Professional Documents

Culture Documents

According Jis 1993: Nominal Dimensional HXB T1 T2 R A Ix Iy Ix Iy ZX Zy

According Jis 1993: Nominal Dimensional HXB T1 T2 R A Ix Iy Ix Iy ZX Zy

Uploaded by

Bambang SotejoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

According Jis 1993: Nominal Dimensional HXB T1 T2 R A Ix Iy Ix Iy ZX Zy

According Jis 1993: Nominal Dimensional HXB T1 T2 R A Ix Iy Ix Iy ZX Zy

Uploaded by

Bambang SotejoCopyright:

Available Formats

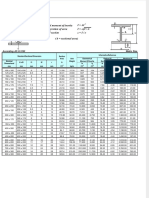

ACCORDING JIS 1993 METRIC SIZE

Sectional Informative Reference

Standard Sectional Dimension

Area Unit Geometrical Radius of Modulus of

Nominal Mass moment of inertia gyration of area Section

Dimensional HxB t1 t2 r A Ix Iy ix iy Zx Zy

mmxmm mmxmm mm mm mm cm2 kg/m cm4 cm4 cm cm cm3 cm3

100 x 100 100 x 100 6 8 10 21.90 17.20 383 134.0 4.18 2.47 76.5 26.7

125 x 125 125 x 125 6.5 9 0 30.31 23.80 847 293.0 5.29 3.11 136.0 47.0

150 x 75 150 x 75 5 7 8 17.85 14.00 666 49.5 6.11 1.66 88.8 13.2

150 x 100 148 x 100 6 9 11 26.84 21.10 1 020 151.0 6.17 2.37 138.0 30.1

150 x 150 150 x 150 7 10 11 40.14 31.50 1 640 563.0 6.39 3.75 219.0 75.1

175 x 175 175 x 175 7.5 11 12 51.21 40.20 2 880 984.0 7.50 4.38 330.0 112.0

198 x 99 4.5 7 11 23.18 18.20 1 580 114.0 8.26 2.21 160.0 23.0

200 x 100

200 x 100 5.5 8 11 27.16 21.30 1 840 134.0 8.24 2.22 184.0 26.8

200 x 200 200 x 200 8 12 13 63.53 49.90 4 720 1 600 8.62 5.02 472.0 160.0

248 x 124 5 8 12 32.68 25.70 3 540 255.0 10.40 2.79 285.0 41.1

250 x 125

250 x 125 6 9 12 37.66 29.60 4 050 294.0 10.40 2.79 324.0 47.0

250 x 250 250 x 250 9 14 16 92.18 72.40 10 800 3 650 10.80 6.29 867.0 292.0

298 x 149 5.5 8 13 40.80 32.00 6 320 442.0 12.40 3.29 424.0 59.3

300 x 150

300 x 150 6.5 9 13 46.78 36.70 7 210 508.0 12.40 3.29 481.0 67.7

300 x 300 300 x 300 10 15 18 119.80 94.00 20 400 6 750 13.10 7.51 1 360 450.0

346 x 174 6 9 14 52.68 41.40 11 100 792.0 14.50 3.88 641.0 91.0

350 x 175

350 x 175 7 11 14 63.14 49.60 13 600 984.0 14.70 3.95 775.0 112.0

350 x 350 350 x 350 12 19 20 173.90 137.00 40 300 13 600 15.20 8.84 2 300 776.0

400 x 200 396 x 199 7 11 16 72.16 56.60 20 000 1 450 16.70 4.48 1 010 145.0

400 x 200 400 x 200 8 13 16 84.10 66.00 23 700 1 740 16.8 4.54 1 190 174.0

*400 x 400 400 x 400 13 21 22 218.70 172.00 66 600 22 400 17.5 10.10 3 330 1 120

450 x 200 450 x 200 9 14 18 96.80 76.00 33 500 1 870 18.6 4.40 1 490 187.0

500 x 200 500 x 200 10 16 20 114.20 89.60 47 800 2 140 20.5 4.33 1 910 214.0

600 x 200 600 x 200 11 17 22 134.40 106.00 77 600 2 280 24.0 4.12 2 590 228.0

600 x 300 588 x 300 12 20 28 192.50 151.00 118 000 9 020 24.8 6.85 4 020 601.0

*700 x 300 700 x 300 13 24 28 235.50 185.00 201 000 10 800 29.3 6.78 5 760 722.0

*800 x 300 800 x 300 14 26 28 267.40 210.00 292 000 11 700 33.0 6.62 7 290 782.0

Note: * Dimensions are import product

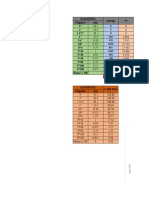

SPECIFICATION

FOR WIDE FLANGE SHAPE

DIMENSIONAL TOLERANCE JIS G3192 (HOT ROLLED H-SECTIONS

PERMISSIBLE VARIATIONS mm

ITEM, mm (in.)

(in.)

FLANGE WIDTH, B +3.0 (0.118)

Nominal depths of under 400(15.748) +3.0 (0.118)

Depth, H

400 to 600 (23.622), excl. +4.0 (0.157)

600 and over +5.0 (0.197)

Under 16 (0.630) +1.5 (0.059)

Flang 16 to 25 (0.984). Excl +2.0 (0.079)

e, t2 25 to 40 (1.575), excl. +2.5 (0.098)

Thickness

40 and over +3.0 (0.118)

Under 16 (0.630) +1.0 (0.039)

Web, 16 to 25 (0.984). Excl +1.5 (0.024)

t1 25 to 40 (1.575), excl. +2.0 (0.079)

40 and over +2.5 (0.098)

7 m (23 ft) and under +4.0 (1.575)

0

Length

Over 7 m (23ft) 40 (1.575) plus 5 (0.197) for each

additional meter or fraction there of

Nominal depths Not more than 1.2 percent of flange

Out-of- 300 (11.811) and under width B or 2.0 (0.079) at minimum

Square,

Nominal depths Not more than 1.5 percent of flange

T

300 (11.811) and under width B or 2.0 (0.079) at minimum

Nominal depths Not more than 0.20 percent

Camber 300 (11.811) and under of length

of Sweep Nominal depths Not more than 0.10 percent

over 300 (11.811) of length

Nominal depths +3.0 (0.118)

Web Off over 300 (11.811)

Center, s Nominal depths +4.5 (0.177)

over 300 (11.811)

Not more than 0.16 percent

Ends Out-of-Square,e of flange width B or depth H,

or 3.0 (0.118) at minimum

CHEMICAL COMPOSITION

CHEMICAL COMPOSITION

SYMBOL OF GRADE

C

SS400 -

CORRESPONDING SPECIFICATION

CLASSIFIED BY TENSILE STRENGTH

TYPE OF MATERIAL

Tensile strength class (N/mm2)

General Structure 400

MECHANICAL PROPERTIES

YIELD POINT / mm2

CLASSIFICATION Thickness (mm)

16 or under

JIS G3101 SS400 245

PECIFICATION

FOR WIDE FLANGE SHAPE

JIS G3192 (HOT ROLLED H-SECTIONS)

APPLICATION

Horizontal or vertical

curvature in the direction

of length

ACCORDING TO JIS G 3101

CHEMICAL COMPOSITION (%)

Si Mn P S

- - 0.050 max 0.050 max

BY TENSILE STRENGTH SPECIFICATIONS

Special Specification JIS ASTM BS 4360 DIN

G 3101 SS

- A 36 Gr. 43A St 33

400

D POINT / mm2 TENSILE ELONGATION, %

ickness (mm) STRENGTH Thickness (mm)

over 16 N/mm2 5 or under 5 to 16 over 16

235 400-510 21 17 21

You might also like

- Catenary Sag-Tension Calculator (Even and Uneven)Document2 pagesCatenary Sag-Tension Calculator (Even and Uneven)mohsin160100% (1)

- Reservoir Fluids - Zoltan E. HEINEMANNDocument152 pagesReservoir Fluids - Zoltan E. HEINEMANNTeresa Long100% (1)

- 1 IwfDocument6 pages1 IwfBackup polinemaNo ratings yet

- Tabel Baja JISDocument2 pagesTabel Baja JISAlfin HidayatullahNo ratings yet

- G3192 - WFDocument2 pagesG3192 - WFAdhie RakhmadiNo ratings yet

- Dokumen - Tips - Tabel Baja Profil WFPDFDocument7 pagesDokumen - Tips - Tabel Baja Profil WFPDFEvan ImamNo ratings yet

- Tabel Baja Profil WF PDFDocument15 pagesTabel Baja Profil WF PDFNielson SaefatuNo ratings yet

- Tabel Baja WF PDFDocument19 pagesTabel Baja WF PDFRafly PutraNo ratings yet

- Tabel BajaDocument14 pagesTabel Bajadudududu lalalalaNo ratings yet

- H Beam1 PDFDocument1 pageH Beam1 PDFGerryNo ratings yet

- PDF.H Beam PDFDocument1 pagePDF.H Beam PDFPaulo MoreiraNo ratings yet

- H Beam Weight-TWC PDFDocument1 pageH Beam Weight-TWC PDFSankar CdmNo ratings yet

- PDF.H Beam PDFDocument1 pagePDF.H Beam PDFSith SopanhaNo ratings yet

- PDF.H BeamDocument1 pagePDF.H BeamLuwalhati TomilasNo ratings yet

- Jis3192 - HDocument1 pageJis3192 - HAdhie RakhmadiNo ratings yet

- WT/M (KG) Section (MM) Area (cm2) Rmin (CM) Rmed (CM) 1x16 (cm2) 2x16 (cm2) A+bk (cm2) C.G Ixx (cm4) ZXX (cm3)Document2 pagesWT/M (KG) Section (MM) Area (cm2) Rmin (CM) Rmed (CM) 1x16 (cm2) 2x16 (cm2) A+bk (cm2) C.G Ixx (cm4) ZXX (cm3)santoshNo ratings yet

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)Document49 pagesSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)rohitnrgNo ratings yet

- EC3 - Tables Steel Structures 103 PDFDocument1 pageEC3 - Tables Steel Structures 103 PDFDxfmaster LOLNo ratings yet

- Weight Sectional Dimension H B Kg/m. Lb/ft. Mm. In. Mm. In. Mm. In. Nominal Size Mm. TDocument12 pagesWeight Sectional Dimension H B Kg/m. Lb/ft. Mm. In. Mm. In. Mm. In. Nominal Size Mm. TnoppadolNo ratings yet

- Extracted Pages From MASTER BUSBAR SMPDocument2 pagesExtracted Pages From MASTER BUSBAR SMPSimilikiti Weleh WelehNo ratings yet

- Diagrama de Masas Ejercicio ExamenDocument834 pagesDiagrama de Masas Ejercicio ExamenpaoloNo ratings yet

- ANEXODocument2 pagesANEXOAlbert Paolo BVNo ratings yet

- Splice DesignDocument13 pagesSplice Designtitir bagchiNo ratings yet

- Section EquivalentsDocument18 pagesSection EquivalentsmaheshbandhamNo ratings yet

- Wideflange PDFDocument4 pagesWideflange PDFandNo ratings yet

- Universal - Beam Halaman 5Document1 pageUniversal - Beam Halaman 5GunawanNo ratings yet

- H Sections in Accordance With JIS G 3192Document5 pagesH Sections in Accordance With JIS G 3192Fadhlan RosNo ratings yet

- Gi Pipe Size Is 1239Document4 pagesGi Pipe Size Is 1239sshnvlNo ratings yet

- Hal 8-9Document5 pagesHal 8-9Ru RiaNo ratings yet

- Cell FormDocument2 pagesCell FormMochamad rizalNo ratings yet

- Table-1 Properties of Rolled Steel SectionsDocument40 pagesTable-1 Properties of Rolled Steel Sectionsramanathan appu0% (1)

- Power Shed Worksheet Ver 104 1908 2022Document148 pagesPower Shed Worksheet Ver 104 1908 2022janioNo ratings yet

- Hitungan Mekanika Fluida Rev01Document19 pagesHitungan Mekanika Fluida Rev01misfat nawalNo ratings yet

- Pendiente 9.973 DV 35.750 DH 358.46Document2 pagesPendiente 9.973 DV 35.750 DH 358.46YaxsNo ratings yet

- Side Girt Design-RwphDocument23 pagesSide Girt Design-Rwphasvenk309100% (1)

- Deflection For UDL and Point Load at The Centre by Heritier Mbuyi TshikalaDocument9 pagesDeflection For UDL and Point Load at The Centre by Heritier Mbuyi TshikalaWataNo ratings yet

- 30 10 0.005 0 0.015 1 Sistema Internacional 6.364 Nota: Cambiar Solo Color AzulDocument8 pages30 10 0.005 0 0.015 1 Sistema Internacional 6.364 Nota: Cambiar Solo Color Azulerick cardenasNo ratings yet

- Reinforcement Abstract As On 04.05.2015Document5 pagesReinforcement Abstract As On 04.05.2015Nirmalya SenNo ratings yet

- Project: (G+4) Hotel Owner: Ato Wondafrash Tesfaye Location: Wolega (Gimbi)Document2 pagesProject: (G+4) Hotel Owner: Ato Wondafrash Tesfaye Location: Wolega (Gimbi)Frezer AmareNo ratings yet

- Design properties of HEA profiles for S235 steel class (γ = 1.00, units = mm)Document18 pagesDesign properties of HEA profiles for S235 steel class (γ = 1.00, units = mm)scarto08No ratings yet

- Shear Stress Vs Shear StrainDocument12 pagesShear Stress Vs Shear StrainAbrar AfzalNo ratings yet

- Catalogue Mondea 2023 Fix (2) XDocument38 pagesCatalogue Mondea 2023 Fix (2) XyanurulNo ratings yet

- Tugas BanjirDocument4 pagesTugas BanjirnindiaNo ratings yet

- Diametro Peso (G) % Pulgadas MM 3" 2" 1 1/2" 1" 3/4" 3/8" N°4 N°10 N°20 N°40 N°60 N°100 N°200 Menor A 200 4895 100Document6 pagesDiametro Peso (G) % Pulgadas MM 3" 2" 1 1/2" 1" 3/4" 3/8" N°4 N°10 N°20 N°40 N°60 N°100 N°200 Menor A 200 4895 100Eduar SalazarNo ratings yet

- Pipe Size Table: 1/2 (15 DN) 3/4 (20 DN) 1 (25 DN)Document1 pagePipe Size Table: 1/2 (15 DN) 3/4 (20 DN) 1 (25 DN)Hadi KoraniNo ratings yet

- Stranded Overhead Shield Wire (Ground Wire) : Product DescriptionDocument1 pageStranded Overhead Shield Wire (Ground Wire) : Product DescriptionNguyen KhoaNo ratings yet

- Memoria de Calculo Desague - MH - Rev0Document5 pagesMemoria de Calculo Desague - MH - Rev0Junior Diaz VenturaNo ratings yet

- I SectionsDocument2 pagesI SectionsThanawatNo ratings yet

- Tables of Properties of HC Copper ConductorsDocument7 pagesTables of Properties of HC Copper ConductorsSaid WahdanNo ratings yet

- Z Section PropertiesDocument2 pagesZ Section PropertiesmaheshbandhamNo ratings yet

- 0 Converter UnitsDocument1 page0 Converter Unitsenid38No ratings yet

- Sifat-Sifat Penampang Pipa Fy 1600 kg/cm2: Diam. Thick. A P V I WDocument7 pagesSifat-Sifat Penampang Pipa Fy 1600 kg/cm2: Diam. Thick. A P V I WNovly IbrahimNo ratings yet

- Memoria de Calculo Desague - MH - Rev0Document5 pagesMemoria de Calculo Desague - MH - Rev0Junior Diaz VenturaNo ratings yet

- Extracted Pages From MASTER BUSBAR SMPDocument2 pagesExtracted Pages From MASTER BUSBAR SMPSimilikiti Weleh WelehNo ratings yet

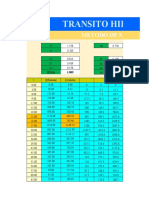

- Transito de AvenidasDocument11 pagesTransito de AvenidasJhonatan Christian Guinea PerezNo ratings yet

- Cast Iron Flanged Pipes IS7181 IS1537 Weight ChartDocument1 pageCast Iron Flanged Pipes IS7181 IS1537 Weight ChartSukanta chakrabortyNo ratings yet

- Cast Iron Flanged Pipes IS7181 IS1537 Weight Chart PDFDocument1 pageCast Iron Flanged Pipes IS7181 IS1537 Weight Chart PDFhussain28097373100% (1)

- Peso Inicial Seco: Analisis Granulometrico Por Tamisado AstmDocument16 pagesPeso Inicial Seco: Analisis Granulometrico Por Tamisado AstmJerry Florentino Cusi AranaNo ratings yet

- Standard Sectional Reference Dimension (MM.) Geometrical Moment Sectional Area (CM) of Inertia (CM) L LDocument2 pagesStandard Sectional Reference Dimension (MM.) Geometrical Moment Sectional Area (CM) of Inertia (CM) L LnoppadolNo ratings yet

- TA VI JEMBATAN XLSXDocument66 pagesTA VI JEMBATAN XLSXboonico NiccoNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Cambridge International General Certificate of Secondary Education (9-1)Document26 pagesCambridge International General Certificate of Secondary Education (9-1)Pranav BISUMBHERNo ratings yet

- Colligative PropertiesDocument26 pagesColligative PropertiesYAWAR SAEED100% (1)

- ViewDocument398 pagesViewRodrique KazambaNo ratings yet

- Icrtet0171 SRP171Document7 pagesIcrtet0171 SRP171Amanulla KhanNo ratings yet

- CHE 4173 Sustainable Processing II: Water Network - Limiting Water Profile & MRPDDocument91 pagesCHE 4173 Sustainable Processing II: Water Network - Limiting Water Profile & MRPDLeon TanNo ratings yet

- New Lancer's Convent Class 8 Subject - Science SA1 A..Multiple Choice Questions (1 20 20)Document9 pagesNew Lancer's Convent Class 8 Subject - Science SA1 A..Multiple Choice Questions (1 20 20)Vandana MudgalNo ratings yet

- 23 07 00 General HVAC Insulation RequirementsDocument5 pages23 07 00 General HVAC Insulation RequirementsolivaresjhonNo ratings yet

- Thermocouples & RTD'S: Catalog Section ADocument33 pagesThermocouples & RTD'S: Catalog Section AJesus GarciaNo ratings yet

- Om40-Opm-Crn-Mto-00001-A01 - Cathodic Protection MtoDocument2 pagesOm40-Opm-Crn-Mto-00001-A01 - Cathodic Protection MtoDAYONo ratings yet

- Liberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Document1 pageLiberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Felicia CioabaNo ratings yet

- Interprime 198: Product DescriptionDocument4 pagesInterprime 198: Product DescriptionAndri AjaNo ratings yet

- BOQ and MeasurmentDocument12 pagesBOQ and MeasurmentBipin Ramesh JainNo ratings yet

- 12 Chapter 4Document32 pages12 Chapter 4အသွ်င္ ေကသရNo ratings yet

- STEELDocument52 pagesSTEELIan Bondoc100% (1)

- Bolted Aboveground Thermosetting Fiberglass-Reinforced Plastic Panel-Type Tanks For Water StorageDocument85 pagesBolted Aboveground Thermosetting Fiberglass-Reinforced Plastic Panel-Type Tanks For Water StorageVasile MariusNo ratings yet

- 2-Document II-2-Civil Specifications Part 2Document674 pages2-Document II-2-Civil Specifications Part 2GAT 1124No ratings yet

- Analysis Report: Residential Building, Dhapasi, KathmanduDocument7 pagesAnalysis Report: Residential Building, Dhapasi, KathmanduKalpanaNo ratings yet

- A 498 - 98 Qtq5oc1sruqDocument4 pagesA 498 - 98 Qtq5oc1sruqsingaravelan narayanasamyNo ratings yet

- Spec Sheet FlexaPrene Welding CableDocument2 pagesSpec Sheet FlexaPrene Welding CableJosh SaundersNo ratings yet

- Design of Flexible Retaining Walls (Sheet-Piles) :: Lebanese University. Faculty of Engineering. Department-1Document24 pagesDesign of Flexible Retaining Walls (Sheet-Piles) :: Lebanese University. Faculty of Engineering. Department-1eliasjamhourNo ratings yet

- Specification CEFO G2 - ENDocument15 pagesSpecification CEFO G2 - ENLeo Gamarra LanguideyNo ratings yet

- Maple Leaf International School: Final Examination 2021 Subject: Chemistry Paper: 2 Class: Ix TIME: 1 Hour 15 MinutesDocument12 pagesMaple Leaf International School: Final Examination 2021 Subject: Chemistry Paper: 2 Class: Ix TIME: 1 Hour 15 MinuteszareenNo ratings yet

- CYCOLOY™ Resin - C1200HF - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - C1200HF - Asia - Technical - Data - SheetShrikantNo ratings yet

- HydrogelsDocument31 pagesHydrogelsGuilherme HenriqueNo ratings yet

- Subject: Chemistry Chapter #: 6: Quantitative Chemistry - How Much? (Moles)Document26 pagesSubject: Chemistry Chapter #: 6: Quantitative Chemistry - How Much? (Moles)Haider Ali100% (2)

- MCQ Question Bank For Unit 1: A Is Lattice Parameter) Is (B) A/2Document14 pagesMCQ Question Bank For Unit 1: A Is Lattice Parameter) Is (B) A/2Shubham MagarNo ratings yet

- Irc Code ListDocument6 pagesIrc Code Listmoondonoo7No ratings yet

- Tds 1141091 enDocument2 pagesTds 1141091 enNicolae SdrailaNo ratings yet