Professional Documents

Culture Documents

Advances in Dynamic Relaxation Techniques For Nonlinear Finite Element Analysis

Advances in Dynamic Relaxation Techniques For Nonlinear Finite Element Analysis

Uploaded by

Joaquin VieraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advances in Dynamic Relaxation Techniques For Nonlinear Finite Element Analysis

Advances in Dynamic Relaxation Techniques For Nonlinear Finite Element Analysis

Uploaded by

Joaquin VieraCopyright:

Available Formats

Advances in Dynamic Relaxation

Techniques for Nonlinear Finite

R. G. Sauve Element Analysis

D. R. Metzger Traditionally, the finite element technique has been applied to static and steady-state

problems using implicit methods. When nonlinearities exist, equilibrium iterations must

be performed using Newton-Raphson or quasi-Newton techniques at each load level. In

Applied Mechanics,

Ontario Hydro Technologies,

the presence of complex geometry, nonlinear material behavior, and large relative sliding

800 Kipling Avenue, KB223,

of material interfaces, solutions using implicit methods often become intractable. A

Toronto, Ontario, Canada M8Z 5S4 dynamic relaxation algorithm is developed for inclusion in finite element codes. The

explicit nature of the method avoids large computer memory requirements and makes

possible the solution of large-scale problems. The method described approaches the

steady-state solution with no overshoot, a problem which has plagued researchers in the

past. The method is included in a general nonlinear finite element code. A description

of the method along with a number of new applications involving geometric and

material nonlinearities are presented.

1 Introduction

Over the past number of years, numerous papers (Wood, cially attractive in computational mechanics since all quanti-

1967; Otters, 1966; Day, 1965; Underwood, 1983; Pica and ties are treated as vectors and the large storage requirements

Hinton, 1980; and Brew and Brotton, 1971) have been pro- associated with large matrices (i.e., stiffness matrix) are

duced that describe the use of dynamic relaxation (DR) in avoided. In addition, the computational effort increases only

the solution of finite difference approximations to the partial proportionally to the number of degrees of freedom so that

differential equations. The purpose of this paper is to de- large-scale problems involving tens of thousands of degrees

scribe recent developments in the use of DR within the finite of freedom are possible (e.g., no bandwidth limitations). A

element method for large-scale geometric and material non- comparison between implicit and explicit methods regarding

linear steady-state solutions. Traditionally, the finite element computational effort and storage requirements are shown in

method has been applied to steady-state problems using Figs. 1 and 2, respectively. The simple logic of the procedure

implicit methods, where large numbers of equations are permits an elegant algorithmic structure providing a conve-

formed and solved using direct solvers such as frontal, sky- nient framework for treatment of nonlinearities. For exam-

line, or Cholesky-type methods. When nonlinearities exist, ple, the implementation of robust contact algorithms for

equilibrium iterations must be performed using Newton- treating large relative sliding of material interfaces is

Raphson or quasi-Newton techniques at each load level. In

the presence of complex geometry, nonlinear material behav-

ior, large local material rotations, and large relative sliding of

material interfaces, solutions using implicit methods often

become intractable. Alternatives, such as iterative methods

which avoid the use of direct solvers, are available. An

interesting paper by Wood (1967) compared the convergence o

<J

properties of the Jacobi, Gauss-Seidel, successive over relax- c

ation (SOR), and DR. The results obtained in (Wood, 1967) o

indicate that SOR has the fastest rate of convergence with •a

&

DR running a close second; however, DR can be more a.

efficiently implemented into the finite element method. O

The explicit nature of dynamic relaxation makes it espe-

N 1/3 *

Contributed by the Pressure Vessels and Piping Division and presented

at the Pressure Vessels and Piping Conference, New Orleans, Louisiana,

June 21-25, 1992, of THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS. Log(Number of Elements (N))

Manuscript received by the PVP Division, 1992; revised manuscript re- Fig. 1 Comparison of operation count for nonlinear transient anal-

ceived December 15, 1994. Associate Technical Editor: W. K. Liu. ysis

170/ Vol. 117, MAY 1995 Transactions of the ASME

Copyright © 1995 by ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

M

*" t+ C= F ext

t-Atl t t + At2

t - Atl/2 t + At2/2

e

a • C

3

** w$)V^*J ^ V ,/

i: r r

o

e

• x = M"1 rF * - E l ] (Acceleration)

1

-— N" —»

3 ext int*

. t + At2/2 .t-Atl/2 1/2 ..t ,,, . .. ,

Number of Elements (N) • x =x + At x (Velocity)

Fig. 2 Comparison of memory requirement for transient analysis t + At2 t ... . t + At2/2

• x = x + At2 x (Coordinates)

straightforward since drastic changes in model connectivity • Update Time t + At2

pose no problem. In addition, equilibrium is tested directly

on the current configuration considering the Cauchy (i.e., • Obtain F-t*t and Repeat

true) stress acting on the body and no iteration is necessary.

The underlying ideas behind the DR method proposed in Stability governed by Courant Condition

this work follow Underwood (1983) in which problem-depen- Fig. 3 Central difference operator

dent, adaptive damping, mass, and time step are derived

which attenuate the transient response leaving the steady-

state solution for an applied loading. The method described ations, x, velocities, x, coordinates/displacements, x, and

herein approaches the steady-state solution with no over- stresses, cr, are known at time /. In order to obtain the

shoot. In addition, special consideration is given to rotational quantities at a new time t + At, where A Ms a constant time

degrees of freedom for which DR was thought to be unsuit- increment, a new velocity is introduced as

able. Many previous works (Pica and Hinton, 1980; Brew and x'+A'^^x'~A'/1 + Atx' (2)

Brotton, 1971; and Kant and Patel, 1990) developed using

DR allow overshoot of the solution. While this is not a severe The superscript t + At/2 indicates that X ' + A , / 2 is a half-step

limitation for problems which are strictly linear in nature, approximation and is a constant velocity with which the

this is clearly not acceptable for nonlinear problems such as configuration moves from time t to time / + A/. The new

those involving hysteretic elastic-plastic materials and contact coordinates are then given as

problems where responses are history-dependent. Recent +A

+ Atx' '^ (3)

work (Kant and Patel, 1990) has suggested a DR method for

solving nonlinear structural problems; but it is plagued by In this new updated configuration, the stresses are evaluated

overshoot, thus limiting the solution to small deformation using appropriate constitutive laws. These stresses are used

and linear materials. An algorithm for DR which is applica- in the discretized equilibrium equations to obtain updated

ble to highly nonlinear problems and compatible with the accelerations.

finite element method is developed in this work. A number The temporal integration scheme described in the forego-

of new DR applications including material and geometric ing is explicit in that the unknown quantities x' + Al/7, xx+Al

nonlinearity, creep, and incompressibility are presented to are defined in terms of known quantities from a previous

demonstrate both the accuracy and efficacy of the proposed time increment when the equations are applied. It is impor-

algorithm. This paper covers the development and implemen- tant to note that the new configuration defined by the

tation of the DR algorithm along with applications followed coordinates x' is obtained first while the velocities \X+A'/2

by concluding remarks. which correspond to this current configuration are computed

at the end of the procedure. The name central difference is

obvious when the accelerations are obtained in terms or

2 Dynamic Relaxation and Explicit Techniques coordinates, for a constant time step, At

2.1 Explicit Operator. The central difference operator -A/

is used for the time integration of the discretized equations i< = I . . I (4)

of motion given by At2

dx At each time step, all constitutive calculations and element

M- = ¥•' ¥' (1) geometry are evaluated in an updated configuration frame

dt defined by current coordinates, x ' + 4 ' . Using a lumped (i.e.,

where M is the mass matrix, F' nt , Fe'xt are the element diagonal) mass matrix, M, avoids the need for a formation of

internal and external force vectors, respectively. system equations into a banded stiffness matrix and a system

solver. This operator is explicit and as such is conditionally

F/nt^/BVdV stable, so that values of the time step A? must be maintained

J

v at values below a critical time step based on the Courant

stability limit Atcr < 2/<*>max, where cumax is the highest fre-

B = matrix relating element nodal velocities to element ve- quency of the system. In other words, stability is only ensured

locity strains. when the time step is smaller than the time it takes an elastic

Here a brief description of the explicit central difference stress wave or acoustic sound wave to travel the smallest

integration is included, while a more complete presentation discrete element dimension in the overall finite element

on the topic is given in (Belytschko, 1983). In the explicit model. The temporal discretization using the central differ-

integration scheme, all discretized quantities such as acceler- ence operator is represented in Fig. 3. The choice of this

Journal of Pressure Vessel Technology MAY 1995, Vol. 1 1 7 / 1 7 1

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Initial Conditions

Forces

p. t+At Exerted on

Node DOF's

Contact ?t Accelerations

Surface at Node "'-M-'IFL-FL]

Conditions DOF's

z

Critical

X Rigid Wall

Time At, Boundary

Step Condition

Internal + Hourglass Velocities

p t + At= F t+At + F t+At at Node . t + At/2

Element Forces int int hg DOF's

DEVIATORIC

rRic^--A

VOLUMETRIC

Update Update

External Geometry

Load F„Clt New Node

Coordinates

Update

Time

t+At

Fig. 4 Explicit nonlinear transient computational cycle

operator is based on the premise that it has the highest stable M f+Al/2 it-to/2 ) + C(x l+At/2 + X t-Al/1 ) / 2

time step among the explicit operators available and that A7 (*

with a proper implementation, it does not require a special

starting scheme. The overall implementation into a solution + F.' = F' (8)

strategy which is applicable to both linear and highly nonlin-

ear problems is shown in Fig. 4. This strategy is identical for M

i(+A//2

dynamic relaxation, with the exceptions noted in the next A7 ~2

sections.

M

2.2 Dynamic Relaxation. The idea behind dynamic re- (V' - FM + c\ <-A«A1

_ _ X (9)

laxation is based on viewing the solution of a static problem At 2

as the steady-state solution of a damped wave equation. To maintain the efficiency and form of the central differ-

Thus, the equation of motion for structural dynamics is ence operator, as well as ensuring that the mode associated

pertinent to the development of dynamic relaxation, and the with the applied loading distribution is critically damped, a

central difference operator can be used to develop an algo- diagonal mass matrix M is used along with a critical damping

rithm for DR. matrix C, is given by

For time t, the equations of motion are given as

C = 2coM (10)

Mx' + Cx' + K(x')u' F

exl (5) where <w = undamped natural frequency corresponding to

the participating mode of loading.

The damping matrix and displacement vector are repre-

Substituting for C yields

sented by C and u', respectively. Time t in dynamic relax-

ation refers to an iteration (cycle) counter. As described in [AtM-i(F;n - F(M) + k>-W(l - coAt)]

jj(+A(/2 _

the section on explicit temporal integration, nonlinear prob- (11)

lems are handled using a nonlinear internal force vector F int (1 + o>At)

directly, in lieu of forming a tangent stiffness K(x') at every

The current coordinates are calculated as

time step. Thus, K(x')u' is replaced by F;'nt.

Referring to Fig. 3, the central difference expressions for x ' + A ' = x' + Atx,+^ (12)

acceleration and velocity are given as +A

The current displacement vector u ' ' is obtained as

+A/

J./ + A//2 u' = u' + Atx'+A,/2 (13)

(6)

At At

By a judicious choice of <w, A;, and M, the transient re-

where A? is a constant time increment. The average value of sponse can be attenuated, resulting in the steady-state re-

velocity is taken as sponse and the solution to

Fin. = Text (14)

x' = (x' + A '/ 2 + x ' - A ^ ) / 2 (7)

Thus, in the dynamic relaxation solution, F int and Fex[ repre-

Substituting into the equation of motion yields sent the real system, whereas, M, a>, and At are arbitrary.

1 7 2 / Vol. 117, MAY 1995 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Care must be taken in the specification of M in order to The critical time step A/ cr is then obtained as

maintain the stability of the central difference operator. The

participating frequency w is dependent on M, F int , and F ext . ^min

A<„r = (18)

Consequently, focus is placed on the choice of the mass ~c7

matrix to ensure stability while optimizing the rate of conver-

gence. In the implementation, the density is adjusted for each

In Underwood (1983), the convergence rate of dynamic element such that the transit time for each element is the

relaxation is given in terms of the spectral radius R of the same. In the program, the element densities are obtained for

iterative error equations Afci. = 1.05. The dynamic relaxation solution is then calcu-

lated based on a unit time step (i.e., Af = 1.0) to ensure that

stability is maintained. If the time step drops below 1.001

R-W-l (15) during the solution, then the element densities are recalcu-

lated for Atcr = 1.05 and the solution resumes.

where wmax and w are the highest and lowest frequencies of In addition, at cycle t, a current estimate of a> is obtained

the discretized equations of motion representing the numeri- as

cal model. By maximizing the ratio oj/com.dx (minimizing R), a -|V2

more rapid convergence rate is obtained. The highest fre- (u') K'u'

(19)

quency wmax is mesh and material-dependent, whereas the

lowest frequency &> is based on the lowest participating mode

(u'fMu1

of the structure corresponding to the load distribution. For where the estimate of the stiffness K' is obtained as an

numerical models where the mode of loading corresponds to approximate diagonal stiffness as

a very low structural frequency and the mesh discretization is

such that the local element frequencies are high, a slower [F.'

convergence rate can be expected. By adjusting the mass K' = (20)

matrix and choosing a suitable time step, this affect can be

minimized. In component form for degree of freedom (

One of the key issues in the use of dynamic relaxation for \p.t -ff-M]

nonlinear analysis is the problem of overshoot. In problems [ f mt; f

inl, J

involving severe material nonlinearity (i.e., elasto-plasticity), Kh = 4 2 (21)

A/*'- '"

overshoot is unacceptable. In the past, work in dynamic

relaxation has been limited to linear elastic and in some To account for the possibility of unstable regions which

cases mildly nonlinear geometric problems. Thus, overshoot may be encountered in nonlinear problems, only positive

was a minor issue in these cases. In problems involving values of w are admissible (e.g., co = max(<u', 0.0)). In deal-

material nonlinearity, the solution using dynamic relaxation ing with convergence problems, it is highly desirable to have

must always approach from below the true response. Typi- a measure of convergence upon which the final solution is

cally, the problem has been in obtaining accurate assess- based. It is important to choose a criterion that will neither

ments for the lowest participating frequency of the structure lead to unproductive cycles nor inaccurate results. In this

for use in the critical damping approximation. algorithm the convergence criteria are based upon the follow-

In the method used herein, the Rayleigh quotient is used ing inequalities:

to obtain an accurate approximation for w as + A,/2

HFe'xt ~ F

i'ntll2 \\Atx' \\

T •i 1/2 </u +A < u,, (22)

u Ku W&.H2 llu' '|| 2

(16)

uTMu where || H2 denotes Euclidean norm. The tolerances / to , and

Mto, are normally taken as 0.01 and 0.001, respectively. For

where u is the current displacement vector, K is the current most of the problems encountered, these tolerances provide

tangent stiffness matrix, and superscript T indicates trans- a good balance of accuracy and efficiency. All the numerical

pose of the matrix. This avoids an eigensolution of the cases presented in this work were run with these values. The

problem, which would otherwise nullify the benefits of dy- algorithm, as implemented in the finite element code (Sauve,

namic relaxation. Details of the dynamic relaxation algorithm 1993), is summarized in Table 1.

implemented for nonlinear problems are presented in the

following section.

4 Applications

3 Dynamic Relaxation Algorithm In order to demonstrate the DR algorithm, a number of

cases are presented. They describe problems which use a

The algorithm proposed herein is designed to exploit the variety of element formulations, available in the computer

simplicity of an explicit nonlinear solution module in an code described in Sauve (1993), including nonlinear struc-

existing in-house computer code (Sauve, 1993). As discussed tural elements such as three-dimensional beams and shells

in Section 2.2., it it important to obtain good estimates of M and a three-dimensional continuum element. The elements

and it) to ensure that the mode associated with externally have been derived to exploit the features of the explicit

applied loads is critically damped and no overshoot occurs. method. All the solutions to the cases presented in this

The key is to provide updated estimates of w at each cycle of section are obtained with the DR algorithm implemented in

dynamic relaxation. In the algorithm, wmax is based on the the computer code described in Sauve (1993).

transit time of a wave over the smallest element in a struc-

tural continuum. That is, 4.1 Nonlinear Geometric Cantilever Plate. A cantilever

beam shown in Fig. 5 was modeled using both three-dimen-

2CD sional shell elements (Sauve and Dubey, 1991) and eight-

«W - 7— (17)

noded underintegrated solid elements. This model serves to

test the use of DR in problems involving geometric nonlin-

where CD is the speed of sound of a dilatational wave, and earity. It consists of a 1-in2 cross section of length 10 in. with

L m i n is the minimum effective element length in the problem. a uniformly applied pressure 2.85 psi. The modulus of elastic-

Journal of Pressure Vessel Technology MAY 1995, Vol. 1 1 7 / 1 7 3

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 1 Dynamic relaxation algorithm

I Initialize M for Ata = 1.05 for each element, set At == 1.0.

II At cycle t for load increment ;'.

(0 x'=M-'[Fe'xt-F/nl]

GO (velocities)

(1 + <o'At) (1 + rn'M)

x ' + A ' = x' + A / x ' + 4 ' ^ (coordinates)

+A +A

u' ' = u' + A / x ' '^ (displacements)

Uii) Update external force vector Fc'xl

(iv) Check error norms

\Kt ~ Fi'„tll2 l|Afx' + 4 * % „

tol

HFe'J|2 ^ l|u' + A '|| 2 <

"""

If satisfied go to next load increment i + 1

(o) Obtain current internal force vector F/ n j A '

and current stable time step A/cr

(vi) Update density if Afc < 1.001

(vii) Obtain current estimate of at'

^-[Fi'„t, A '-c,.i/A ? ir A ^

K'n = max (K'a, 0)

XM„(U;.)2

(viii) Go to ( 0 and repeat

1.0 .. ,. 1 , .1 —i—'—i i ,r,M

^ i 1 -i T • ' o.o

• 4 layer

. shell -

0.0 * .

:

\ x Y| ^ ^ ^

~^^

.

-400. ^

M

^

„ -1.0 : \ \ 1 X

^^^^-^

c Y

u • \ \ ^^^5~^^^^?^ j ^ ^ ^ i > & -600.

e \ 'N, _

I -2.0 - \ ^^~^c3§3^ -800.

Q \ ^~^y -

a.

\ -1000.

\x -

' • ' - - .

P

-3.0 -1200.

•

0 0.01 0.02 0.03 0.04 0.05

I . I . I

Cycles x 1000

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

-4.0 Fig. 6 Element hydrostatic stress—dynamic relaxation confined

Cycles x 1000 uniaxial strain test for incompressibility condition

Fig. 5 Geometric nonlinear beam test dynamic relaxation

bility of the element formulation (Sauve, 1993) to handle the

incompressibility condition when Poisson's ratio approaches

ity and Poisson's ratio are 12,000 psi and 0.20, respectively. or equals 0.5. In this problem, the element hydrostatic stress

The application of this load results in a relatively large tip is equal to the applied pressure when the incompressibility

displacement of 3.35 in. This is in agreement with results condition is imposed by Poisson's ratio = 0.5. As observed in

obtained for the same problem in Bathe et al. (1974). The Fig. 6, 50 DR cycles result in a converged solution. It is of

deformed geometry is shown in Fig. 5 along with a history of interest to note that in the initial cycles a number of partici-

DR cycles versus tip displacement. As observed in Fig. 5, it pating frequencies corresponding to damped waves are con-

requires 600 cycles to obtain a converged result using the sidered by the algorithm, and gradually settles to the specific

shell elements, whereas it takes 1800 cycles with the three-di- mode in which the loading is dominant. No overshoot is

mensional solid elements. The slower convergence with the observed. A number of cases for various values of Poisson's

solids arises from the finer mesh used. This changes the ratio were run using DR. The results are in excellent agree-

spectral radius of convergence, in that wmax is far higher ment with classical results, as shown in Fig. 7.

than the lowest participating mode frequency.

4.3 Moment-Loaded Nonlinear Beam. This test repre-

4.2 Incompressibility Condition. A cube, shown in Fig. sents a severe case of geometric nonlinear deformation. As

6, consisting of 27 eight-noded hexahedron elements, is sub- shown in Fig. 8, it consists of bending an initially straight

jected to a pressure of 1000 psi in the y direction, with the beam into a circular shape. The moment, M, required to

remaining sides constrained. This test demonstrates the capa- bend the beam of length L into a circular shape is given by

174/ Vol. 117, MAY 1995 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

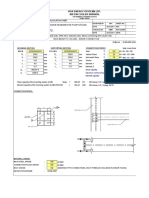

Undeformed Geometry

Response Under Static Loading At Time= 0.0 Hrs

Creep Response At Time= 200400. Hrs

86 percent power fuel channel—mesh 60 x 8- DR creep

0 0.1 0.2 0.3

Poissons Ratio

Fig. 7 Comparison of analytical versus numerical results confined

uniaxial strain test for incompresslbility condition

-6.0

Q

a.

P

-12.0

o 10 12 20

-15.0 Hours (xlOOOO)

0.0 0.2 0.40.80.6 1.0 1.2 1.4 1.6 1.8 2.0 Fig. 10 Fuel channel creep using dynamic relaxation—time his-

Cycles x 1000 tory of midspan displacement

Fig. 8 Tip displacement (node 13) moment-loaded nonlinear

beam—dynamic relaxation

handling viscoplastic problems was that nonlinear implicit

EI 2TTEI

solution methods such as Newton or quasi-Newton methods

M= — = — — (23) did not provide converged solutions in this application. This

R L is not surprising given the complexity of the creep law (Sauve

et a l , 1989) and the extensive sliding contact between the

Nonlinear beam elements available in Sauve (1993) were tubes. The DR algorithm described in this work overcomes

used in this case. When the moment M, corresponding to the this convergence problem by considering each time step for

curvature formula, is applied, as shown in Fig. 8, the correct creep as a load step while maintaining the initial operating

fully circular shape is obtained. Again, no overshoot is ob- mechanical loads such as weight of fuel, deadweight, and

served in the DR solution. coolant. In Fig. 9, the finite element model is shown along

4.4 Creep of Nuclear Fuel Channel Assemblies. The with the converged response under operating mechanical

salient features of the proposed algorithm are demonstrated loads and creep at 200,400 h, which corresponds to approxi-

in a larger-scale complex problem involving both geometric mately 30 yr reactor life. The model consists of 960 three-di-

and material nonlinearity. Throughout the operating life of mensional shell elements (Sauve and Dubey, 1991) and 1098

CANDU nuclear reactors, creep deformation of fuel channel nodes (6588 degrees of freedom). The time history of re-

assemblies occurs. The horizontal fuel channel assembly is sponse for the midspan displacement of the PT and CT is

comprised of a pressure tube (PT) contained by a concentric shown in Fig. 10. Of interest is the way the DR algorithm

calandria tube (CT), as shown in Fig. 9. The pressure tubes converges to a solution at each increment of time.

are clamped at both end fittings by rolled joints and sup- In Fig. 11, a map of DR cycles versus displacement of

ported by the calandria tubes using garter springs at interme- node 271 (midspan of PT) is shown. As observed, the largest

diate points. The pressure tubes contain the fuel bundles and number of cycles occurs at the initial loading stage followed

the D 2 0 coolant. The creep of zirconium alloys, from which by a moderately decreasing amount of cycles during the

the assemblies are comprised, is dependent on time, temper- creep stage. In the initial creep stage smaller increments in

ature, stress, and fast neutron flux. Creep deformation may displacement correspond to smaller time steps for creep. The

limit the useful lifetime of the pressure tubes. Sag due to increments at which the specified time steps for creep are

creep may cause the pressure tube to deflect to a point where increased can be identified from the apparent increases in

its curvature is large enough to inhibit the free passage of DR cycles followed by a stable period in which the number of

fuel bundles and cause thermal problems due to redistribu- cycles remains relatively constant. The evolution of contact

tion of coolant flow. In addition, contact between the pres- between the PT and CT gradually stiffens the system so that

sure and calandria tubes in a region with a high concentra- a higher participating mode is excited. As discussed earlier in

tion of hydrogen isotopes may lead to conditions which Section 2.2, this leads to faster convergence. Comparison of

reduce the fracture resistance of the PT. results with the approximate solution method given in Sauve

One motivating factor for developing a DR scheme for et al. (1989) indicate excellent correlation.

Journal of Pressure Vessel Technology MAY 1995, Vol. 117/175

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

nonlinear problems for which solutions are now being sought,

DR must be seriously considered as a viable alternative in

future finite element code development. The algorithm pre-

sented herein was easily adapted into an existing finite ele-

ment framework. In our implementation, it has been used

successfully with three-dimensional nonlinear beam, shell,

and hexahedron elements, a three-dimensional contact algo-

rithm, and objective material rate formulations. An area

where further research could contribute is in methods to

accelerate convergence for problems in which the participat-

ing frequency of the overall model is much lower than the

highest frequency of the mesh.

References

Bathe, K. J., Ozdemir, H., and Wilson, E. L., 1974, "Static and Dy-

namic Geometric and Material Non-Linear Analysis," SESM Report No.

74-4, Department of Civil Engineering, University of California, Berkeley,

CA.

Belytschko, T., 1983, "An Overview of Semidiscretization and Time

Integration Procedures," Computational Methods for Transient Analysis,

eds„ T. Belytschko and T. J. R. Hughes, North Holland, pp. 1-66.

Brew, J. S., and Brotton, D. M., 1971, "Non-Linear Structural Analysis

by Dynamic Relaxation," International Journal Numerical of Methods in

Engineering, Vol. 3, pp. 436-483.

Day, A. S., 1965, "An Introduction to Dynamic Relaxation," The Engi-

neer, Vol. 219, pp. 218-221.

Kant, T„ and Patcl, S„ 1990, "Transicnt/Pseudo-Transient Finite Ele-

0 1 2 3 4 5 6 7 8 9 10 11 ment Small/Large Deformation Analysis of Two-Dimensional Problems,"

Cycles (x 1000) Computers and Structures, Vol. 36, No. 3, pp. 421-427.

Fig. 11 Fuel channel creep using dynamic relaxation —200,000 h Otters, J. R. H., 1966, "Dynamic Relaxation," Proceedings Institute of

creep—DR cycles Civil Engineers, Vol. 35, pp. 633-656.

Pica, A., and Hinton, E., 1980, "Transient and Pseudo-Transient Anal-

ysis of Mindlin Plates," International Journal of Numerical Methods in

Engineering, Vol. 15, pp. 189-208.

Sauve, R. G., 1993, " H 3 D M A P Version 5.2—A General Three-Dimen-

5 Concluding Remarks sional Finite Element Computer Code for Linear and Non-Linear Analy-

ses of Structures," Ontario Hydro Research Division Report No. 92-256-K,

A DR algorithm which provides both an efficient and Rev. 2.

accurate solution to problems involving varying degrees of Sauve, R. G., and Dubey, R. N., 1991, "Efficient Shell Elements for

nonlinearity has been presented in this work. It is adaptive to Three-Dimensional Non-Linear Structural Dynamic Analysis," Structural

the problem and requires no special tuning factors or user Dynamics: Recent Advances, eds., M. Petyt, H. Wolfe, and C. Mei,

Elsevier Applied Science, pp. 264-276.

intervention. Accuracy is simply controlled by a tolerance on Sauve, R. G., Badie, N., and Holt, R., 1989, "Simulation of Fuel

displacement and force error. It has been implemented into a Channel Response in CANDU Nuclear Reactors," Proceedings of the 10th

general finite element code (Sauve, 1993) and is currently in Structural Mechanics in Reactor Technology, Paper No. L08/4, pp. 219-224.

use on a wide variety of problems. Given the current ad- Underwood, P., 1983, "Dynamic Relaxation," Computational Methods

for Transient Analysis, Vol. 1, pp. 245-265.

vances being made in desktop computer hardware (i.e., Wood, W. L., 1967, "Comparison of Dynamic Relaxation With Three

RISC-based and parallel processors) and the class of highly Other Iterative Methods," The Engineer, Vol. 224, pp. 683-687.

176/ Vol. 117, MAY 1995 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

You might also like

- Free Standing Tension StructuresDocument255 pagesFree Standing Tension StructuresJoaquin VieraNo ratings yet

- Accuracies of Numerical Solution Methods For The Elastic-Perfectly Plastic ModelDocument6 pagesAccuracies of Numerical Solution Methods For The Elastic-Perfectly Plastic ModelArunNo ratings yet

- 1984 - Peirce, Shih, Needleman - A Tangent Modulus Method For Rate Dependent SolidsDocument13 pages1984 - Peirce, Shih, Needleman - A Tangent Modulus Method For Rate Dependent SolidsIgnasi AliguerNo ratings yet

- Hydraulic and Pneumatic Actuators 1 PDFDocument109 pagesHydraulic and Pneumatic Actuators 1 PDFRaghavendra GajakoshNo ratings yet

- Advanced Soil Mechanics - Course NotesDocument49 pagesAdvanced Soil Mechanics - Course NotesMarius Strydom100% (3)

- Momentum and Simple 1D Collisions Phet Lab: M M V V P V 'Document2 pagesMomentum and Simple 1D Collisions Phet Lab: M M V V P V 'caleb f0% (1)

- Libro Ingenieria Sismo Resistente Prc3a1cticas y Exc3a1menes UpcDocument6 pagesLibro Ingenieria Sismo Resistente Prc3a1cticas y Exc3a1menes UpcAli MedinaNo ratings yet

- (1996) - Acta Cryst-Dynamical - RHEED - Calculations - From - The - Surface - of - A - Semi-Infinite - CrystalDocument6 pages(1996) - Acta Cryst-Dynamical - RHEED - Calculations - From - The - Surface - of - A - Semi-Infinite - CrystalXiaobing HuangNo ratings yet

- Burstedde Ghattas 09Document10 pagesBurstedde Ghattas 09Rac RaKyeNo ratings yet

- The Spectral Element Method: An Efficient Tool To Simulate The Seismic Response of 2D and 3D Geological StructuresDocument26 pagesThe Spectral Element Method: An Efficient Tool To Simulate The Seismic Response of 2D and 3D Geological Structuresyedulla jyothiNo ratings yet

- Icfd10 Eg 30i1Document8 pagesIcfd10 Eg 30i1NextScribeNo ratings yet

- The Finite Element Method For Flow and Heat Transfer AnalysisDocument15 pagesThe Finite Element Method For Flow and Heat Transfer AnalysisShimaa BarakatNo ratings yet

- Review On Finite Element Method Erhunmwun, Id Ikponmwosa, UbDocument4 pagesReview On Finite Element Method Erhunmwun, Id Ikponmwosa, UbAmanuel GirmaNo ratings yet

- Carrayrou 2002Document12 pagesCarrayrou 2002Kyawlin AungNo ratings yet

- Comput. Methods Appl. Mech. Engrg.: F. Auricchio, L. Beirão Da Veiga, T.J.R. Hughes, A. Reali, G. SangalliDocument13 pagesComput. Methods Appl. Mech. Engrg.: F. Auricchio, L. Beirão Da Veiga, T.J.R. Hughes, A. Reali, G. SangalliJorge Luis Garcia ZuñigaNo ratings yet

- 2D Mesh-Free Modeling For Elasto-Plastic Problems in Large Deformation Based On Power Law BehaviorDocument3 pages2D Mesh-Free Modeling For Elasto-Plastic Problems in Large Deformation Based On Power Law Behaviorchafik elkihalNo ratings yet

- Chemical Engineering Science: Ali Mesbah, Herman J.M. Kramer, Adrie E.M. Huesman, Paul M.J. Van Den HofDocument16 pagesChemical Engineering Science: Ali Mesbah, Herman J.M. Kramer, Adrie E.M. Huesman, Paul M.J. Van Den HofMr. BaiGNo ratings yet

- Método de Volumen Finito de Alta Orden para Resolver Fluidos ViscoelásticosDocument14 pagesMétodo de Volumen Finito de Alta Orden para Resolver Fluidos ViscoelásticosAaron Arango AyalaNo ratings yet

- The Finite Element Method in Electromagnetics BookDocument3 pagesThe Finite Element Method in Electromagnetics BookDenis CarlosNo ratings yet

- Quadrature Rules For Isogeometric Shell Formulations: Study Using A Real-World Application About Metal FormingDocument16 pagesQuadrature Rules For Isogeometric Shell Formulations: Study Using A Real-World Application About Metal FormingJorge Luis Garcia ZuñigaNo ratings yet

- 1994 - Implicit and Dynamic Explicit Solutions of Blade Forging Using The Finite Element MethodDocument6 pages1994 - Implicit and Dynamic Explicit Solutions of Blade Forging Using The Finite Element MethodNguyen Hoang DungNo ratings yet

- Accelerated SGD For Non-Strongly-Convex Least SquaresDocument64 pagesAccelerated SGD For Non-Strongly-Convex Least SquaresMin WANNo ratings yet

- Analysis of Traffic FlowDocument7 pagesAnalysis of Traffic FlowmansNo ratings yet

- Paper 14Document6 pagesPaper 14Walid BecharNo ratings yet

- Adaptive Dynamic Relaxation Algorithm For Non-Linear Hyperelastic StructuresDocument19 pagesAdaptive Dynamic Relaxation Algorithm For Non-Linear Hyperelastic StructuresJoaquin VieraNo ratings yet

- The Finite Element Method For Flow and Heat Transfer: Advances in Polymer Technology June 1984Document16 pagesThe Finite Element Method For Flow and Heat Transfer: Advances in Polymer Technology June 1984priyono slametNo ratings yet

- Mignone 2007 ApJS 170 228Document15 pagesMignone 2007 ApJS 170 228Nikhil Arun KumarNo ratings yet

- Taylor-SPH: A Two-Steps Time Discretization Scheme Using The SPH Method For Shock Wave PropagationDocument13 pagesTaylor-SPH: A Two-Steps Time Discretization Scheme Using The SPH Method For Shock Wave PropagationIsabel H. CidNo ratings yet

- Comparison of Implicit and Explicit Finite Element Methods For Dynamic ProblemsDocument9 pagesComparison of Implicit and Explicit Finite Element Methods For Dynamic ProblemsWiwat TanwongwanNo ratings yet

- An Explicit Method Based On The Implicit Runge-KutDocument16 pagesAn Explicit Method Based On The Implicit Runge-KutMarcela DiasNo ratings yet

- Guenther R Uecker 2012 ParisDocument5 pagesGuenther R Uecker 2012 ParisFelipe RincónNo ratings yet

- Advances in Engineering Software: A. El Ayadi, B. Picoux, G. Lefeuve-Mesgouez, A. Mesgouez, C. PetitDocument10 pagesAdvances in Engineering Software: A. El Ayadi, B. Picoux, G. Lefeuve-Mesgouez, A. Mesgouez, C. Petitvinod choudhariNo ratings yet

- Yang - 1992 - Axisymmetric Infinite Elements For SSI Analysis PDFDocument10 pagesYang - 1992 - Axisymmetric Infinite Elements For SSI Analysis PDFali381No ratings yet

- Mic 2021 2 2Document35 pagesMic 2021 2 2lapuNo ratings yet

- Computers and Geotechnics: Masahide Otsubo, Catherine O'Sullivan, Tom ShireDocument13 pagesComputers and Geotechnics: Masahide Otsubo, Catherine O'Sullivan, Tom ShireSai Manohar RamachandranNo ratings yet

- Compendio Applied Mathematics and Computational PhysicsDocument274 pagesCompendio Applied Mathematics and Computational PhysicsVicky SiilantriitaNo ratings yet

- Linear-Scaling Ab-Initio Calculations For Large and Complex SystemsDocument10 pagesLinear-Scaling Ab-Initio Calculations For Large and Complex SystemsZuxin JinNo ratings yet

- An Implicit Non-Staggered Cartesian Grid Method For Incompressible Viscous Flows in Complex GeometriesDocument24 pagesAn Implicit Non-Staggered Cartesian Grid Method For Incompressible Viscous Flows in Complex GeometriesUday BhaskarNo ratings yet

- Parameter Preserving Model Order Reduction of A Flow MeterDocument4 pagesParameter Preserving Model Order Reduction of A Flow MeterbobehabNo ratings yet

- Application of Newton-Raphson Method in Optimal Design of Water Distribution NetworksDocument16 pagesApplication of Newton-Raphson Method in Optimal Design of Water Distribution NetworksRufo Daskeo Jr.No ratings yet

- Matlab CodeDocument10 pagesMatlab Codesoheilvb6No ratings yet

- Solution To Industry Benchmark Problems With The Lattice-Boltzmann Code XFlowDocument22 pagesSolution To Industry Benchmark Problems With The Lattice-Boltzmann Code XFlowCFDiran.irNo ratings yet

- Solution of Confined Seepage Problems Below Hydraulic Structures by Finite Element MethodDocument13 pagesSolution of Confined Seepage Problems Below Hydraulic Structures by Finite Element MethodMoiz Khan YousufzaiNo ratings yet

- Practical Application of Fractal Analysis: Problems and SolutionsDocument8 pagesPractical Application of Fractal Analysis: Problems and SolutionsCezara RasinarNo ratings yet

- Finite Elements in Solid MechanicsDocument4 pagesFinite Elements in Solid MechanicspaulovribeiroNo ratings yet

- Alkylation 2Document22 pagesAlkylation 2aysar JarullahNo ratings yet

- Ices Report 17-18: August 2017Document38 pagesIces Report 17-18: August 2017Jorge Luis Garcia ZuñigaNo ratings yet

- Direct Nonlinear Analysis Using Alpha MethodDocument15 pagesDirect Nonlinear Analysis Using Alpha MethodNathanNo ratings yet

- 1 s2.0 S2468013317301316 MainDocument7 pages1 s2.0 S2468013317301316 MainSayiqa JabeenNo ratings yet

- Method: ElementDocument14 pagesMethod: Element2BA17ME092 Shivaprasad B BayannavarNo ratings yet

- Reflection of An Open-Ended Coaxial Line and Application To Nondestructive Measurement of MaterialsDocument6 pagesReflection of An Open-Ended Coaxial Line and Application To Nondestructive Measurement of MaterialsthomasNo ratings yet

- Adobe Scan 10 Jul 2023 1Document23 pagesAdobe Scan 10 Jul 2023 1RoshanNo ratings yet

- Computers and Geotechnics: A. Riahi, J.H. Curran, H. BidhendiDocument12 pagesComputers and Geotechnics: A. Riahi, J.H. Curran, H. Bidhendizimbazimba75No ratings yet

- A Finite Element Method For CompressibleDocument14 pagesA Finite Element Method For CompressiblenapoleonmNo ratings yet

- Application of Newton-Raphson Method in Optimal Design of Water Distribution NetworksDocument16 pagesApplication of Newton-Raphson Method in Optimal Design of Water Distribution NetworksAhmed adelNo ratings yet

- Journal of Computational Physics: Armando Coco, Giovanni RussoDocument38 pagesJournal of Computational Physics: Armando Coco, Giovanni RussoAnonymous tIwg2AyNo ratings yet

- Simulations of Minerals Using Density-Functional TDocument11 pagesSimulations of Minerals Using Density-Functional TacanalesmahuzierNo ratings yet

- Unified Analysis of Finite Volume Methods For Second Order ElliptDocument17 pagesUnified Analysis of Finite Volume Methods For Second Order Ellipt5ggq85c8r4No ratings yet

- Finite Element Method: Q I I Q I I Q I IDocument12 pagesFinite Element Method: Q I I Q I I Q I ISharmin SumiNo ratings yet

- Finite Element/finite Volume Approaches With Adaptive Time Stepping Strategies For Transient Thermal ProblemsDocument19 pagesFinite Element/finite Volume Approaches With Adaptive Time Stepping Strategies For Transient Thermal Problemsprajjwal patidarNo ratings yet

- Makni 1994Document13 pagesMakni 1994sebas panezNo ratings yet

- Application of Implicit-Explicit High Order RungeDocument43 pagesApplication of Implicit-Explicit High Order RungeJosue AzurinNo ratings yet

- Inversion Techniques Applied To Resistivity InversDocument19 pagesInversion Techniques Applied To Resistivity InversIvonaNo ratings yet

- Kingspan Isoeste Assembly 391088-0-0 (Isotelha PIR)Document5 pagesKingspan Isoeste Assembly 391088-0-0 (Isotelha PIR)Joaquin VieraNo ratings yet

- Kingspan Isoeste 4881 - Fechamento Frigo e IsofachadaDocument3 pagesKingspan Isoeste 4881 - Fechamento Frigo e IsofachadaJoaquin VieraNo ratings yet

- Construction and Building Materials: Frank Küsel, Elsabe KearsleyDocument13 pagesConstruction and Building Materials: Frank Küsel, Elsabe KearsleyJoaquin VieraNo ratings yet

- Dynamic Relaxation Analysis of The Non-Linear Static Response of Pretensioned Cable RoofsDocument9 pagesDynamic Relaxation Analysis of The Non-Linear Static Response of Pretensioned Cable RoofsJoaquin VieraNo ratings yet

- Lewis Mode Los 2Document8 pagesLewis Mode Los 2Joaquin VieraNo ratings yet

- Note Dynamic Relaxation: Ax A A Is A Real Positive Definite Matrix (E.g. It Could Be A Typical Stiffness Matrix)Document3 pagesNote Dynamic Relaxation: Ax A A Is A Real Positive Definite Matrix (E.g. It Could Be A Typical Stiffness Matrix)Joaquin VieraNo ratings yet

- Accelerated Relaxation' or Direct Solution? Future Prospects For FemDocument11 pagesAccelerated Relaxation' or Direct Solution? Future Prospects For FemJoaquin VieraNo ratings yet

- Adaptive Dynamic Relaxation Algorithm For Non-Linear Hyperelastic StructuresDocument19 pagesAdaptive Dynamic Relaxation Algorithm For Non-Linear Hyperelastic StructuresJoaquin VieraNo ratings yet

- B.H.V. Topping and A.I. KhanDocument46 pagesB.H.V. Topping and A.I. KhanJoaquin VieraNo ratings yet

- A Simplified Finite Element Model For Structural Cable Bending MechanismDocument15 pagesA Simplified Finite Element Model For Structural Cable Bending MechanismJoaquin VieraNo ratings yet

- Lewis Mode LosDocument10 pagesLewis Mode LosJoaquin VieraNo ratings yet

- HuuDocument10 pagesHuuJoaquin VieraNo ratings yet

- linkwitzDirectAproach FDDocument15 pageslinkwitzDirectAproach FDJoaquin VieraNo ratings yet

- Topic 2 - Linear MotionDocument11 pagesTopic 2 - Linear MotionJerome GiovanieNo ratings yet

- Exam3 T111Document15 pagesExam3 T111ammuNo ratings yet

- Strength of Materials: Engr. John Lester L. Morillo Bs Che / Adamson UniversityDocument29 pagesStrength of Materials: Engr. John Lester L. Morillo Bs Che / Adamson UniversityKing CalmaNo ratings yet

- Direction: Choose The Letter of The Best AnswerDocument7 pagesDirection: Choose The Letter of The Best AnswerJudith Aziel SingqueNo ratings yet

- Pages From B SC Physics Syllabus UG CBCS 2017Document4 pagesPages From B SC Physics Syllabus UG CBCS 2017ShinojNo ratings yet

- Analysis of Large Scale Rock Slopes: Doctoral Thesis 1999:01Document24 pagesAnalysis of Large Scale Rock Slopes: Doctoral Thesis 1999:01Zamara AdNo ratings yet

- Paul BourkeDocument290 pagesPaul Bourkeibrahim sugarNo ratings yet

- Wilks 2001Document9 pagesWilks 2001Pawan KumarNo ratings yet

- 311 ch133552 100107183003 Phpapp01Document26 pages311 ch133552 100107183003 Phpapp01khajaimad100% (1)

- Homework 3Document4 pagesHomework 3sdphysicsNo ratings yet

- Connection DesignDocument94 pagesConnection DesignAnand.5100% (1)

- Openfoam Cavity HeatDocument4 pagesOpenfoam Cavity HeatShripad PachputeNo ratings yet

- Fluid Mechanics PDFDocument73 pagesFluid Mechanics PDFSanjan KSNo ratings yet

- Ghidaoui 2004Document14 pagesGhidaoui 2004Abedalkareem GhazalNo ratings yet

- Working of DifferentialDocument4 pagesWorking of DifferentialMegh BantawaNo ratings yet

- Sub ModellingDocument3 pagesSub ModellingktkambleNo ratings yet

- Fizika SkriptaDocument14 pagesFizika SkriptaMarkoNo ratings yet

- Pde EquationsDocument44 pagesPde EquationsJagadish SNo ratings yet

- Reynolds NumberDocument7 pagesReynolds NumberpallaviNo ratings yet

- Compressibility Factor Z CalcDocument3 pagesCompressibility Factor Z CalcknsaravanaNo ratings yet

- XI Test Paper JEE (Main) Dt. 01.02.2023Document5 pagesXI Test Paper JEE (Main) Dt. 01.02.2023ujjwal guptaNo ratings yet

- New Ps GuruDocument5 pagesNew Ps GurubrushaNo ratings yet

- Statics of Rigid Bodies Module 3Document29 pagesStatics of Rigid Bodies Module 3Alegria delos ReyesNo ratings yet

- 300+ TOP Thermodynamics Multiple Choice Questions and AnswersDocument1 page300+ TOP Thermodynamics Multiple Choice Questions and AnswersBhutto WaqarNo ratings yet

- How To Learn Math and PhysicsDocument13 pagesHow To Learn Math and PhysicsDHANANJAY KAPSE100% (1)

- 11 GVF PDFDocument68 pages11 GVF PDFRamu Nagulagani100% (1)

- Constructing Mom MemberDocument17 pagesConstructing Mom MemberminhnguyenvonhatNo ratings yet