Professional Documents

Culture Documents

Color Code For Piping Material Identification

Color Code For Piping Material Identification

Uploaded by

McmiltondmordomOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Color Code For Piping Material Identification

Color Code For Piping Material Identification

Uploaded by

McmiltondmordomCopyright:

Available Formats

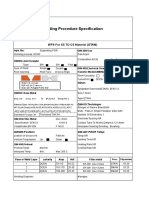

Rev.

DGS 1300 016 1

Page

2 of 7

ABU DHABI GAS INDUSTRIES LTD. (GASCO)

COLOR CODE FOR PIPING MATERIAL IDENTIFICATION

TABLE OF CONTENTS

1. GENERAL .................................................................................................................................................................. 3

1.1 INTRODUCTION............................................................................................................................................................. 3

1.2 PURPOSE..................................................................................................................................................................... 3

1.3 DEFINITIONS ................................................................................................................................................................ 3

2. CODES AND STANDARDS.......................................................................................................................................... 4

3. REFERENCE DOCUMENTS ......................................................................................................................................... 4

4. DOCUMENT PRECEDENCE ........................................................................................................................................ 4

5. SPECIFICATION DEVIATION/CONCESSION CONTROL ................................................................................................ 5

6. SUBSTITUTION ......................................................................................................................................................... 5

7. PAINTING MATERIAL ................................................................................................................................................ 5

8. MARKING REQUIREMENTS....................................................................................................................................... 5

8.1 PIPES .......................................................................................................................................................................... 5

8.2 FITTINGS ..................................................................................................................................................................... 5

8.3 FLANGES - LINE BLINDS - SPACERS .................................................................................................................................... 5

8.4 GASKETS ..................................................................................................................................................................... 6

8.5 DUAL GRADE STAINLESS STEEL ........................................................................................................................................ 6

9. COLOR CODES .......................................................................................................................................................... 6

DGS 1300-016 REV1

Rev.

DGS 1300 016 1

Page

3 of 7

ABU DHABI GAS INDUSTRIES LTD. (GASCO)

COLOR CODE FOR PIPING MATERIAL IDENTIFICATION

1. GENERAL

1.1 Introduction

This specification gives minimum requirements for the color coding of pipe and piping components

for ABU DHABI GAS INDUSTRIES LTD. (GASCO) facilities.

1.2 Purpose

The purpose of this specification is to ensure the consistency in selection of color code for the

piping material identification.

This specification covers the method of identification by color code of pipe, fittings, flanges, gaskets

and line blinds supplied as bulk material.

This specification supplements but does not replace the marking normally required by the relevant

stock code.

Consequently, this specification shall be read in conjunction with the material requisition, stock

code description (if any) or the piping classes and the relevant codes and standards referenced

within.

This specification does not cover:

Piping components as strainers, valves, sight glasses.

Piping materials assembled in equipment and machinery or any other package unit.

Bolting materials.

This specification does not include consideration of the SUPPLIER'S standard, practices or

alternative recommendations. Such deviations shall, however, be clearly stated as "exceptions" for

approval by CONTRACTOR.

If no exceptions are stated at bid stage, it shall be mutually understood that the supplied items will

be in exact accordance with this specification.

1.3 Definitions

Where used in this specification, the following terms shall have the meanings indicated below

unless otherwise clearly indicated by context of their use.

COMPANY – ABU DHABI GAS INDUSTRIES LTD. (GASCO)

CONCESSION REQUEST – A deviation requested by the CONTRACTOR or VENDOR, usually

after receiving the contract package or purchase order. Often, it refers to an authorization to use,

repair, recondition, reclaim, or release materials, components or equipment already in progress or

completely manufactured but which does not meet or comply with COMPANY requirements. A

CONCESSION REQUEST is subject to COMPANY approval.

CONTRACTOR – The party(s) which carry(s) out all or part of the design, engineering,

procurement, construction, commissioning or management of the PROJECT.

MANUFACTURER/VENDOR/SUPPLIER – The party(s) which manufacture(s) and/or supply(s) the

material/equipment, and provide(s) technical documents/drawings and services to perform the

duties specified by COMPANY/CONTRACTOR.

SUBCONTRACTOR/SUBVENDOR/SUBSUPLLIER – The party(s) which carry(s) out all or part of

the design, procurement, installation and testing of the System(s) as specified by the

SUBCONTRACTOR/VENDOR.

DRAWINGS – Drawings provided by the CONTRACTOR/VENDOR.

DGS 1300-016 REV1

Rev.

DGS 1300 016 1

Page

4 of 7

ABU DHABI GAS INDUSTRIES LTD. (GASCO)

COLOR CODE FOR PIPING MATERIAL IDENTIFICATION

PROJECT – (To be defined)

SHALL – Indicates a mandatory requirement.

SHOULD - Indicates a strong recommendation.

2. CODES AND STANDARDS

The following codes and standards, to the extent specified herein, form a part of this specification.

When an edition date is not indicated for a code or standard, the latest edition in force at the time of

contract award shall apply.

BRITISH STANDARDS INSTITUTE (BSI)

BS 4800 Paint colors for Building Purposes

BS 5383 Material Identification of Steel, Nickel Alloy and Titanium Alloy Tubes

by Continuous Character Marking and Color Coding of Steel Tubes

AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME)

ASME B16.20 Metallic gaskets for pipe flanges - Ring joints spiral-wound and

jacketed

INTERNATIONAL STANDARDS ORGANIZATION (ISO)

BS EN ISO 9001 Quality Management Systems - Requirements.

BS EN ISO 9004 Quality Management Systems – Guidelines for Performance

Improvements

3. REFERENCE DOCUMENTS

The following reference documents, to the extent specified herein, form a part of this specification.

When an edition date is not indicated for a document, the latest edition in force at the time of the

project execution shall apply.

Design General Specifications

DGS 1300 015 Pipes and Piping components

DGS 6600-010 Painting

4. DOCUMENT PRECEDENCE

It shall be the CONTRACTOR, Manufacturer, or Vendor’s responsibility to be knowledgeable of the

requirements of the referenced Codes and Standards.

The VENDOR shall notify the CONTRACTOR of any apparent conflict between this specification,

the related data sheets, the Codes and Standards and any other specifications noted herein.

Resolution and/or interpretation precedence shall be obtained from the COMPANY in writing before

proceeding with the design/manufacture.

In cases of conflict, the order of precedence shall be:

Material requisition,

Stock code description (if any),

This specification,

Referenced codes and standards

DGS 1300-016 REV1

Rev.

DGS 1300 016 1

Page

5 of 7

ABU DHABI GAS INDUSTRIES LTD. (GASCO)

COLOR CODE FOR PIPING MATERIAL IDENTIFICATION

5. SPECIFICATION DEVIATION/CONCESSION CONTROL

Deviations from this specification are only acceptable where the MANUFACTURER has listed in his

quotation the requirements he cannot, nor does not wish to comply with, and the

COMPANY/CONTRACTOR has accepted in writing the deviations before the order is placed.

In the absence of a list of deviations, it will be assumed that the MANUFACTURER complies fully

with this specification.

Any technical deviations to the Purchase Order and its attachments, such as, the Data Sheets and

Narrative Specifications shall be obtained by the CONTRACTOR only through CONCESSION

REQUEST format. CONCESSION REQUESTS require the COMPANY’S review/approval prior to

the changes being implemented. Technical changes implemented prior to COMPANY approval is

subject to rejection.

6. SUBSTITUTION

In case of material substitution, color identification of basic material shall be applied (substitution to

be approved by CONTRACTOR).

7. PAINTING MATERIAL

The paint used for color coding shall be free of metallic pigments particularly the paint used for

marking of austenitic stainless steels shall not have any properties detrimental to the component for

example shall not contain any tin, copper, lead and zinc, neither shall the paint be chlorinated

rubber. Refer DGS-6600-010-A.

8. MARKING REQUIREMENTS

Surface to be color coded shall be clean, dry, and free from grease, rust, scale or other foreign

matter.

Color coding can be applied on sound primer.

Flange faces and ends of materials to be welded shall not be painted.

Color painting shall not interfere with permanent marking.

8.1 Pipes

The color shall be applied as a full length stripe within the same quadrant as the character marking

required by material specification.

Stripe will stop about 50 mm before the weld bevel.

The minimum width of stripe shall be

Pipe diameter over 1" = 12 mm

Pipe diameter 1" and lower = 9 mm

8.2 Fittings

Diameter 6" and above = same as for pipes

Diameter 4" and smaller = each fitting shall be marked one side with a color spot 12 mm

diameter minimum.

8.3 Flanges - Line blinds - Spacers

They shall be marked on the outside edge full thickness. Width of stripe shall be 12 mm minimum.

Care shall be taken to avoid color painting on flange gasket surfaces, weld bevel or any surface

intended for welding.

DGS 1300-016 REV1

Rev.

DGS 1300 016 1

Page

6 of 7

ABU DHABI GAS INDUSTRIES LTD. (GASCO)

COLOR CODE FOR PIPING MATERIAL IDENTIFICATION

8.4 Gaskets

Spiral wound gaskets

Spiral wound gaskets shall be color coded on the outside edge of the centering ring in full

accordance with ASME B16-20.

Other type of gaskets shall not be color-coded.

8.5 Dual Grade Stainless Steel

In addition to the Safety/Process identification color codes, for DUAL GRADE 316/316L piping, the

color code in Section 9.0 of this specification shall be transferred to the finished pipe. A band

denoting DUAL GRADE shall be within 0.5m of the Safety/Process identification color code band.

9. COLOR CODES

CARBON STEEL (standard) A 106 Gr B NONE

A 672 Gr C 60 Cl 23

A 234 Gr WPB & WPB-W

A 105

A 516 Gr 70

GALVANIZED CARBON STEEL ALL NONE

ALUMINIZED CARBON STEEL ALL RED

(04-E-51)

CARBON STEEL PWHT A 672 Gr C 60 Cl 22 YELLOW

A 234 Gr WPB-W PWHT (10-E-53)

CARBON STEEL API 5L Gr.X60 GREY

MSS SP75 WPHY (00-A-05)

A694 Gr F60

CARBON STEEL SOUR SERVICE A 106 Gr B SS WHITE

(00-E-55)

A 672 Gr C 60 SS Cl 22

A 234 Gr WPB & WPB-W SS

A 105 SS

A 516 Gr 65 SS

A 516 Gr 65 SS + S5

LOW TEMPERATURE A 333 Gr 6 LIGHT GREEN

CARBON STEEL A 671 Gr CC 60 Cl 23 + S2 (14-E-51)

A 420 Gr WPL6 & WPL6 W

A 350 Gr LF2

A 516 Gr 70 + S5

A 671 Gr CC 60 Cl 22 + S2

LOW TEMPERATURE A 333 Gr 6 SS BROWN

DGS 1300-016 REV1

Rev.

DGS 1300 016 1

Page

7 of 7

ABU DHABI GAS INDUSTRIES LTD. (GASCO)

COLOR CODE FOR PIPING MATERIAL IDENTIFICATION

CARBON STEEL SOUR SERVICE A 420 Gr WPL6 & WPL6 W SS (06-D-45)

A 350 Gr LF2 SS

A 516 Gr 70 + S5 SS

A 671 Gr CC 60 Cl 22 + S2 SS

SUPER AUSTENITIC STEEL A 312 UNS S31254 RED

A 182 F44 (04-C-33)

A 403 WPS S31254

A 240 UNS S31254

INCOLOY 825 B 423 UNS N08825 YELLOW

B 425 UNS N08825 (10-E-49)

B 366 UNS N08825

STAINLESS STEELS A 312 Gr TP 316 L BLACK

A 403 Gr WP316 L & WP-WX316L (00-E-53)

A 182 Gr F316 L

A 240 Gr TP 316 L

A 312 Gr TP 347 GREEN

A 358 Gr TP 347 Cl 1 (14-E-53)

A 403 Gr WP-S347 & WP-WX347

A 182 Gr F347

A 240 Gr TP 347

STAINLESS STEEL A312 Gr. TP316/316L-S & WX GREEN-YELLOW

(DUAL GRADE) A358 Gr. TP316/316L Cl 1 (12-E-53)

A403 Gr. WP316/316L-S

&WP316/316L-WX

A182 Gr. F316/316L

A240 Gr. TP316/316L

A358 Gr. TP316/316L Cl 2 BLACK (00-E-53)

STAINLESS STEEL A358 Gr. TP316 Cl 1 GREEN-YELLOW

A358 Gr. TP316 Cl 2 (12-E-53)

ALLOY STEELS A 335 Gr P11 BLUE

A 691 Gr 1 1/4 Cl 22 (18-E-50)

A 234 Gr WP11 & WP11-W Cl 1

A 182 Gr F11 Cl 2

A 387 Gr 11 Cl 2

DGS 1300-016 REV1

You might also like

- Itp For FastenersDocument1 pageItp For FastenersSuraj ShettyNo ratings yet

- API Standard 660: Shell-and-Tube Heat ExchangersDocument3 pagesAPI Standard 660: Shell-and-Tube Heat ExchangersJessy Prior0% (2)

- Bentley Autopipe v8 CrackDocument3 pagesBentley Autopipe v8 CrackAdi M. Mutawali100% (2)

- U1CDocument4 pagesU1CAdriana HernandezNo ratings yet

- 175 170200Document2 pages175 170200Vijay BhaleraoNo ratings yet

- Case StudyDocument5 pagesCase StudyChris VNo ratings yet

- M16 M4 Service Rifle FamiliarizationDocument16 pagesM16 M4 Service Rifle FamiliarizationAnonymous mcJZ1wVX89No ratings yet

- Band 6 Eit ExampleDocument37 pagesBand 6 Eit Exampleapi-294518117100% (1)

- PT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)Document3 pagesPT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)lailatul kodriNo ratings yet

- GTL-81-01 Rev 03 Protective CoatingsDocument36 pagesGTL-81-01 Rev 03 Protective CoatingsPurush Purush100% (1)

- Piston ValveDocument28 pagesPiston ValveDamien BouticourtNo ratings yet

- API 5L GR.B SteelDocument2 pagesAPI 5L GR.B SteelYosua Rielys PNo ratings yet

- NB-T 47003.1-2009 钢制焊接常压容器Document92 pagesNB-T 47003.1-2009 钢制焊接常压容器Yu Chen100% (1)

- PD CR 12952-17-2002Document24 pagesPD CR 12952-17-2002navaronefraNo ratings yet

- EN 10213 Material SpecificationsDocument1 pageEN 10213 Material Specifications김창배No ratings yet

- Material P Group Table 4 PDFDocument1 pageMaterial P Group Table 4 PDFshantilalNo ratings yet

- Sleeve CoatingDocument30 pagesSleeve Coatingmusheer100% (1)

- Cahier de Soudage G 11950 - Ver B - WPS 14Document1 pageCahier de Soudage G 11950 - Ver B - WPS 14YassineElabdNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- 08chapter6 ShaftfixingsDocument12 pages08chapter6 Shaftfixingsreinaldosidejunior100% (1)

- C0M-07 FRP Tank-VesselDocument2 pagesC0M-07 FRP Tank-VesselHong Trung DuongNo ratings yet

- WSA 109 - 2011 Flange Gaskets Working SheetDocument1 pageWSA 109 - 2011 Flange Gaskets Working SheetAbit BronjaNo ratings yet

- Socket and Butt FusionDocument39 pagesSocket and Butt FusionMurugesan JeyaramanNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix Terbarufebri100% (1)

- P02-S01 Rev 5 Sep 2021 Piping Material Specifications For Process FluidsDocument21 pagesP02-S01 Rev 5 Sep 2021 Piping Material Specifications For Process FluidsMohamed AdelNo ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981No ratings yet

- Siemens: 1200 MW DGEN Mega Power ProjectDocument4 pagesSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNo ratings yet

- Deaerators BrochureDocument4 pagesDeaerators BrochurefahimshkNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Method Statement OF Air Blowing / Water Flushing of PipesDocument19 pagesMethod Statement OF Air Blowing / Water Flushing of Pipesarun kumar100% (1)

- JIS B8363 60 Cone Hose Adapter Fittings CataloguDocument30 pagesJIS B8363 60 Cone Hose Adapter Fittings CataloguCGM MechanicalNo ratings yet

- 2019 Section I ChangesDocument57 pages2019 Section I ChangesDonChincheNo ratings yet

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchNo ratings yet

- Garnituri DIN 2697Document12 pagesGarnituri DIN 2697Dumitru SorinaNo ratings yet

- Soft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesDocument4 pagesSoft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesEduardoNo ratings yet

- Letter For Testing of PQRDocument1 pageLetter For Testing of PQRPA PROJECTS PVT LTDNo ratings yet

- Color Coding 005 Rev 03Document16 pagesColor Coding 005 Rev 03megastar0604100% (1)

- 20G Boiler Steel Pipe PDFDocument5 pages20G Boiler Steel Pipe PDFHeza FirdausNo ratings yet

- MSS SP 25 Marking System For Valves PDFDocument29 pagesMSS SP 25 Marking System For Valves PDFMariano Emir Garcia OdriozolaNo ratings yet

- Standart Cina Untuk WeldingDocument52 pagesStandart Cina Untuk Weldingandristy90No ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- SA 516 Gr60Document8 pagesSA 516 Gr60Mohammad HassanNo ratings yet

- A F E S: Process Piping 670.200Document17 pagesA F E S: Process Piping 670.200puwarin najaNo ratings yet

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyNo ratings yet

- Rockwool Insulation LRB MatressDocument1 pageRockwool Insulation LRB MatressJaveed KhanNo ratings yet

- Covered Electrodes For Stainless Steel: Avesta Electrodes Product ProgrammeDocument4 pagesCovered Electrodes For Stainless Steel: Avesta Electrodes Product Programmekamals55No ratings yet

- Table QW-253 Welding Variables Procedure Specifications (WPS) - Shielded Metal-Arc Welding (SMAW)Document2 pagesTable QW-253 Welding Variables Procedure Specifications (WPS) - Shielded Metal-Arc Welding (SMAW)BabarNo ratings yet

- 09 154 155 Standards in Pipeline ConstructionDocument2 pages09 154 155 Standards in Pipeline ConstructionRjeb mohamedNo ratings yet

- Discussion Point With LT - Packinox Bundle Replacement (VA) PDFDocument113 pagesDiscussion Point With LT - Packinox Bundle Replacement (VA) PDFAjadNo ratings yet

- Pfi ListDocument3 pagesPfi Listalay2986100% (1)

- Wem Pu 6089 A PDFDocument74 pagesWem Pu 6089 A PDFolalekanNo ratings yet

- I Object: Repair Procedure For Tank BottomDocument6 pagesI Object: Repair Procedure For Tank BottomZouhair BenmabroukNo ratings yet

- L1 34258 en T Union S 2 - UV 418 TT en MDPK 5aDocument2 pagesL1 34258 en T Union S 2 - UV 418 TT en MDPK 5aKrishna VachaNo ratings yet

- DGS 2020-003 REV 2 - Wood & PlasticsDocument11 pagesDGS 2020-003 REV 2 - Wood & PlasticscarloNo ratings yet

- DGS 2020-001 REV 2 - MasonryDocument13 pagesDGS 2020-001 REV 2 - MasonrycarloNo ratings yet

- Internal Cleaning of PipingDocument14 pagesInternal Cleaning of PipingMcmiltondmordomNo ratings yet

- 1300-060 REV 1 - Feb 2011Document15 pages1300-060 REV 1 - Feb 2011Tarik SerbesNo ratings yet

- DGS 1300 160 Bolt TorquingDocument12 pagesDGS 1300 160 Bolt TorquingMcmiltondmordom100% (1)

- DGS 1482-004 REV 2 - Geotechnical InvestigationDocument13 pagesDGS 1482-004 REV 2 - Geotechnical InvestigationcarloNo ratings yet

- DGS 0710-002 Rev 2Document15 pagesDGS 0710-002 Rev 2Mahmoud GamalNo ratings yet

- Internal Cleaning of PipingDocument14 pagesInternal Cleaning of PipingMcmiltondmordomNo ratings yet

- DGS 1300 160 Bolt TorquingDocument12 pagesDGS 1300 160 Bolt TorquingMcmiltondmordom100% (1)

- Galvanizing ProcedureDocument11 pagesGalvanizing ProcedureMcmiltondmordomNo ratings yet

- Shop InvestigationDocument10 pagesShop InvestigationMcmiltondmordomNo ratings yet

- Fisher Optimized Antisurge Control Valves: High Reliability To Meet World-Class Production DemandsDocument12 pagesFisher Optimized Antisurge Control Valves: High Reliability To Meet World-Class Production DemandsBeomHee LeeNo ratings yet

- Btech It Curriculum Reg2015 PDFDocument362 pagesBtech It Curriculum Reg2015 PDFParth GuptaNo ratings yet

- Science Technology and Society: International School of Technology, Arts and Culinary of Davao City INCDocument83 pagesScience Technology and Society: International School of Technology, Arts and Culinary of Davao City INCLore StefanNo ratings yet

- Poljoprivredni TraktoriDocument13 pagesPoljoprivredni TraktoriDražan MiloložaNo ratings yet

- Mks - TksDocument12 pagesMks - TksNguyen Duong HieuNo ratings yet

- 3D Game Studio A4 ManualDocument14 pages3D Game Studio A4 ManualMichael KrisNo ratings yet

- Account Statement From 3 Jul 2018 To 3 Jan 2019: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument8 pagesAccount Statement From 3 Jul 2018 To 3 Jan 2019: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceGopagani DharshanNo ratings yet

- 11th Assessment Scheme Model PaperDocument19 pages11th Assessment Scheme Model PaperMushtaqAnsariNo ratings yet

- Numerical-Experimental Assessment of Stress Intensity Factors in Ultrasonic Very-High-Cycle Fatigue (VHCF)Document26 pagesNumerical-Experimental Assessment of Stress Intensity Factors in Ultrasonic Very-High-Cycle Fatigue (VHCF)mohamadNo ratings yet

- G2 - Afga Graphic - Technologies and ProductsDocument103 pagesG2 - Afga Graphic - Technologies and Products331623468No ratings yet

- Provaset 2P - #Provaset2PDocument2 pagesProvaset 2P - #Provaset2PICOdata GmbHNo ratings yet

- Sliding Sleeves Catalog Evolution Oil ToolsDocument35 pagesSliding Sleeves Catalog Evolution Oil ToolsEvolution Oil Tools100% (1)

- Dale Hunt 80 MeterDocument7 pagesDale Hunt 80 MeterbuffeNo ratings yet

- B.O.Q As Approved by NTPC of Package-V As On 06.05.2011Document102 pagesB.O.Q As Approved by NTPC of Package-V As On 06.05.2011Baren RoyNo ratings yet

- Dra10 Series: 10W Ul / Cul / Tuv / CeDocument3 pagesDra10 Series: 10W Ul / Cul / Tuv / CeHector0412No ratings yet

- PowerDocument152 pagesPowerAkshaya kumar mohantyNo ratings yet

- Control Mouse Using Hand Gesture and VoiceDocument10 pagesControl Mouse Using Hand Gesture and VoiceIJRASETPublicationsNo ratings yet

- Standard Turnouts PDFDocument8 pagesStandard Turnouts PDFfbturaNo ratings yet

- OP15 Manual Pages 2023Document44 pagesOP15 Manual Pages 2023Mónyka Martín MenaNo ratings yet

- Kawasaki: 2003 Kawasaki Z1000 (ZR1000-A1)Document61 pagesKawasaki: 2003 Kawasaki Z1000 (ZR1000-A1)Patti NealonNo ratings yet

- Thermal Shield STS - 584728main Wings-Ch4b-Pgs182-199 PDFDocument18 pagesThermal Shield STS - 584728main Wings-Ch4b-Pgs182-199 PDFdiegobhiNo ratings yet

- Tugas 2 - PPT PMK - Asphalt PaverDocument29 pagesTugas 2 - PPT PMK - Asphalt PaveryuliaNo ratings yet

- Best Practices For Exception HandlingDocument9 pagesBest Practices For Exception Handlingshil.kamal100% (22)

- GroundingDocument11 pagesGroundingKandasamyNo ratings yet

- AB0001Document11 pagesAB0001SMNo ratings yet

- Ramjets & Pulse JetsDocument10 pagesRamjets & Pulse JetsInterogator5No ratings yet

- Matlab Code For QPSKDocument3 pagesMatlab Code For QPSKVikramaditya Reddy100% (1)