB11001 & AboveDocument3 pagesTitle: Backhoe (Boom) Model Number: B900 Serial Number: B4UB11001 & AboveHarinath SundaramNo ratings yet

- dw616 1Document3 pagesdw616 1Erksat TrhdzNo ratings yet

- SAB 120 and SAB 151 A-Frame Screw Compressor Units With OHU 04123 Oil SeparatorDocument42 pagesSAB 120 and SAB 151 A-Frame Screw Compressor Units With OHU 04123 Oil SeparatorEugen ButucNo ratings yet

- Plano Skate CotasDocument1 pagePlano Skate CotasDavid Alfonso Contreras QuintanaNo ratings yet

- Vista Explodida - c550g - 1Document73 pagesVista Explodida - c550g - 1DaveNo ratings yet

- Cub Cadet 2500 Parts ManualDocument43 pagesCub Cadet 2500 Parts Manualafant70% (1)

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDocument3 pagesPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshNo ratings yet

- Mercury Gear Case ComponentsDocument43 pagesMercury Gear Case Componentswguenon100% (1)

- Plug Socket Price-List 170121Document3 pagesPlug Socket Price-List 170121tesemaNo ratings yet

- TOTO Sanitary Catalog July 2021Document40 pagesTOTO Sanitary Catalog July 2021Yansen HardjokoNo ratings yet

- 2.8 Monitoring Izin Kerja (Working Permit) : Laporan Bulanan K3Document89 pages2.8 Monitoring Izin Kerja (Working Permit) : Laporan Bulanan K3marchelinda ayuningtyasNo ratings yet

- AHU Coil SelectionDocument7 pagesAHU Coil SelectiondheerajdorlikarNo ratings yet

- 2019 Self Lubricating Roller and Conveyor Chain CatalogDocument5 pages2019 Self Lubricating Roller and Conveyor Chain CatalogUSA Roller ChainNo ratings yet

- Machine Taper: Explanation Use TypesDocument12 pagesMachine Taper: Explanation Use TypesGanesh DixitNo ratings yet

- Clark Equipment: CompanyDocument316 pagesClark Equipment: Companyreman partsNo ratings yet

- Session Plan (Julaps)Document10 pagesSession Plan (Julaps)Wiljhon Espinola JulapongNo ratings yet

- Bobcat Parts List PDFDocument3,533 pagesBobcat Parts List PDFGanapati Hegde50% (6)

- Kom Electronics ShopDocument9 pagesKom Electronics ShopYashpal MsisNo ratings yet

- Q1W3 Install Metallic NonmetallicDocument12 pagesQ1W3 Install Metallic NonmetallicCloud DullasNo ratings yet

- Lista Generala Piese Schimb FessmannDocument5 pagesLista Generala Piese Schimb FessmannAfumatoare VanbetNo ratings yet

- TypewriterDocument7 pagesTypewriterMyk Twentytwenty NBeyondNo ratings yet