Professional Documents

Culture Documents

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanCopyright:

Available Formats

Page 1 of 2

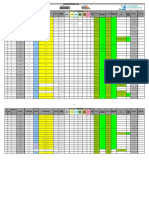

Inspection Date :12 December 2019 Report no : IES-TEPccL-UT-09

Project Name : RPCL(Patuakhali 1320MW) UT Equipment : Soundwel-SUB100

Location : Dhankhali,Patuakhali Range : 0-100

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Pipe Joint Calibration block : IIW V2 Block, Reference block

Materials : SA106B Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Single Vee

Couplent : Lube Oil

ULTRASONIC TEST REPORT

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Pile-mz-1-14 Joint No-05 12 250mm left ward to 14.10 18.60 100% 73.1 A 100.0 6.60 13.00 1.10 Repair Find the defect IP,SL

right

Pile-mz-1-11 Joint No-01 12 380mm left ward to 13.40 21.06 100% 73.1 A 80.0 6.00 12.40 1.00 Repair Find the defect IP,SL

right

Joint No-02 12 500mm left ward to 13.60 18.00 100% 73.1 A 75.0 8.00 13.00 0.60 Repair Find the defect IP,SL

right

Joint No-03 12 210mm left ward to 12.90 17.36 100% 73.1 A 90.0 7.80 12.80 0.10 Repair Find the defect IP,SL

right

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Inspection Date :12 December 2019 Report no : IES-TEPccL-UT-09

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: TEPCCL Witness

Name: Md.Shaharia Alam Name:

IES: ASNT Level –II (Ultrasonic Test) TEPCCL – Field Supervisor

Signature: Signature:

Date: 12/12/2019 Date: 12/12/2019

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

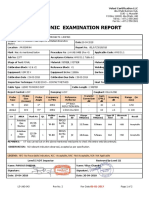

Page 2 of 2

Project Name : RPCL(Patuakhali 1320MW) UT Equipment : Soundwel-SUB100

Location : Dhankhali,Patuakhali Range : 0-100

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Pipe Joint Calibration block : IIW V2 Block, Reference block

Materials : SA106B Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Single Vee

Couplent : Lube Oil

ULTRASONIC TEST REPORT

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Pile-mz-1-14 Joint No-05 12 - - - - 73.1 - - - - - Accepted Satisfactory,After

Recheck

Pile-mz-1-11 Joint No-01 12 - - - - 73.1 - - - - - Accepted Satisfactory,After

Recheck

Joint No-02 12 - - - - 73.1 - - - - - Accepted Satisfactory,After

Recheck

Joint No-03 12 - - - - 73.1 - - - - - Accepted Satisfactory,After

Recheck

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: TEPCCL Witness

Name: Md.Shaharia Alam Name:

IES: ASNT Level –II (Ultrasonic Test) TEPCCL – Field Supervisor

Signature: Signature:

Date: 12/12/2019 Date: 12/12/2019

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

You might also like

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Báo Cáo PTDocument3 pagesBáo Cáo PTSang Nguyen QuangNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- Material Test Report: (Established 1918)Document1 pageMaterial Test Report: (Established 1918)Adrian GalvisNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- !certificate of !calibration: International Agent For"Contracting EstDocument8 pages!certificate of !calibration: International Agent For"Contracting EstZara BhaiNo ratings yet

- Fir Ris-Am-116Document1 pageFir Ris-Am-116ansarmulla711No ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Liquid Penetrant Testing Report: Sievert Emirates Inspection LLCDocument1 pageLiquid Penetrant Testing Report: Sievert Emirates Inspection LLCAvijit DebnathNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Liquid Penetrant Test: Visual Inspection Results: Additional DetailsDocument4 pagesLiquid Penetrant Test: Visual Inspection Results: Additional DetailsWisüttisäk PeäröönNo ratings yet

- Test RequestDocument2 pagesTest RequestAshraf alZeidyNo ratings yet

- Interloop Satellite Stitching Unit: RecommendationDocument13 pagesInterloop Satellite Stitching Unit: RecommendationFraz AhmadNo ratings yet

- Item - 2 - 80. SN - 3499-03-388Document1 pageItem - 2 - 80. SN - 3499-03-388Jhonatan GonzalezNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Work Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionDocument2 pagesWork Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionRejoy Baby100% (1)

- B Punch Rfi Issuing Dated 29-7-2020Document4 pagesB Punch Rfi Issuing Dated 29-7-2020bishalNo ratings yet

- 84518-56 MM RevisedDocument1 page84518-56 MM RevisedDeepak MehtaNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- DQ2 Ine 520TK 051 VBT 001Document2 pagesDQ2 Ine 520TK 051 VBT 001Deepu CNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- QC BLASTING REport 5Document1 pageQC BLASTING REport 5RonNo ratings yet

- WELDING MACHINE ChecklistDocument1 pageWELDING MACHINE Checklistsakthi venkatNo ratings yet

- SSC SA-3564 777 Piston ParkingDocument5 pagesSSC SA-3564 777 Piston ParkingM Ferry AnwarNo ratings yet

- 1.internal Concrete Pour Register Updated On 25-01-2023Document9 pages1.internal Concrete Pour Register Updated On 25-01-2023721917114 47No ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- After Cooler InspectionAE3Document1 pageAfter Cooler InspectionAE3boy qsiNo ratings yet

- Shree Ved Industries India PVT - LTD.: Chemical Composition Grain SizeDocument1 pageShree Ved Industries India PVT - LTD.: Chemical Composition Grain SizeRahul KumarNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Rev. Fecha Descripción Autor Del DocumentoDocument12 pagesRev. Fecha Descripción Autor Del DocumentoJose Carlos Moraga LópezNo ratings yet

- Liquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Document4 pagesLiquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Riesky FirdyanNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalpravinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalDocument4 pagesSaudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalpravinNo ratings yet

- Approved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ADocument131 pagesApproved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ALionell Logesh0% (1)

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Document2 pagesUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENo ratings yet

- Released 208184011 01 Lempb 049Document49 pagesReleased 208184011 01 Lempb 049haifa ayachiNo ratings yet

- RCDR FormatDocument7 pagesRCDR Formatqudrat7khan7devizaiNo ratings yet

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- Process Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Document15 pagesProcess Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Silas OnyekweNo ratings yet

- Hydro TestDocument22 pagesHydro TestPramod GrNo ratings yet

- Equipo: OC: #Doc.: Rev.: Bombas de Pulpa X01780 172-X01780-144-46-DS-002 1Document13 pagesEquipo: OC: #Doc.: Rev.: Bombas de Pulpa X01780 172-X01780-144-46-DS-002 1Jose Carlos Moraga LópezNo ratings yet

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Document1 pagePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNo ratings yet

- PSV Bombas AcpilodosDocument1 pagePSV Bombas AcpilodosJulian Camilo Segura BermudezNo ratings yet

- 30-11-2021 UT ReportDocument3 pages30-11-2021 UT ReportMD Shadikul Huq ShezanNo ratings yet

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh PT Test ReportDocument2 pagesMD - Akibur Sheikh PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- Sujan Das PT Test ReportDocument2 pagesSujan Das PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- UT REport For Nornal Probe Shah CementDocument1 pageUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNo ratings yet

- IES PadDocument1 pageIES PadMD Shadikul Huq ShezanNo ratings yet

- Heder 02 Hydrolic Test Dyeing Floor DistributionDocument4 pagesHeder 02 Hydrolic Test Dyeing Floor DistributionMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh WQTDocument2 pagesMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNo ratings yet

- Heder Boiler Room Hydrolic TestDocument5 pagesHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Help For Report ShezanDocument5 pagesHelp For Report ShezanMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Date Description Serial No Quantity Weight/ PecessDocument12 pagesDate Description Serial No Quantity Weight/ PecessMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Tested by Ies-Industrial Engineering Services: Data and Test SpecimenDocument7 pagesTested by Ies-Industrial Engineering Services: Data and Test SpecimenMD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Ultrasonic Thickness Test ReportDocument3 pagesIes-Industrial Engineering Services: Ultrasonic Thickness Test ReportMD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Air Reciver Vessel-2 (Compressor Unit-2)Document5 pagesAir Reciver Vessel-2 (Compressor Unit-2)MD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Air Reciver Vessel-1 (Compressor Unit-2)Document5 pagesAir Reciver Vessel-1 (Compressor Unit-2)MD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- WeldMetal - GasConsumption-MODI (Version 1)Document239 pagesWeldMetal - GasConsumption-MODI (Version 1)Roshin99No ratings yet

- Hydrometallurgy in Extraction ProcessesDocument40 pagesHydrometallurgy in Extraction ProcessesRon EstolanoNo ratings yet

- Presentation 2019.11.18 NFPA 51B 2018 FormattedDocument44 pagesPresentation 2019.11.18 NFPA 51B 2018 FormattedDandung Yunianto123No ratings yet

- Conformal Cooling For Plastics Injection MouldingDocument5 pagesConformal Cooling For Plastics Injection MouldingAlberto ConzNo ratings yet

- Bibliografia Corrosion 4020Document2 pagesBibliografia Corrosion 4020jcbecerrat5801No ratings yet

- Ips C Pi 270 18 PDFDocument1 pageIps C Pi 270 18 PDFGERAILLYNo ratings yet

- Inspection of HDGDocument56 pagesInspection of HDGPeter FowlesNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- ASME Sec IX Groove To Fillet WeldDocument3 pagesASME Sec IX Groove To Fillet WeldAzhar Ali50% (2)

- 5 - Double Layer Roll Forming MachineDocument6 pages5 - Double Layer Roll Forming MachineJHON SEGURA GONZALEZNo ratings yet

- DIN-En-10083-1-2006 - Steels For Quenching and Tempering - Delivery ConditionsDocument58 pagesDIN-En-10083-1-2006 - Steels For Quenching and Tempering - Delivery ConditionsSebastian PopNo ratings yet

- Naungzh/Jan2009 Chapter 1 - Fire Chemistry 1Document40 pagesNaungzh/Jan2009 Chapter 1 - Fire Chemistry 1S M Hasan100% (1)

- Solid Carbide Spiral 'O' Flute, Aluminum Cutting CNC Router Bits - ToolsToday - Industrial Quality Router BitsDocument7 pagesSolid Carbide Spiral 'O' Flute, Aluminum Cutting CNC Router Bits - ToolsToday - Industrial Quality Router BitsHector InbacuanNo ratings yet

- SUP706 and SUP706B Support Material - EN PolyJet Best PracticeDocument4 pagesSUP706 and SUP706B Support Material - EN PolyJet Best PracticemikermemeNo ratings yet

- En 10051-2010Document16 pagesEn 10051-2010yousab creator2No ratings yet

- Causes and Cures For Shell-CrackDocument7 pagesCauses and Cures For Shell-Crack'Apiz AlexandriaNo ratings yet

- Updated SP-511Document7 pagesUpdated SP-511Feroz GullNo ratings yet

- Interzinc 2265: Product DescriptionDocument4 pagesInterzinc 2265: Product DescriptionIsabelo AbaoNo ratings yet

- 5 60 Lecture23Document4 pages5 60 Lecture23sgybleeNo ratings yet

- Opti CutterDocument2 pagesOpti CutterI-predictionNo ratings yet

- ClassificationDocument2 pagesClassificationjeffkarthick1No ratings yet

- LHV Castable (1-2-4)Document2 pagesLHV Castable (1-2-4)Aleem QureshiNo ratings yet

- Dimensions of PipesDocument4 pagesDimensions of PipesArun babuNo ratings yet

- 302 Epoxy Ester Floor Paint TDSDocument2 pages302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- PDS Simacover Tar Epoxy 3404-00Document4 pagesPDS Simacover Tar Epoxy 3404-00Aulia RahmahNo ratings yet

- Sandvik Part - 6 PDFDocument9 pagesSandvik Part - 6 PDFEliel AbadNo ratings yet

- Concrete Mix DesignsDocument1 pageConcrete Mix DesignsjaymarNo ratings yet

- Calculo Maquinado CuñeroDocument3 pagesCalculo Maquinado Cuñeroluigiv67No ratings yet

- Crosby 1016313 DatasheetDocument1 pageCrosby 1016313 Datasheetedi hendrikusNo ratings yet

- 3rd Summative Test in Science 4Document2 pages3rd Summative Test in Science 4Aranzado RubensonNo ratings yet