Professional Documents

Culture Documents

JSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.

JSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.

Uploaded by

mehtab uddinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.

JSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.

Uploaded by

mehtab uddinCopyright:

Available Formats

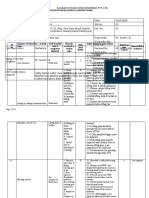

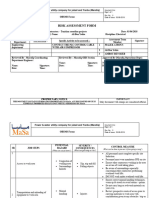

Classification: Internal Use

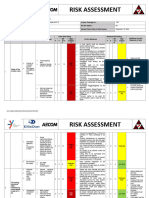

OPERATIONS MANAGEMENT SYSTEM OMS No. SHEM02.02

Rev. # (1) Date July 2021

SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA Next review Date June 2024

Format

Page 1 of 3

JOB SAFETY ANALYSIS (to be filled out by Operations/Maintenance Staff or Group Leader together with JSA Team Members)

Area: Job Description: To do work JSA number: Requester name:

on Concrete mixer, Concrete pump,

vibrator, De-watering pump.

Job Location: Mention Applicable Procedures:

Team Leader: Dept: Use additional sheets if necessary.

Name & ID: Date: Attachments: Yes / No If Yes state number of pages:

No. Job Steps Potential Hazards Risk Level Steps to Reduce Hazard Remaining Risk Level

1. Ground for mixture ma-

chine should be leveled

a) Tilting of mixture properly so that the ma-

machine. chine can rest firmly.

2. All rotating parts like

1 Manual concreting gears, chains & rollers

should be guarded or bar-

b) Workers may come

ricaded.

in contact with the

rotating parts of

the machines Fall of mixture hopper

hoist & anchoring break

will be checked & ad-

justed.

2 Concreting with ready mix Injury due to unsafe 1. Speed limit should be

concrete driving of transit more than 15 kmph.

mixture 2. Proper ramp for concrete

unloading in bucket/pump

should be provided.

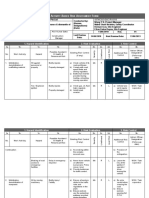

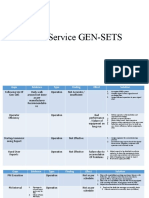

Classification: Internal Use

OPERATIONS MANAGEMENT SYSTEM OMS No. SHEM02.02

Rev. # (1) Date July 2021

SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA Next review Date June 2024

Format

Page 2 of 3

No. Job Steps Potential Hazards Risk Level Steps to Reduce Hazard Remaining Risk Level

3. One signal man should be

deputed for proper signal-

ing.

Adequate turning area

and end stoppage for

transit mixer should be

provided.

a) Worker may come 1. All rotating parts should

in contact with the be barricaded /guarded.

3 De-watering rotating parts of 2. Earthing & other electrical

machine. line should be checked

b) Electric Shock before operation.

Vibrator shall be properly

4 Use of Vibrator Electric shock earthed and cable joints

should be avoided.

1. Trained person should be

deployed for vibration ac-

tivity.

Excessive vibration 2. Proper supervision should

5 Placing of Concrete directional charge be ensured.

Technical specification

should be strictly fol-

lowed.

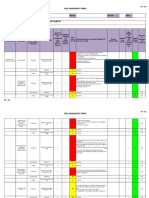

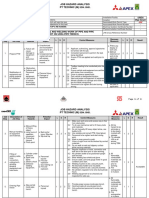

Section A: JSA Preparation /review Section B: JSA Approval

Classification: Internal Use

OPERATIONS MANAGEMENT SYSTEM OMS No. SHEM02.02

Rev. # (1) Date July 2021

SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA Next review Date June 2024

Format

Page 3 of 3

1- Team Leader (PK maintenance / execution Supervisor): I have led the JSA team 5-Approved by Maintenance \Technical Manager

during the preparation phase and I have agreed to the highlighted risks, mitigation

Name & ID: Dept:

actions and listed steps of this JSA

Sign: Date:

Name & ID: Dept:

Sign: Date:

2-Contractor/Operator/Technician: I have reviewed and agreed with all steps of this 6-Acknowledged by Area Operation \ Owner Manager

JSA

Name & ID: Dept:

Name & ID: Dept:

Sign: Date:

Sign: Date:

Name & ID: Dept: 7-Approved by Department Sr. Manager: (Only required if any of the remaining

risks is higher than Insignificant)

Sign: Date:

Name & ID: Dept:

Name & ID: Dept:

Sign:

Sign: Date:

3-Operation Supervisor: I have reviewed and agreed with all steps of this JSA 8- Acknowledged by Director (Only required if any of the remaining risks is either

Significant or Major).

Name & ID: Dept:

Name & ID: Sign: Date:

Sign:

4-EHSS representative: I have reviewed and agreed with all steps of this JSA 8- Approved by President: (Only required if any of the remaining risks is either

Significant or Major).

Name & ID: Dept:

Name & ID: Sign: Date:

Sign: Date:

You might also like

- Job Safety Analysis For Pipeline WeldingDocument4 pagesJob Safety Analysis For Pipeline WeldingImranuddin Syed83% (6)

- Risk Assessment For Installation & Testing Commissioning of PumpsDocument17 pagesRisk Assessment For Installation & Testing Commissioning of PumpsAnandu Ashokan80% (10)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan80% (5)

- Lifting Risk AssessmentDocument4 pagesLifting Risk AssessmentMohamedSaid100% (2)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Hik CentralDocument70 pagesHik CentralQuocKhanh PhạmNo ratings yet

- SopDocument2 pagesSopAndrew MartinNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanNo ratings yet

- Scaffolding Erection and DismantlingDocument14 pagesScaffolding Erection and DismantlingDylan GreyNo ratings yet

- 1.08 Navigation in Restricted VisibilityDocument7 pages1.08 Navigation in Restricted Visibilitypokoko33% (3)

- RRLDocument24 pagesRRLKarlaNo ratings yet

- RA INSTALLATION Electrical PannelDocument7 pagesRA INSTALLATION Electrical PannelAmrou Ben RjebNo ratings yet

- Risk Assessment - CableDocument6 pagesRisk Assessment - Cablemohamad hafiz0% (2)

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- GrindingDocument1 pageGrindingRohit SinghNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectiondeepakkumaryadav841441No ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Units Vehicle Forklift Use For Loading & Unloading Material.Document5 pagesMSHEM-02.11-C Level 2 JSA - Veolia - RO Units Vehicle Forklift Use For Loading & Unloading Material.Abdullah AbedNo ratings yet

- Demolition WorksDocument9 pagesDemolition WorksSuriya Prakash.mNo ratings yet

- Connect The PLC Control Cable With Air CompressorDocument5 pagesConnect The PLC Control Cable With Air CompressorAmrou Ben RjebNo ratings yet

- Risk Assessment - Vessel InstallationDocument5 pagesRisk Assessment - Vessel InstallationKono Nor AtanNo ratings yet

- Swing Grinding JhaDocument6 pagesSwing Grinding JhaDwitikrushna RoutNo ratings yet

- JSA Formet New Hydrotesting WorkDocument5 pagesJSA Formet New Hydrotesting Worksakthi venkatNo ratings yet

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- GOVBUS g3 5Document6 pagesGOVBUS g3 5Ivan Jay EsminoNo ratings yet

- SOP For Manual Loading of Ore - 19Document7 pagesSOP For Manual Loading of Ore - 19syed aquibNo ratings yet

- Persons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityDocument4 pagesPersons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityFaisal RazaNo ratings yet

- Example JSA Job Safety AnalysisDocument13 pagesExample JSA Job Safety AnalysisSiti MaisarahNo ratings yet

- Extracted Pages From 1NHDA15-RUDN-08-CCC-ST-MES-00004-A-METHOD STATEMENT FOR INSTALLING OF SKI - SEGMENT.01Document21 pagesExtracted Pages From 1NHDA15-RUDN-08-CCC-ST-MES-00004-A-METHOD STATEMENT FOR INSTALLING OF SKI - SEGMENT.01Sreejith SureshNo ratings yet

- Field Service GEN-SETSDocument6 pagesField Service GEN-SETSJoeNo ratings yet

- Operations Management System: SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA FormatDocument11 pagesOperations Management System: SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA Formatmehtab uddinNo ratings yet

- HIRA - Pier ArmDocument14 pagesHIRA - Pier ArmBhagat DeepakNo ratings yet

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- 03 - HIRARD Piling WorkDocument3 pages03 - HIRARD Piling WorkJames JoviNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Hot Work: Job Hazard Analysis PT Technic (M)Document4 pagesHot Work: Job Hazard Analysis PT Technic (M)ShahrizatSmailKassim100% (1)

- HIRA Cage Ladder & Life Line Installation01Document3 pagesHIRA Cage Ladder & Life Line Installation01R. Ayyanuperumal Ayyanuperumal100% (1)

- Jsa Unloading LoadingDocument2 pagesJsa Unloading LoadingRais ZaynNo ratings yet

- HSE-TBRA-OP15 - Offloading Riser To Storage Yard & Dismantling of RiserDocument5 pagesHSE-TBRA-OP15 - Offloading Riser To Storage Yard & Dismantling of Riserhseassistant.cgaNo ratings yet

- Team (Formal) JSA: Job Safety AnalysisDocument1 pageTeam (Formal) JSA: Job Safety AnalysisSujeed AbdulNo ratings yet

- Project Risk Assessment For Design and ConstructionDocument32 pagesProject Risk Assessment For Design and ConstructionAjas Aju100% (33)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- Doc5.hirard PilingDocument3 pagesDoc5.hirard PilingJames JoviNo ratings yet

- JHA - MISPL-TEIPL-SEIPL-CIV-JHA-002 - Area Development & Office MobilizationDocument14 pagesJHA - MISPL-TEIPL-SEIPL-CIV-JHA-002 - Area Development & Office MobilizationAvesh ChauahanNo ratings yet

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Document5 pagesOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibNo ratings yet

- Waterproofing Risk AssessmentDocument8 pagesWaterproofing Risk AssessmentEnahs ZedlaumorNo ratings yet

- Construction of Masjid and CafeteriaDocument10 pagesConstruction of Masjid and CafeteriaFaisal RazaNo ratings yet

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Document3 pagesRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanNo ratings yet

- HIRADC GGC - StructureDocument6 pagesHIRADC GGC - Structurefarizal EnterpriseNo ratings yet

- HIRA - Pier ConstructionDocument8 pagesHIRA - Pier ConstructionMMRDACA07 SAFETYNo ratings yet

- RA - Excavation REV.001Document4 pagesRA - Excavation REV.001awadudalhassanNo ratings yet

- HS017 - Risk - Management - Form - Pump UnitDocument5 pagesHS017 - Risk - Management - Form - Pump UnitHenry OkoyeNo ratings yet

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- Risk Assessment/ JSA Lifting &rigging OperationDocument5 pagesRisk Assessment/ JSA Lifting &rigging Operationuz9143895No ratings yet

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- ER06 BunkeringDocument2 pagesER06 BunkeringNang D. VuNo ratings yet

- HIRARC - Working at HeightDocument3 pagesHIRARC - Working at HeightAmpala Vanan100% (1)

- Marafiq Risk Assessment 02Document5 pagesMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- JSA - Undergound MappingDocument2 pagesJSA - Undergound Mappingshamierrul shahliNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Ashraf Ul Hidaya Vol 07 BG KKK QANNNON KDocument267 pagesAshraf Ul Hidaya Vol 07 BG KKK QANNNON Kmehtab uddinNo ratings yet

- Gharelo Ilaj KTKKKSB HHSDocument44 pagesGharelo Ilaj KTKKKSB HHSmehtab uddinNo ratings yet

- AL - TAdawoood FansDocument775 pagesAL - TAdawoood Fansmehtab uddinNo ratings yet

- BSKCKSDHFKJHJDSSHJJDSJJFDocument256 pagesBSKCKSDHFKJHJDSSHJJDSJJFmehtab uddinNo ratings yet

- Chemistry - PG-Course BookDocument22 pagesChemistry - PG-Course Bookmehtab uddinNo ratings yet

- Faizan e MuhabbatDocument297 pagesFaizan e Muhabbatmehtab uddinNo ratings yet

- Operations Management System: SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA FormatDocument11 pagesOperations Management System: SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA Formatmehtab uddinNo ratings yet

- Mehtab CV and PDFDocument22 pagesMehtab CV and PDFmehtab uddinNo ratings yet

- Daily Tool Box TalkDocument55 pagesDaily Tool Box Talkmehtab uddin100% (1)

- Excavation Work and SurvaingDocument5 pagesExcavation Work and Survaingmehtab uddinNo ratings yet

- Operations Management System: SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA FormatDocument2 pagesOperations Management System: SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA Formatmehtab uddinNo ratings yet

- JSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document12 pagesJSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)mehtab uddinNo ratings yet

- Planning Analysis and Design of SubwayDocument3 pagesPlanning Analysis and Design of SubwaySoundhar Thala ThalaNo ratings yet

- Mano SettuDocument7 pagesMano SettuRobert RajuNo ratings yet

- Sales Director in Columbus OH Resume Nick StathopoulosDocument2 pagesSales Director in Columbus OH Resume Nick StathopoulosNickStathopoulosNo ratings yet

- AR5700D USER ManualDocument68 pagesAR5700D USER ManualJuan GarciaNo ratings yet

- Software Requirements Specification: Version 1.0 ApprovedDocument5 pagesSoftware Requirements Specification: Version 1.0 ApprovedIT002 Bhavya antalaNo ratings yet

- Serdi 4.5Document4 pagesSerdi 4.5Yeam_90No ratings yet

- Microwave Engineering and Antennas: OPEN EMS (Alternative For CST)Document10 pagesMicrowave Engineering and Antennas: OPEN EMS (Alternative For CST)Amit GhoshNo ratings yet

- Vacuum Circuit Breaker 8 BK 80 36 KVDocument2 pagesVacuum Circuit Breaker 8 BK 80 36 KVranjan kumarNo ratings yet

- TIA SS7 TT SSN Website Repository Proc TablesDocument8 pagesTIA SS7 TT SSN Website Repository Proc TablesArun VermaNo ratings yet

- 4 Location of Hydraulic Components PDFDocument10 pages4 Location of Hydraulic Components PDFwesley candidoNo ratings yet

- 01-IGDOM Workbook M4L1Document4 pages01-IGDOM Workbook M4L1Jerry CardishNo ratings yet

- Modelo Mk6ES - PQ Reference Manual.U08.3Document66 pagesModelo Mk6ES - PQ Reference Manual.U08.3Mario Vladimir Suarez ChanchayNo ratings yet

- Algorithmic Problem SolvingDocument27 pagesAlgorithmic Problem SolvingMuhammad hanzlaNo ratings yet

- Omnii XT15 User GuideDocument350 pagesOmnii XT15 User GuideHunter HemsleyNo ratings yet

- Essay PibmDocument2 pagesEssay Pibmpriyanshi srivastavaNo ratings yet

- BIOS Vs UEFI-WPS OfficeDocument10 pagesBIOS Vs UEFI-WPS OfficeElvin Cagas100% (1)

- Wsne ConsultingDocument12 pagesWsne Consultingarun ranaNo ratings yet

- Codigo Ansi de Funciones de ProteccionesDocument5 pagesCodigo Ansi de Funciones de ProteccionesGerman SchwabNo ratings yet

- ForeScout Solution BrochureDocument6 pagesForeScout Solution BrochuresisiwansNo ratings yet

- MadlabDocument19 pagesMadlabAditya PatilNo ratings yet

- WMS - Bulk Picking and Packing Workbench: Demo ScriptDocument24 pagesWMS - Bulk Picking and Packing Workbench: Demo ScriptNaveen Shankar MauwalaNo ratings yet

- Building Simulation, Solar Potential and Consumption Analysis of Residential Dwellings, in DubaiDocument108 pagesBuilding Simulation, Solar Potential and Consumption Analysis of Residential Dwellings, in DubaiRandy BenemeritoNo ratings yet

- Wu XueyinDocument137 pagesWu XueyinSayed AhmedNo ratings yet

- Emerging Exponential Technologies: 20MBA302 Model Question Paper-2 Third Semester MBA Degree Examination, March 2022Document2 pagesEmerging Exponential Technologies: 20MBA302 Model Question Paper-2 Third Semester MBA Degree Examination, March 2022Shravan BhagavNo ratings yet

- DS2000 Manual en UnlockedDocument142 pagesDS2000 Manual en UnlockedАлексей ХоролецNo ratings yet

- US Department of Energy DOE: Strategic Plan 2011Document60 pagesUS Department of Energy DOE: Strategic Plan 2011Linda Louise HillNo ratings yet

- Udyog Aadhar CertificateDocument1 pageUdyog Aadhar CertificateRajendra JoshiNo ratings yet