Professional Documents

Culture Documents

Bimetallic Steam Traps

Bimetallic Steam Traps

Uploaded by

asad_naqviOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bimetallic Steam Traps

Bimetallic Steam Traps

Uploaded by

asad_naqviCopyright:

Available Formats

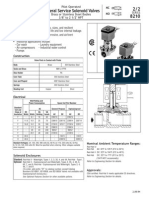

TI-P623-07

ST Issue 2

Cert. No. LRQ 0963008 ISO 9001

ABL Series Bimetallic Steam Traps

12 11

10

8 9 13 4 2 3 5 6 1 7

Description

The ABL range of bimetallic steam traps are made of forged steel. They have a check valve, a built in strainer screen and an external device for adjusting the discharge temperature of the condensate. They are designed for high capacity constant pressure process applications. These steam traps operate with no loss of steam and quickly drain air, non-condensable gases and large quantities of cold water on start-up.

Materials

No. Part 1 Body sub assembly 2 Gland packing 3 Gland nut 4 Adjustment pin ABL405 / ABL505 ABL414 / ABL514 Cap 5 gasket ABL425 / ABL525 ABL440 / ABL540 6 Cap 7 Element gasket 8 Bimetallic element 9 Strainer screen ABL405 / ABL505 Cover ABL414 / ABL514 10 gasket ABL425 / ABL525 ABL440 / ABL540 11 Cover 12 Cover bolt 13 Element screw Material Steel ASTM A105 N Graphite Stainless steel ASTM A276 316L Stainless steel ASTM A276 316L Copper / graphite Copper / graphite Copper / graphite Stainless steel / graphite Steel ASTM A105 Graphite / stainless steel Stainless steel Stainless steel AISI 304L Copper / graphite Copper / graphite Copper / graphite Stainless steel / graphite Steel ASTM A105 Steel ASTM A193 B7 Steel

Sizes and pipe connections

1" and 2" screwed BSP/NPT and socket weld ends (ANSI B 16.11) DN40 and DN50 with PN40, PN64, ANSI 150, ANSI 300 and ANSI 600 flanges

Limiting conditions

Body design conditions Class 600 ABL405 / ABL505 5 bar g PMO - Maximum operating pressure ABL414 / ABL514 14 bar g ABL425 / ABL525 25 bar g ABL440 / ABL540 40 bar g TMO - Maximum operating temperature Minimum operating pressure 400C 0.1 bar g

DPMX - The back pressure for correct operation must not exceed 90% of the upstream pressure. Designed for a maximum cold hydraulic test pressure of 150 bar g

Certification

This product is available with certification to EN 10204 3.1.B. Note: All certification / inspection requirements must be stated at the time of order placement.

Temperature C

400 A 300 200 100 0 B 0 5* 14* 20 25* C D 40* 60 Pressure bar g Steam saturation curve E 80

Operating range

The product must not be used in this region. *PMO A A A A A B C D E F Maximum operating pressure (see Limiting conditions). Flanged Flanged Flanged Flanged Flanged ANSI 150 PN40 ANSI 300 PN64 ANSI 600, screwed and socket weld

F 100

Local regulations may restrict the use of this product to below the conditions quoted. In the interests of development and improvement of the product, we reserve the right to change the specification.

Copyright 2002

Dimensions / weights (approximate) in mm and kg

Capacities

30 000 20 000

D Withdrawal distance for bimetallic element

Condensate kg / h

10 000

ABL405, ABL505

ABL414, ABL514

ABL425, ABL525

3 000 2 000 1500 0.1

A E Withdrawal distance for gland packing.

0.2 0.3 0.5

10

20 30 40

Differential pressure bar (x 100 = kPa) Hot water capacity Cold water capacity

Size Connections 1" - 2" BSP / NPT / SW PN40 PN64 DN40 ANSI 150 ANSI 300 ANSI 600 PN40 PN64 DN50 ANSI 150 ANSI 300 ANSI 600

A 270 270 290 270 270 290 270 290 270 270 320

B 75 75 75 75 75 75 75 75 75 75 75

C 100 100 100 100 100 100 100 100 100 100 100

D 150 150 150 150 150 150 150 150 150 150 150

E Weight 100 13.0 100 17.0 100 20.0 100 15.0 100 18.0 100 19.0 100 17.0 100 20.0 100 15.0 100 18.0 100 19.0

Spare parts

The spare parts available are detailed below. No other parts are supplied as spares. Available spare Bimetallic assembly kit 5, 7, 8, 9, 10

How to order spares Always order spares by using the description given in the column headed 'Available spare' and state the size and model of the bimetallic steam trap. Example: 1 - Bimetallic assembly kit for a 1" Spirax Sarco ABL405 bimetallic steam trap. Recommended tightening torques Item 4 6 12 13 405, 414, 425 505, 514, 525 440, 540 5 A/F 36 A / F 24 A / F 24 A /F 8 mm socket 100 - 110 70 - 77 120 - 132 10.8 - 13.2 or mm Nm

Safety information, installation and maintenance

For full details see the Installation and Maintenance Instructions (IM-P623-05) supplied with the product.

How to order

Example: 1 off DN40 Spirax Sarco ABL405 bimetallic steam trap with PN40 flanges.

12 10

8 9 13 4 7

5 6

ABL Series Bimetallic Steam Traps

TI-P623-07

ST Issue 2

ABL440, ABL540

5 000 4 000

You might also like

- Forged Steel Valves PDFDocument12 pagesForged Steel Valves PDFDiwakar NigamNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- ANSI TIA EIA 222 G Wind Load CalculationsDocument2 pagesANSI TIA EIA 222 G Wind Load Calculationsasad_naqvi100% (5)

- Maccaferri Soft Soil Stabilization Design SpreadsheetDocument13 pagesMaccaferri Soft Soil Stabilization Design SpreadsheetAlbaro Andres TorricoNo ratings yet

- Flat Slab ExcelDocument6 pagesFlat Slab Excelasad_naqvi67% (3)

- Aspen Plus IGCC ModelDocument19 pagesAspen Plus IGCC ModelSampath Attuluri100% (1)

- Working Environment: Norsok StandardDocument52 pagesWorking Environment: Norsok StandardFoad MirzaieNo ratings yet

- Manual Spirax SarcoDocument2 pagesManual Spirax SarcoAlex CarreraNo ratings yet

- Valve Spirax Sarco 25P Ti-3-015-UsDocument2 pagesValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- 11422Document10 pages11422balajivangaruNo ratings yet

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNo ratings yet

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocument24 pagesDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymNo ratings yet

- Tyco Catalogue NetDocument34 pagesTyco Catalogue NetAhmad Nasser0% (1)

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Purga Fondo BBV 980 A PDFDocument2 pagesPurga Fondo BBV 980 A PDFaugusto7777No ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- Steam TrapDocument2 pagesSteam TrapAmpornchai PhupolNo ratings yet

- Adco Ball ValveDocument20 pagesAdco Ball ValverajeshygawdeNo ratings yet

- AV13 Air Vent For Steam Systems: DescriptionDocument2 pagesAV13 Air Vent For Steam Systems: DescriptionUtku KepcenNo ratings yet

- DBB CatalogueDocument20 pagesDBB Cataloguerawrr90No ratings yet

- PressureDocument84 pagesPressureHangloque GabanoNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- Staal 40: Swing Check ValvesDocument4 pagesStaal 40: Swing Check ValvesEric LarrondoNo ratings yet

- Comeval Cast Steel Gate Valve ANSI 150 PDFDocument5 pagesComeval Cast Steel Gate Valve ANSI 150 PDFblizanacNo ratings yet

- Faslt 0020 enDocument6 pagesFaslt 0020 enshashikanth79No ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- Ep31492 PDFDocument11 pagesEp31492 PDFJilJilNo ratings yet

- Flash Vessel Spirax Sarco FV-FINALDocument3 pagesFlash Vessel Spirax Sarco FV-FINALkawkatr100% (1)

- Valves & Controls: Kunkle Safety and Relief ProductsDocument2 pagesValves & Controls: Kunkle Safety and Relief ProductsgbogboiweNo ratings yet

- ASCO Valve 8345 Spec R2Document2 pagesASCO Valve 8345 Spec R2Calvin HaleyNo ratings yet

- 11502Document9 pages11502balajivangaruNo ratings yet

- CraneDocument32 pagesCranesabes26100% (1)

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- Specification - 9110 - 201510 at Globe (Rev.03)Document10 pagesSpecification - 9110 - 201510 at Globe (Rev.03)Công PhạmNo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- Valve ActuatorDocument8 pagesValve Actuatornixsol75No ratings yet

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoNo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- Ball Valves: For SteamDocument8 pagesBall Valves: For SteamcontorrresjulianNo ratings yet

- Aloyco Stainess Steel ValvesDocument26 pagesAloyco Stainess Steel Valvescristi_molins100% (1)

- Odular YPE A F S AF: IR Ilter EriesDocument9 pagesOdular YPE A F S AF: IR Ilter ErieshadeNo ratings yet

- Valvula Bola Sarco m40Document3 pagesValvula Bola Sarco m40radacoNo ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46No ratings yet

- Boiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSDocument2 pagesBoiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSzarni77No ratings yet

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDocument20 pagesLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimNo ratings yet

- Vctds-02233 Model 171c (Asme) - enDocument12 pagesVctds-02233 Model 171c (Asme) - enDGWNo ratings yet

- Spirax Sarco 25 PDocument2 pagesSpirax Sarco 25 Pmairimsp2003No ratings yet

- Pulse Valves - Turbocontrols - It PDFDocument40 pagesPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanNo ratings yet

- Cast Steel Gate Valve - VS01 (ASME 150)Document4 pagesCast Steel Gate Valve - VS01 (ASME 150)sghinausNo ratings yet

- FlowCon EVS Tech 08.2013Document7 pagesFlowCon EVS Tech 08.2013Jeff Anderson CollinsNo ratings yet

- Pilot Operated Pressure Regulator 6" 25P: Typical ApplicationsDocument2 pagesPilot Operated Pressure Regulator 6" 25P: Typical ApplicationsMatias MancillaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Steel Column Capacity ChecksDocument1 pageSteel Column Capacity Checksasad_naqviNo ratings yet

- HandrailDocument1 pageHandrailasad_naqviNo ratings yet

- Single Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIDocument12 pagesSingle Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIasad_naqvi100% (2)

- In-Line Crushing Device For Pneumatic Conveying System Solves Material Flow Prob/emDocument2 pagesIn-Line Crushing Device For Pneumatic Conveying System Solves Material Flow Prob/emasad_naqviNo ratings yet

- ConnectionDocument7 pagesConnectionasad_naqviNo ratings yet

- Education Summary Form: 1. Personal DetailsDocument2 pagesEducation Summary Form: 1. Personal Detailsasad_naqviNo ratings yet

- Design Guide For Cold Formed Steel Beams With Web Penetration 1 - AISI - USADocument22 pagesDesign Guide For Cold Formed Steel Beams With Web Penetration 1 - AISI - USAasad_naqviNo ratings yet

- Safety Shoes: Work WearDocument1 pageSafety Shoes: Work Wearasad_naqviNo ratings yet

- AM Army Type Trolley HoistDocument2 pagesAM Army Type Trolley Hoistasad_naqviNo ratings yet

- Problem Set 6Document4 pagesProblem Set 6ronaldNo ratings yet

- HP Client Management Interface Technical WhitepaperDocument39 pagesHP Client Management Interface Technical Whitepaperpottytoddy1422No ratings yet

- Final Report 2.0Document22 pagesFinal Report 2.0kunalmpatekar10No ratings yet

- Lec 14 - Chap 8 - RegistersDocument41 pagesLec 14 - Chap 8 - RegistersAliRazaNo ratings yet

- Great ExpectationsDocument5 pagesGreat ExpectationsAnastasia MoraruNo ratings yet

- CV 53001 IntroductionDocument49 pagesCV 53001 IntroductionVictor OmotoriogunNo ratings yet

- Neutral Grounding Resistor (NGR)Document14 pagesNeutral Grounding Resistor (NGR)vennapusa VenkateshNo ratings yet

- Thesis Silpakorn ArchitectureDocument8 pagesThesis Silpakorn Architecturerokafjvcf100% (1)

- Foxconn G41mxe (Rev 1.0)Document34 pagesFoxconn G41mxe (Rev 1.0)alejandro correaNo ratings yet

- Inox Pipelines Method StatementDocument11 pagesInox Pipelines Method StatementIlija RunjajicNo ratings yet

- CKLA Grade 7 Unit 3 Dr. Jekyll and Mr. Hyde ABDocument155 pagesCKLA Grade 7 Unit 3 Dr. Jekyll and Mr. Hyde ABYolanda FrutosNo ratings yet

- (Cultural Memory in The Present) Hent de Vries (Editor) - Samuel Weber (Editor) - Religion and Media-Stanford University Press (2001)Document670 pages(Cultural Memory in The Present) Hent de Vries (Editor) - Samuel Weber (Editor) - Religion and Media-Stanford University Press (2001)Mauricio BaezNo ratings yet

- Contemporary ArtsDocument19 pagesContemporary ArtsMarl Rina EsperanzaNo ratings yet

- Ugc BooksDocument7 pagesUgc BooksNandha KumarNo ratings yet

- Respiration in Plants Class 11 QuestionsDocument3 pagesRespiration in Plants Class 11 QuestionsAshok KumarNo ratings yet

- MasterSeal 940 MasterFlex Aquastop - EngDocument7 pagesMasterSeal 940 MasterFlex Aquastop - EngyounesshammouyouNo ratings yet

- 860 KF Thermoprep: ManualDocument59 pages860 KF Thermoprep: ManualKarla CalderónNo ratings yet

- Environmental Engineering Laboratory Open-Ended Lab ReportDocument13 pagesEnvironmental Engineering Laboratory Open-Ended Lab ReportMaliyana Azmi50% (2)

- Prepared byDocument28 pagesPrepared byshuvobosu262No ratings yet

- Salary Bank Statement 2939Document4 pagesSalary Bank Statement 2939Mohit ChinchkhedeNo ratings yet

- Slab Using Staad ProDocument13 pagesSlab Using Staad ProErnesto SuarezNo ratings yet

- Christmascollbrassquintet PDFDocument269 pagesChristmascollbrassquintet PDFturtle249100% (3)

- United States Patent (16) Patent N6. US 6,564,491 B2Document5 pagesUnited States Patent (16) Patent N6. US 6,564,491 B2edef345No ratings yet

- Normal DistributionDocument4 pagesNormal DistributionSwathi MithaiNo ratings yet

- الملف الشامل للانجليزي للاختبار الفصلي للترم الثاني ١٤٤٣Document87 pagesالملف الشامل للانجليزي للاختبار الفصلي للترم الثاني ١٤٤٣Nawaf AlhussainiNo ratings yet

- Introduction To ANSYS Introduction To ANSYS Icem CFD: WKH 2 1 Workshop 2.1 Mesh Preparation - P Engine BlockDocument20 pagesIntroduction To ANSYS Introduction To ANSYS Icem CFD: WKH 2 1 Workshop 2.1 Mesh Preparation - P Engine Blockgreelmind7584No ratings yet

- Product Bulletin Fisher 846 Electro Pneumatic Transducer en 135686 PDFDocument12 pagesProduct Bulletin Fisher 846 Electro Pneumatic Transducer en 135686 PDFJesus RochaNo ratings yet